ASTM A841/A841M-98e1

(Specification)Standard Specification for Steel Plates for Pressure Vessels, Produced by Thermo-Mechanical Control Process (TMCP)

Standard Specification for Steel Plates for Pressure Vessels, Produced by Thermo-Mechanical Control Process (TMCP)

SCOPE

1.1 This specification covers steel plates produced by the thermo-mechanical control process (TMCP). The plates are intended primarily for use in welded pressure vessels.

1.2 The TMCP method consists of rolling-reduction and cooling rate controls which result in mechanical properties in the finished plate that are equivalent to those attained using conventional rolling and heat treating processes which entail reheating after rolling. A description of the TMCP method is given in Appendix X1.

1.3 Due to the inherent characteristics of the TMCP method, the plates cannot be formed at elevated temperatures without sustaining significant losses in strength and toughness. The plates may be formed and post-weld heat-treated at temperatures not exceeding 1200oF [650oC], providing the requirements of 6.1 are met.

1.4 The maximum nominal thickness of plates furnished under this specification may not exceed 4 in. [100 mm].

1.5 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents. Therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: A 841/A 841M – 98

Standard Specification for

Steel Plates for Pressure Vessels, Produced by

Thermo-Mechanical Control Process (TMCP)

This standard is issued under the fixed designation A 841/A 841M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—An editorial correction was made in Table 1 in September 1999.

1. Scope Examination of Steel Plates

A 578/A 578M Specification for Straight-Beam Ultrasonic

1.1 This specification covers steel plates produced by the

Examination of Plain and Clad Steel Plates for Special

thermo-mechanical control process (TMCP). The plates are

Applications

intended primarily for use in welded pressure vessels.

1.2 The TMCP method consists of rolling-reduction and

3. General Requirements and Ordering Information

cooling rate controls which result in mechanical properties in

3.1 Material supplied to this material specification shall

the finished plate that are equivalent to those attained using

conform to Specification A 20/A 20M. These requirements

conventional rolling and heat treating processes which entail

outline the testing and retesting methods and procedures,

reheating after rolling. A description of the TMCP method is

permissible variations in dimensions, quality and repair of

given in Appendix X1.

defects, marking, loading, etc.

1.3 Due to the inherent characteristics of the TMCP method,

3.2 Specification A 20/A 20M also establishes the rules for

the plates cannot be formed at elevated temperatures without

ordering information which should be complied with when

sustaining significant losses in strength and toughness. The

purchasing material to this specification.

plates may be formed and post-weld heat-treated at tempera-

3.2.1 When the material is to be subjected to warm forming

tures not exceeding 1200°F [650°C], providing the require-

or post-weld heat treatment, the order must indicate the

ments of 6.1 are met.

temperatures and times-at-temperature that will be utilized in

1.4 The maximum nominal thickness of plates furnished

such operations. (See 6.1 and Specification A 20/A 20M,

under this specification may not exceed 4 in. [100 mm].

Supplementary Requirement S3.)

1.5 The values stated in either inch-pound units or SI units

3.3 In addition to the basic requirements of this specifica-

are to be regarded separately as standard. Within the text, the

tion, certain supplementary requirements are available when

SI units are shown in brackets. The values stated in each

additional control, testing, or examination is required to meet

system are not exact equivalents. Therefore, each system must

end use requirements. These include:

be used independently of the other. Combining values from the

3.3.1 Vacuum treatment,

two systems may result in nonconformance with this specifi-

3.3.2 Additional or special tension testing,

cation.

3.3.3 Additional or special impact testing, and

2. Referenced Documents 3.3.4 Nondestructive examination.

3.4 The purchaser is referred to the listed supplementary

2.1 ASTM Standards:

requirements in this specification and to the detailed require-

A 20/A 20M Specification for General Requirements for

3 ments in Specification A 20/A 20M.

Steel Plates for Pressure Vessels

3.5 If the requirements of this specification are in conflict

A 435/A 435M Specification for Straight-Beam Ultrasonic

3 with the requirements of Specification A 20/A 20M, the re-

Examination of Steel Plates

quirements of this specification shall prevail.

A 577/A 577M Specification for Ultrasonic Angle-Beam

1 4. Manufacture

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

4.1 Steelmaking Practice—The steel shall be killed and

A01.11 on Steel Plates for Boilers and Pressure Vessels.

shall conform to the fine austenitic grain size requirement of

Current edition approved Sept 10, 1998. Published December 1998. Originally

Specification A 20/A 20M.

published as A 841/A 841M – 85. Last previous edition A 841/A 841M – 95.

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

4.2 The plates shall be produced by the thermo-mechanical

cation SA-841/SA-841M in Section II of that Code.

Annual Book of ASTM Standards, Vol 01.04.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 841/A 841M

TABLE 2 Product Analysis Tolerances

control process.

Tolerances, %

Element Specified Limit

5. Chemical Composition

Over,

Under, Minimum

Maximum

5.1 The chemical composition on heat analysis shall con-

Carbon to 0.15, incl 0.02 0.03

form to the requirements listed in Table 1, except as otherwise

over 0.15 0.03 0.04

provided in Supplementary Requirement S17 of Specification

Manganese to 0.60, incl 0.05 0.06

over 0.60 to 0.90, incl 0.06 0.08

A 20/A 20M when that requirement is involved.

over 0.90 to 1.20, incl 0.08 0.10

5.2 If a product analysis is made on a sample taken from the

over 1.20 to 1.35, incl 0.09 0.11

standard location (see Specification A 20/A 20M), the results

over 1.35 to 1.65, incl 0.09 0.12

Phosphorus to 0.020, incl . . . 0.005

of the analysis shall not deviate from the limits for the heat

over 0.020 . . . 0.010

analysis by more than the values given in Table 2.

Sulfur to 0.020, incl . . . 0.005

over 0.020 . . . 0.010

6. Mechanical Requirements

Silicon to 0.30, incl 0.02 0.03

over 0.30 to 0.40, incl 0.05 0.05

6.1 When the material is to be subjected to warm forming or

over 0.40 0.06 0.06

post-weld heat treatment, the test coupons shall be subjected to Nickel to 1.00, incl . . . 0.03

Chromium to 0.90, incl . . . 0.04

heat treatment to simulate such fabrication operations. (See

Molybdenum to 0.20, incl . . . 0.01

3.2.1 and Specification A 20/A 20M, Supplementary Require-

Copper to 1.00, incl . . . 0.03

ment S3.)

Vanadium to 0.10, incl . . . 0.01

Columbium to 0.10, incl . . . 0.01

6.2 Tension Test Requirements—The plates as represented

Aluminum to 0.15, incl 0.005 0.01

by the tension-test specimens shall conform to the require-

ments shown in Table 3.

6.2.1 Number and Location of Test Coupons—Two tension

TABLE 3 Tensile Requirements

tests shall be made from each plate-as-rolled. One test coupon

shall be taken from a corner of the plate on each end.

Class 1 Class 2

6.3 Notch Toughness Test Requirements:

ksi [MPa] ksi [MPa]

6.3.1 Longitudinal Charpy V-notch tests shall be made in

Yield strength, min:

accordance with Specification A 20/A 20M.

to 2.5 in. [to 65 mm] 50 [345] 60 [415]

over 2.5 in. [over 65 mm] 45 [310] 55 [380]

Tensile strength

TABLE 1 Chemical Requirements

to 2.5 in. [to 65 mm] 70–90 80–100

[485–620] [550–690]

over 2.5 in. [over 65 mm] 65–85 75–95

Grade A Grade B Grade C

[450–585] [515–655]

Element

A

Composition % Composition % Composition %

Elongation in 2 in. [50 mm], min, % :

to 2.5 in. [to 65 mm] 22 22

Carbon, max 0.20 0.15 0.10

over 2.5 in. [over 65 mm] 22 22

Manganese

A

A A Elongation in 8 in. [200 mm], min, % :

t |La 1.5 in. [40 mm] 0.70–1.35 0.70–1.35 0.70-1.60

to 2.5 in. [to 65 mm] 18 . . .

t > 1.5 in. [40 mm] 1.00–1.60 1.00–1.60 1.00-1.60

over 2.5 in. [over 65 mm] 18 . . .

Phosphorus, max 0.030 0.030 0.030

A

Sulfur, max 0.030

...

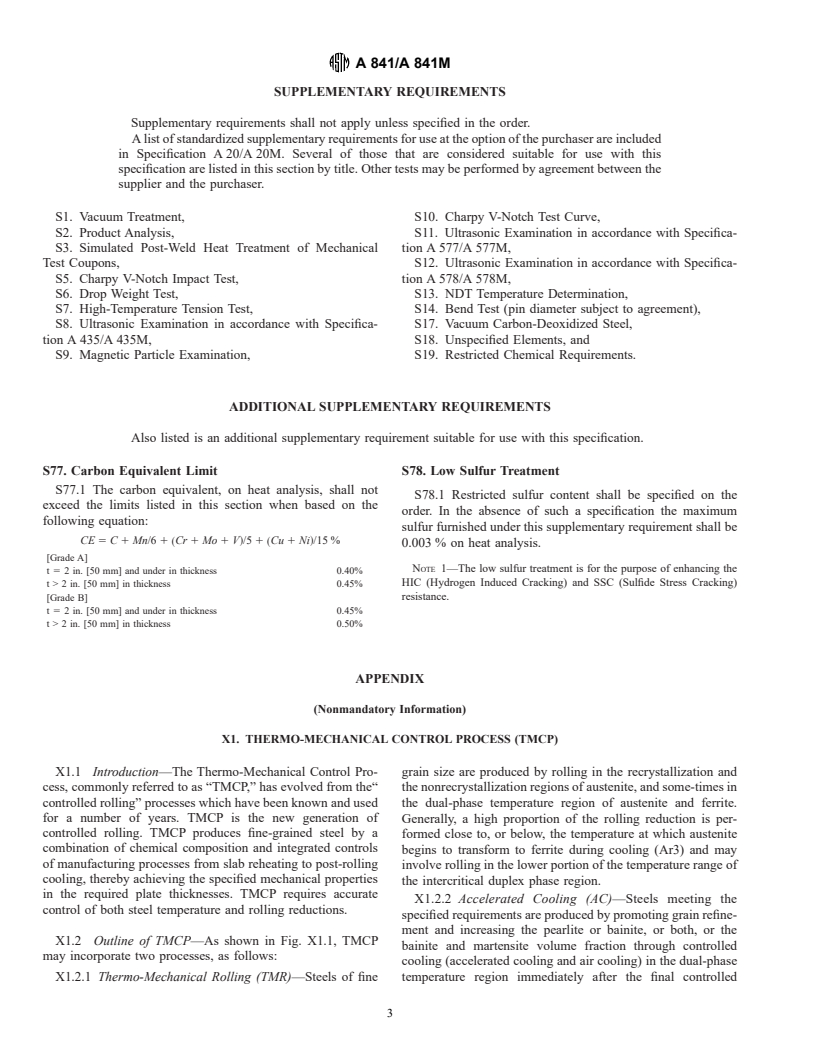

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.