ASTM E716-16(2021)e1

(Practice)Standard Practices for Sampling and Sample Preparation of Aluminum and Aluminum Alloys for Determination of Chemical Composition by Spark Atomic Emission Spectrometry

Standard Practices for Sampling and Sample Preparation of Aluminum and Aluminum Alloys for Determination of Chemical Composition by Spark Atomic Emission Spectrometry

SIGNIFICANCE AND USE

5.1 The practice for taking a sample of molten metal during production and producing a chill cast disk, used in conjunction with the following appropriate quantitative spark atomic emission spectrochemical methods, Test Methods E607 and E1251, is suitable for use in manufacturing control or certifying, or both, that the entire lot of alloy sampled meets established composition limits.

5.2 The practice for melting a piece of a product to produce a chill cast disk analyzed in conjunction with the following appropriate quantitative spark atomic emission spectrochemical methods, Test Methods E607 and E1251, is suitable, if a representative sample is taken, for determining if the piece sampled meets Aluminum Association composition limits.

5.3 The practice for direct analysis of product is suitable for determining an approximate composition of the piece analyzed.

SCOPE

1.1 These practices describe procedures for producing a chill cast disk sample from molten aluminum during the production process, and from molten metal produced by melting pieces cut from products.

1.2 These practices describe a procedure for obtaining qualitative results by direct analysis of product using spark atomic emission spectrometry.

1.3 These practices describe procedures for preparation of samples and products prior to analysis.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 6.1 and 7.2.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: E716 − 16 (Reapproved 2021)

Standard Practices for

Sampling and Sample Preparation of Aluminum and

Aluminum Alloys for Determination of Chemical

Composition by Spark Atomic Emission Spectrometry

This standard is issued under the fixed designation E716; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—An editorial change was made to 8.3 in January 2022.

1. Scope* 2. Referenced Documents

1.1 These practices describe procedures for producing a 2.1 ASTM Standards:

chill cast disk sample from molten aluminum during the B985Practice for SamplingAluminum Ingots, Billets, Cast-

production process, and from molten metal produced by ings and Finished or Semi-Finished Wrought Aluminum

melting pieces cut from products. Products for Compositional Analysis

E135Terminology Relating to Analytical Chemistry for

1.2 These practices describe a procedure for obtaining

Metals, Ores, and Related Materials

qualitative results by direct analysis of product using spark

E401Practice for Bonding Thin Spectrochemical Samples

atomic emission spectrometry.

and Standards to a Greater Mass of Material (Withdrawn

1.3 These practices describe procedures for preparation of

1995)

samples and products prior to analysis.

E607 Test Method for Atomic Emission Spectrometric

Analysis Aluminum Alloys by the Point to Plane Tech-

1.4 The values stated in SI units are to be regarded as

standard. The values given in parentheses are mathematical nique Nitrogen Atmosphere (Withdrawn 2011)

E1251Test Method for Analysis of Aluminum and Alumi-

conversions to inch-pound units that are provided for informa-

tion only and are not considered standard. num Alloys by Spark Atomic Emission Spectrometry

1.5 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 3.1 For definitions of terms used in this practice, refer to

priate safety, health, and environmental practices and deter- Terminology E135.

mine the applicability of regulatory limitations prior to use.

4. Summary of Practices

Specific precautionary statements are given in 6.1 and 7.2.

1.6 This international standard was developed in accor-

4.1 Molten metal representative of the furnace melt is

dance with internationally recognized principles on standard-

poured or drawn by vacuum into a specified mold to produce

ization established in the Decision on Principles for the

a chill-cast disk.The disk is machined to a specified depth that

Development of International Standards, Guides and Recom-

representstheaveragecompositionandproducesanacceptable

mendations issued by the World Trade Organization Technical

surface for analysis by spark atomic emission spectrometry.

Barriers to Trade (TBT) Committee.

1 2

These practices are under the jurisdiction of ASTM Committee E01 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Analytical Chemistry for Metals, Ores, and Related Materials and are the direct contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

responsibility of Subcommittee E01.04 on Aluminum and Magnesium. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Nov. 15, 2021. Published November 2021. Originally the ASTM website.

approved in 1980. Last previous edition approved in 2016 as E716–16. DOI: The last approved version of this historical standard is referenced on

10.1520/E0716-16R21E01. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E716 − 16 (2021)

NOTE 2—Molten aluminum in contact with rust may initiate a thermite

4.2 Pieces of solid aluminum fabricated, cast, or wrought

reaction.

products are remelted and cast into molds or briquetted then

remelted and cast into molds. 6.2 Sample Molds shall be capable of producing homog-

enous chill-cast disks having smooth surfaces, free of surface

4.3 Product can be qualitatively analyzed directly without

pockets and porosity. These chill cast disks should have a

remelting after suitable surface preparation. Product with

spectrochemical response similar to the reference materials

insufficient mass for direct analysis may be bonded to more

usedinpreparingtheanalyticalcurvesandshouldatleasthave

massive material prior to analysis.

a spark to spark repeatability of no more than 2% relative on

4.4 Special practices are included for the sampling and

major elements.They must be representative of the melt in the

analysis of aluminum-silicon alloys, containing greater than

region excited. Several types of molds have been found

14% silicon.

acceptable:

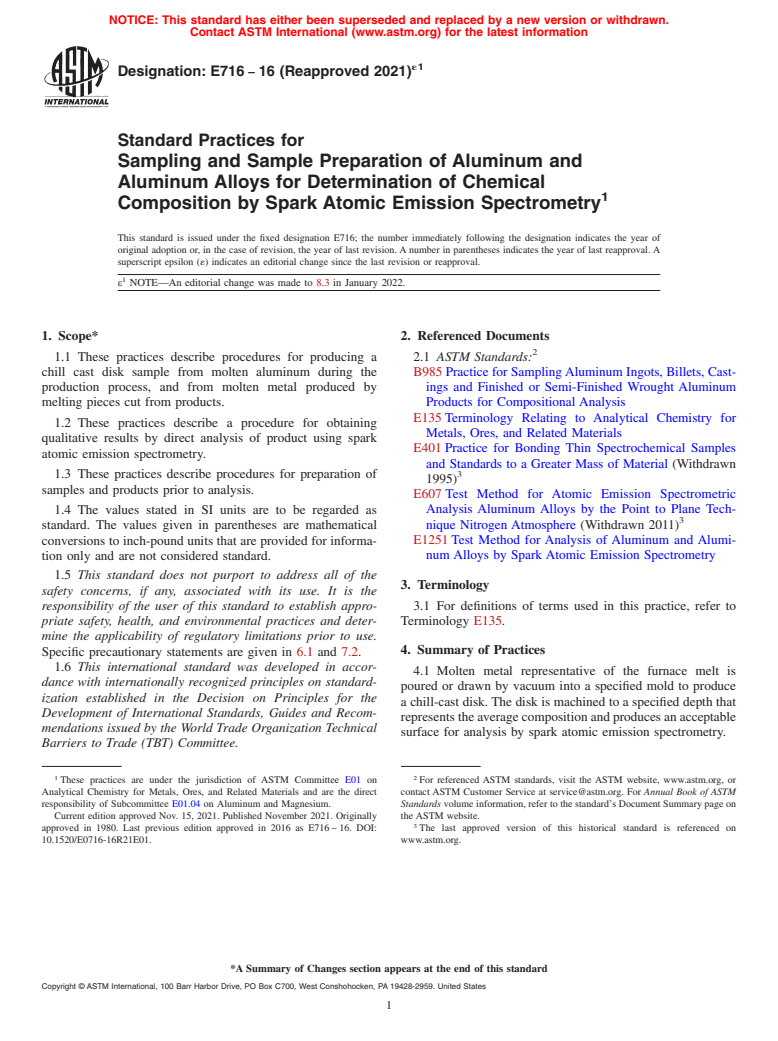

6.2.1 TypeB Mold center-pour mold, is shown in Fig. 1.

5. Significance and Use

Thismoldproducesahorizontallycastdiskwiththesprueover

5.1 The practice for taking a sample of molten metal during

the center of one side. The mold dimensions are such as to

production and producing a chill cast disk, used in conjunction

produce a disk approximately 50mm to 64mm (1.97in. to

with the following appropriate quantitative spark atomic emis- 2.5in.) in diameter by 6mm to 13mm (0.24in. to 0.50in.) in

sion spectrochemical methods,Test Methods E607 and E1251,

thickness.Acircular central recess 10mm to 20mm (0.4in. to

is suitable for use in manufacturing control or certifying, or

0.8in.) in diameter on one side of the disk facilitates machin-

both, that the entire lot of alloy sampled meets established

ing of that side in preparation for excitation. It also promotes

composition limits.

more uniform freezing of the raised peripheral area, but the

corresponding raised portion of the mold must not be so large

5.2 The practice for melting a piece of a product to produce

astorestrictthethroatforthesprue.Aslighttaper,1°to2°,on

a chill cast disk analyzed in conjunction with the following

the hinged portion of the mold facilitates opening when a disk

appropriate quantitative spark atomic emission spectrochemi-

has been cast. The mold material should be steel or cast iron

cal methods, Test Methods E607 and E1251, is suitable, if a

and should weigh approximately 3.5kg to 4.5kg (8lb to

representative sample is taken, for determining if the piece

10lb).AspecialTypeBmoldisrecommendedforhypereutetic

sampled meets Aluminum Association composition limits.

aluminum-silicon alloys. It produces the thinner samples

5.3 Thepracticefordirectanalysisofproductissuitablefor

13mm (0.24 in.) thick.

determining an approximate composition of the piece ana-

NOTE 3—About sample molds: Previously two relatively simple types

lyzed.

of massive iron or steel sample molds were considered suitable, Type A

and Type B. Type A molds produced vertical chill cast samples with the

6. Apparatus

sprueandriserontheedgeofthesample,asopposedtotheTypeBwhich

producesahorizontalchillcastsamplewiththesprueandriserontheback

6.1 Ladle, capable of holding a minimum of 250g (8.8oz)

of the sample. The Type A sampler was later found to not produce a

ofmoltenmetal,withahandleofsufficientlengthtoreachinto

repeatable sparking surface, even in the restricted sparking areas. The

a furnace, trough, or crucible. The ladle should be lightly

Type A mold was removed from the list of recommended conventional

coatedwithatightlyadheringladlewashthatwillserveinpart

molds. Because many people are familiar with the terms “Type A” and

to prevent contamination of the sample and also prevent “Type B” molds, reference to “Type B” mold remains in the text of this

standard even though reference to the “Type A” no longer appears.

contact of molten aluminum with metal oxides, that is, rust.

(Warning—Traces of moisture in the coating may cause

dangerous spattering.)

NOTE 1—Asuitable ladle wash may be prepared as follows: Mix 255g

(9oz) of fine whiting (CaCO ) with 3.8L (1gal) of water and boil for

TypeB molds, available from Danton Machine and Welding Incorporated, 713

20min.Add 127g (4.5oz) of sodium silicate solution (40°Bé to 42°Bé)

FortuneCrescent,Kingston,ONCanadaK7P2T4,havebeenfoundsuitableforthis

and boil for 30min. Stir well before using. purpose.

FIG. 1 Type B Mold

´1

E716 − 16 (2021)

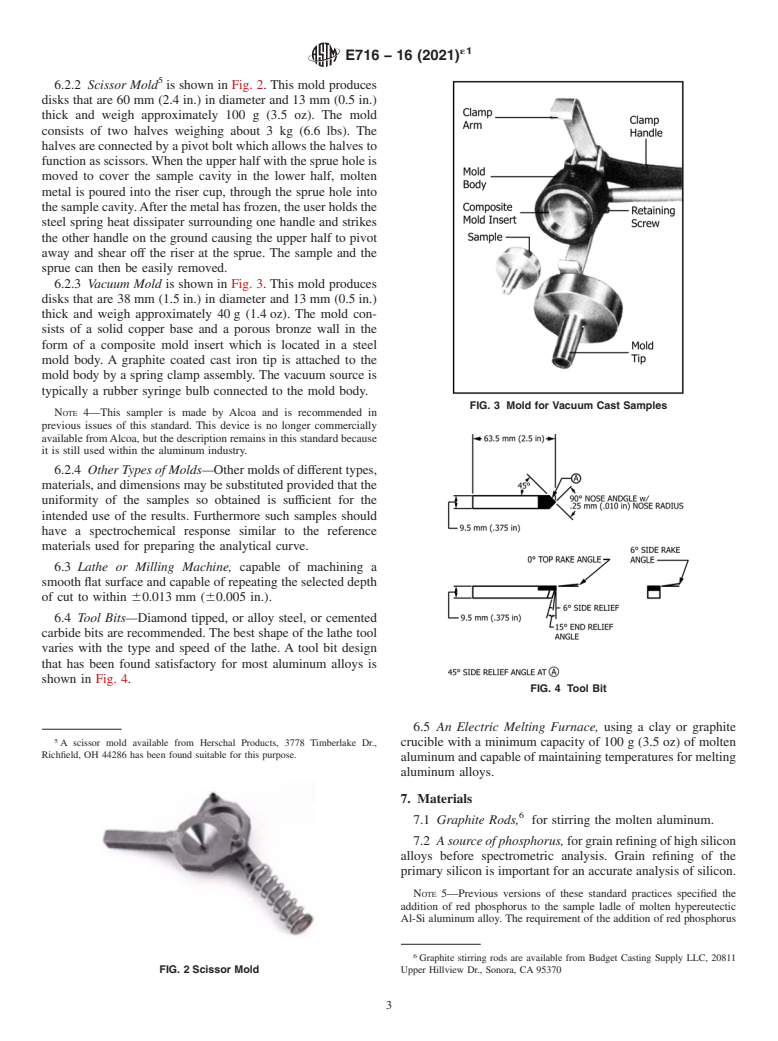

6.2.2 Scissor Mold is shown in Fig. 2. This mold produces

disks that are 60 mm (2.4 in.) in diameter and 13 mm (0.5 in.)

thick and weigh approximately 100 g (3.5 oz). The mold

consists of two halves weighing about 3 kg (6.6 lbs). The

halvesareconnectedbyapivotboltwhichallowsthehalvesto

functionasscissors.Whentheupperhalfwiththesprueholeis

moved to cover the sample cavity in the lower half, molten

metal is poured into the riser cup, through the sprue hole into

thesamplecavity.Afterthemetalhasfrozen,theuserholdsthe

steel spring heat dissipater surrounding one handle and strikes

the other handle on the ground causing the upper half to pivot

away and shear off the riser at the sprue. The sample and the

sprue can then be easily removed.

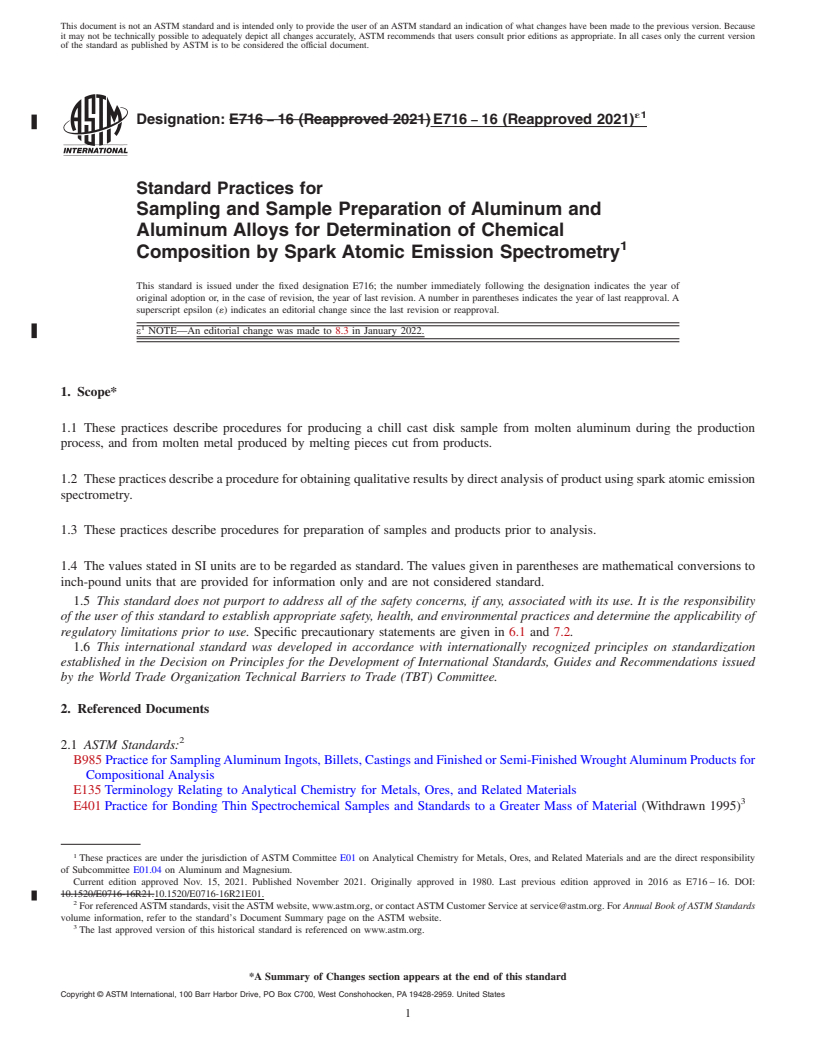

6.2.3 Vacuum Mold is shown in Fig. 3. This mold produces

disks that are 38mm (1.5in.) in diameter and 13mm (0.5in.)

thick and weigh approximately 40g (1.4oz). The mold con-

sists of a solid copper base and a porous bronze wall in the

form of a composite mold insert which is located in a steel

mold body. A graphite coated cast iron tip is attached to the

mold body by a spring clamp assembly. The vacuum source is

typically a rubber syringe bulb connected to the mold body.

FIG. 3 Mold for Vacuum Cast Samples

NOTE 4—This sampler is made by Alcoa and is recommended in

previous issues of this standard. This device is no longer commercially

available fromAlcoa, but the description remains in this standard because

it is still used within the aluminum industry.

6.2.4 OtherTypesofMolds—Othermoldsofdifferenttypes,

materials,anddimensionsmaybesubstitutedprovidedthatthe

uniformity of the samples so obtained is sufficient for the

intended use of the results. Furthermore such samples should

have a spectrochemical response similar to the reference

materials used for preparing the analytical curve.

6.3 Lathe or Milling Machine, capable of machining a

smooth flat surface and capable of repeating the selected depth

of cut to within 60.013mm (60.005 in.).

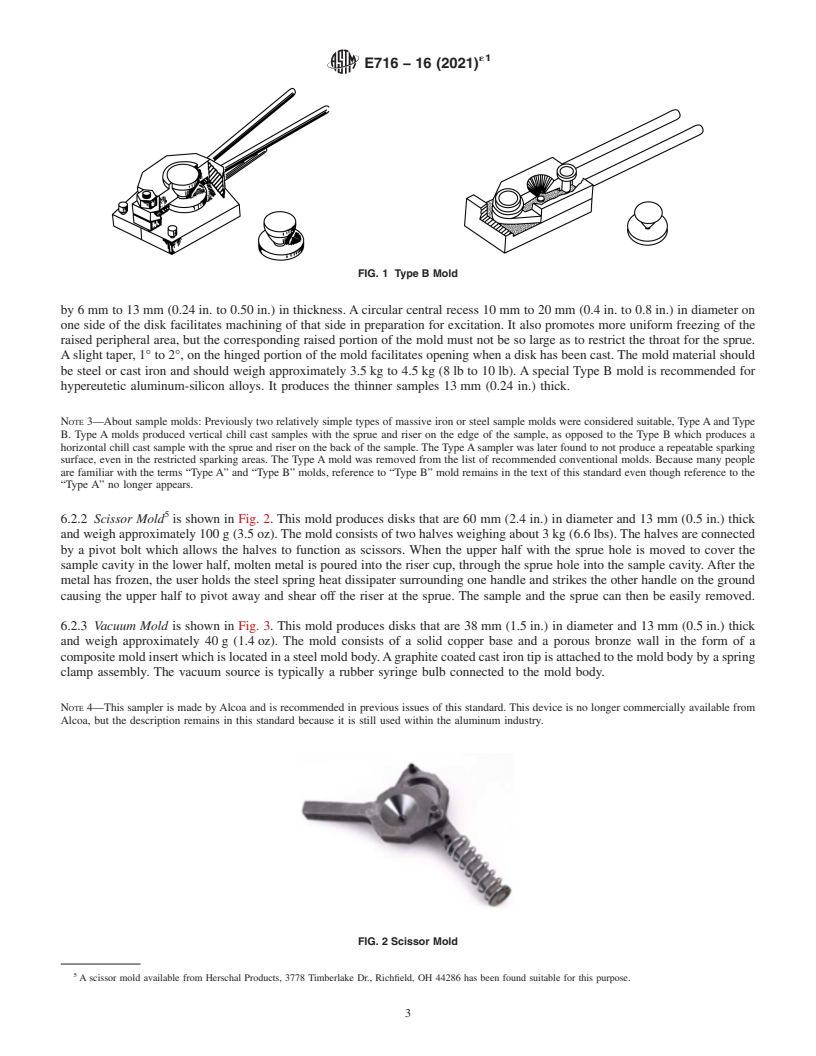

6.4 Tool Bits—Diamond tipped, or alloy steel, or cemented

carbide bits are recommended.The best shape of the lathe tool

varies with the type and speed of the lathe. A tool bit design

that has been found satisfactory for most aluminum alloys is

shown in Fig. 4.

FIG. 4 Tool Bit

6.5 An Electric Melting Furnace, using a clay or graphite

A scissor mold available from Herschal Products, 3778 Timberlake Dr., crucible with a minimum capacity of 100 g (3.5 oz) of molten

Richfield, OH 44286 has been found suitable for this purpose.

aluminumandcapableofmaintainingtemperaturesformelting

aluminum alloys.

7. Materials

7.1 Graphite Rods, for stirring the molten aluminum.

7.2 Asourceofphosphorus,forgrainrefiningofhighsilicon

alloys before spectrometric analysis. Grain refining of the

primary silicon is important for an accurate analysis of silicon.

NOTE 5—Previous versions of these standard practices specified the

addition of red phosphorus to the sample ladle of molten hypereutectic

Al-Si aluminum alloy. The requirement of the addition of red phosphorus

Graphite stirring rods are available from Budget Casting Supply LLC, 20811

FIG. 2 Scissor Mold Upper Hillview Dr., Sonora, CA 95370

´1

E716 − 16 (2021)

was based on the assumption that the larger quantity of molten aluminum grinding. Sanding or grinding tends to smear the relatively soft aluminum

alloy (which was sampled by the ladle) had not previously been grain phase over the harder constituent phases or cause hard grains to be torn

refined with phosphorus. Red phosphorus is no longer available without a from the sample and may cause biased results for spark atomic emission

speciallicense.Therecommendedreplacementgrainrefiningadditiveisa spectrometry.

copper-8 % phosphorus alloy. The entire molten bath should be refined

8.1.4.1 The machined surface must be smooth and free of

before the sample ladle removes the smaller amount of molten metal for

scuffs, pits, or inclusions. The ideal surface is neither polished

the sample. If the sample must be taken prior to grain refinement of the

main bath, either a small amount of copper-8 % phosphorus alloy should nor visibly grooved but should be a surface showing very fine

be added to the ladle, with the expectation that the copper concentration

tool marks. More specifically, the ideal surface may be defined

of the spectrometric analysis will be wrong, or a phosphorus chemical

as approximately a 1.6×10−3-mm (63-µin.) standard machine

compound without an interfering element should be added. This other

finish. A surface much finer or much coarser may result in an

compound will be hazardous and must be handled carefully by an

apparentanalyticaldifference.Furthermore,itisimportantthat

experienced chemist. A suitable compound is phosphorus penta-chloride

(PCl ). In either case, the phosphorus recovery after the alloying addition

both sample and reference material have the same machine

will be low, in a range of 15% to 40%.

finish. Analysis can be made 360° around the disk in the

annular area adjacent to the edge, avoiding the center area.

8. Preparation of Samples

8.1.5 Other Accepted Molds—If molds other than TypeB,

8.1 Molten Metal:

the scissor mold, or the vacuum mold are used, the same

8.1.1 When molten metal is to be sampled, the temperature

instructionsgivenin8.1wouldapply.Inaddition,sinceamold

mustbewellabovethepointatwhichanysolidphasecouldbe

of different dimensions may result in a different freezing

present. Using the ladle or a separate skimming tool, coated

pattern, each new type of mold must be evaluated in order to

withadry,tightlyadheringmoldwash(Note1)andfreeofany

ascertain the proper depth of machining to represent the true

remaining previous metal, push as much dross as possible

composition of the melt.

awayfromthesamplingarea.Next,diptheladlesidewaysinto

8.2 Remelting and Casting a Sample from Fabricated and

the clear area well below the surface and stir momentarily.

Cast Products:

Then turn the ladle upright, and quickly withdraw. Two things

are thus accomplished, namely, heating the ladle prevents 8.2.1 Chill-Cast Disk by TypeB Mold, the Scissor Mold, or

the Vacuum Mold—When the metal to be analyz

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E716 − 16 (Reapproved 2021) E716 − 16 (Reapproved 2021)

Standard Practices for

Sampling and Sample Preparation of Aluminum and

Aluminum Alloys for Determination of Chemical

Composition by Spark Atomic Emission Spectrometry

This standard is issued under the fixed designation E716; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—An editorial change was made to 8.3 in January 2022.

1. Scope*

1.1 These practices describe procedures for producing a chill cast disk sample from molten aluminum during the production

process, and from molten metal produced by melting pieces cut from products.

1.2 These practices describe a procedure for obtaining qualitative results by direct analysis of product using spark atomic emission

spectrometry.

1.3 These practices describe procedures for preparation of samples and products prior to analysis.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to

inch-pound units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. Specific precautionary statements are given in 6.1 and 7.2.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

B985 Practice for Sampling Aluminum Ingots, Billets, Castings and Finished or Semi-Finished Wrought Aluminum Products for

Compositional Analysis

E135 Terminology Relating to Analytical Chemistry for Metals, Ores, and Related Materials

E401 Practice for Bonding Thin Spectrochemical Samples and Standards to a Greater Mass of Material (Withdrawn 1995)

These practices are under the jurisdiction of ASTM Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials and are the direct responsibility

of Subcommittee E01.04 on Aluminum and Magnesium.

Current edition approved Nov. 15, 2021. Published November 2021. Originally approved in 1980. Last previous edition approved in 2016 as E716 – 16. DOI:

10.1520/E0716-16R21.10.1520/E0716-16R21E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E716 − 16 (2021)

E607 Test Method for Atomic Emission Spectrometric Analysis Aluminum Alloys by the Point to Plane Technique Nitrogen

Atmosphere (Withdrawn 2011)

E1251 Test Method for Analysis of Aluminum and Aluminum Alloys by Spark Atomic Emission Spectrometry

3. Terminology

3.1 For definitions of terms used in this practice, refer to Terminology E135.

4. Summary of Practices

4.1 Molten metal representative of the furnace melt is poured or drawn by vacuum into a specified mold to produce a chill-cast

disk. The disk is machined to a specified depth that represents the average composition and produces an acceptable surface for

analysis by spark atomic emission spectrometry.

4.2 Pieces of solid aluminum fabricated, cast, or wrought products are remelted and cast into molds or briquetted then remelted

and cast into molds.

4.3 Product can be qualitatively analyzed directly without remelting after suitable surface preparation. Product with insufficient

mass for direct analysis may be bonded to more massive material prior to analysis.

4.4 Special practices are included for the sampling and analysis of aluminum-silicon alloys, containing greater than 14 % silicon.

5. Significance and Use

5.1 The practice for taking a sample of molten metal during production and producing a chill cast disk, used in conjunction with

the following appropriate quantitative spark atomic emission spectrochemical methods, Test Methods E607 and E1251, is suitable

for use in manufacturing control or certifying, or both, that the entire lot of alloy sampled meets established composition limits.

5.2 The practice for melting a piece of a product to produce a chill cast disk analyzed in conjunction with the following appropriate

quantitative spark atomic emission spectrochemical methods, Test Methods E607 and E1251, is suitable, if a representative sample

is taken, for determining if the piece sampled meets Aluminum Association composition limits.

5.3 The practice for direct analysis of product is suitable for determining an approximate composition of the piece analyzed.

6. Apparatus

6.1 Ladle, capable of holding a minimum of 250 g (8.8 oz) of molten metal, with a handle of sufficient length to reach into a

furnace, trough, or crucible. The ladle should be lightly coated with a tightly adhering ladle wash that will serve in part to prevent

contamination of the sample and also prevent contact of molten aluminum with metal oxides, that is, rust. (Warning—Traces of

moisture in the coating may cause dangerous spattering.)

NOTE 1—A suitable ladle wash may be prepared as follows: Mix 255 g (9 oz) of fine whiting (CaCO ) with 3.8 L (1 gal) of water and boil for 20 min.

Add 127 g (4.5 oz) of sodium silicate solution (40 °Bé to 42 °Bé) and boil for 30 min. Stir well before using.

NOTE 2—Molten aluminum in contact with rust may initiate a thermite reaction.

6.2 Sample Molds shall be capable of producing homogenous chill-cast disks having smooth surfaces, free of surface pockets and

porosity. These chill cast disks should have a spectrochemical response similar to the reference materials used in preparing the

analytical curves and should at least have a spark to spark repeatability of no more than 2 % relative on major elements. They must

be representative of the melt in the region excited. Several types of molds have been found acceptable:

6.2.1 Type B Mold center-pour mold, is shown in Fig. 1. This mold produces a horizontally cast disk with the sprue over the center

of one side. The mold dimensions are such as to produce a disk approximately 50 mm to 64 mm (1.97 in. to 2.5 in.) in diameter

Type B molds, available from Danton Machine and Welding Incorporated, 713 Fortune Crescent, Kingston, ON Canada K7P 2T4, have been found suitable for this

purpose.

´1

E716 − 16 (2021)

FIG. 1 Type B Mold

by 6 mm to 13 mm (0.24 in. to 0.50 in.) in thickness. A circular central recess 10 mm to 20 mm (0.4 in. to 0.8 in.) in diameter on

one side of the disk facilitates machining of that side in preparation for excitation. It also promotes more uniform freezing of the

raised peripheral area, but the corresponding raised portion of the mold must not be so large as to restrict the throat for the sprue.

A slight taper, 1° to 2°, on the hinged portion of the mold facilitates opening when a disk has been cast. The mold material should

be steel or cast iron and should weigh approximately 3.5 kg to 4.5 kg (8 lb to 10 lb). A special Type B mold is recommended for

hypereutetic aluminum-silicon alloys. It produces the thinner samples 13 mm (0.24 in.) thick.

NOTE 3—About sample molds: Previously two relatively simple types of massive iron or steel sample molds were considered suitable, Type A and Type

B. Type A molds produced vertical chill cast samples with the sprue and riser on the edge of the sample, as opposed to the Type B which produces a

horizontal chill cast sample with the sprue and riser on the back of the sample. The Type A sampler was later found to not produce a repeatable sparking

surface, even in the restricted sparking areas. The Type A mold was removed from the list of recommended conventional molds. Because many people

are familiar with the terms “Type A” and “Type B” molds, reference to “Type B” mold remains in the text of this standard even though reference to the

“Type A” no longer appears.

6.2.2 Scissor Mold is shown in Fig. 2. This mold produces disks that are 60 mm (2.4 in.) in diameter and 13 mm (0.5 in.) thick

and weigh approximately 100 g (3.5 oz). The mold consists of two halves weighing about 3 kg (6.6 lbs). The halves are connected

by a pivot bolt which allows the halves to function as scissors. When the upper half with the sprue hole is moved to cover the

sample cavity in the lower half, molten metal is poured into the riser cup, through the sprue hole into the sample cavity. After the

metal has frozen, the user holds the steel spring heat dissipater surrounding one handle and strikes the other handle on the ground

causing the upper half to pivot away and shear off the riser at the sprue. The sample and the sprue can then be easily removed.

6.2.3 Vacuum Mold is shown in Fig. 3. This mold produces disks that are 38 mm (1.5 in.) in diameter and 13 mm (0.5 in.) thick

and weigh approximately 40 g (1.4 oz). The mold consists of a solid copper base and a porous bronze wall in the form of a

composite mold insert which is located in a steel mold body. A graphite coated cast iron tip is attached to the mold body by a spring

clamp assembly. The vacuum source is typically a rubber syringe bulb connected to the mold body.

NOTE 4—This sampler is made by Alcoa and is recommended in previous issues of this standard. This device is no longer commercially available from

Alcoa, but the description remains in this standard because it is still used within the aluminum industry.

FIG. 2 Scissor Mold

A scissor mold available from Herschal Products, 3778 Timberlake Dr., Richfield, OH 44286 has been found suitable for this purpose.

´1

E716 − 16 (2021)

FIG. 3 Mold for Vacuum Cast Samples

6.2.4 Other Types of Molds—Other molds of different types, materials, and dimensions may be substituted provided that the

uniformity of the samples so obtained is sufficient for the intended use of the results. Furthermore such samples should have a

spectrochemical response similar to the reference materials used for preparing the analytical curve.

6.3 Lathe or Milling Machine, capable of machining a smooth flat surface and capable of repeating the selected depth of cut to

within 60.013 mm (60.005 in.).

6.4 Tool Bits—Diamond tipped, or alloy steel, or cemented carbide bits are recommended. The best shape of the lathe tool varies

with the type and speed of the lathe. A tool bit design that has been found satisfactory for most aluminum alloys is shown in Fig.

4.

6.5 An Electric Melting Furnace, using a clay or graphite crucible with a minimum capacity of 100 g (3.5 oz) of molten aluminum

and capable of maintaining temperatures for melting aluminum alloys.

FIG. 4 Tool Bit

´1

E716 − 16 (2021)

7. Materials

7.1 Graphite Rods, for stirring the molten aluminum.

7.2 A source of phosphorus, for grain refining of high silicon alloys before spectrometric analysis. Grain refining of the primary

silicon is important for an accurate analysis of silicon.

NOTE 5—Previous versions of these standard practices specified the addition of red phosphorus to the sample ladle of molten hypereutectic Al-Si

aluminum alloy. The requirement of the addition of red phosphorus was based on the assumption that the larger quantity of molten aluminum alloy (which

was sampled by the ladle) had not previously been grain refined with phosphorus. Red phosphorus is no longer available without a special license. The

recommended replacement grain refining additive is a copper-8 % phosphorus alloy. The entire molten bath should be refined before the sample ladle

removes the smaller amount of molten metal for the sample. If the sample must be taken prior to grain refinement of the main bath, either a small amount

of copper-8 % phosphorus alloy should be added to the ladle, with the expectation that the copper concentration of the spectrometric analysis will be

wrong, or a phosphorus chemical compound without an interfering element should be added. This other compound will be hazardous and must be handled

carefully by an experienced chemist. A suitable compound is phosphorus penta-chloride (PCl ). In either case, the phosphorus recovery after the alloying

addition will be low, in a range of 15 % to 40 %.

8. Preparation of Samples

8.1 Molten Metal:

8.1.1 When molten metal is to be sampled, the temperature must be well above the point at which any solid phase could be present.

Using the ladle or a separate skimming tool, coated with a dry, tightly adhering mold wash (Note 1) and free of any remaining

previous metal, push as much dross as possible away from the sampling area. Next, dip the ladle sideways into the clear area well

below the surface and stir momentarily. Then turn the ladle upright, and quickly withdraw. Two things are thus accomplished,

namely, heating the ladle prevents metal freezing on the wall and obtaining metal well beneath the surface minimizes the danger

of inclusion of small particles of oxide.

8.1.2 Unless the mold is already hot, cast a preliminary disk into the clean mold in order to preheat it and discard this disk. Remove

excess metal from the ladle, dip into the molten metal as before, and fill the mold with an even rate of pour which allows the escape

of air from the mold. Do not dump the metal into the mold. Avoid overfilling the sprue, otherwise the mold may be difficult to

open. Allow the metal to freeze quietly without jarring. The surface of the disk must be free of any shrinkage, inclusions, cracks,

or roughness.

8.1.3 Chill Cast Disk Using Vacuum Mold—Skim the dross from the molten metal as in 8.1.1, using a skimming tool. Attach the

cast iron mold tip to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.