ASTM D4296-83(2009)

(Practice)Standard Practice for Sampling Pitch

Standard Practice for Sampling Pitch

SIGNIFICANCE AND USE

Sampling is as important as testing. If the sampling is improperly done, the sample of the material will be in error, and the analysis will not represent the true properties of the material, and it may be impossible or impracticable to take another sample; whereas, if the sample is properly taken and the analysis is in error, another analysis can readily be made of the original sample.

Samples may be taken for either of the following two purposes:

To represent as nearly as possible an average of the bulk of the materials sampled, or

To ascertain the maximum variation in characteristics which the material possesses.

A good sampling plan has the following characteristics:

It protects the consumer against the acceptance of a bad batch of material.

It protects the producer against the rejection of a good batch of material.

It gives long-range protection to the consumer.

It encourages the producer to keep his process in control.

It minimizes the cost of sampling, inspection of testing, and administration.

It provides information concerning the quality of the product.

Sampling Integrity—When one takes a sample, one is attempting to represent a batch or lot of material with that sample. Different forms of pitch, and pitch in different types of containers, need to have different sampling plans and appropriate sampling equipment. Each sampling plan should be designed so that it accomplishes its objective, which is to ascertain the characteristics or quality of a batch or lot of material.

SCOPE

1.1 This practice covers procedures for sampling pitch at points of manufacture, storage, and delivery.

1.2 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements are given in Section 11.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4296 − 83(Reapproved 2009)

Standard Practice for

Sampling Pitch

This standard is issued under the fixed designation D4296; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This practice covers procedures for sampling pitch at 4.1 Sampling is as important as testing. If the sampling is

points of manufacture, storage, and delivery. improperly done, the sample of the material will be in error,

and the analysis will not represent the true properties of the

1.2 The values stated in SI units are to be regarded as

material, and it may be impossible or impracticable to take

standard. The values in parentheses are for information only.

another sample; whereas, if the sample is properly taken and

1.3 This standard does not purport to address all of the

the analysis is in error, another analysis can readily be made of

safety concerns, if any, associated with its use. It is the

the original sample.

responsibility of the user of this standard to establish appro-

4.2 Samples may be taken for either of the following two

priate safety and health practices and determine the applica-

purposes:

bility of regulatory limitations prior to use. Specific warning

4.2.1 To represent as nearly as possible an average of the

statements are given in Section 11.

bulk of the materials sampled, or

2. Terminology

4.2.2 To ascertain the maximum variation in characteristics

which the material possesses.

2.1 Definitions:

2.1.1 bulk sample—a large sample, either from one place or

4.3 A good sampling plan has the following characteristics:

made up of several incremental samples of the same material.

4.3.1 It protects the consumer against the acceptance of a

2.1.2 composite sample—a thoroughly mixed gross sample. bad batch of material.

4.3.2 It protects the producer against the rejection of a good

2.1.3 gross sample—a large sample made up of several

batch of material.

portions (increments) of a mass of material.

4.3.3 It gives long-range protection to the consumer.

2.1.4 increment—a portion of a material to be combined

4.3.4 It encourages the producer to keep his process in

with other portions of the same material to provide a larger

control.

sample which will represent the whole material.

4.3.5 It minimizes the cost of sampling, inspection of

2.1.5 representative sample—a part of a homogeneous

testing, and administration.

material, or a part of the composited and mixed portions of a

4.3.6 It provides information concerning the quality of the

material, which carries all the true properties and physical

product.

characteristics of the whole material.

4.4 Sampling Integrity—When one takes a sample, one is

2.1.6 sample—a part taken as representative of a whole

attempting to represent a batch or lot of material with that

material.

sample. Different forms of pitch, and pitch in different types of

containers, need to have different sampling plans and appro-

3. Summary of Practice

priate sampling equipment. Each sampling plan should be

3.1 Samples of liquid pitches are taken from process lines,

designed so that it accomplishes its objective, which is to

storage, and shipment containers in increments required to

ascertain the characteristics or quality of a batch or lot of

prepare a representative sample for testing.

material.

3.2 Samples of solid pitches are taken from loading

systems, storage, and shipment containers in increments re-

5. Selection of Samples

quired to prepare a representative sample for testing.

5.1 Pitches shall be sampled by the producer at the point of

manufacture or storage, and at such time as to allow the tests

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum

controlling acceptance or rejection of quality, as specified by

Products, Liquid Fuels, and Lubricantsand is the direct responsibility of Subcom-

mittee D02.05 on Properties of Fuels, Petroleum Coke and Carbon Material. the consumer, to be made in advance of a shipment.

Current edition approved Oct. 1, 2009. Published November 2009. Originally

5.2 Samples of pitches shall be taken by the consumer from

approved in 1983. Last previous edition approved in 2004 as D4296–83(2004).

DOI: 10.1520/D4296-83R09. the shipment containers immediately upon delivery and receipt

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4296 − 83 (2009)

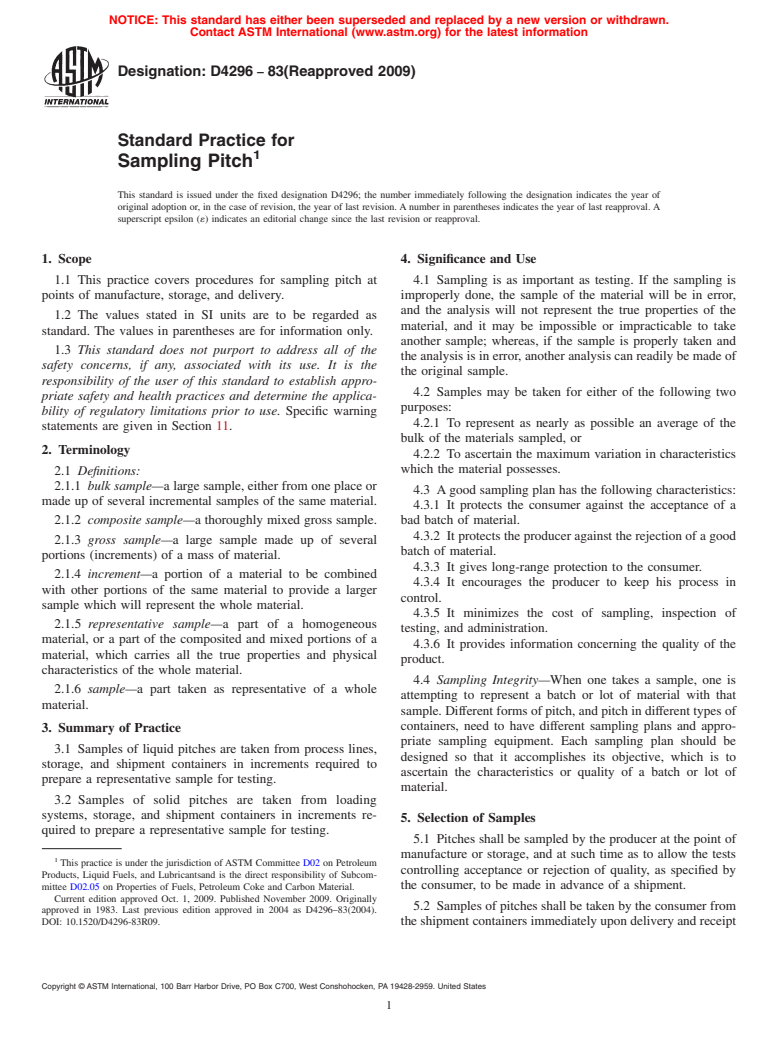

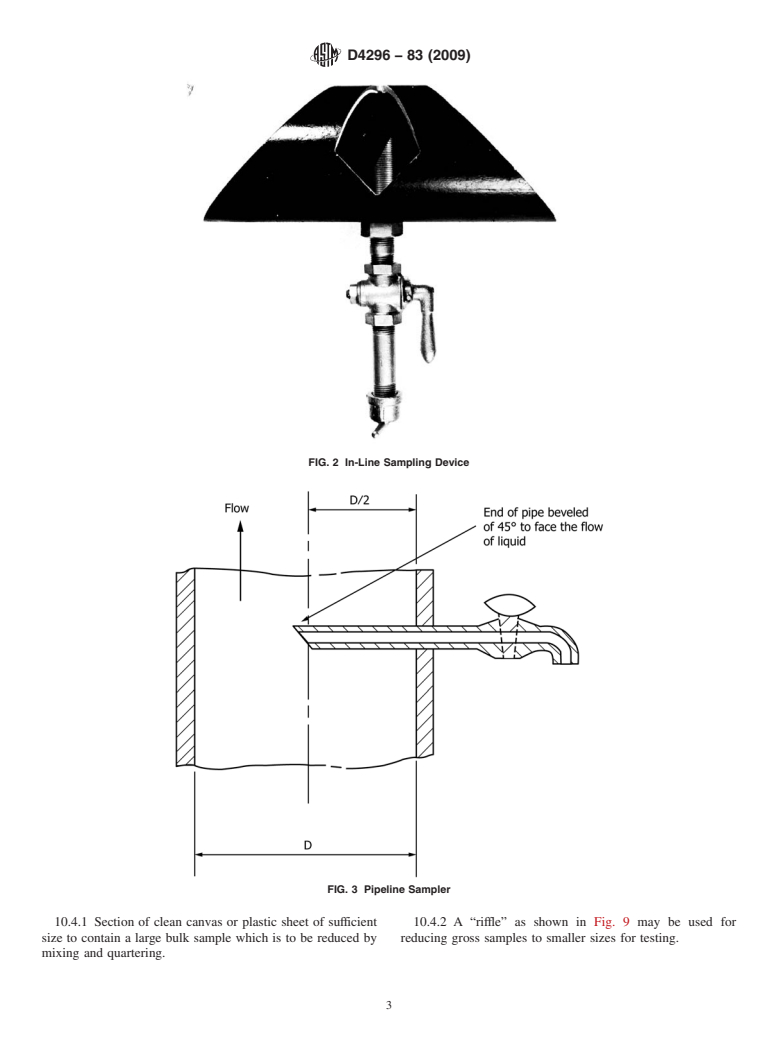

and tests controlling acceptance or rejection of quality, as 10.1.1 If so equipped, pipe lines and storage tanks may be

described by the consumer’s specifications, shall be made as sampled from valves installed in the lines or up the side of the

soon as possible. tanks.Atypical tank valve is shown in Fig. 1, and suitable line

valves are illustrated in Fig. 2 and Fig. 3.

6. Size of Samples

10.1.2 For sampling tank trucks, a pipe connection with

attached sample valve similar to the one shown in Fig. 2 may

6.1 The sample size of liquid materials shall be as follows:

be inserted between the outlet pipe and unloading line.

6.1.1 From process lines, 1 L (1 qt).

10.1.3 A weighted sample bottle similar to those shown in

6.1.2 From bulk storage, 1 L (1 qt) or 1-L aliquot of

Fig. 4 and Fig. 5, or a “thief sampler” as shown in Fig. 6,ora

composite sample.

“dip sampler” similar to that shown in Fig. 7, may be used to

6.1.3 From bulk shipment containers, 1 L (1 qt) or 1-L

sample production and storage tanks, tank cars, and tank

aliquot of composite sample.

trucks.

6.1.4 From barrels or drums, 0.5 L(1 pt) or 0.5-Laliquot of

10.1.4 A “tube” or “thief” sampler may be used to sample

composite sample.

materials in drums or barrels.

6.2 The sample size of solid materials shall be as follows:

10.2 Sampling Equipment for Solid Materials:

6.2.1 From storage area, 4 L (1 gal) or 4-L aliquot of

10.2.1 Samples from loading systems may be taken with a

composite sample.

shovel, metal or plastic scoop, or metal can.

6.2.2 From bulk shipment containers, 4 L (1 gal) aliquot of

10.2.2 A shovel may be used to sample storage bins, pitch

composite sample.

piles, pitch bays, hopper cars, and dump trucks.

6.2.3 From barrels or drums, 0.5-L(1 pt) or 0.5-Laliquot of

10.2.3 A sampling spear as shown in Fig. 8 may be used to

composite sample.

sample materials in drums, barrels, bags, and silos.

7. Collection of Gross Sample

10.3 Sampling Containers:

7.1 Acollection of gross sample represents a lot or batch of

10.3.1 Containers for liquid materials shall be wide-mouth

material and is composed of a number of increments.

cans with line screw caps or triple-seal friction-top cans.

7.1.1 Collect the increments regularly and systematically, so

10.3.2 Containers for formed pitches or crushed solid pitch

that the entire quantity of pitch sampled will be represented

shall be triple-seal friction-top cans, sealable plastic or paper

proportionately in the gross sample, and with such frequency

cartons with inert inside coating, plastic sacks placed in other

that a gross sample of the required amount will be collected.

containers suitable for handling, or substantial strength paper

bag which can be stapled closed.

8. Size of Increments

10.4 Mixing Equipment for Solid Materials:

8.1 To collect samples, use a shovel or specially designed

tool or mechanical means for taking equal portions or incre-

ments. When samples are collected from the surface of loaded

shipments, the gross sample shall consist of nine increments of

approximately equal quantity. When sampling from piles,

conveyer belts, and so forth, the gross sample shall consist of

not less than 25 nor more than 50 increments of approximately

equal quantity.

9. Protection and Preservation of Samples

9.1 Sample containers shall be new or reusable containers

which can be thoroughly cleaned with a solvent and wiped dry

with a clean dry cloth.

9.2 Care shall be taken to prevent the sample from becom-

ing contaminated. Immediately after filling, hot liquid sample

containers shall be positively covered, but not tightly sealed.

Containers of solid materials shall be tightly and positively

sealed.

9.3 While sampling during inclement weather, attention

shall be paid to prevent water from dropping into the hot liquid

sample or samples of solid materials.

9.4 Immediately after filling and sealing, the sampling

containers shall be properly marked for identification with a

suitable pencil on the container itself, not on the lid.

10. Apparatus

10.1 Sampling Equipment for Liquid Materials: FIG. 1 Typical Submerged Sampling Device

D4296 − 83 (2009)

FIG. 2 In-Line Sampling Device

FIG. 3 Pipeline Sampler

10.4.1 Section of clean canvas or plastic sheet of sufficient 10.4.2 A “riffle” as shown in Fig. 9 may be used for

size to contain a large bulk sample which is to be reduced by

reducing gross samples to smaller sizes for testing.

mixing and quartering.

D4296 − 83 (2009)

FIG. 4 Weighted Sampling Can

10.4.3 A “shovel” may be used to reduce gross samples to 11.3 Sampling from rail cars shall be avoided when there is

smaller sizes by mixing and quartering as shown in Fig. 10. a possibility of shunting operations taking place. It is recom-

mended that flags be placed on both ends of the car to prevent

10.5 Mixing Equipment for Liquid Materials:

accidental movement during sampling.

10.5.1 Sample sizes of 4 L (1 gal) or less can be mixed by

thorough stirring with a metal rod or wide blade metal paddle.

11.4 It is recommended that no fewer than two persons be

10.5.2 A heavy duty electric stirrer is recommended for

present when samples are taken from hot bulk vessels such as

sample volumes over 4 L (1 gal) to 20 L (5 gal) in size.

storage tanks, tank cars, and tank trucks.

11. Hazards

12. Sampling Liquid Pitch

11.1 The sampler shall wear protective clothing, goggles,

12.1 The following three sampling methods are recom-

and rubber or heat-resistant gloves to protect oneself from

mended for sampling vertical tanks not capable of being

accidental contact with hot liquid pitch.

agitated:

11.2 For prolonged exposure to the presence of pitch vapors 12.1.1 Sample-Valve Method—Locate valves, with easy and

or pitch dust, a suitable respirator mask should be worn to safe access provided, on the side of the tank with the first in the

avoidinhalationofpitchvaporsordust.Itisrecommendedthat top third of the tank, but no higher than 1 m (3 ft) from the top;

an appropriate barrier cream be applied to exposed areas of the thesecondinthemiddleofthetank;andthethirdinthebottom

skin. third of the tank, but no lower than 1.1m(3 ⁄2 ft) from the

D4296 − 83 (2009)

NOTE 1—This type sampler is lowered into the tank with the stopper in place. When the desired depth is reached, the stopper is removed by means

of the attached wire, cord, or chain and the container allowed to fill. Complete filling is indicated by the cessation of bubbles of air from the can at the

surface of the liquid. The sampler is then withdrawn from the tank and the contents poured into the clean sampler container. A clean can (bottle) must

be used for each sample taken.

FIG. 5 Throw-Away Container Sampler

bottom. A recommended design of the sample valve is shown 12.1.3.2 Normally, there is not enough undrained residue

in Fig. 1. Draw a minimum of 4 L (1 gal) of the product from

from the first sample to affect the properties of the next sample

each sample valve for test or composite.

taken from a different level. However, if substantial material

12.1.2 Thief Sampling Method—Take samples at the top,

difference is suspected at various levels of the material, discard

middle and lower sections of the tank by lowering a thief

the first of successive samples to rinse the bottle and then

sampler into the material. A satisfactory type with instructions

return the bottle to the same level for another sample.

for use is shown in Fig. 6. The samples may be tested

12.1.3.3 The three samples may be tested separately for

separately or combined and mixed thoroughly for a composite

consistency to detect stratification or they may be combined,

analysis.

thoroughly mixed, anda1to4-L( ⁄4 to 1-gal) aliquot of the

12.1.3 Weighted Sample Bottle Method—Take samples at

composite taken for determining the average characteristics of

the top, middle, and lower sections of the tank by lowering the

the material.

bottle into the material. Two types of weighted sampling

bottles are illustrated in Fig. 4 and Fig. 5.

12.2 Sampling Bulk Storage Tanks Equipped with Mechani-

12.1.3.1 The essential feature of the method is to drop the

cal Agitators or Recirculating Pumps—When the tank is

stoppered bottle into the material to the desired depth, and then

equipped with operating mechanical agitators or recirculating

pull the stopper by means of an attached chain. When the

pumping systems which are performing adequate mixing of the

material fills the bottle, lift out of the liquid and empty into a

tank contents, take a single sample by any of the methods

clean container. Drain the bottle as completely as possible,

described in 12.1.1, 12.1.2,or 12.1.3 to use for test purposes.

re-insert the stopper, lower into the material to the next

sampling depth. 12.3 Sampling Tank Cars and Tank Trucks:

D4296 − 83 (2009)

12.3.2 If incremental samples are required for subsequent

composite, samples may be taken as described in 12.1.2 or

12.1.3.

12.3.3 When tank cars or tank trucks are being loaded or

unloaded, samples may conveniently be taken from the pipe

line through which material is flowing by insertion of a

sampling pipe into the rising section of the pipe line on the

discharge side of the pump, or in a completely filled line in

which gravity creates the material’s flow.

12.3.3.1 A suitable in-line sampling pipe is shown in Fig. 2

and Fig. 3. Turn the opening of the sampling pipe to face the

flow of the liquid. Provide the pipe with a valve or plug cock

and discharge into a sample receiver. Before the sample is

taken, draw 4 L (1 gal) of the material from the pipe valve and

discard.

12.3.3.2 Take samples of 1 L(1 qt) at such frequency during

the loading or unloading to providea4to8-L(1to 2-gal)

composite of the material. At the completion of the loading or

unloading, thoroughly mix the collected sample and take a 0.5

NOTE 1—This type sampler is lowered into the tank with bottom valve

to 4-L ( ⁄8 to 1-gal) portion for testing.

open (there is no top closu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.