ASTM D6926-16

(Practice)Standard Practice for Preparation of Asphalt Mixture Specimens Using Marshall Apparatus

Standard Practice for Preparation of Asphalt Mixture Specimens Using Marshall Apparatus

SIGNIFICANCE AND USE

4.1 Compacted asphalt mixture specimens molded by this procedure are used for various physical tests such as stability, flow, indirect tensile strength, fatigue, creep, and modulus. Density and void analysis are also conducted on specimens for mixture design and evaluation of field compaction.

Note 1: Uncompacted mixtures are used for determination of theoretical maximum specific gravity.

Note 2: The quality of the results produced by this practice are dependent on the competence of the personnel performing the procedure and the capability, calibration, and maintenance of the equipment used. Agencies that meet the criteria of Specification D3666 are generally considered capable of competent and objective testing, sampling, inspection, etc. Users of this practice are cautioned that compliance with Specification D3666 alone does not completely ensure reliable results. Reliable results depend on many factors; following the suggestions of Specification D3666 or some similar acceptable guideline provides a means of evaluating and controlling some of those factors.

SCOPE

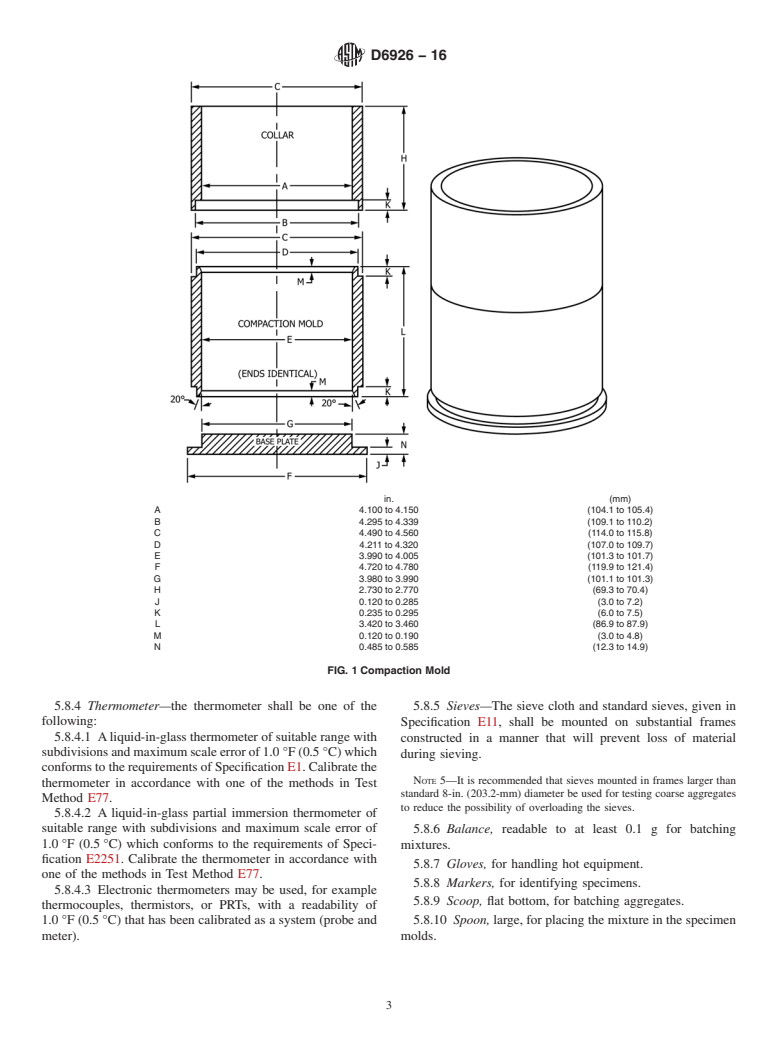

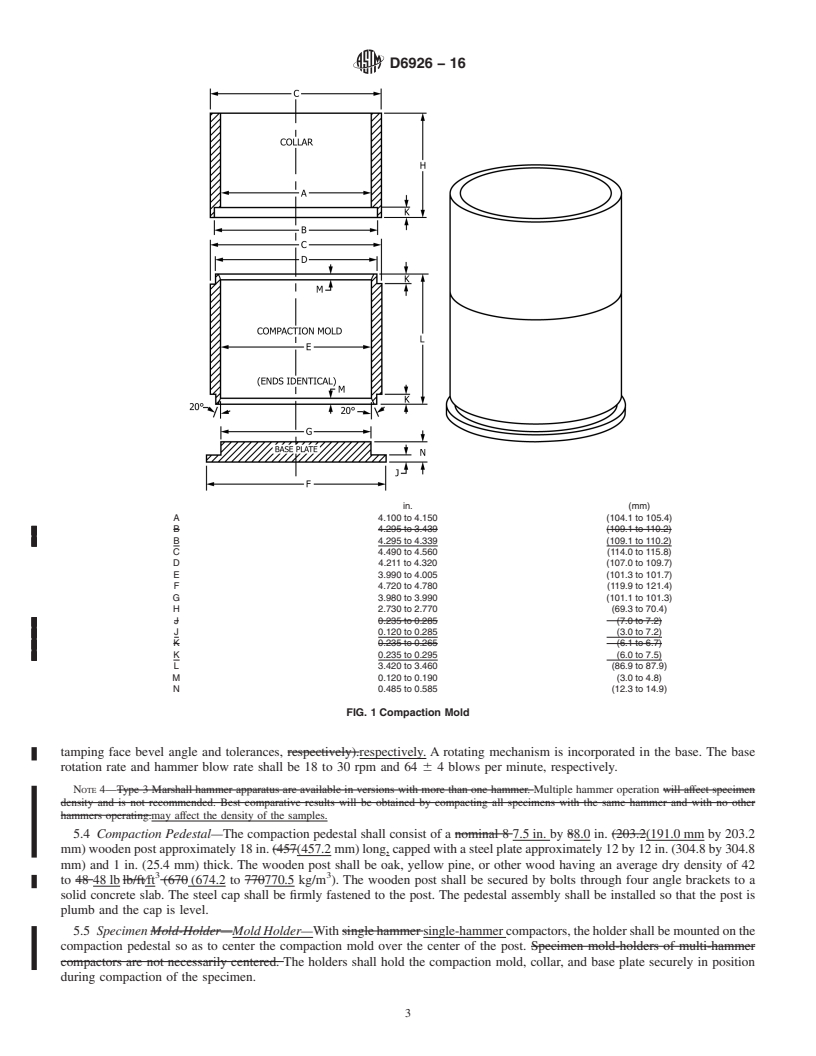

1.1 This practice covers preparation and compaction of 4 in. (101.6 mm) diameter by nominal 2.5 in. (63.5 mm) high cylindrical asphalt paving mixture specimens. This practice is intended for use with laboratory and plant-produced asphalt mixtures with aggregate up to 1 in. (25.4 mm) maximum size and for recompaction of asphalt paving mixture samples.

1.2 There are three types of Marshall compaction apparatus in use. The following types of hammer arrangements are included in this practice:

1.2.1 Manually held hammer handle is attached to a flat compaction foot through a spring-loaded swivel and is hand operated (original standard developed by the United States Army Corps of Engineers).

1.2.2 Hammer handle restrained laterally (fixed) but not vertically, attached to a flat compaction foot through a spring-loaded swivel and is either mechanically or hand operated. There may or may not be a constant surcharge on top of the hammer handle. Mechanical hammers are available that operate at (1) nominal 55 blows per minute or (2) equal to or greater than 75 blows per minute.

1.2.3 Hammer handle restrained laterally (fixed) with constant surcharge on top of hammer, is attached to a slanted compaction foot on a rotating mold base, and is mechanically operated. This method must be used as a referee method.

1.3 Although the mass and height of mass drop for each apparatus are the same, density achieved in compacted specimens with the same number of blows will be different. It is up to the owner or specifier to establish the specific required number of blows to be used for compaction of the specimen in relation to the field.

1.4 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6926 − 16

Standard Practice for

Preparation of Asphalt Mixture Specimens Using Marshall

1

Apparatus

This standard is issued under the fixed designation D6926; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 The text of this standard references notes and footnotes

which provide explanatory material. These notes and footnotes

1.1 This practice covers preparation and compaction of 4 in.

(excluding those in tables and figures) shall not be considered

(101.6 mm) diameter by nominal 2.5 in. (63.5 mm) high

as requirements of the standard.

cylindrical asphalt paving mixture specimens. This practice is

intended for use with laboratory and plant-produced asphalt

2. Referenced Documents

mixtures with aggregate up to 1 in. (25.4 mm) maximum size

2

and for recompaction of asphalt paving mixture samples. 2.1 ASTM Standards:

D8 Terminology Relating to Materials for Roads and Pave-

1.2 There are three types of Marshall compaction apparatus

ments

in use. The following types of hammer arrangements are

D3666 Specification for Minimum Requirements for Agen-

included in this practice:

cies Testing and Inspecting Road and Paving Materials

1.2.1 Manually held hammer handle is attached to a flat

D4402 Test Method for Viscosity Determination of Asphalt

compaction foot through a spring-loaded swivel and is hand

at Elevated Temperatures Using a Rotational Viscometer

operated (original standard developed by the United States

D6927 Test Method for Marshall Stability and Flow of

Army Corps of Engineers).

Asphalt Mixtures

1.2.2 Hammer handle restrained laterally (fixed) but not

E1 Specification for ASTM Liquid-in-Glass Thermometers

vertically, attached to a flat compaction foot through a spring-

E11 Specification for Woven Wire Test Sieve Cloth and Test

loaded swivel and is either mechanically or hand operated.

Sieves

There may or may not be a constant surcharge on top of the

E77 Test Method for Inspection and Verification of Ther-

hammer handle. Mechanical hammers are available that oper-

mometers

ateat (1)nominal55blowsperminuteor (2)equaltoorgreater

E2251 Specification for Liquid-in-Glass ASTM Thermom-

than 75 blows per minute.

eters with Low-Hazard Precision Liquids

1.2.3 Hammer handle restrained laterally (fixed) with con-

stant surcharge on top of hammer, is attached to a slanted

3. Terminology

compaction foot on a rotating mold base, and is mechanically

operated. This method must be used as a referee method.

3.1 Definitions:

3.1.1 For definitions of terms used in this practice, refer to

1.3 Although the mass and height of mass drop for each

Terminology D8.

apparatus are the same, density achieved in compacted speci-

3.2 Definitions of Terms Specific to This Standard:

mens with the same number of blows will be different. It is up

3.2.1 lab mix lab compacted (LMLC) asphalt mixture,

to the owner or specifier to establish the specific required

n—asphalt mix samples that are prepared in the laboratory by

number of blows to be used for compaction of the specimen in

weighing and blending each constituent then compacting the

relation to the field.

blended mixture after two hours of curing at the compaction

1.4 Units—The values stated in inch-pound units are to be

temperature or curing time specified by the owner, using a

regarded as standard. The values given in parentheses are

laboratory compaction apparatus.

mathematical conversions to SI units that are provided for

3.2.1.1 Discussion—LMLC typically occurs during the as-

information only and are not considered standard.

phalt mixture design phase.

1

This practice is under the jurisdiction of ASTM Committee D04 on Road and

Paving Materials and is the direct responsibility of Subcommittee D04.20 on

2

Mechanical Tests of Asphalt Mixtures. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 15, 2016. Published January 2017. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2004. Last previous edition approved in 2010 as D6926 – 10. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D6926-16. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6926 − 16

3.2.2 plant mix laboratory compacted (PMLC) asphalt A typical manual compaction hammer is shown in Fig. 2.A

misture, n—asphalt mix samples that are manufactured in a typical mechanical hammer is showed in Fig. 3.

production plant, sampled prior to

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6926 − 10 D6926 − 16

Standard Practice for

Preparation of Bituminous Asphalt Mixture Specimens

1

Using Marshall Apparatus

This standard is issued under the fixed designation D6926; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers preparation and compaction of 102 mm (4 in.)4 in. (101.6 mm) diameter by nominal 64 mm (2.5 in.)

2.5 in. (63.5 mm) high cylindrical bituminous paving mixture specimens by means of the original manual Marshall method and

subsequent variations of the method (Test Method asphalt paving mixture specimens. D6927). This practice is intended for use with

laboratory and plant produced bituminous plant-produced asphalt mixtures with aggregate up to 25 mm (1 in.) 1 in. (25.4 mm)

maximum size and for recompaction of asphalt pavement paving mixture samples.

1.2 There are three types of Marshall compaction apparatus in use. The following types of hammer arrangements are included

in this practice:

1.2.1 Manually held hammer handle is attached to a flat compaction foot through a spring loaded spring-loaded swivel and is

hand operated (original standard developed by the United States Army Corps of Engineers).

1.2.2 Hammer handle restrained laterally (fixed) but not vertically, attached to a flat compaction foot through a spring loaded

spring-loaded swivel and is either mechanically or hand operated. There may or may not be a constant surcharge on top of the

hammer handle. Mechanical hammers are available that operate at (1) nominal 55 blows per minute andor (2) equal to or greater

than 75 blows per minute.

1.2.3 Hammer handle restrained laterally (fixed) with constant surcharge on top of hammer, is attached to a slanted compaction

foot, foot on a rotating mold base, and is mechanically operated. This method must be used as a referee method.

1.3 Although the mass and height of mass drop for each apparatus are the same, density achieved in compacted specimens with

the same number of blows will be different. It is up to the user owner or specifier to establish the specific required number of blows

to be used for compaction of the specimen in relation to the field.

1.4 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are

mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of the standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D2493D8 Standard Viscosity-Temperature Chart for AsphaltsTerminology Relating to Materials for Roads and Pavements

D3666 Specification for Minimum Requirements for Agencies Testing and Inspecting Road and Paving Materials

D4402 Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer

D6927 Test Method for Marshall Stability and Flow of Asphalt Mixtures

E1 Specification for ASTM Liquid-in-Glass Thermometers

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

E77 Test Method for Inspection and Verification of Thermometers

E2251 Specification for Liquid-in-Glass ASTM Thermometers with Low-Hazard Precision Liquids

1

This practice is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.20 on Mechanical

Tests of BituminousAsphalt Mixtures.

Current edition approved June 15, 2010Dec. 15, 2016. Published September 2010January 2017. Originally approved in 2004. Last previous edition approved in 20042010

as D6926–04D6926 – 10. DOI: 10.1520/D6926-10.10.1520/D6926-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6926 − 16

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this practice, refer to Terminology D8.

3.2 Definitions of Term

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.