ASTM F2009-20

(Test Method)Standard Test Method for Determining the Axial Disassembly Force of Taper Connections of Modular Prostheses

Standard Test Method for Determining the Axial Disassembly Force of Taper Connections of Modular Prostheses

SIGNIFICANCE AND USE

4.1 This test method helps to assess the axial locking force of a modular taper. Some types of devices that may utilize this type of connection are the modular shoulder and modular hip prostheses. Additional means of evaluating the locking mechanisms of tapers may be appropriate, depending upon the design of the device.

4.2 This test method may not be appropriate for all implant applications. The user is cautioned to consider the appropriateness of the practice in view of the materials and design being tested and their potential application.

4.3 While this test method may be used to measure the force required to disengage tapers, any comparison of such data for various component designs must take into consideration the size of the implant and the type of locking mechanism evaluated.

SCOPE

1.1 This test method establishes a standard methodology for determining the force required, under laboratory conditions, to disassemble tapers of implants that are otherwise not intended to release. Some examples are the femoral components of a total or partial hip replacement or shoulder in which the head and base component are secured together by a self-locking taper.

1.2 This test method has been developed primarily for evaluation of metal and ceramic head designs on metal tapers but may have application to other materials and designs.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2009 − 20

Standard Test Method for

Determining the Axial Disassembly Force of Taper

1

Connections of Modular Prostheses

This standard is issued under the fixed designation F2009; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Test Method

3.1 The axial disassembly test method provides a means to

1.1 This test method establishes a standard methodology for

measure the axial locking strength of the taper connection for

determining the force required, under laboratory conditions, to

modular prostheses.

disassemble tapers of implants that are otherwise not intended

to release. Some examples are the femoral components of a

3.2 Following assembly, an axial tensile force is applied to

total or partial hip replacement or shoulder in which the head

disassemble the taper connection and the maximum force is

and base component are secured together by a self-locking

recorded.

taper.

4. Significance and Use

1.2 This test method has been developed primarily for

4.1 This test method helps to assess the axial locking force

evaluation of metal and ceramic head designs on metal tapers

of a modular taper. Some types of devices that may utilize this

but may have application to other materials and designs.

type of connection are the modular shoulder and modular hip

1.3 The values stated in SI units are to be regarded as

prostheses.Additional means of evaluating the locking mecha-

standard. No other units of measurement are included in this

nisms of tapers may be appropriate, depending upon the design

standard.

of the device.

1.4 This standard does not purport to address all of the

4.2 This test method may not be appropriate for all implant

safety concerns, if any, associated with its use. It is the

applications. The user is cautioned to consider the appropriate-

responsibility of the user of this standard to establish appro-

ness of the practice in view of the materials and design being

priate safety, health, and environmental practices and deter-

tested and their potential application.

mine the applicability of regulatory limitations prior to use.

4.3 Whilethistestmethodmaybeusedtomeasuretheforce

1.5 This international standard was developed in accor-

required to disengage tapers, any comparison of such data for

dance with internationally recognized principles on standard-

various component designs must take into consideration the

ization established in the Decision on Principles for the

size of the implant and the type of locking mechanism

Development of International Standards, Guides and Recom-

evaluated.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

5. Apparatus

5.1 The cone portion of the assembly shall be constrained

2. Referenced Documents

by suitable fixtures that can sustain high loads.

2

2.1 ASTM Standards:

5.2 The fixtures shall be constructed so that the line of load

E4 Practices for Force Verification of Testing Machines

application is aligned with the axes of the male and female

taper components within 61°.

5.2.1 For example, modular heads may be assembled by a

1

This test method is under the jurisdiction ofASTM Committee F04 on Medical solid metal 100° cone as shown in Fig. 1. The cone should

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

provide line contact around the diameter of the head.

F04.22 on Arthroplasty.

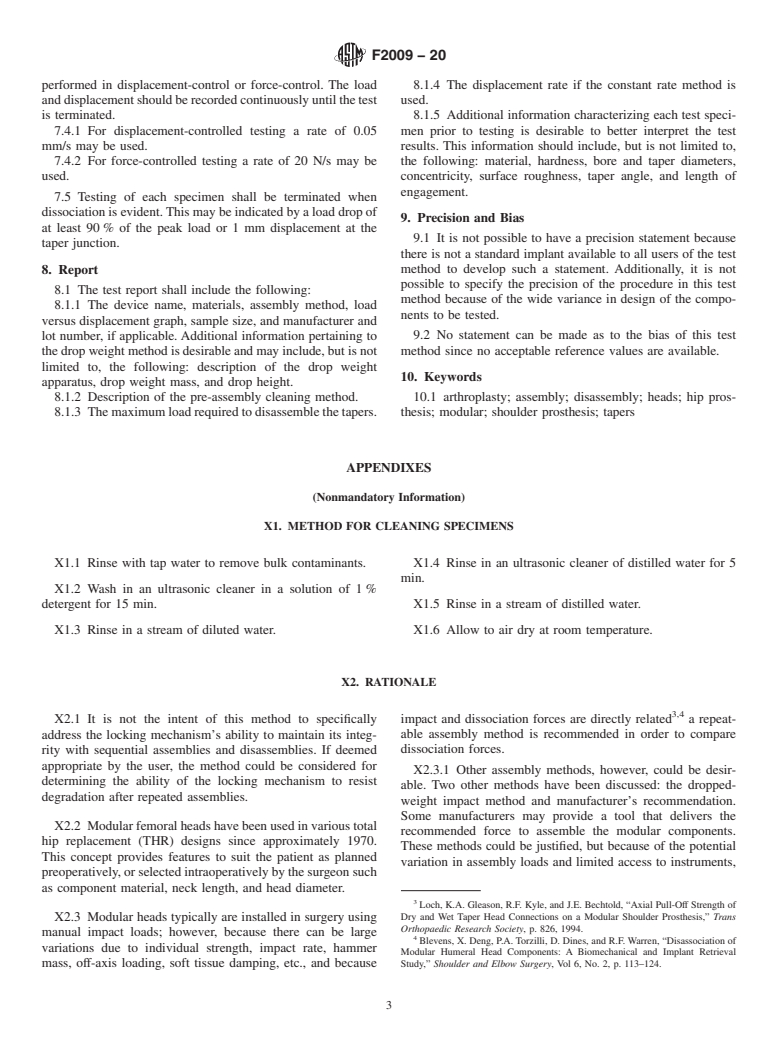

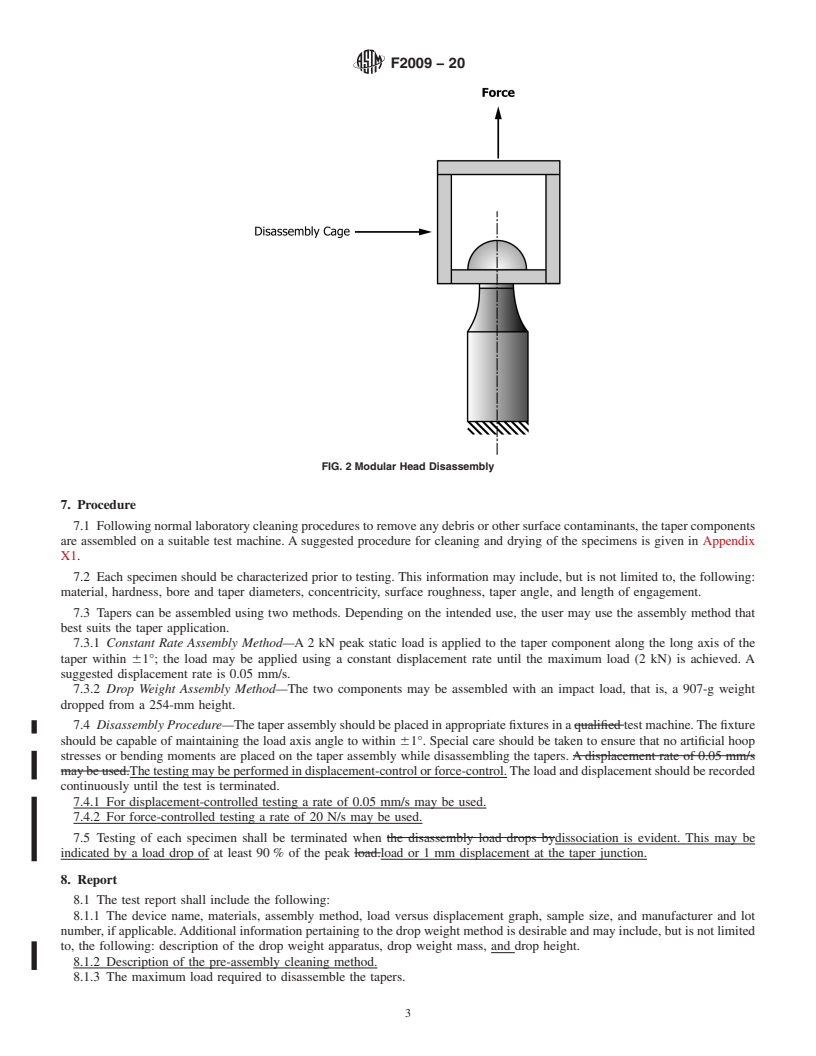

5.2.2 For example, modular heads may be disassembled

Current edition approved March 1, 2020. Published May 2020. Originally

with a metal cage that surrounds the head and provides even

approved in 2000. Last previous edition approved in 2011 as F2009 – 00 (2011).

DOI: 10.1520/F2009-20.

contact around the inferior edge of the head as shown in Fig. 2.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.2.3 One method to minimize misalignment and off-axis

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

loading during constant rate assembly is to include thrust

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. bearing for self-centering of the taper with the assembly cone.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2009 − 20

5.3 The testing machine shall conform to the requirements

of Practices E4. Th

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2009 − 00 (Reapproved 2011) F2009 − 20

Standard Test Method for

Determining the Axial Disassembly Force of Taper

1

Connections of Modular Prostheses

This standard is issued under the fixed designation F2009; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method establishes a standard methodology for determining the force required, under laboratory conditions, to

disassemble tapers of implants that are otherwise not intended to release. Some examples are the femoral components of a total

or partial hip replacement or shoulder in which the head and base component are secured together by a self-locking taper.

1.2 This test method has been developed primarily for evaluation of metal and ceramic head designs on metal tapers but may

have application to other materials and designs.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E4 Practices for Force Verification of Testing Machines

3

F1636 Specification for Bores and Cones for Modular Femoral Heads (Withdrawn 2001)

3. Summary of Test Method

3.1 The axial disassembly test method provides a means to measure the axial locking strength of the taper connection for

modular prostheses.

3.2 Following assembly, an axial tensile force is applied to disassemble the taper connection and the maximum force is

recorded.

4. Significance and Use

4.1 This test method helps to assess the axial locking force of a modular taper. Examples of these devices are described in

Specification F1636. Some types of devices that may utilize this type of connection are the modular shoulder and modular hip

prostheses. Additional means of evaluating the locking mechanisms of tapers may be appropriate, depending upon the design of

the device.

4.2 This test method may not be appropriate for all implant applications. The user is cautioned to consider the appropriateness

of the practice in view of the materials and design being tested and their potential application.

4.3 While this test method may be used to measure the force required to disengage tapers, any comparison of such data for

various component designs must take into consideration the size of the implant and the type of locking mechanism evaluated.

1

This test method is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.22 on Arthroplasty.

Current edition approved March 1, 2011March 1, 2020. Published April 2011May 2020. Originally approved in 2000. Last previous edition approved in 20052011 as F2009

– 00 (2005).(2011). DOI: 10.1520/F2009-00R11.10.1520/F2009-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2009 − 20

5. Apparatus

5.1 The cone portion of the assembly shall be constrained by suitable fixtures that can sustain high loads.

5.2 The fixtures shall be constructed so that the line of load application is aligned with the axes of the male and female taper

components within 61°.

5.2.1 For example, modular heads may be assembled by a solid metal 100° cone as shown in Fig. 1. The cone should provide

line contact around the diameter of the head.

5.2.2 For example, modular heads may be disassembled with a metal cage

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.