ASTM C692-13

(Test Method)Standard Test Method for Evaluating the Influence of Thermal Insulations on External Stress Corrosion Cracking Tendency of Austenitic Stainless Steel

Standard Test Method for Evaluating the Influence of Thermal Insulations on External Stress Corrosion Cracking Tendency of Austenitic Stainless Steel

SIGNIFICANCE AND USE

5.1 An inherent characteristic of some alloys of austenitic stainless steel is their tendency to crack at stress points when exposed to certain corrosive environments. The mechanisms of ESCC are complex and not completely understood but are apparently related to certain metallurgical properties. Chloride and fluoride ions have the potential to induce stress corrosion cracking in the absence of inhibiting ions.3

5.2 Chlorides are common to many environments, so great care shall be taken to protect austenitic stainless steel from chloride contamination.

5.3 Most thermal insulations will not, of themselves, cause stress corrosion cracking. Preproduction qualification tests are used to evaluate that under the conditions of the laboratory test that specific thermal insulation materials do not cause cracking of sensitized austenitic stainless steel. Insulation systems have the potential to act as collecting media by means of transmigration and concentration of corrosive ions on heated stainless steel surfaces. Exposure to elevated temperature results in evaporation of water and increased chemical reaction rates. Environments containing corrosive ions, moisture, and oxygen will increase the chance for stress corrosion cracking.

5.4 Insulation materials are available that are specially formulated to inhibit stress corrosion cracking in the presence of chlorides through modifications in basic composition or incorporation of certain chemical additives.

5.5 The ability of the 28-day test to measure the corrosion potential of insulation materials is documented by Karnes,4 whose data appear to have been used for construction of the acceptability curve used in Specification C795 and other specifications.

5.6 The metal for all of the coupons used in this test method (C692) shall be qualified (see Section 14) to ascertain that under conditions of the test, chloride ions will cause the metal to crack, and deionized water alone will not cause cracks.

SCOPE

1.1 This test method covers two procedures for the laboratory evaluation of thermal insulation materials to determine whether they contribute to external stress corrosion cracking (ESCC) of austenitic stainless steel due to soluble chlorides within the insulation. This laboratory procedure is not intended to cover all of the possible field conditions that contribute to ESCC.

1.2 While the 1977 edition of this test method (Dana test) is applicable only to wicking-type insulations, the procedures in this edition are intended to be applicable to all insulating materials, including cements, some of which disintegrate when tested in accordance with the 1977 edition. Wicking insulations are materials that wet through and through when partially (50 to 75 %) immersed in water for a short period of time (10 min or less).

1.3 These procedures are intended primarily as a preproduction test for qualification of the basic chemical composition of a particular manufacturer's product and are not intended to be routine tests for ongoing quality assurance or production lot compliance. Test Methods C871, on the other hand, is used for confirmation of acceptable chemical properties of subsequent lots of insulation previously found acceptable by this test method.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C692 −13

Standard Test Method for

Evaluating the Influence of Thermal Insulations on External

Stress Corrosion Cracking Tendency of Austenitic Stainless

1

Steel

This standard is issued under the fixed designation C692; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This test method covers two procedures for the labora- 2.1 ASTM Standards:

tory evaluation of thermal insulation materials to determine A240/A240MSpecification for Chromium and Chromium-

whether they contribute to external stress corrosion cracking Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

(ESCC) of austenitic stainless steel due to soluble chlorides Vessels and for General Applications

withintheinsulation.Thislaboratoryprocedureisnotintended A370Test Methods and Definitions for Mechanical Testing

to cover all of the possible field conditions that contribute to of Steel Products

ESCC. C168Terminology Relating to Thermal Insulation

C795Specification for Thermal Insulation for Use in Con-

1.2 Whilethe1977editionofthistestmethod(Danatest)is

tact with Austenitic Stainless Steel

applicable only to wicking-type insulations, the procedures in

C871Test Methods for ChemicalAnalysis of Thermal Insu-

this edition are intended to be applicable to all insulating

lationMaterialsforLeachableChloride,Fluoride,Silicate,

materials,includingcements,someofwhichdisintegratewhen

and Sodium Ions

testedinaccordancewiththe1977edition.Wickinginsulations

G30 Practice for Making and Using U-Bend Stress-

are materials that wet through and through when partially (50

Corrosion Test Specimens

to 75%) immersed in water for a short period of time (10 min

or less).

3. Terminology

1.3 Theseproceduresareintendedprimarilyasapreproduc-

3.1 Definitions: Refer to Terminology C168 for definitions

tion test for qualification of the basic chemical composition of

relating to insulation.

a particular manufacturer’s product and are not intended to be

routine tests for ongoing quality assurance or production lot 4. Summary of Test Method

compliance.Test Methods C871, on the other hand, is used for

4.1 The procedures in this test method consist of using a

confirmation of acceptable chemical properties of subsequent

specimenofinsulationtoconductdistilled(ordeionized)water

lots of insulation previously found acceptable by this test

by wicking or dripping to an outside surface, through the

method.

insulation, to a hot inner surface of stressedType 304 stainless

1.4 The values stated in inch-pound units are to be regarded

steelforaperiodof28days.Ifleachablechloridesarepresent,

as standard. The values given in parentheses are mathematical they are carried along with the water and concentrated at the

conversions to SI units that are provided for information only

hot surface by evaporation in much the same way as has been

and are not considered standard. experienced in actual industrial process situations.

1.5 This standard does not purport to address all of the

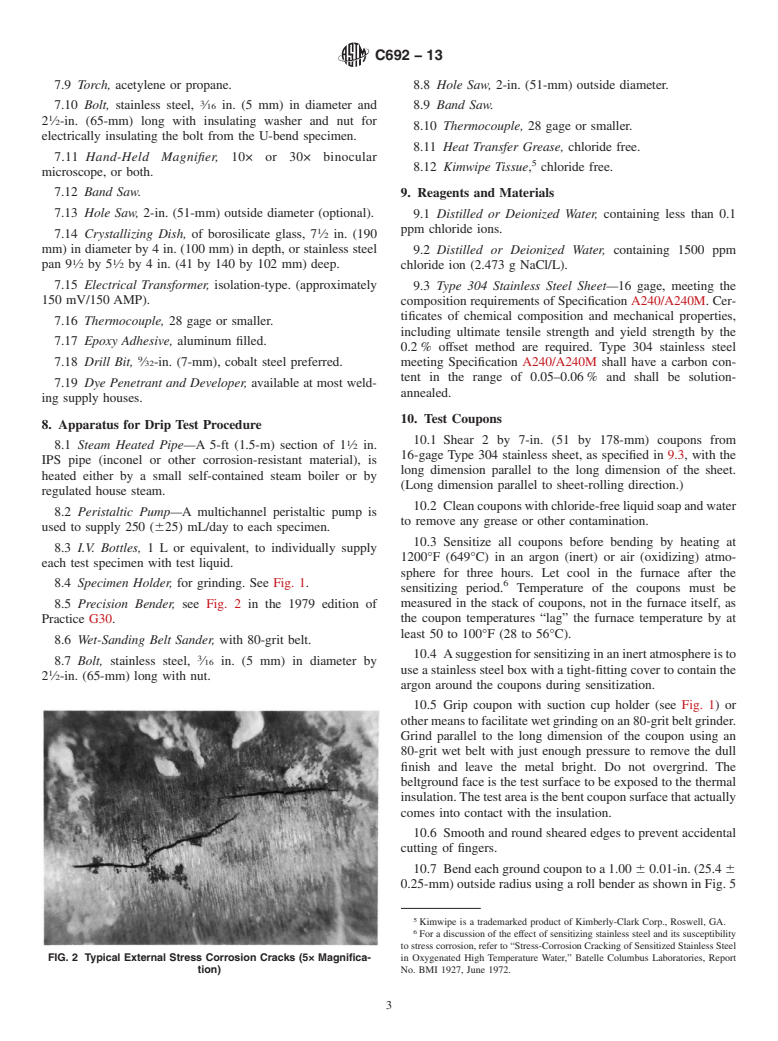

4.2 Exposed stainless steel coupons are examined visually,

safety concerns, if any, associated with its use. It is the

and under 10 to 30× magnification, if necessary, to detect

responsibility of the user of this standard to establish appro-

ESCC after the prescribed period of exposure.

priate safety and health practices and determine the applica-

5. Significance and Use

bility of regulatory limitations prior to use.

5.1 An inherent characteristic of some alloys of austenitic

stainless steel is their tendency to crack at stress points when

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC16onThermal

InsulationandisthedirectresponsibilityofSubcommitteeC16.31onChemicaland

2

Physical Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2013. Published May 2013. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ε1

approved in 1971. Last previous edition approved 2008 as C692–08 . DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C0692-13. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C692−13

1

exposedtocertaincorrosiveenvironments.Themechanismsof component, then the 1 ⁄2-in. (38-mm) wide test specimen is

3

ESCC are complex and not completely understood but are sliced into two ⁄4-in. (19-mm) thick segments.The two halves

apparently related to certain metallurgical properties. Chloride are held to

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: C692 − 08 C692 − 13

Standard Test Method for

Evaluating the Influence of Thermal Insulations on External

Stress Corrosion Cracking Tendency of Austenitic Stainless

1

Steel

This standard is issued under the fixed designation C692; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Fig. 4 was editorially corrected in December 2010.

1. Scope

1.1 This test method covers two procedures for the laboratory evaluation of thermal insulation materials to determine whether

they contribute to external stress corrosion cracking (ESCC) of austenitic stainless steel due to soluble chlorides within the

insulation. This laboratory procedure is not intended to cover all of the possible field conditions that contribute to ESCC.

1.2 While the 1977 edition of this test method (Dana test) is applicable only to wicking-type insulations, the procedures in this

edition are intended to be applicable to all insulating materials, including cements, some of which disintegrate when tested in

accordance with the 1977 edition. Wicking insulations are materials that wet through and through when partially (50 to 75 %)

immersed in water for a short period of time (10 min or less).

1.3 These procedures are intended primarily as a preproduction test for qualification of the basic chemical composition of a

particular manufacturer’s product and are not intended to be routine tests for ongoing quality assurance or production lot

compliance. Test Methods C871, on the other hand, is used for confirmation of acceptable chemical properties of subsequent lots

of insulation previously found acceptable by this test method.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A240/A240M Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and

for General Applications

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

C168 Terminology Relating to Thermal Insulation

C795 Specification for Thermal Insulation for Use in Contact with Austenitic Stainless Steel

C871 Test Methods for Chemical Analysis of Thermal Insulation Materials for Leachable Chloride, Fluoride, Silicate, and

Sodium Ions

G30 Practice for Making and Using U-Bend Stress-Corrosion Test Specimens

3. Terminology

3.1 Definitions: Refer to Terminology C168 for definitions relating to insulation.

1

This test method is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.31 on Chemical and

Physical Properties.

Current edition approved Oct. 1, 2008May 1, 2013. Published October 2008May 2013. Originally approved in 1971. Last previous edition approved 20062008 as

ε1

C692 – 06.C692 – 08 . DOI: 10.1520/C0692-08.10.1520/C0692-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C692 − 13

4. Summary of Test Method

4.1 The procedures in this test method consist of using a specimen of insulation to conduct distilled (or deionized) water by

wicking or dripping to an outside surface, through the insulation, to a hot inner surface of stressed Type 304 stainless steel for a

period of 28 days. If leachable chlorides are present, they are carried along with the water and concentrated at the hot surface by

evaporation in much the same way as has been experienced in actual industrial process situations.

4.2 Exposed stainless steel coupons are examined visually, and under 10 to 30× magnification, if necessary, to detect ESCC

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.