ASTM D4616-95(2018)

(Test Method)Standard Test Method for Microscopical Analysis by Reflected Light and Determination of Mesophase in a Pitch

Standard Test Method for Microscopical Analysis by Reflected Light and Determination of Mesophase in a Pitch

SIGNIFICANCE AND USE

5.1 Sometimes coal tar and petroleum pitches are heat treated thereby forming mesophase spheroids. The mesophase may be partially soluble in quinoline and cannot be estimated by the quinoline insoluble test (Test Method D2318). This test method provides for the identification, quantitative estimation, and size determination of mesophase spheroids.

5.2 The mesophase initially forms as spheroids that may coalesce to form a variety of asymmetrical shapes. The smallest mesophase particle that can be detected with certainty at 400× or 500× magnification is 4 μm in diameter; mesophase particles sizes less than 4 μm should be ignored. If mesophase material less than 4 μm in size is of interest, then magnifications of 1000× to 1800× shall be used and the results should be appropriately identified. This method is limited to determining minor levels of mesophase, that is, ≤20 % mesophase.

SCOPE

1.1 This test method covers laboratory procedures for the preparation of granular and melted samples for microscopic analysis using reflected light to identify and estimate the amount and size of the mesophase.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D4616 −95 (Reapproved 2018)

Standard Test Method for

Microscopical Analysis by Reflected Light and

Determination of Mesophase in a Pitch

This standard is issued under the fixed designation D4616; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E562Test Method for Determining Volume Fraction by

Systematic Manual Point Count

1.1 This test method covers laboratory procedures for the

preparation of granular and melted samples for microscopic

3. Terminology

analysis using reflected light to identify and estimate the

3.1 Definitions of Terms Specific to This Standard:

amount and size of the mesophase.

3.1.1 cenospheres—usually a minor component of coal tar

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

pitch. They are formed by the rapid pyrolysis of unconfined

as standard. The values given in parentheses are mathematical

coal particles that are carried over from the coke oven to the

conversions to SI units that are provided for information only

tar. Microscopically, they appear like hollow spheres or seg-

and are not considered standard.

ments thereof (see Fig. 1), and are typically sized from about

1.3 This standard does not purport to address all of the

10µm to 500µm. In polarized light (crossed polarizers), a

safety concerns, if any, associated with its use. It is the

cenospheremaybeopticallyactive.Thesizeoftheanisotropic

responsibility of the user of this standard to establish appro-

pattern or mosaic depends upon the rank of the coal carbon-

priate safety, health, and environmental practices and deter-

ized. Cenospheres are harder than the continuous phase and

mine the applicability of regulatory limitations prior to use.

polish in relief (see Fig. 1).

1.4 This international standard was developed in accor-

3.1.2 coke-oven-coke—usually a minor component of coal

dance with internationally recognized principles on standard-

tar pitch. It originates in carry-over from the coke oven to the

ization established in the Decision on Principles for the

tar side. It differs from cenospheres only in terms of its shape

Development of International Standards, Guides and Recom-

and porosity. Coke-oven-coke is angular and less porous.

mendations issued by the World Trade Organization Technical

3.1.3 isotropic phase—usually the predominant, and

Barriers to Trade (TBT) Committee.

continuous, phase. It is a complex mixture of organic aromatic

2. Referenced Documents

compounds composed mainly of carbon and hydrogen. At

2.1 ASTM Standards: room temperature, the isotropic phase is a glass-like solid. It is

optically inactive in polarized light (see Fig. 1 and Fig. 2).

D329Specification for Acetone

D1160TestMethodforDistillationofPetroleumProductsat

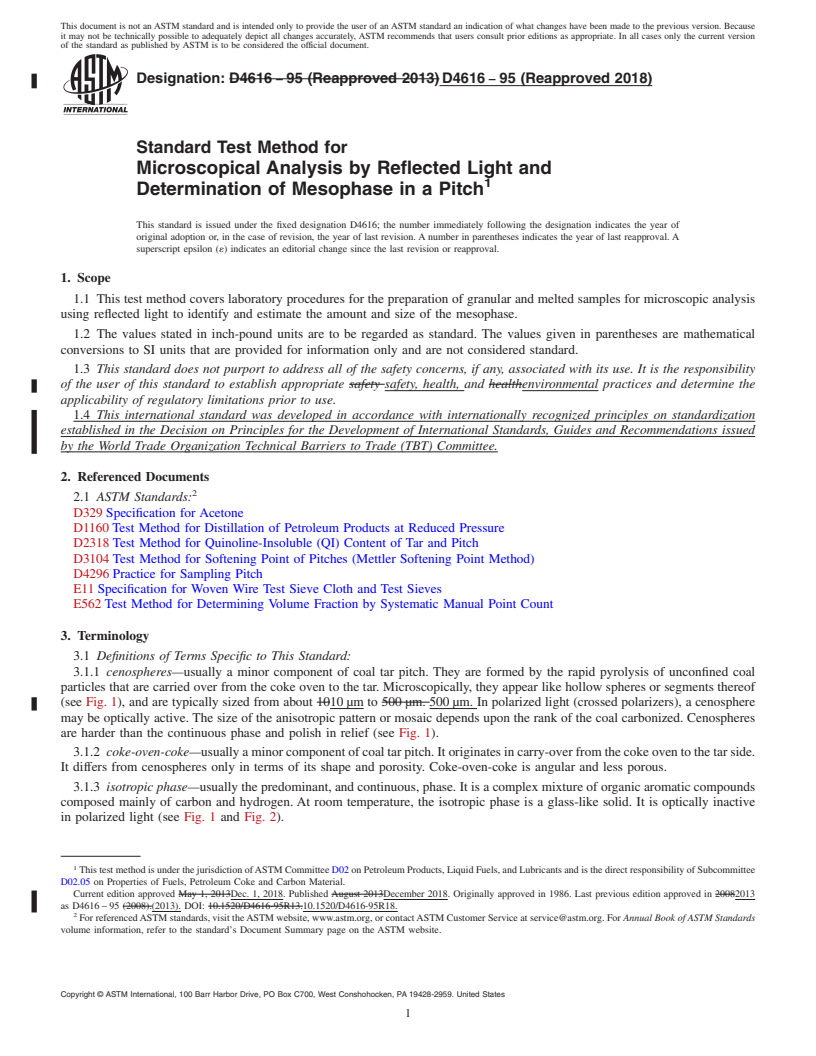

3.1.4 mesophase—an optically anisotropic liquid crystal

Reduced Pressure

carbonaceous phase that forms from the parent liquor when

D2318Test Method for Quinoline-Insoluble (QI) Content of

molecular size, shape, and distribution are favorable. In the

Tar and Pitch

early stages of its development, mesophase usually appears as

D3104Test Method for Softening Point of Pitches (Mettler

spheroids. The planar molecules are lined up equatorially as

Softening Point Method)

shown schematically in Fig. 3. This equatorial arrangement

D4296Practice for Sampling Pitch

may be distinguished in crossed polarized light. Under crossed

E11Specification forWovenWireTest Sieve Cloth andTest

polarizers, the distinctive mesophase spheroids, with their

Sieves

complex extinction patterns shown in Fig. 2, can be readily

seen.

This test method is under the jurisdiction of ASTM Committee D02 on

3.1.4.1 spheroids—Atmagnificationsof400×and500×,the

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

minimumspheroidsizewhichcanberesolvedwithconfidence

SubcommitteeD02.05onPropertiesofFuels,PetroleumCokeandCarbonMaterial.

Current edition approved Dec. 1, 2018. Published December 2018. Originally

is 4µm in diameter.At magnifications of 1000× to 1800×, the

approved in 1986. Last previous edition approved in 2013 as D4616–95(2013).

DOI: 10.1520/D4616-95R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AmorecompletediscussionwillbefoundinapaperbyHonda,H.,Kimura,H.,

Standards volume information, refer to the standard’s Document Summary page on andSanada,Y.,“ChangesofPleochroismandExtinctionContoursinCarbonaceous

the ASTM website. Mesophase,” Carbon, 9, 1971, pp. 695–697.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4616−95 (2018)

minimumspheroidsizethatcanberesolvedwithconfidenceis combustion black (see Fig. 5a). Normal QI with concentric

about 2µm in diameter. Typically, the upper size may be symmetry is produced by thermal cracking later in the

100µm. Mesophase spheroids are relatively soft and do not cokingcycleunderreducingconditions,andisreferredtoas

formreliefstructures(seeFig.4).Quinolineinsolubleparticles thermal black (see Fig. 5b). These two symmetries can only

4,5

often aggregate at the interface between the continuous isotro- bedifferentiatedusingelectronmicroscopy. Thequinoline

pic phase and mesophase. insolubles content determined by Test Method D2318 is

sometimes greater than that anticipated on the basis of the

3.1.4.2 isotropicphase—Theisotropicphaseismoresoluble

concentration of the quinoline insolubles during distillation

than the mesophase in solvents such as toluene. Solvent

orheattreatmenttoproducethefinalpitch.Thedifferenceis

etching is achieved by soaking the polished surface in toluene

known as the “secondary” quinoline insolubles content, and

for a few seconds, rinsing the surface with cold flowing water,

is traditionally regarded as the mesophase content. This

and drying in a current of hot air. Etching produces sharply

equivalence of secondary quinoline insolubles and mesoph-

defined mesophase spheroids (see Fig. 4).

ase is erroneous because the mesophase may be partially

3.1.5 mineral matter—formed when minute particles of the

soluble in quinoline.

cokeovenchargearecarriedoverintothecokeovencollecting

3.1.7 pyrolytic carbon—acarbonthatoriginatesasadeposit

main during the charging operation.The tiny coal particles are

on the upper walls, tunnel head, and standpipes of a coke oven

digested in the collecting main tar, resulting in a residue that is

due to thermal cracking. It is usually a minor phase in coal tar

rich in mineral matter. This mineral matter is identified under

pitch, highly variable in shape and porosity, and may be sized

bright field illumination by its high reflectivity, in the case of

up to 500µm. It is usually optically active under crossed

pyrite, and its low reflectance in the case of clay, quartz, and

polarizers.Thefinesizeddomainsarecommonlyreferredtoas

carbonates. The association of mineral matter with insoluble

spherulitic, while the coarser anisotropic domains are called

organic matter from coal aids in its identification.

pyrolytic. Spherulitic and pyrolytic carbons are highly

3.1.6 normal quinoline insolubles—(sometimes termed

reflecting,relativelyhardmaterialsandstandoutinrelieffrom

“true,” natural or “primary” quinoline insolubles)—a carbon

the softer isotropic phase.

black-like solid phase in coal tar pitch that is produced by

3.1.8 reactorcoke—amaterialthatoriginatesonthewallsof

thermal cracking of organic compounds in the tunnel head

the pipestill reactor used in the distillation or heat treatment to

above the coal charge in a by-product coke oven. The indi-

produce pitch from either coal tars or petroleum oils. It is

vidual spherically-shaped particles are usually less than 2µm

thermally more advanced than reactor mesophase. It is usually

in diameter. A typical coal tar pitch may contain from about

a minor component of pitch and may be sized up to 200µm. It

1% to about 20% (by weight) of normal quinoline insolubles.

may be angular or rounded, and it may be relatively porous

The normal quinoline insolubles are relatively hard. They are

with a coarse appearance under crossed polarizers. It is

outlinedinbrightincidentlightbecausetheystandoutinrelief

distinguished from the reactor mesophase mentioned in 3.1.9

from the softer isotropic phase (see Fig. 1).

by its relative hardness, which causes it to show up in relief in

3.1.6.1 Discussion—SometimesthetermprimaryQIisused bright field illumination.

to describe all quinoline insoluble materials that are carried

3.1.9 reactor mesophase—a material that originates on the

overduringthecokingoperation(cenospheres,mineralmatter,

walls of the pipestill or reactor used in the distillation or heat

normal, QI, and so forth).

treatment to produce pitch from either coal tars or petroleum

3.1.6.2 normal quinoline insoluble material—Observed un-

oils.Itisusuallyaminorcomponentofpitchandmaybesized

der crossed polarizers, the normal quinoline insoluble material

up to 200µm. It may be angular or rounded, and it may be

displays a Brewster cross pattern (see Fig. 1 and Fig. 2). This

relatively porous. Under crossed polarizers reactor mesophase

interference figure remains stationary when the specimen is

has a coarse mosaic appearance. In contradistinction to the

rotated through 360°. The onionskin arrangement can be

reactor coke mentioned in 3.1.8, reactor mesophase is com-

observedinparticleswithaminimumdiameterof2µmathigh

paratively soft and shows no relief in bright field illumination.

magnification (1000× to 2000×) under cross polarizers.

3.1.10 refractory—usually a minor component that origi-

natesfromthecokeovenwalls,doors,andpatchesduetowear

3.1.6.3 Discussion—The quinoline insolubles content is de-

termined by Test Method D2318 and represents the total and degeneration; another component is charge hole sealant. It

can be recognized under the microscope through optical

amount of natural quinoline insolubles, cenospheres, coke-

oven-coke, pyrolytic carbon, refractory, reactor coke, and free properties, hardness, shape, and associated minerals.

ash in a pitch. Additionally, the quinoline insolubles will

4. Summary of Test Method

contain any insoluble species from the isotropic phase and the

insoluble portion of the mesophase. Hence, the quinoline

4.1 Arepresentativesamplewithasofteningpointofatleast

soluble fraction is composed of the bulk of the isotropic phase

212°F (100°C), as measured by Test Method D3104 (Mettler

and the soluble fraction of the mesophase. However, the

quinolineinsolubletestisnotnecessarilyatruemeasureofthe

Bertau, B.L., and Souffrey, B., “Composition of Tar and Pitches as a Result of

solid constituents of pitch.

theSpecificAspectsoftheCokingPlant,” Coke Making International,Vol2,1990,

Normal QI with radial symmetry is produced by oxy-

pp. 61–63.

cracking during the early portion of the coking cycle when

Lafdi, K., Bonnamy, S., and Oberlin, A., “TEM Studies of Coal Tars—Crude

partially oxidizing conditions can exist, and is referred to as Tar and its Insoluble Fractions,” Carbon, Vol 28, No. 1, 1990, pp. 57–63.

D4616−95 (2018)

method), is crushed to a specific particle size and encapsulated flat,scratch-freesurface.Lapsmaybemadeofaluminum,iron,

in resin.Alternatively, a representative molten pitch sample is brass, bronze, lead, glass, wax, or wood. Equipment that has

poured into a mold, or a representative crushed sample is 8in. (203mm) diameter disk laps that can rotate at 150 to 400

meltedandpouredintoamold.IftheMettlersofteningpointis r/min, and that has an automatic sample holder attachment is

9,8

less than 212°F (100°C), it is raised to 212°F to 248°F recommended.

(100°Cto120°C)byvacuumdistillation.Theencapsulated,or

6.8 Sample Cleaner—Some equipment is essential for

molded, sample is ground and polished to a flat surface for

cleaning the specimens between the different grinding or

examination in reflected light.

polishing stages. This may be an ultrasonic device or a simple

4.2 The mesophase spheroid content of a representative stream of water and an air jet for drying.

sampleisidentifiedandtheproportiondeterminedonavolume

6.9 Microscope—Any polarizing microscope with the capa-

basis by observing a statistically adequate number of points.

bility for observations by reflected light (for example, metal-

Only the area proportion is determined on a surface section of

lurgical or opaque-ore microscopes) may be employed. The

a sample; however, the area and volume proportion are the

polarizer may be of the Nicol prism or sheet type. All optical

same when the components are randomly distributed through-

components(objective,eyepiece,polarizer,andanalyzer)shall

out the sample.

be of a quality to permit examination of the dry specimen at

magnifications up to 400× to 500× under crossed polarizers.

5. Significance and Use

For magnifications greater than 500×, 0.1 immersion objec-

5.1 Sometimes coal tar and petroleum pitches are heat

tives shall be used. The analyzer should be oriented 90° with

treated thereby forming mesophase spheroids. The mesophase

respect to the polarizer for cross polarizer examination. Any

may be partially soluble in quinoline and cannot be estimated

light source that can be regulated for stable output with

by the quinoline insoluble test (Test Method D2318). This test

sufficient intensity for photography with cross polarizers may

method provides for the identification, quantitative estimation,

be used. The microscope shall have a circular stage that is

and size determination of mesophase spheroids.

capable of rotating a specimen through 360°. The stage shall

alsobeofsuchtypethatthespecimencanbequicklyadvanced

5.2 The mesophase initially forms as spheroids that may

coalesce to form a variety of asymmetrical shapes. The by definite fixed increments in two perpendicular directions,

suchasastagewithclickstops.Ifanelectricallyoperatedstage

smallest mesophase particle that can be detected with certainty

at 400× or 500× magnification is 4 µm in diameter; mesophase is used, incremental steps in one direction across the specimen

may be actuated by the counter switches. One eyepiece of the

particles sizes less than 4 µm should be ignored. If mesophase

material less than 4 µm in size is of interest, then magnifica- microscope should be fitted with a graticule or cross-hair. If

tionsof1000×to1800×shallbeusedandtheresultsshouldbe other

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4616 − 95 (Reapproved 2018)

Standard Test Method for

Microscopical Analysis by Reflected Light and

Determination of Mesophase in a Pitch

This standard is issued under the fixed designation D4616; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E562 Test Method for Determining Volume Fraction by

Systematic Manual Point Count

1.1 This test method covers laboratory procedures for the

preparation of granular and melted samples for microscopic

3. Terminology

analysis using reflected light to identify and estimate the

amount and size of the mesophase. 3.1 Definitions of Terms Specific to This Standard:

3.1.1 cenospheres—usually a minor component of coal tar

1.2 The values stated in inch-pound units are to be regarded

pitch. They are formed by the rapid pyrolysis of unconfined

as standard. The values given in parentheses are mathematical

coal particles that are carried over from the coke oven to the

conversions to SI units that are provided for information only

tar. Microscopically, they appear like hollow spheres or seg-

and are not considered standard.

ments thereof (see Fig. 1), and are typically sized from about

1.3 This standard does not purport to address all of the

10 µm to 500 µm. In polarized light (crossed polarizers), a

safety concerns, if any, associated with its use. It is the

cenosphere may be optically active. The size of the anisotropic

responsibility of the user of this standard to establish appro-

pattern or mosaic depends upon the rank of the coal carbon-

priate safety, health, and environmental practices and deter-

ized. Cenospheres are harder than the continuous phase and

mine the applicability of regulatory limitations prior to use.

polish in relief (see Fig. 1).

1.4 This international standard was developed in accor-

3.1.2 coke-oven-coke—usually a minor component of coal

dance with internationally recognized principles on standard-

tar pitch. It originates in carry-over from the coke oven to the

ization established in the Decision on Principles for the

tar side. It differs from cenospheres only in terms of its shape

Development of International Standards, Guides and Recom-

and porosity. Coke-oven-coke is angular and less porous.

mendations issued by the World Trade Organization Technical

3.1.3 isotropic phase—usually the predominant, and

Barriers to Trade (TBT) Committee.

continuous, phase. It is a complex mixture of organic aromatic

2. Referenced Documents

compounds composed mainly of carbon and hydrogen. At

room temperature, the isotropic phase is a glass-like solid. It is

2.1 ASTM Standards:

D329 Specification for Acetone optically inactive in polarized light (see Fig. 1 and Fig. 2).

D1160 Test Method for Distillation of Petroleum Products at

3.1.4 mesophase—an optically anisotropic liquid crystal

Reduced Pressure

carbonaceous phase that forms from the parent liquor when

D2318 Test Method for Quinoline-Insoluble (QI) Content of

molecular size, shape, and distribution are favorable. In the

Tar and Pitch

early stages of its development, mesophase usually appears as

D3104 Test Method for Softening Point of Pitches (Mettler

spheroids. The planar molecules are lined up equatorially as

Softening Point Method)

shown schematically in Fig. 3. This equatorial arrangement

D4296 Practice for Sampling Pitch

may be distinguished in crossed polarized light. Under crossed

E11 Specification for Woven Wire Test Sieve Cloth and Test

polarizers, the distinctive mesophase spheroids, with their

Sieves

complex extinction patterns shown in Fig. 2, can be readily

seen.

This test method is under the jurisdiction of ASTM Committee D02 on

3.1.4.1 spheroids—At magnifications of 400× and 500×, the

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

minimum spheroid size which can be resolved with confidence

Subcommittee D02.05 on Properties of Fuels, Petroleum Coke and Carbon Material.

Current edition approved Dec. 1, 2018. Published December 2018. Originally

is 4 µm in diameter. At magnifications of 1000× to 1800×, the

approved in 1986. Last previous edition approved in 2013 as D4616 – 95 (2013).

DOI: 10.1520/D4616-95R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM A more complete discussion will be found in a paper by Honda, H., Kimura, H.,

Standards volume information, refer to the standard’s Document Summary page on and Sanada, Y., “Changes of Pleochroism and Extinction Contours in Carbonaceous

the ASTM website. Mesophase,” Carbon, 9, 1971, pp. 695–697.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4616 − 95 (2018)

minimum spheroid size that can be resolved with confidence is combustion black (see Fig. 5a). Normal QI with concentric

about 2 µm in diameter. Typically, the upper size may be symmetry is produced by thermal cracking later in the

100 µm. Mesophase spheroids are relatively soft and do not coking cycle under reducing conditions, and is referred to as

form relief structures (see Fig. 4). Quinoline insoluble particles thermal black (see Fig. 5b). These two symmetries can only

4,5

often aggregate at the interface between the continuous isotro- be differentiated using electron microscopy. The quinoline

pic phase and mesophase. insolubles content determined by Test Method D2318 is

sometimes greater than that anticipated on the basis of the

3.1.4.2 isotropic phase—The isotropic phase is more soluble

concentration of the quinoline insolubles during distillation

than the mesophase in solvents such as toluene. Solvent

or heat treatment to produce the final pitch. The difference is

etching is achieved by soaking the polished surface in toluene

known as the “secondary” quinoline insolubles content, and

for a few seconds, rinsing the surface with cold flowing water,

is traditionally regarded as the mesophase content. This

and drying in a current of hot air. Etching produces sharply

equivalence of secondary quinoline insolubles and mesoph-

defined mesophase spheroids (see Fig. 4).

ase is erroneous because the mesophase may be partially

3.1.5 mineral matter—formed when minute particles of the

soluble in quinoline.

coke oven charge are carried over into the coke oven collecting

3.1.7 pyrolytic carbon—a carbon that originates as a deposit

main during the charging operation. The tiny coal particles are

on the upper walls, tunnel head, and standpipes of a coke oven

digested in the collecting main tar, resulting in a residue that is

due to thermal cracking. It is usually a minor phase in coal tar

rich in mineral matter. This mineral matter is identified under

pitch, highly variable in shape and porosity, and may be sized

bright field illumination by its high reflectivity, in the case of

up to 500 µm. It is usually optically active under crossed

pyrite, and its low reflectance in the case of clay, quartz, and

polarizers. The fine sized domains are commonly referred to as

carbonates. The association of mineral matter with insoluble

spherulitic, while the coarser anisotropic domains are called

organic matter from coal aids in its identification.

pyrolytic. Spherulitic and pyrolytic carbons are highly

3.1.6 normal quinoline insolubles—(sometimes termed

reflecting, relatively hard materials and stand out in relief from

“true,” natural or “primary” quinoline insolubles)—a carbon

the softer isotropic phase.

black-like solid phase in coal tar pitch that is produced by

3.1.8 reactor coke—a material that originates on the walls of

thermal cracking of organic compounds in the tunnel head

the pipestill reactor used in the distillation or heat treatment to

above the coal charge in a by-product coke oven. The indi-

produce pitch from either coal tars or petroleum oils. It is

vidual spherically-shaped particles are usually less than 2 µm

thermally more advanced than reactor mesophase. It is usually

in diameter. A typical coal tar pitch may contain from about

a minor component of pitch and may be sized up to 200 µm. It

1 % to about 20 % (by weight) of normal quinoline insolubles.

may be angular or rounded, and it may be relatively porous

The normal quinoline insolubles are relatively hard. They are

with a coarse appearance under crossed polarizers. It is

outlined in bright incident light because they stand out in relief

distinguished from the reactor mesophase mentioned in 3.1.9

from the softer isotropic phase (see Fig. 1).

by its relative hardness, which causes it to show up in relief in

bright field illumination.

3.1.6.1 Discussion—Sometimes the term primary QI is used

to describe all quinoline insoluble materials that are carried

3.1.9 reactor mesophase—a material that originates on the

over during the coking operation (cenospheres, mineral matter,

walls of the pipestill or reactor used in the distillation or heat

normal, QI, and so forth).

treatment to produce pitch from either coal tars or petroleum

3.1.6.2 normal quinoline insoluble material—Observed un-

oils. It is usually a minor component of pitch and may be sized

der crossed polarizers, the normal quinoline insoluble material

up to 200 µm. It may be angular or rounded, and it may be

displays a Brewster cross pattern (see Fig. 1 and Fig. 2). This

relatively porous. Under crossed polarizers reactor mesophase

interference figure remains stationary when the specimen is

has a coarse mosaic appearance. In contradistinction to the

rotated through 360°. The onionskin arrangement can be

reactor coke mentioned in 3.1.8, reactor mesophase is com-

observed in particles with a minimum diameter of 2 µm at high

paratively soft and shows no relief in bright field illumination.

magnification (1000× to 2000×) under cross polarizers.

3.1.10 refractory—usually a minor component that origi-

3.1.6.3 Discussion—The quinoline insolubles content is de- nates from the coke oven walls, doors, and patches due to wear

and degeneration; another component is charge hole sealant. It

termined by Test Method D2318 and represents the total

amount of natural quinoline insolubles, cenospheres, coke- can be recognized under the microscope through optical

properties, hardness, shape, and associated minerals.

oven-coke, pyrolytic carbon, refractory, reactor coke, and free

ash in a pitch. Additionally, the quinoline insolubles will

4. Summary of Test Method

contain any insoluble species from the isotropic phase and the

insoluble portion of the mesophase. Hence, the quinoline

4.1 A representative sample with a softening point of at least

soluble fraction is composed of the bulk of the isotropic phase

212 °F (100 °C), as measured by Test Method D3104 (Mettler

and the soluble fraction of the mesophase. However, the

quinoline insoluble test is not necessarily a true measure of the

Bertau, B.L., and Souffrey, B., “Composition of Tar and Pitches as a Result of

solid constituents of pitch.

the Specific Aspects of the Coking Plant,” Coke Making International, Vol 2 , 1990,

Normal QI with radial symmetry is produced by oxy-

pp. 61–63.

cracking during the early portion of the coking cycle when 5

Lafdi, K., Bonnamy, S., and Oberlin, A., “TEM Studies of Coal Tars—Crude

partially oxidizing conditions can exist, and is referred to as Tar and its Insoluble Fractions,” Carbon, Vol 28, No. 1, 1990, pp. 57–63.

D4616 − 95 (2018)

method), is crushed to a specific particle size and encapsulated flat, scratch-free surface. Laps may be made of aluminum, iron,

in resin. Alternatively, a representative molten pitch sample is brass, bronze, lead, glass, wax, or wood. Equipment that has

poured into a mold, or a representative crushed sample is 8 in. (203 mm) diameter disk laps that can rotate at 150 to 400

melted and poured into a mold. If the Mettler softening point is r/min, and that has an automatic sample holder attachment is

9,8

less than 212 °F (100 °C), it is raised to 212 °F to 248 °F recommended.

(100 °C to 120°C) by vacuum distillation. The encapsulated, or

6.8 Sample Cleaner—Some equipment is essential for

molded, sample is ground and polished to a flat surface for

cleaning the specimens between the different grinding or

examination in reflected light.

polishing stages. This may be an ultrasonic device or a simple

4.2 The mesophase spheroid content of a representative stream of water and an air jet for drying.

sample is identified and the proportion determined on a volume

6.9 Microscope—Any polarizing microscope with the capa-

basis by observing a statistically adequate number of points.

bility for observations by reflected light (for example, metal-

Only the area proportion is determined on a surface section of

lurgical or opaque-ore microscopes) may be employed. The

a sample; however, the area and volume proportion are the

polarizer may be of the Nicol prism or sheet type. All optical

same when the components are randomly distributed through-

components (objective, eyepiece, polarizer, and analyzer) shall

out the sample.

be of a quality to permit examination of the dry specimen at

magnifications up to 400× to 500× under crossed polarizers.

5. Significance and Use

For magnifications greater than 500×, 0.1 immersion objec-

5.1 Sometimes coal tar and petroleum pitches are heat

tives shall be used. The analyzer should be oriented 90° with

treated thereby forming mesophase spheroids. The mesophase

respect to the polarizer for cross polarizer examination. Any

may be partially soluble in quinoline and cannot be estimated

light source that can be regulated for stable output with

by the quinoline insoluble test (Test Method D2318). This test

sufficient intensity for photography with cross polarizers may

method provides for the identification, quantitative estimation,

be used. The microscope shall have a circular stage that is

and size determination of mesophase spheroids.

capable of rotating a specimen through 360°. The stage shall

5.2 The mesophase initially forms as spheroids that may also be of such type that the specimen can be quickly advanced

by definite fixed increments in two perpendicular directions,

coalesce to form a variety of asymmetrical shapes. The

smallest mesophase particle that can be detected with certainty such as a stage with click stops. If an electrically operated stage

is used, incremental steps in one direction across the specimen

at 400× or 500× magnification is 4 µm in diameter; mesophase

particles sizes less than 4 µm should be ignored. If mesophase m

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4616 − 95 (Reapproved 2013) D4616 − 95 (Reapproved 2018)

Standard Test Method for

Microscopical Analysis by Reflected Light and

Determination of Mesophase in a Pitch

This standard is issued under the fixed designation D4616; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers laboratory procedures for the preparation of granular and melted samples for microscopic analysis

using reflected light to identify and estimate the amount and size of the mesophase.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D329 Specification for Acetone

D1160 Test Method for Distillation of Petroleum Products at Reduced Pressure

D2318 Test Method for Quinoline-Insoluble (QI) Content of Tar and Pitch

D3104 Test Method for Softening Point of Pitches (Mettler Softening Point Method)

D4296 Practice for Sampling Pitch

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

E562 Test Method for Determining Volume Fraction by Systematic Manual Point Count

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 cenospheres—usually a minor component of coal tar pitch. They are formed by the rapid pyrolysis of unconfined coal

particles that are carried over from the coke oven to the tar. Microscopically, they appear like hollow spheres or segments thereof

(see Fig. 1), and are typically sized from about 1010 μm to 500 μm. 500 μm. In polarized light (crossed polarizers), a cenosphere

may be optically active. The size of the anisotropic pattern or mosaic depends upon the rank of the coal carbonized. Cenospheres

are harder than the continuous phase and polish in relief (see Fig. 1).

3.1.2 coke-oven-coke—usually a minor component of coal tar pitch. It originates in carry-over from the coke oven to the tar side.

It differs from cenospheres only in terms of its shape and porosity. Coke-oven-coke is angular and less porous.

3.1.3 isotropic phase—usually the predominant, and continuous, phase. It is a complex mixture of organic aromatic compounds

composed mainly of carbon and hydrogen. At room temperature, the isotropic phase is a glass-like solid. It is optically inactive

in polarized light (see Fig. 1 and Fig. 2).

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.05 on Properties of Fuels, Petroleum Coke and Carbon Material.

Current edition approved May 1, 2013Dec. 1, 2018. Published August 2013December 2018. Originally approved in 1986. Last previous edition approved in 20082013

as D4616 – 95 (2008).(2013). DOI: 10.1520/D4616-95R13.10.1520/D4616-95R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4616 − 95 (2018)

FIG. 1 Photomicrographs of a Coal Tar Pitch at 500× Magnification in Polarized Light (Crossed Polarizers) and Bright Light Showing

the Isotropic Phase, Natural Quinoline Insolubles, and a Cenosphere.

FIG. 2 Photomicrographs of a Heat-Treated Coal Tar Pitch at 500× Magnification in Polarized Light (Crossed Polarizers) Showing Natu-

ral Quinoline Insolubles and Mesophase Spheroids

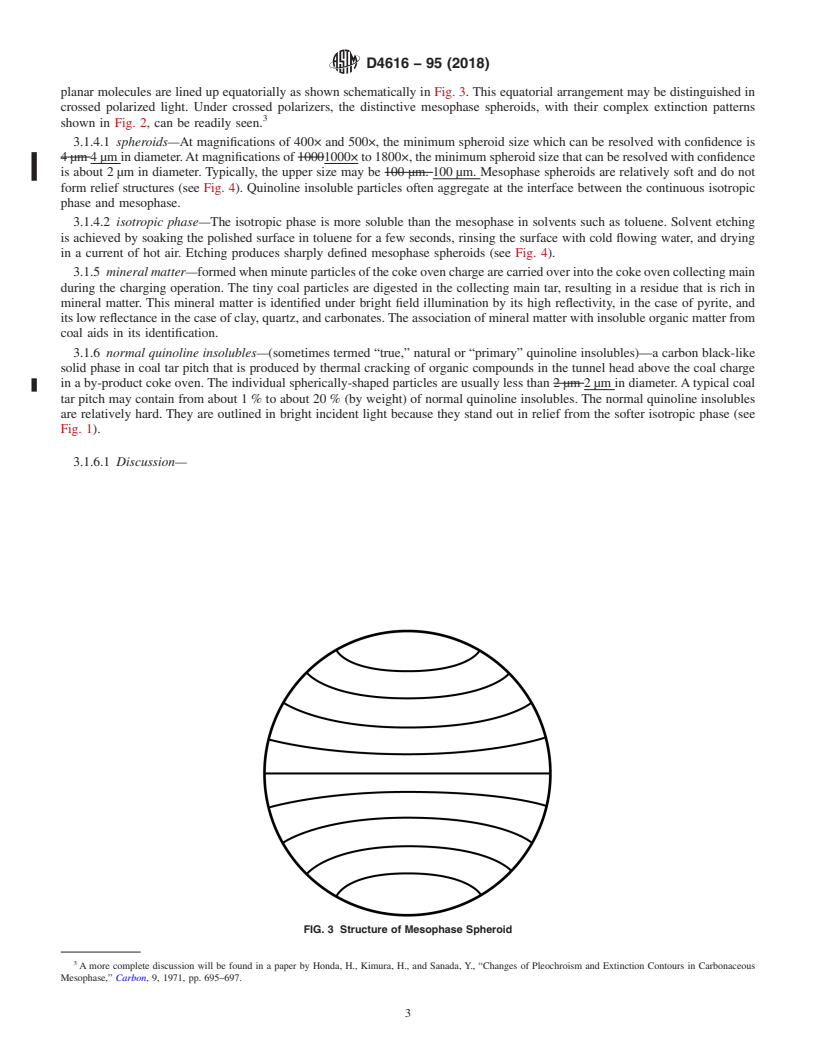

3.1.4 mesophase—an optically anisotropic liquid crystal carbonaceous phase that forms from the parent liquor when molecular

size, shape, and distribution are favorable. In the early stages of its development, mesophase usually appears as spheroids. The

D4616 − 95 (2018)

planar molecules are lined up equatorially as shown schematically in Fig. 3. This equatorial arrangement may be distinguished in

crossed polarized light. Under crossed polarizers, the distinctive mesophase spheroids, with their complex extinction patterns

shown in Fig. 2, can be readily seen.

3.1.4.1 spheroids—At magnifications of 400× and 500×, the minimum spheroid size which can be resolved with confidence is

4 μm 4 μm in diameter. At magnifications of 10001000× to 1800×, the minimum spheroid size that can be resolved with confidence

is about 2 μm in diameter. Typically, the upper size may be 100 μm. 100 μm. Mesophase spheroids are relatively soft and do not

form relief structures (see Fig. 4). Quinoline insoluble particles often aggregate at the interface between the continuous isotropic

phase and mesophase.

3.1.4.2 isotropic phase—The isotropic phase is more soluble than the mesophase in solvents such as toluene. Solvent etching

is achieved by soaking the polished surface in toluene for a few seconds, rinsing the surface with cold flowing water, and drying

in a current of hot air. Etching produces sharply defined mesophase spheroids (see Fig. 4).

3.1.5 mineral matter—formed when minute particles of the coke oven charge are carried over into the coke oven collecting main

during the charging operation. The tiny coal particles are digested in the collecting main tar, resulting in a residue that is rich in

mineral matter. This mineral matter is identified under bright field illumination by its high reflectivity, in the case of pyrite, and

its low reflectance in the case of clay, quartz, and carbonates. The association of mineral matter with insoluble organic matter from

coal aids in its identification.

3.1.6 normal quinoline insolubles—(sometimes termed “true,” natural or “primary” quinoline insolubles)—a carbon black-like

solid phase in coal tar pitch that is produced by thermal cracking of organic compounds in the tunnel head above the coal charge

in a by-product coke oven. The individual spherically-shaped particles are usually less than 2 μm 2 μm in diameter. A typical coal

tar pitch may contain from about 1 % to about 20 % (by weight) of normal quinoline insolubles. The normal quinoline insolubles

are relatively hard. They are outlined in bright incident light because they stand out in relief from the softer isotropic phase (see

Fig. 1).

3.1.6.1 Discussion—

FIG. 3 Structure of Mesophase Spheroid

A more complete discussion will be found in a paper by Honda, H., Kimura, H., and Sanada, Y., “Changes of Pleochroism and Extinction Contours in Carbonaceous

Mesophase,” Carbon, 9, 1971, pp. 695–697.

D4616 − 95 (2018)

FIG. 4 Photomicrographs of a Heat Treated Coal Tar Pitch at 500× Magnification in Bright Field Showing the Effectiveness of Etching

With Toluene to Accentuate the Interface Between Mesophase Spheroids and the Isotropic Phase

Sometimes the term primary QI is used to describe all quinoline insoluble materials that are carried over during the coking

operation (cenospheres, mineral matter, normal, QI, and so forth).

3.1.6.2 normal quinoline insoluble material—Observed under crossed polarizers, the normal quinoline insoluble material

displays a Brewster cross pattern (see Fig. 1 and Fig. 2). This interference figure remains stationary when the specimen is rotated

through 360°. The onionskin arrangement can be observed in particles with a minimum diameter of 2 μm 2 μm at high

magnification (1000(1000× to 2000×) under cross polarizers.

3.1.6.3 Discussion—

The quinoline insolubles content is determined by Test Method D2318 and represents the total amount of natural quinoline

insolubles, cenospheres, coke-oven-coke, pyrolytic carbon, refractory, reactor coke, and free ash in a pitch. Additionally, the

quinoline insolubles will contain any insoluble species from the isotropic phase and the insoluble portion of the mesophase. Hence,

the quinoline soluble fraction is composed of the bulk of the isotropic phase and the soluble fraction of the mesophase. However,

the quinoline insoluble test is not necessarily a true measure of the solid constituents of pitch.

Normal QI with radial symmetry is produced by oxycracking during the early portion of the coking cycle when partially

oxidizing conditions can exist, and is referred to as combustion black (see Fig. 5a). Normal QI with concentric symmetry is

produced by thermal cracking later in the coking cycle under reducing conditions, and is referred to as thermal black (see Fig.

4,5

5b). These two symmetries can only be differentiated using electron microscopy. The quinoline insolubles content determined

by Test Method D2318 is sometimes greater than that anticipated on the basis of the concentration of the quinoline insolubles

during distillation or heat treatment to produce the final pitch. The difference is known as the “secondary” quinoline insolubles

content, and is traditionally regarded as the mesophase content. This equivalence of secondary quinoline insolubles and

mesophase is erroneous because the mesophase may be partially soluble in quinoline.

3.1.7 pyrolytic carbon—a carbon that originates as a deposit on the upper walls, tunnel head, and standpipes of a coke oven due

to thermal cracking. It is usually a minor phase in coal tar pitch, highly variable in shape and porosity, and may be sized up to

500 μm. 500 μm. It is usually optically active under crossed polarizers. The fine sized domains are commonly referred to as

spherulitic, while the coarser anisotropic domains are called pyrolytic. Spherulitic and pyrolytic carbons are highly reflecting,

relatively hard materials and stand out in relief from the softer isotropic phase.

Bertau, B.L., and Souffrey, B., “Composition of Tar and Pitches as a Result of the Specific Aspects of the Coking Plant,” Coke Making International, Vol 2 , 1990, pp.

61–63.

Lafdi, K., Bonnamy, S., and Oberlin, A., “TEM Studies of Coal Tars—Crude Tar and its Insoluble Fractions,” Carbon, Vol 28, No. 1, 1990, pp. 57–63.

D4616 − 95 (2018)

FIG. 5 The Structure of a Normal Quinoline Insoluble Particles

3.1.8 reactor coke—a material that originates on the walls of the pipestill reactor used in the distillation or heat treatment to

produce pitch from either coal tars or petroleum oils. It is thermally more advanced than reactor mesophase. It is usually a minor

component of pitch and may be sized up to 200 μm. 200 μm. It may be angular or rounded, and it may be relatively porous with

a coarse appearance under crossed polarizers. It is distinguished from the reactor mesophase mentioned in 3.1.9 by its relative

hardness, which causes it to show up in relief in bright field illumination.

3.1.9 reactor mesophase—a material that originates on the walls of the pipestill or reactor used in the distillation or heat

treatment to produce pitch from either coal tars or petroleum oils. It is usually a minor component of pitch and may be sized up

to 200 μm. 200 μm. It may be angular or rounded, and it may be relatively porous. Under crossed polarizers reactor mesophase

has a coarse mosaic appearance. In contradistinction to the reactor coke mentioned in 3.1.8, reactor mesophase is comparatively

soft and shows no relief in bright field illumination.

3.1.10 refractory—usually a minor component that originates from the coke oven walls, doors, and patches due to wear and

degeneration; another component is charge hole sealant. It can be recognized under the microscope through optical properties,

hardness, shape, and associated minerals.

4. Summary of Test Method

4.1 A representative sample with a softening point of at least 212°F (100°C),212 °F (100 °C), as measured by Test Method

D3104 (Mettler method), is crushed to a specific particle size and encapsulated in resin. Alternatively, a representative molten pitch

sample is poured into a mold, or a representative crushed sample is melted and poured into a mold. If the Mettler softening point

is less than 212°F (100°C),212 °F (100 °C), it is raised to 212212 °F to 248°F (100248 °F (100 °C to 120°C) by vacuum

distillation. The encapsulated, or molded, sample is ground and polished to a flat surface for examination in reflected light.

4.2 The mesophase spheroid content of a representative sample is identified and the proportion determined on a volume basis

by observing a statistically adequate number of points. Only the area proportion is determined on a surface section of a sample;

however, the area and volume proportion are the same when the components are randomly distributed throughout the sample.

5. Significance and Use

5.1 Sometimes coal tar and petroleum pitches are heat treated thereby forming mesophase spheroids. The mesophase may be

partially soluble in quinoline and cannot be estimated by the quinoline insoluble test (Test Method D2318). This test method

provides for the identification, quantitative estimation, and size determination of mesophase spheroids.

5.2 The mesophase initially forms as spheroids that may coalesce to form a variety of asymmetrical shapes. The smallest

mesophase particle that can be detected with certainty at 400× or 500× magnification is 4 μm in diameter; mesophase particles sizes

less than 4 μm should be ignored. If mesophase material less than 4 μm in size is of interest, then magnifications of 10001000×

to 1800× shall be used and the results should be appropriately identified. This method is limited to determining minor levels of

mesophase, that is, ≤20 % mesophase.

6. Apparatus

6.1 Grinder, Pulverizer, or Mill, for crushing the re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.