ASTM A901-03(2008)

(Specification)Standard Specification for Amorphous Magnetic Core Alloys, Semi-Processed Types

Standard Specification for Amorphous Magnetic Core Alloys, Semi-Processed Types

ABSTRACT

This specification covers the requirements to which flat-cast, amorphous, semi-processed, iron-base magnetic core alloys must conform. These alloys shall be produced by a rapid-quenching, direct-casting process, resulting in metals with noncrystalline structure. The alloys shall be made to meet specified maximum core-loss values and shall be intended primarily for commercial power frequency applications. Desirable core-loss and permeability characteristics shall be developed by further heat treatment in a magnetic field. Amorphous magnetic core alloys are normally composed of iron with small amounts of alloying elements such as boron and silicon. There are no specific chemical requirements in this specification. Material produced to this specification shall conform to the required physical and mechanical properties such as density, ductility, thermal expansion, thermal conductivity, volume resistivity, lamination factor, surface, edge, and pinholes. The alloy shall also conform to the magnetic property requirements such as DC induction, DC coercive field strength, DC residual induction, core loss, and specific exciting power.

SCOPE

1.1 This specification covers the general requirements to which flat-cast, amorphous, semi-processed, iron-base magnetic core alloys must conform.

1.2 These alloys are produced by a rapid-quenching, direct-casting process, resulting in metals with noncrystalline structure. The metallic alloys are made to meet specified maximum core-loss values and are intended primarily for commercial power frequency (50- and 60-Hz) applications in magnetic devices. Desirable core-loss and permeability characteristics are developed by further heat treatment in a magnetic field by the purchaser. The heat treatment typically consists of heating the material to a temperature of 320 to 420°C in a dry, inert atmosphere for 5 to 10 min, although soak times of up to 2 h may be used for large transformer cores. A magnetic field may be required during annealing as designated by the producer. Exact optimum annealing conditions depend on the processing of the material and the size and shape of the device.

1.3 Some of these alloys are sensitive to mechanical stress. Care must be exercised in minimizing any stresses on the material in its final application, otherwise, its magnetic properties will be impaired significantly.

1.4 This specification is developed to aid in the purchase of transformer grade amorphous strip. It provides the chemical, physical, and magnetic parameters and procedures for quality control tests.

1.5 The values stated in customary (cgs-emu and inch-pound) units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units which are provided for information only and are not considered standard.

Note 1—For more information on procedures associated with this specification, refer to the following: Practices A 34/A 34M, A 664, A 700, and B 490; Test Methods A 370 and A 773/A 773M.

1.6 This standard does not purport to address the safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A901 – 03 (Reapproved 2008)

Standard Specification for

Amorphous Magnetic Core Alloys, Semi-Processed Types

This standard is issued under the fixed designation A901; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

and B490; Test Methods A370 and A773/A773M.

1. Scope

1.6 This standard does not purport to address the safety

1.1 This specification covers the general requirements to

which flat-cast, amorphous, semi-processed, iron-base mag- concerns associated with its use. It is the responsibility of the

netic core alloys must conform. user of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

1.2 These alloys are produced by a rapid-quenching, direct-

casting process, resulting in metals with noncrystalline struc- tions prior to use.

ture. The metallic alloys are made to meet specified maximum

2. Referenced Documents

core-loss values and are intended primarily for commercial

2.1 ASTM Standards:

power frequency (50- and 60-Hz) applications in magnetic

A34/A34M Practice for Sampling and Procurement Testing

devices. Desirable core-loss and permeability characteristics

of Magnetic Materials

are developed by further heat treatment in a magnetic field by

A340 Terminology of Symbols and Definitions Relating to

the purchaser. The heat treatment typically consists of heating

Magnetic Testing

the material to a temperature of 320 to 420°C in a dry, inert

A370 Test Methods and Definitions for Mechanical Testing

atmosphere for 5 to 10 min, although soak times of up to 2 h

of Steel Products

may be used for large transformer cores.Amagnetic field may

A664 PracticeforIdentificationofStandardElectricalSteel

be required during annealing as designated by the producer.

Grades in ASTM Specifications

Exact optimum annealing conditions depend on the processing

A700 PracticesforPackaging,Marking,andLoadingMeth-

of the material and the size and shape of the device.

ods for Steel Products for Shipment

1.3 Some of these alloys are sensitive to mechanical stress.

A712 Test Method for Electrical Resistivity of Soft Mag-

Care must be exercised in minimizing any stresses on the

netic Alloys

material in its final application, otherwise, its magnetic prop-

A773/A773M Test Method for dc Magnetic Properties of

erties will be impaired significantly.

Materials Using Ring and Permeameter Procedures with

1.4 This specification is developed to aid in the purchase of

dc Electronic Hysteresigraphs

transformer grade amorphous strip. It provides the chemical,

A900/A900M Test Method for Lamination Factor ofAmor-

physical, and magnetic parameters and procedures for quality

phous Magnetic Strip

control tests.

B490 Practice for Micrometer Bend Test for Ductility of

1.5 The values stated in customary (cgs-emu and inch-

Electrodeposits

pound) units are to be regarded as standard. The values given

C693 Test Method for Density of Glass by Buoyancy

in parentheses are mathematical conversions to SI units which

D3455 Test Methods for Compatibility of Construction

are provided for information only and are not considered

MaterialwithElectricalInsulatingOilofPetroleumOrigin

standard.

NOTE 1—For more information on procedures associated with this

3. Terminology

specification, refer to the following: Practices A34/A34M, A664, A700,

3.1 The terms and symbols used in this specification are

defined in Terminology A340.

This specification is under the jurisdiction of ASTM Committee A06 on

4. Dimensions

Magnetic Properties and is the direct responsibility of Subcommittee A06.02 on

Material Specifications.

4.1 Width—Tolerances on nominal as-cast strip shall be

Current edition approved Nov. 1, 2008. Published December 2008. Originally

+0.004, −0.020 in. (+0.1 mm, −0.5 mm) from specified

approved in 1990. Last previous edition approved in 2003 as A901–03. DOI:

purchase width.

10.1520/A0901-03R08.

Theprocessofheattreatmentinamagneticfieldiscoveredbyapatentheldby

General Electric Co. Interested parties are invited to submit information regarding

the identification of acceptable alternatives to this patented item to the Committee For referenced ASTM standards, visit the ASTM website, www.astm.org, or

on Standards, ASTM International Headquarters. Your comments will receive contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

careful consideration at a meeting of the responsible technical committee, which Standards volume information, refer to the standard’s Document Summary page on

you may attend. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A901 – 03 (2008)

4.2 Thickness—The nominal thickness shall be 0.001 in. 7.7 Surface—The strip surface and edges shall have no

(0.025 mm) as measured by a 0.25-in. (6.35-mm) diameter wrinkles, dimples, cracks, folds, flakes, or other injurious

anvil micrometer. The nominal thickness may vary 60.0002 imperfections that would make the material unsuitable for the

in. (60.005 mm), but the maximum thickness variation across fabrication of transformer cores.

the width shall be within 610% of the mean thickness, or as

7.8 Edge—The strip edge shall have no slivers with a

agreed upon between the purchaser and the producer.

maximum dimension exceeding 0.004 in. (0.1 mm).

7.9 Camber—Thestripedgeshallshownoexcessivelateral

5. Material Requirements

curvature(camber).Maximumdeviationfromastraightlineof

5.1 Amorphous magnetic core alloys are composed princi-

an 8-ft (2.4-m) strip edge shall not exceed 0.1 in. (2.5 mm).

pally of iron with small amounts of alloying elements such as

7.10 Pinholes—The strip shall have no pinholes exceeding

boron and silicon. Other chemical elements are in residual

0.08 in. (2.0 mm). Maximum hole frequency, visible against a

amountsorcanbeaddedtoimprovefabricationorthephysical

2 −4

light source, shall not be more than 1 per 3 in. (19.4 310

ormagneticproperties.Theproducershallprovide,onrequest,

m ).

a statement of the nominal chemistry being supplied. The

nominal composition for one particular alloy, in weight per-

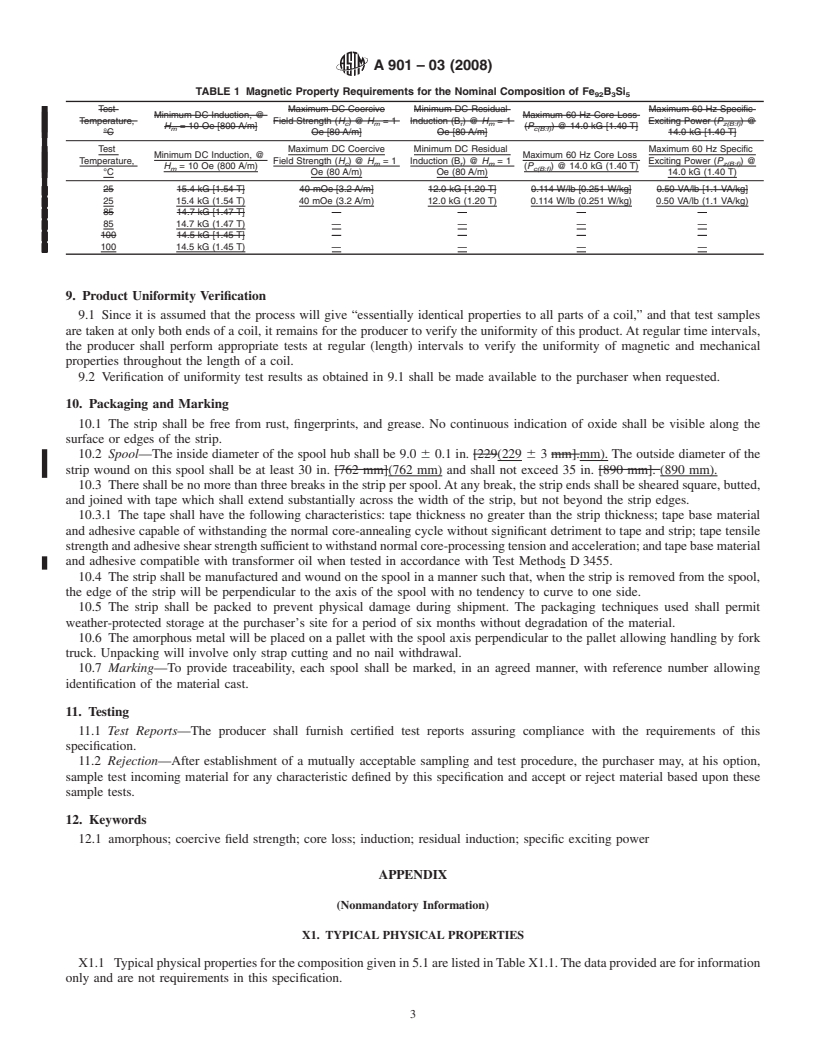

8. Magnetic Property Requirements

cent, is: iron 92, silicon 5, and boron 3.

8.1 Test Procedure—The magnetic quality of each batch of

6. Sampling

material (as defined in 6.1) shall be determined by obtaining

test samples from both ends of a batch (or lot). These samples

6.1 Acontinuously cast strip in one coil without breaks will

shall be annealed in a dry, inert atmosphere with an applied

constituteonetestlot.Inpractice,thismayrepresentquantities

up to 2200 lb (1000 kg), depending on the width of the strip. magnetic field of at least 10 Oe (800A/m) using the time and

temperature sequence recommended by the producer. The

6.2 Test samples normally shall be taken from both ends of

the continuous strip of each test lot. Other sample frequencies samples may be either in toroidal or flat strip form as agreed

upon between the producer and the purchaser.

maybeusedasagreeduponbytheproducerandthepurchaser.

6.3 For small coils, less than 100 lb (45 kg), and for coils

8.2 Amorphous magnetic core alloys are purchased to

containing splices, the test lot shall be as agreed upon between

specified maximum core loss requirements. The purchaser

the producer and the purchaser.

shallmakecleartotheproducerthelimitingvaluesofcoreloss

requiredfortheorderedmaterial.Forthenominalcomposition

7. Physical and Mechanical Property Requireme

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A 901–97 Designation: A 901 – 03 (Reapproved 2008)

Standard Specification for

Amorphous Magnetic Core Alloys, Semi-Processed Types

This standard is issued under the fixed designation A901; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the general requirements to which flat-cast, amorphous, semi-processed, iron-base magnetic core

alloys must conform.

1.2 These alloys are produced by a rapid-quenching, direct-casting process, resulting in metals with noncrystalline structure.

The metallic alloys are made to meet specified maximum core-loss values and are intended primarily for commercial power

frequency(50-and60-Hz)applicationsinmagneticdevices.Desirablecore-lossandpermeabilitycharacteristicsaredevelopedby

further heat treatment in a magnetic field by the purchaser. The heat treatment typically consists of heating the material to a

temperature of 320 to 420°C in a dry, inert atmosphere for 5 to 10 min, although soak times of up to 2 h may be used for large

transformer cores. A magnetic field may be required during annealing as designated by the producer. Exact optimum annealing

conditions depend on the processing of the material and the size and shape of the device.

1.3 Some of these alloys are sensitive to mechanical stress. Care must be exercised in minimizing any stresses on the material

in its final application, otherwise, its magnetic properties will be impaired significantly.

1.4 This specification is developed to aid in the purchase of transformer grade amorphous strip. It provides the chemical,

physical, and magnetic parameters and procedures for quality control tests.

1.5The values stated in either customary (cgs-emu and inch-pound) units or SI units are to be regarded separately as standard.

Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each

system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this

specification.

1.5 The values stated in customary (cgs-emu and inch-pound) units are to be regarded as standard. The values given in

parentheses are mathematical conversions to SI units which are provided for information only and are not considered standard.

NOTE 1—For more information on procedures associated with this specification, refer to the following: Practices A34, A664, A700, and

B490A34/A34M, A664, A700, and B490; Test Methods A370 and A773 and A773/A773M.

1.6 This standard does not purport to address the safety concerns associated with its use. It is the responsibility of the user of

this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use.

2. Referenced Documents

2.1 ASTM Standards:

A3434/A34M Practice for Sampling and Procurement Testing of Magnetic Materials

A340 Terminology of Symbols and Definitions Relating to Magnetic Testing

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A664 Practice for Identification of Standard Electrical- and Lamination- Electrical Steel Grades in ASTM Specifications

A700 Practices for Packaging, Marking, and Loading Methods for Steel Products for Domestic Shipment

A712 Test Method for Electrical Resistivity of Soft Magnetic Alloys

A773/A773M TestMethodforD-CdcMagneticPropertiesofMaterialsUsingRingandPermeameterProcedureswithD-Cdc

Electronic Hysteresigraphs

A900/A900M Test Method for Lamination Factor of Amorphous Magnetic Strip

This specification is under the jurisdiction of ASTM Committee A-6A06 on Magnetic Properties and is the direct responsibility of Subcommittee A06.02 on Material

Specifications.

CurrenteditionapprovedJune10,1997.Nov.1,2008.PublishedDecember1997.2008.OriginallypublishedasA901–90.approvedin1990.Lastpreviouseditionapproved

in 2003 as A901–903.

The process of heat treatment in a magnetic field is covered by a patent held by General Electric Co. Interested parties are invited to submit information regarding the

identification of acceptable alternatives to this patented item to the Committee on Standards, ASTM International Headquarters. Your comments will receive careful

consideration at a meeting of the responsible technical committee, which you may attend.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

, Vol 03.04.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 901 – 03 (2008)

B490 Practice for Micrometer Bend Test for Ductility of Electrodeposits

C693 Test Method for Density of Glass by Buoyancy

D3455 Test Methods for Compatibility of Construction MaterialsMaterial with Electrical Insulating Oil of Petroleum Origin

3. Terminology

3.1 The terms and symbols used in this specification are defined in Terminology A340.

4. Dimensions

4.1 Width—Tolerances on nominal as-cast strip shall be +0.004, −0.020 in. [+0.1(+0.1 mm, −0.5 mm]mm) from specified

purchase width.

4.2 Thickness—The nominal thickness shall be 0.001 in. [0.025 mm](0.025 mm) as measured by a 0.25-in. [6.35-mm](6.35-

mm) diameter anvil micrometer. The nominal thickness may vary 60.0002 in. [60.005 mm],(60.005 mm), but the maximum

thickness variation across the width shall be within 610% of the mean thickness, or as agreed upon between the purchaser and

the producer.

5. Material Requirements

5.1 Amorphous magnetic core alloys are composed principally of iron with small amounts of alloying elements such as boron

and silicon. Other chemical elements are in residual amounts or can be added to improve fabrication or the physical or magnetic

properties.Theproducershallprovide,onrequest,astatementofthenominalchemistrybeingsupplied.Thenominalcomposition

for one particular alloy, in weight percent, is: iron 92, silicon 5, and boron 3.

6. Sampling

6.1 Acontinuously cast strip in one coil without breaks will constitute one test lot. In practice, this may represent quantities up

to 2200 lb [1000 kg],(1000 kg), depending on the width of the strip.

6.2 Test samples normally shall be taken from both ends of the continuous strip of each test lot. Other sample frequencies may

be used as agreed upon by the producer and the purchaser.

6.3 Forsmallcoils,lessthan100lb[45kg],(45kg),andforcoilscontainingsplices,thetestlotshallbeasagreeduponbetween

the producer and the purchaser.

7. Physical and Mechanical Property Requirements

3 (650 kg/m

7.1 Density—The density shall be provided by the producer to a precision of 60.05 g/cm [650 kg/m ]) as measured

by Test Method C693.

7.2 Ductility—Strip bend ductility, with free solidification surface facing inward, shall be such that a minimum 1-m length of

ribbon may be passed 180° around a 0.125-in. [3-mm](3-mm) polished steel rod without cracking or fracture.

7.3 ThermalExpansion—Thenominalcoefficientofthermalexpansionshallbereportedforthetemperaturerange40to400°C.

7.4 Thermal Conductivity—The nominal value measured across the width shall be reported for temperatures of 25, 100, and

400°C. The defined thermal conductivity of the material shall not differ from the reported value by more than 620%.

7.5 Volume Resistivity—The nominal volume resistivity shall be reported as measured by Test Method A712.

7.6 Lamination Factor—The minimum lamination factor of uncoated material shall be 77% as measured in accordance with

Test MethodA900/A900M.The lamination factor for coated material shall be as agreed between the producer and the purchaser.

7.7 Surface—Thestripsurfaceandedgesshallhavenowrinkles,dimples,cracks,folds,flakes,orotherinjuriousimperfections

that would make the material unsuitable for the fabrication of transformer cores.

7.8 Edge—The strip edge shall have no slivers with a maximum dimension exceeding 0.004 in.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.