ASTM C5-79(1997)

(Specification)Standard Specification for Quicklime for Structural Purposes

Standard Specification for Quicklime for Structural Purposes

SCOPE

1.1 This specification covers all classes of quicklime such as crushed lime, granular lime, ground lime, lump lime, pebble lime, and pulverized lime, used for structural purposes.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation:C5–79 (Reapproved 1997)

Standard Specification for

Quicklime for Structural Purposes

This standard is issued under the fixed designation C 5; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

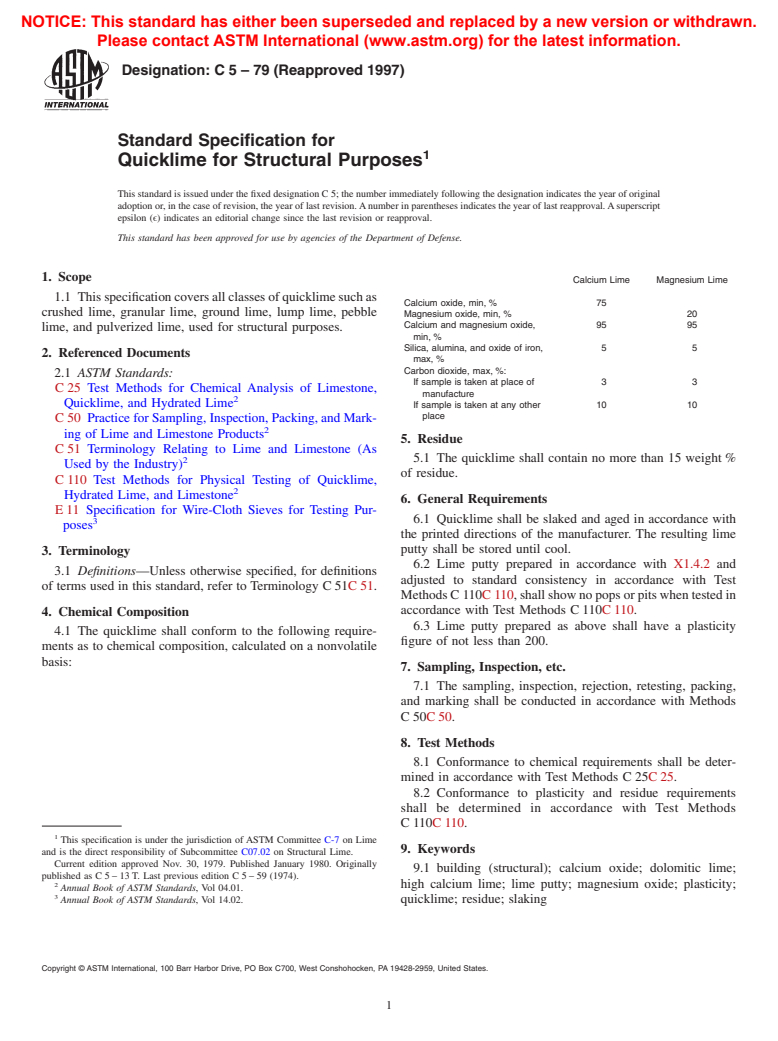

Calcium Lime Magnesium Lime

1.1 Thisspecificationcoversallclassesofquicklimesuchas

Calcium oxide, min, % 75

crushed lime, granular lime, ground lime, lump lime, pebble

Magnesium oxide, min, % 20

Calcium and magnesium oxide, 95 95

lime, and pulverized lime, used for structural purposes.

min, %

Silica, alumina, and oxide of iron, 55

2. Referenced Documents

max, %

Carbon dioxide, max, %:

2.1 ASTM Standards:

If sample is taken at place of 33

C25 Test Methods for Chemical Analysis of Limestone,

manufacture

Quicklime, and Hydrated Lime

If sample is taken at any other 10 10

place

C50 Practice for Sampling, Inspection, Packing, and Mark-

ing of Lime and Limestone Products

5. Residue

C51 Terminology Relating to Lime and Limestone (As

2 5.1 The quicklime shall contain no more than 15 weight %

Used by the Industry)

of residue.

C110 Test Methods for Physical Testing of Quicklime,

Hydrated Lime, and Limestone

6. General Requirements

E11 Specification for Wire-Cloth Sieves for Testing Pur-

6.1 Quicklime shall be slaked and aged in accordance with

poses

the printed directions of the manufacturer. The resulting lime

putty shall be stored until cool.

3. Terminology

6.2 Lime putty prepared in accordance with X1.4.2 and

3.1 Definitions—Unless otherwise specified, for definitions

adjusted to standard consistency in accordance with Test

of terms used in this standard, refer to Terminology C 51C51.

MethodsC 110C110,shallshownopopsorpitswhentestedin

accordance with Test Methods C 110C110.

4. Chemical Composition

6.3 Lime putty prepared as above shall have a plasticity

4.1 The quicklime shall conform to the following require-

figure of not less than 200.

ments as to chemical composition, calculated on a nonvolatile

basis:

7. Sampling, Inspection, etc.

7.1 The sampling, inspection, rejection, retesting, packing,

and marking shall be conducted in accordance with Methods

C50C50.

8. Test Methods

8.1 Conformance to chemical requirements shall be deter-

mined in accordance with Test Methods C 25C25.

8.2 Conformance to plasticity and residue requirements

shall be determined in accordance with Test Methods

C110C110.

This specification is under the jurisdiction of ASTM Committee C-7 on Lime

9. Keywords

and is the direct responsibility of Subcommittee C07.02 on Structural Lime.

Current edition approved Nov. 30, 1979. Published January 1980. Originally

9.1 building (structural); calcium oxide; dolomitic lime;

published asC5–13T. Last previous editionC5–59 (1974).

high calcium lime; lime putty; magnesium oxide; plasticity;

Annual Book of ASTM Standards, Vol 04.01.

Annual Book of ASTM Standards, Vol 14.02. quicklime; residue; slaking

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

C5–79 (1997)

APPENDIX

(Nonmandatory Information)

X1. SLAKING AND PREPARATION OF LIME PUTTY

X1.1 Introduction available for immediate use—a hose throwing a good stream,

if possible. Watch the lime constantly. At the slightest appear-

X1.1.1 Quicklime can never be used as such for structural

ance of escaping steam, hoe thoroughly and quickly, and add

purposes; it must always be slaked first. Since the method of

enough water to stop the steaming. Do not be afraid of using

slaking is an important factor in determining the quality of the

too much water with this kind of lime.

finishedproduct,the following directions for the preparationof

X1.3.3 For medium–slaking lime, add the water to the lime.

lime putty are given, not as a part of the specification, but as

Add enough water so that the lime is about half submerged.

information

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.