ASTM D4630-96(2002)

(Test Method)Standard Test Method for Determining Transmissivity and Storage Coefficient of Low-Permeability Rocks by In Situ Measurements Using the Constant Head Injection Test

Standard Test Method for Determining Transmissivity and Storage Coefficient of Low-Permeability Rocks by In Situ Measurements Using the Constant Head Injection Test

SIGNIFICANCE AND USE

Test Method—The constant pressure injection test method is used to determine the transmissivity and storativity of low-permeability formations surrounding packed-off intervals. Advantages of the method are: (a) it avoids the effect of well-bore storage, (b) it may be employed over a wide range of rock mass permeabilities, and (c) it is considerably shorter in duration than the conventional pump and slug tests used in more permeable rocks.

Analysis—The transient water flow rate data obtained using the suggested test method are evaluated by the curve-matching technique described by Jacob and Lohman (1)2 and extended to analysis of single fractures by Doe et al. (2). If the water flow rate attains steady state, it may be used to calculate the transmissivity of the test interval (3).

Units:

4.3.1 Conversions—The permeability of a formation is often expressed in terms of the unit darcy. A porous medium has a permeability of 1 darcy when a fluid of viscosity 1 cp (1 mPa·s) flows through it at a rate of 1 cm3/s (10−6 m3/s)/1 cm2 (10−4 m2) cross-sectional area at a pressure differential of 1 atm (101.4 kPa)/1 cm (10 mm) of length. One darcy corresponds to 0.987 μm2. For water as the flowing fluid at 20°C, a hydraulic conductivity of 9.66 μm/s corresponds to a permeability of 1 darcy.

SCOPE

1.1 This test method covers a field procedure for determining the transmissivity and storativity of geological formations having permeabilities lower than 103 μm2 (1 millidarcy) using constant head injection.

1.2 The transmissivity and storativity values determined by this test method provide a good approximation of the capacity of the zone of interest to transmit water, if the test intervals are representative of the entire zone and the surrounding rock is fully water-saturated.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4630 – 96 (Reapproved 2002)

Standard Test Method for

Determining Transmissivity and Storage Coefficient of Low-

Permeability Rocks by In Situ Measurements Using the

Constant Head Injection Test

This standard is issued under the fixed designation D4630; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.1.2 storage coeffıcient, S—the storage coefficient of a

formation of thickness, b, is defined as follows:

1.1 This test method covers a field procedure for determin-

ing the transmissivity and storativity of geological formations S 5 S ·b (3)

s

−3 2

having permeabilities lower than 10 µm (1 millidarcy) using

constant head injection.

where:

1.2 The transmissivity and storativity values determined by

S = specific storage.

s

this test method provide a good approximation of the capacity

The ebrss is the specific storage of a material if it were

of the zone of interest to transmit water, if the test intervals are

homogeneous and porous over the entire interval. The specific

representative of the entire zone and the surrounding rock is

storage is given as follows:

fully water-saturated.

S 5rg ~C 1 nC ! (4)

s b w

1.3 The values stated in SI units are to be regarded as the

standard.

1.4 This standard does not purport to address all of the

where:

safety concerns, if any, associated with its use. It is the

C = bulk rock compressibility,

b

responsibility of the user of this standard to establish appro-

C = fluid compressibility, and

w

priate safety and health practices and determine the applica-

n = formation porosity.

bility of regulatory limitations prior to use.

2.2 Symbols:

−1 2

2.2.1 C —bulk rock compressibility (M LT ).

b

2. Terminology

−1 2

2.2.2 C —compressibility of water (M LT ).

w

2.1 Definitions of Terms Specific to This Standard:

2.2.3 G—dimensionless function.

−1

2.1.1 transmissivity, T—the transmissivity of a formation of

2.2.4 K—hydraulic conductivity (LT ).

thickness, b, is defined as follows:

2.2.4.1 Discussion—The use of symbol K for the term

hydraulic conductivity is the predominant usage in ground

T 5 K·b (1)

water literature by hydrogeologists, whereas the symbol k is

commonly used for this term in the rock and soil mechanics

where:

and soil science literature.

K = hydraulic conductivity. −1 −2

2.2.5 P—excess test hole pressure (ML T ).

The hydraulic conductivity, K, is related to the permeability,

3 −1

2.2.6 Q—excess water flow rate (L T ).

k, as follows: 3 −1

2.2.7 Q —maximum excess water flow rate (L T ).

o

K 5 krg/µ (2)

2.2.8 S—storativity (or storage coefficient) (dimensionless).

−1

2.2.9 S —specific storage (L ).

s

2 −1

2.2.10 T—transmissivity (L T ).

where:

2.2.11 b—formation thickness (L).

r = fluid density,

2.2.12 e—fracture aperture (L).

µ = fluid viscosity, and

−2

2.2.13 g—acceleration due to gravity (LT ).

g = acceleration due to gravity.

2.2.14 k—permeability (L ).

2.2.15 n—porosity (dimensionless).

2.2.16 r —radius of test hole (L).

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland

w

RockandisthedirectresponsibilityofSubcommitteeD18.21onGroundWaterand

2.2.17 t—time elapsed from start of test (T).

Vadose Zone Investigations.

2.2.18 a—dimensionless parameter.

Current edition approved Oct. 10, 1996. Published June 1997. Originally

e1

published as D4630–86. Last previous edition D4630–86(1991) .

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4630

−1 −1

2.2.19 µ—viscosity of water (ML T ).

−3

2.2.20 r—density of water (ML ).

3. Summary of Test Method

3.1 Aboreholeisfirstdrilledintotherockmass,intersecting

the geological formations for which the transmissivity and

storativity are desired. The borehole is cored through potential

zonesofinterest,andislatersubjectedtogeophysicalborehole

logging over these intervals. During the test, each interval of

interest is packed off at top and bottom with inflatable rubber

packers attached to high-pressure steel tubing.

3.2 The test itself involves rapidly applying a constant

pressure to the water in the packed-off interval and tubing

string, and recording the resulting changes in water flow rate.

The water flow rate is measured by one of a series of flow

meters of different sensitivities located at the surface. The

initial transient water flow rate is dependent on the transmis-

sivity and storativity of the rock surrounding the test interval

andonthevolumeofwatercontainedinthepacked-offinterval

and tubing string.

4. Significance and Use

4.1 Test Method—The constant pressure injection test

method is used to determine the transmissivity and storativity

of low-permeability formations surrounding packed-off inter-

vals. Advantages of the method are: (a) it avoids the effect of

well-borestorage,(b)itmaybeemployedoverawiderangeof

rock mass permeabilities, and (c) it is considerably shorter in

duration than the conventional pump and slug tests used in

more permeable rocks.

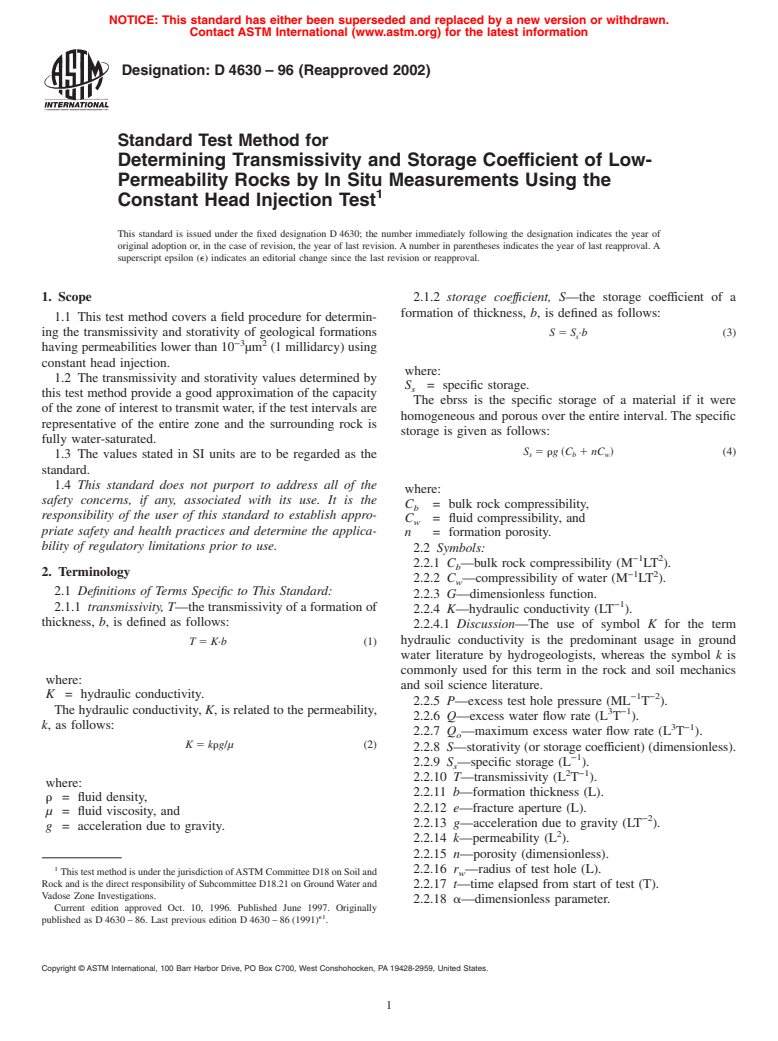

FIG. 1 Equipment Schematic

4.2 Analysis—The transient water flow rate data obtained

using the suggested test method are evaluated by the curve-

5.2 Packers—Hydraulically actuated packers are recom-

matching technique described by Jacob and Lohman (1) and

mended because they produce a positive seal on the borehole

extended to analysis of single fractures by Doe et al. (2). If the

wall and because of the low compressibility of water they are

water flow rate attains steady state, it may be used to calculate

alsocomparativelyrigid.Eachpackershallsealaportionofthe

the transmissivity of the test interval (3).

borehole wall at least 0.5 m in length, with an applied pressure

4.3 Units:

at least equal to the excess constant pressure to be applied to

4.3.1 Conversions—The permeability of a formation is

the packed-off interval and less than the formation fracture

often expressed in terms of the unit darcy. A porous medium

pressure at that depth.

has a permeability of 1 darcy when a fluid of viscosity 1 cp (1

3 3 2

5.3 Pressure Transducers—The pressure shall be measured

mPa·s) flows through it at a rate of 1 cm /s (10−6 m /s)/1 cm

as a function of time, with the transducer located in the

(10−4 m ) cross-sectional area at a pressure differential of 1

packed-off test interval. The pressure transducer shall have an

atm (101.4 kPa)/1 cm (10 mm) of length. One darcy corre-

accuracy of at least 63 kPa (60.4 psi), including errors

sponds to 0.987 µm . For water as the flowing fluid at 20°C, a

introducedbytherecordingsystem,andaresolutionofatleast

hydraulic conductivity of 9.66 µm/s corresponds to a perme-

1 kPa (0.15 psi).

ability of 1 darcy.

5.4 Flow Meters—Suitable flow meters shall be provided

3 3

5. Apparatus

for measuring water flow rates in the range from 10 cm /s to

−3 3

10 cm /s.Commerciallyavailableflowmetersarecapableof

NOTE 1—A schematic of the test equipment is shown in Fig. 1.

2 3

measuring flow rates as low as 10 cm /s with an accuracy of

5.1 Source of Constant Pressure—A pump or pressure

−5 3

61% and with a resolution of 10 cm /s; these can test

intensifier shall be capable of providing an additional amount

−3

permeabilities to 10 md based on a 10-m packer spacing.

of water to the water-filled tubing string and packed-off test

Positive displacement flow meters of either the tank type

interval to produce a constant pressure of up to 1 MPA (145

(Haimson and Doe (4) or bubble-type (Wilson et al. (3) are

psi) in magnitude, preferably with a rise time of less than 1%

−3 3

capableofmeasuringflowratesaslowas10 cm /s;thesecan

of one half of the flow rate decay (Q/Q =0.5).

−4

o

testpermeabilitiesto10 mdbasedona10-mpackerspacing.

5.5 Hydraulic Systems—The inflatable rubber packers shall

be attached to high-pressure steel tubing reaching to the

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

this standard. surface. The packers themselves shall be inflated with water

D 4630

using a separate hydraulic system. The pump or pressure out of solution, and the resulting bubbles will radically modify

intensifier providing the constant pressure shall be attached to the pressure transient characteristics.

thesteeltubingatthesurface.Aremotelycontrolleddown-hole 6.4 Testing:

valve, located in the steel tubing immediately above the upper 6.4.1 Filling and Purging System—Once the packers have

packer, shall be used for shutting in the test interval and for been set, slowly fill the tubing string and packed-off interval

instantaneous starting of tests. with water to ensure that no air bubbles will be trapped in the

testintervalandtubing.Closethedownholevalvetoshutinthe

6. Procedure testinterval,andallowthetestsectionpressures(asdetermined

from downhole pressure transducer reading) to dissipate.

6.1 Drilling Test Holes:

6.4.2 Constant Pressure Test—Pressurize the tubing, typi-

6.1.1 Number and Orientation—The number of test holes

cally to between 300 and 600 kPa (50 to 100 psi) above the

shall be sufficient to supply the detail required by the scope of

shut-in pressure. This range of pressures is in most cases

the project. The test holes shall be directed to intersect major

sufficiently low to minimize distortion of fractures adjacent at

fracture sets, preferably at right angles.

the test hole, but in no case should the pressure exceed the

6.1.2 Test Hole Quality—The drilling procedure shall pro-

minimum principal ground stress. It is necessary to provide

vide a borehole sufficiently smooth for packer seating, shall

sufficient volume of pressurized water to maintain constant

contain no rapid changes in direction, and shall minimize

pressure during testing. Open the down-hole valve, maintain

formation damage.

the constant pressure, and record the water flow rate as a

6.1.3 Test Holes Cored—Core the test holes through zones

function of time. Then close the down-hole valve and repeat

of potential interest to provide information for locating test

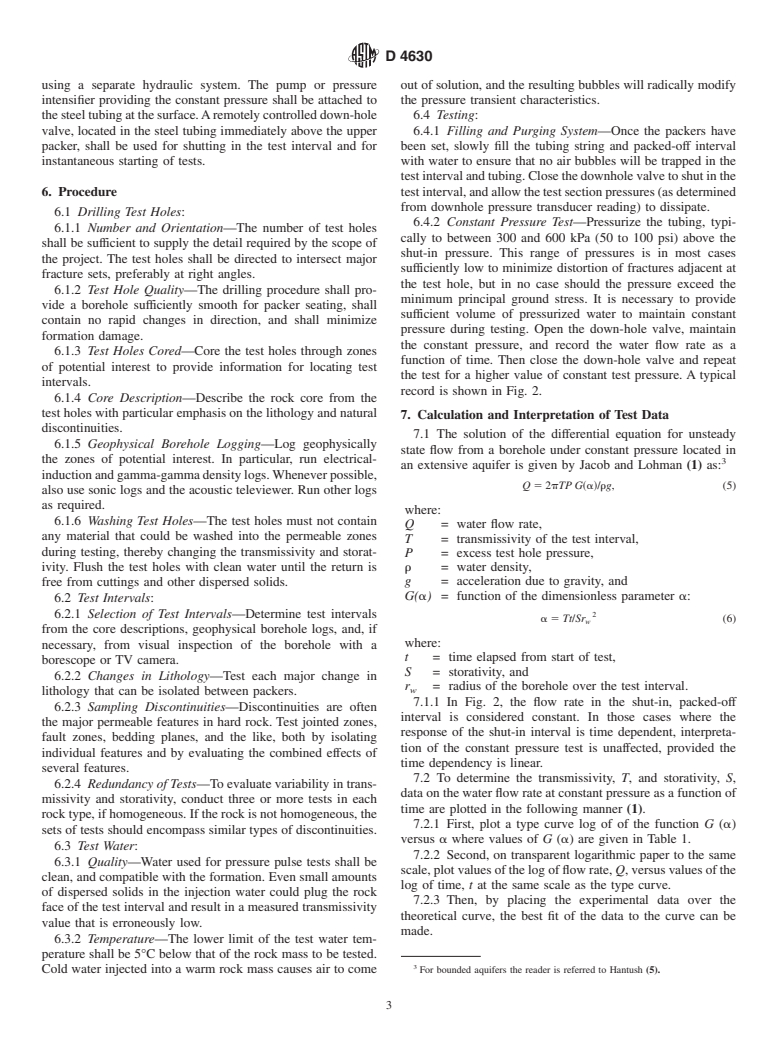

the test for a higher value of constant test pressure. A typical

intervals.

record is shown in Fig. 2.

6.1.4 Core Description—Describe the rock core from the

testholeswithparticularemphasisonthelithologyandnatural

7. Calculation and Interpretation of Test Data

discontinuities.

7.1 The solution of the differential equation for unsteady

6.1.5 Geophysical Borehole Logging—Log geophysically

state flow from a borehole under constant pressure located in

the zones of potential interest. In particular, run electrical- 3

an extensive aquifer is given by Jacob and Lohman (1) as:

inductionandgamma-gammadensitylogs.Wheneverpossible,

Q 52pTP G a /rg, (5)

~ !

also use sonic logs and the acoustic televiewer. Run other logs

as required.

where:

6.1.6 Washing Test Holes—The test holes must not contain

Q = water flow rate,

any material that could be washed into the permeable zones

T = transmissivity of the test interval,

during testing, thereby changing the transmissivity and storat-

P = excess test hole pressure,

ivity. Flush the test holes with clean water until the return is r = water density,

g = acceleration due to gravity, and

free from cuttings and other dispersed solids.

G(a) = function of the dimensionless parameter a:

6.2 Test Intervals:

6.2.1 Selection of Test Intervals—Determine test intervals

a5 Tt/Sr (6)

w

from the core descriptions, geophysical borehole logs, and, if

where:

necessary, from visual inspection of the borehole with a

t = time elapsed from start of test,

borescope or TV camera.

S = storativity, and

6.2.2 Changes in Lithology—Test each major change in

r = radius of the borehole over the test interval.

w

lithology that can be isolated between packers.

7.1.1 In Fig. 2, the flow rate in the shut-in, packed-off

6.2.3 Sampling Discontinuities—Discontinuities are often

interval is considered constant. In those cases where the

the major permeable features in hard rock. Test jointed zones,

response of the shut-in interval is time dependent, interpreta-

fault zones, bedding planes, and the like, both by isolating

tion of the constant pressure test is unaffected, provided the

individual features and by evaluating the combined effects of

time dependency is linear.

several features.

7.2 To determine the transmissivity, T, and storativity, S,

6.2.4 Redundancy of Tests—Toevaluatevariabilityintrans-

dataonthewaterflowrateatconstantpressureasafunctionof

missivity and storativity, conduct three or more tests in each

time are plotted in the following manner (1).

rocktype,ifhomogeneous.Iftherockisnothomogeneous,the

7.2.1 First, plot a type curve log of of the function G (a)

sets of tests should encompass similar types of discontinuities.

versus a where values of G (a) are given in Table 1.

6.3 Test Water:

7.2.2 Second, on transparent logarithmic paper to the same

6.3.1 Quality—Water used for pressure pulse tests shall be

scale,plotvaluesofthelogofflowrate, Q,versusvaluesofthe

clean, and compatible with the formation. Even small amounts

log of time, t at the same scale as the type curve.

of dispersed solids in the injection water could plug the rock

7.2.3 Then, by placing the experimental data over the

face of the test interval and result in a measured transmissivity

theoretical curve, the best fit of the data to the curve can be

value that is erroneously low.

made.

6.3.2 Temperature—The lower limit of the test water tem-

perature shall be 5°C below that of the rock mass to be tested.

Cold water injected into a warm rock mass causes air to come For bounded aquifers the reader is referred to Hantush (5).

D 4630

FIG. 2 Typical Flow Rate Record

−4 12 A

TABLE 1 Values ofG(a) for Values ofa Between 10 and 10

−4 −3 −2 −1 2 3

10 10 10 10 110 10 10

1 56.9 18.34 6.13 2.249 0.985 0.534 0.346 0.251

2 40.4 13.11 4.47 1.716 0.803 0.461 0.311 0.232

3 33.1 10.79 3.74 1.477 0.719 0.427 0.294 0.222

4 28.7 9.41 3.30 1.333 0.667 0.405 0.283 0.215

5 25.7 8.47 3.00 1.234 0.630 0.389 0.274 0.210

6 23.5 7.77 2.78 1.160 0.602 0.377 0.268 0.206

7 21.8 7.23 2.60 1.103 0.580 0.367 0.263 0.203

8 20.4 6.79 2.46 1.057 0.562 0.359 0.258 0.200

9 19.3 6.43 2.35 1.018 0.547 0.352 0.254 0.198

10 18.3 6.13 2.25 0.985 0.534 0.346 0.251 0.196

4 5 6 7 8 9 10 11

10 10 10 10 10 10 10 10

1 0.1964 0.1608 0.1360 0.1177 0.1037 0.0927 0.0838 0.0764

2 0.1841 0.1524 0.1299 0.1131 0.1002 0.0899 0.0814 0.0744

3 0.1777 0.1479 0.1266 0.1106 0.0982 0.0883 0.0801 0.0733

4 0.1733 0.1449 0.1244 0.1089 0.0968 0.0872 0.0792 0.0726

5 0.1701 0.1426 0.1227 0.1076 0.0958 0.0864 0.0785 0.0720

6 0.1675 0.1408 0.1213 0.1066 0.0950 0.0857 0.0779 0.0716

7 0.1654 0.1393 0.1202 0.1057 0.09

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.