ASTM D2884-93(1998)

(Test Method)Standard Test Method for Yield Stress of Heterogeneous Propellants by Cone Penetration Method

Standard Test Method for Yield Stress of Heterogeneous Propellants by Cone Penetration Method

SCOPE

1.1 This test method covers determination of the yield stress of heterogeneous propellants, both of the gel and emulsion types, containing from 0 to 70% solid additives.

1.2 The values stated in SI units are to be regarded as the standard. In cases where materials, products, or equipment are available in inch-pound units only, SI units are omitted.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact

ASTM International (www.astm.org) for the latest information.

Designation: D 2884 – 93 (Reapproved 1998) An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Yield Stress of Heterogeneous Propellants by Cone

Penetration Method

This standard is issued under the fixed designation D 2884; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers determination of the yield

stress of heterogeneous propellants, both of the gel and

emulsion types, containing from 0 to 70 % solid additives.

1.2 The values stated in SI units are to be regarded as the

standard. In cases where materials, products, or equipment are

available in inch-pound units only, SI units are omitted.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

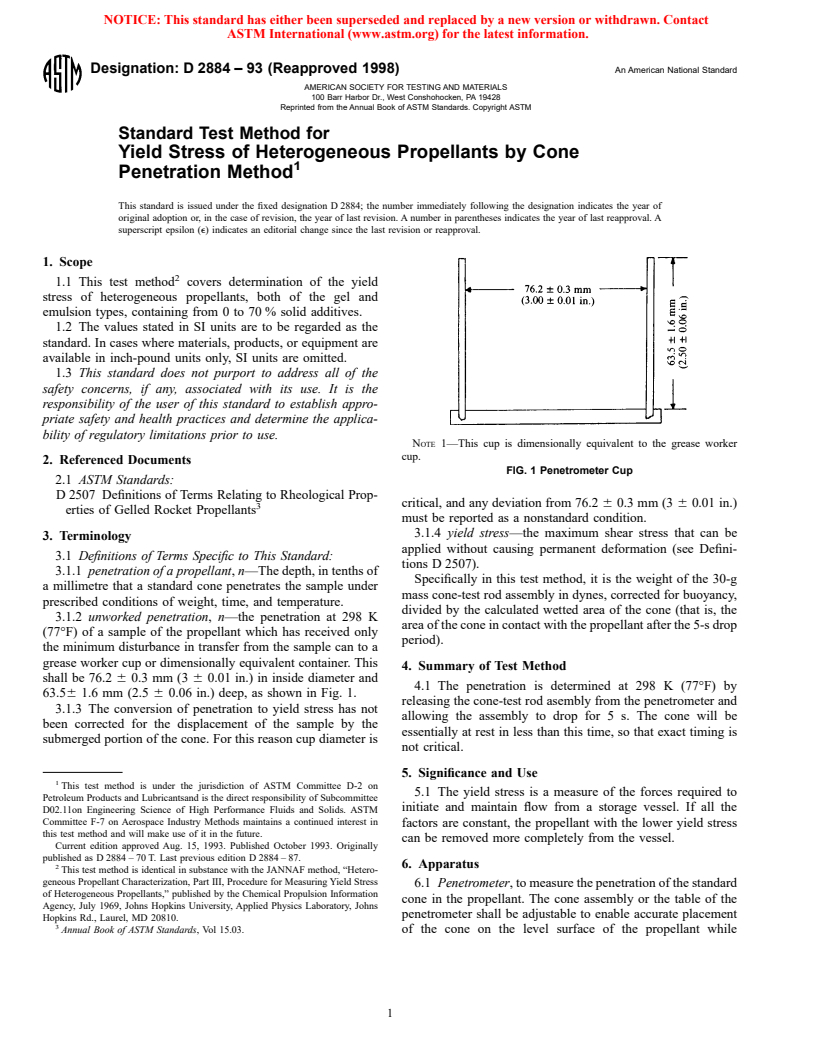

NOTE 1—This cup is dimensionally equivalent to the grease worker

cup.

2. Referenced Documents

FIG. 1 Penetrometer Cup

2.1 ASTM Standards:

D 2507 Definitions of Terms Relating to Rheological Prop-

critical, and any deviation from 76.2 6 0.3 mm (3 6 0.01 in.)

erties of Gelled Rocket Propellants

must be reported as a nonstandard condition.

3.1.4 yield stress—the maximum shear stress that can be

3. Terminology

applied without causing permanent deformation (see Defini-

3.1 Definitions of Terms Specific to This Standard:

tions D 2507).

3.1.1 penetration of a propellant, n—The depth, in tenths of

Specifically in this test method, it is the weight of the 30-g

a millimetre that a standard cone penetrates the sample under

mass cone-test rod assembly in dynes, corrected for buoyancy,

prescribed conditions of weight, time, and temperature.

divided by the calculated wetted area of the cone (that is, the

3.1.2 unworked penetration, n—the penetration at 298 K

area of the cone in contact with the propellant after the 5-s drop

(77°F) of a sample of the propellant which has received only

period).

the minimum disturbance in transfer from the sample can to a

grease worker cup or dimensionally equivalent container. This

4. Summary of Test Method

shall be 76.2 6 0.3 mm (3 6 0.01 in.) in inside diameter and

4.1 The penetration is determined at 298 K (77°F) by

63.56 1.6 mm (2.5 6 0.06 in.) deep, as shown in Fig. 1.

releasing the cone-test rod asembly from the penetrometer and

3.1.3 The conversion of penetration to yield stress has not

allowing the assembly to drop for 5 s. The cone will be

been corrected for the displacement of the sample by the

essentially at rest in less than this time, so that exact timing is

submerged portion of the cone. For this reason cup diameter is

not critical.

5. Significance and Use

This test method is under the jurisdiction of ASTM Committee D-2 on

5.1 The yield stress is a measure of the forces required to

Petroleum Products and Lubricantsand is the direct responsibility of Subcommittee

initiate and maintain flow from a storage vessel. If all the

D02.11on Engineering Science of High Performance Fluids and Solids. ASTM

Committee F-7 on Aerospace Industry Methods maintains a continued interest in

factors are constant, the propellant with the lower yield stress

this test method and will make use of it in the future.

can be removed more completely from the vessel.

Current edition approved Aug. 15, 1993. Published October 1993. Originally

published as D 2884 – 70 T. Last previous edition D 2884 – 87.

6. Apparatus

This test method is identical in substance with the JANNAF method, “Hetero-

geneous Propellant Characterization, Part III, Procedure for Measuring Yield Stress

6.1 Penetrometer, to measure the penetration of the standard

of Heterogeneous Propellants,” published by the Chemical Propulsion Information

cone in the propellant. The cone assembly or the table of the

Agency, July 1969, Johns Hopkins University, Applied Physics Laboratory, Johns

penetrometer shall be adjustable to enable accurate placement

Hopkins Rd., Laurel, MD 20810.

Annual Book of ASTM Standards, Vol 15.03. of the cone on the level surface of the propellant while

NOTICE:¬This¬standard¬has¬either¬been¬superceded¬and¬replaced¬by¬a¬new¬version¬or¬discontinued.¬

Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

D 2884

react with hydrazine gels. The user should plan to have one made to order.

maintaining a zero reading on the indicator. The cone should

fall, when released, without appreciable friction for at least

6.3 Grease Worker Cup, or equivalent container. The cup

42.0 mm but not more than 60.0 mm so the cone will not hit the

shall be made of material known to be compatible with all

bottom of the container. The instrument shall be provided with

propellants which are to be tested in it. Construction may be

leveling screws to maintain the cone shaft in a vertical position

two-piece as shown in Fig. 1, using a silver solder or braze

and a spirit level to determine the attitude of the instrument.

which meets the compatibility requirement to seal the joint.

6.1.1 A 15-g test rod shall be substituted for the regular

Several users have had cups machined in one piece from bar

47.5-g rod in accordance with the manufacturer’s instructions.

stock, or from a rough casting.

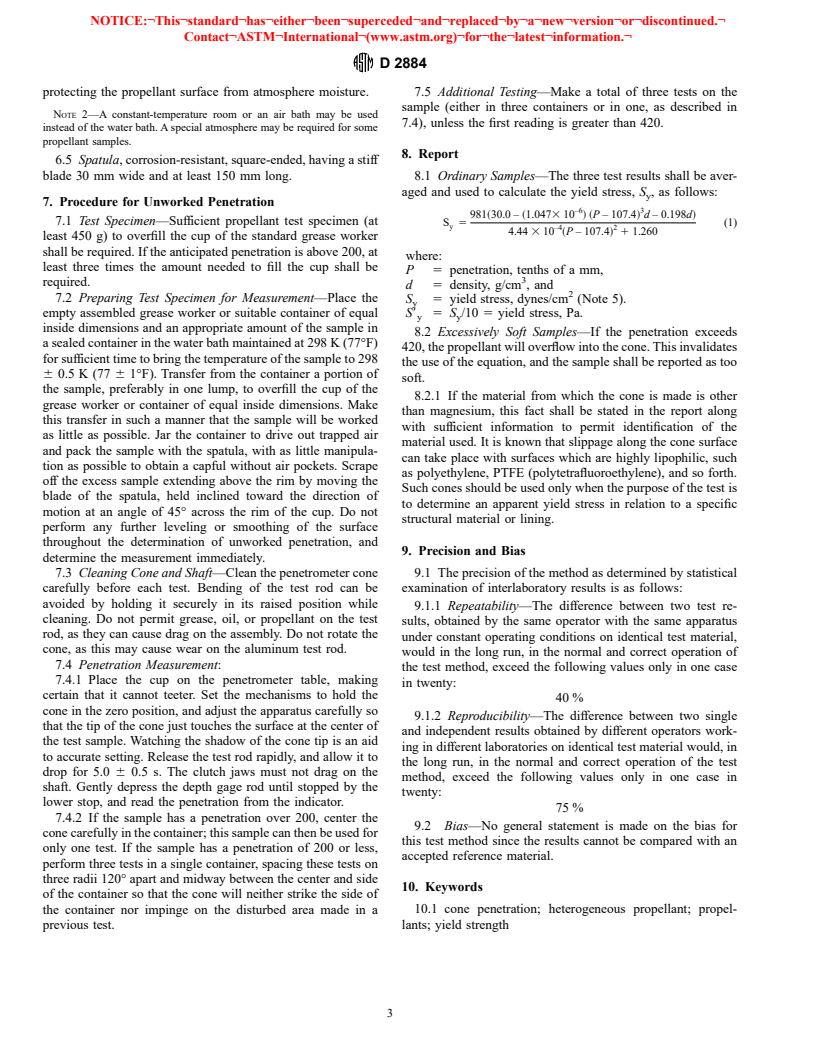

6.2 Cone, of the dimensions shown in Fig. 2.

6.4 Water Bath, capable of regulation to 298 6 0.5 K (77 6

NOTE 1—Some cones have correct dimensions and weight (15.0 g) but 1°F). For unworked penetrations, means must be provided for

NOTE 1—Tolerances on all fractional dimensions shall be ⁄16 in.

NOTE 2—The total mass of the cone shall be 15.00 + 0.05 g and the total mass of its movable attachments shall be 15.00 6 0.05 g.

NOTE 3—Table of Metric Equivalents

in. mm in. mm in. mm in. mm

0.014 0.356 ⁄8 3.18 0.331 8.407 1.136 28.854

0.016 0.406 ⁄32 3.98 0.586 14.884 1.156 29.362

1 1 1

⁄16 1.59 ⁄4 6.35 0.590 14.986 2 ⁄8 53.98

5 5

0.122 3.10 ⁄16 7.94 ⁄8 15.88 2.550 64.77

0.125 3.18 0.329 8.357 1 ⁄8 28.575 2.570 65.28

FIG. 2 Magnesium Penetrometer Cone

NOTICE:¬This¬standard¬has¬either¬been¬superceded¬

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.