ASTM F2562/F2562M-07

(Specification)Standard Specification for Steel Reinforced Thermoplastic Ribbed Pipe and Fittings for Non-Pressure Drainage and Sewerage

Standard Specification for Steel Reinforced Thermoplastic Ribbed Pipe and Fittings for Non-Pressure Drainage and Sewerage

SCOPE

1.1 This specification covers requirements and test methods for materials, dimensions, workmanship, impact resistance, pipe stiffness, flattening, buckling, tensile strength of seam, joint systems, perforations, and markings for steel reinforced thermoplastic pipe and fittings of nominal sizes 8 in. [200 mm] through 120 in. [3000 mm]. The steel reinforced, spirally formed thermoplastic pipes governed by this standard are intended for use in underground applications where soil provides support for their flexible walls. These pipes will be used for gravity flow and non-pressure applications, such as storm sewers, sanitary sewers, industrial waste applications and drainage pipes.

1.2 Units—The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text the SI units are shown in brackets. The values stated in each system may not be exact equivalents: therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 2562/F 2562M – 07

Specification for

Steel Reinforced Thermoplastic Ribbed Pipe and Fittings for

Non-Pressure Drainage and Sewerage

This standard is issued under the fixed designation F 2562/F 2562M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy,

High-Strength Low-Alloy with Improved Formability, and

1.1 This specification covers requirements and test methods

Ultra-High Strength

for materials, dimensions, workmanship, impact resistance,

D 618 Practice for Conditioning Plastics for Testing

pipe stiffness, flattening, buckling, tensile strength of seam,

D 638 Test Method for Tensile Properties of Plastics

joint systems, perforations, and markings for steel reinforced

D 2122 Test Method for Determining Dimensions of Ther-

thermoplastic pipe and fittings of nominal sizes 8 in. [200 mm]

moplastic Pipe and Fittings

through 120 in. [3000 mm]. The steel reinforced, spirally

D 2321 Practice for Underground Installation of Thermo-

formed thermoplastic pipes governed by this standard are

plastic Pipe for Sewers and Other Gravity-Flow Applica-

intended for use in underground applications where soil pro-

tions

vides support for their flexible walls. These pipes will be used

D 2412 Test Method for Determination of External Loading

for gravity flow and non-pressure applications, such as storm

Characteristics of Plastic Pipe by Parallel-Plate Loading

sewers, sanitary sewers, industrial waste applications and

D 2444 Test Method for Determination of the Impact Re-

drainage pipes.

sistance of Thermoplastic Pipe and Fittings by Means of a

1.2 Units—The values stated in either inch-pound units or

Tup (Falling Weight)

SI units are to be regarded separately as standard. Within the

D 3212 Specification for Joints for Drain and Sewer Plastic

text the SI units are shown in brackets. The values stated in

Pipes Using Flexible Elastomeric Seals

each system may not be exact equivalents: therefore, each

D 3350 Specification for Polyethylene Plastics Pipe and

system shall be used independently of the other. Combining

Fittings Materials

values from the two systems may result in non-conformance

F 412 Terminology Relating to Plastic Piping Systems

with the standard.

F 449 Practice for Subsurface Installation of Corrugated

1.3 This standard does not purport to address all of the

PolyethylenePipeforAgriculturalDrainageorWaterTable

safety concerns, if any, associated with its use. It is the

Control

responsibility of the user of this standard to establish appro-

F 477 Specification for Elastomeric Seals (Gaskets) for

priate safety and health practices and determine the applica-

Joining Plastic Pipe

bility of regulatory limitations prior to use.

F 2136 Test Method for Notched, Constant Ligament-Stress

1.4 There is no similar or equivalent ISO standard.

(NCLS) Test to Determine Slow-Crack-Growth Resistance

2. Referenced Documents

of HDPE Resins or HDPE Corrugated Pipe

2.2 American Association of State Highway and Transpor-

2.1 ASTM Standards:

tation Offıcials (AASHTO)

A 1008/A 1008M Specification for Steel, Sheet, Cold-

AASHTO LRFD Bridge Construction Specification Section

Rolled, Carbon, Structural, High-Strength Low-Alloy,

High-Strength Low-Alloy with Improved Formability, So-

AASHTO M294-05 Corrugated Polyethylene Pipe, 300- to

lution Hardened, and Bake Hardenable

1500-mm Diameter

A 1011/A 1011M Specification for Steel, Sheet and Strip,

2.3 Federal Standards:

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

1 2.4 Military Standards:

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.11 on

Composite.

Current edition approved April 1, 2007. Published May 2007.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Association of State Highway and Transportation

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001.

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 2562/F 2562M – 07

MIL-STD-129 Marking for Shipment and Storage 4.3.2 Internal coupling, sealant type—seal is affected by

applying an industrial sealant between the external surface of

3. Terminology

the coupling and the internal surface of the pipe.

4.3.3 Other—Where these connections are impractical or

3.1 Definitions—Definitions used in this specification are in

undesirablebecauseofspace,layoutorotherrequirements,itis

accordance with Terminology F 412, unless otherwise noted.

permissible to use joining methods such as flanging, internal

3.2 Definitions of Terms Specific to This Standard:

coupling (gasketed type), extrusion welding, electro-fusion,

3.2.1 gravity flow, n—aconditionwhereliquidflowthrough

butt fusion, and others. Methods proposed should be evaluated

a piping system results from a downward pipeline slope, but

by the engineer for suitability.

flowislessthanfull,exceptduringconditionswhenthesystem

may become temporarily surcharged in which case, the system

5. Materials

is subject to temporary internal hydrostatic pressure that is

limited to piping system joint capabilities.

5.1 Polyethylene Materials:

3.2.2 steel reinforced thermoplastic pipe, n—ribbedthermo-

5.1.1 Polyethylene materials used in the manufacture of

plastic pipe with steel reinforcing strips encapsulated within

steel reinforced thermoplastic pipe shall meet or exceed the

the ribs (See Fig. 1).

requirements of cell classification of 335420C or E (335430C

3.2.3 encapsulation thicknesses, n—the thicknesses of the

or E for sanitary sewer applications) as defined and described

HDPEcoveringonbothsidesofthesteelreinforcementaswell

in Specification D 3350.

as the thickness of the closure at the top (outside) of the rib and

5.1.2 Polyethylene materials used in the manufacture of

the thickness of the profile directly under (inside) of the

rotationally molded joints, fittings and couplings shall meet or

reinforcement.

exceed the requirements of cell classification 213320C or E

3.2.4 wrap width, n—the width the helically wrapped strip

(213330C or E for sanitary sewer applications) as defined and

covers when measured across the strip, perpendicular to the

described in Specification D 3350.

ribs (See Fig. 1).

5.1.3 Polyethylene materials used in the manufacture of

injection molded joints, fittings and couplings shall meet or

4. Significance and Use

exceed the requirements of cell classification 314420C or E

4.1 Steel reinforced thermoplastic pipes are used for under-

(314430C or E for sanitary sewer applications) as defined and

ground applications where soil provides support to their

described in Specification D 3350.

flexible walls. Their main use is for gravity flow and non-

5.1.4 Slow crack growth resistance of the polyethylene

pressure drainage of surface water, sanitary sewage and indus-

materials shall be determined by testing in accordance with

trial waste.

Test Method F 2136. The applied stress shall be 600 psi [4100

kPa]. The test specimens shall exceed 24 h with no failures.

NOTE 1—Industrial waste disposal lines should be installed only upon

Testing shall be done on polyethylene material taken from the

the specific approval of the governing code, or other authority, and after

finished pipe, joint, fitting or coupling.

determining the suitability of the product under the anticipated environ-

ment, temperature, and other end-use conditions. Users should consult the

5.1.5 Other pipe materials—It is permissible to use mate-

manufacturer for the required product information.

rials other than those specified under base materials as part of

the profile construction, for example to weld the spiral seam

4.2 This specification covers pipe products made in various

together or the welding of couplings, provided that these

stiffness classes according to Table 1 at 5 % deflection when

materials are compatible with the base material, and in no way

tested in accordance with Test Method D 2412. The required

compromise the performance of the pipe products in the

stiffness class shall be determined by structural design calcu-

intended use.

lations based on the application of the pipe.

4.3 This specification covers pipe products using the fol- 5.1.6 Carbon Black Content—The carbon black content

shall be a maximum of 3.0 wt. % of the total of the polyeth-

lowing different joining systems;

4.3.1 Bell and spigot, gasketed type—seal is affected by a ylene compound.

5.1.7 Rework Material—It is permissible to use clean re-

gasket compressed between the spigot and bell ends of the

pipe. work polyethylene material generated from the manufacturer’s

FIG. 1 Steel Reinforced Thermoplastic Ribbed Pipe Profile

F 2562/F 2562M – 07

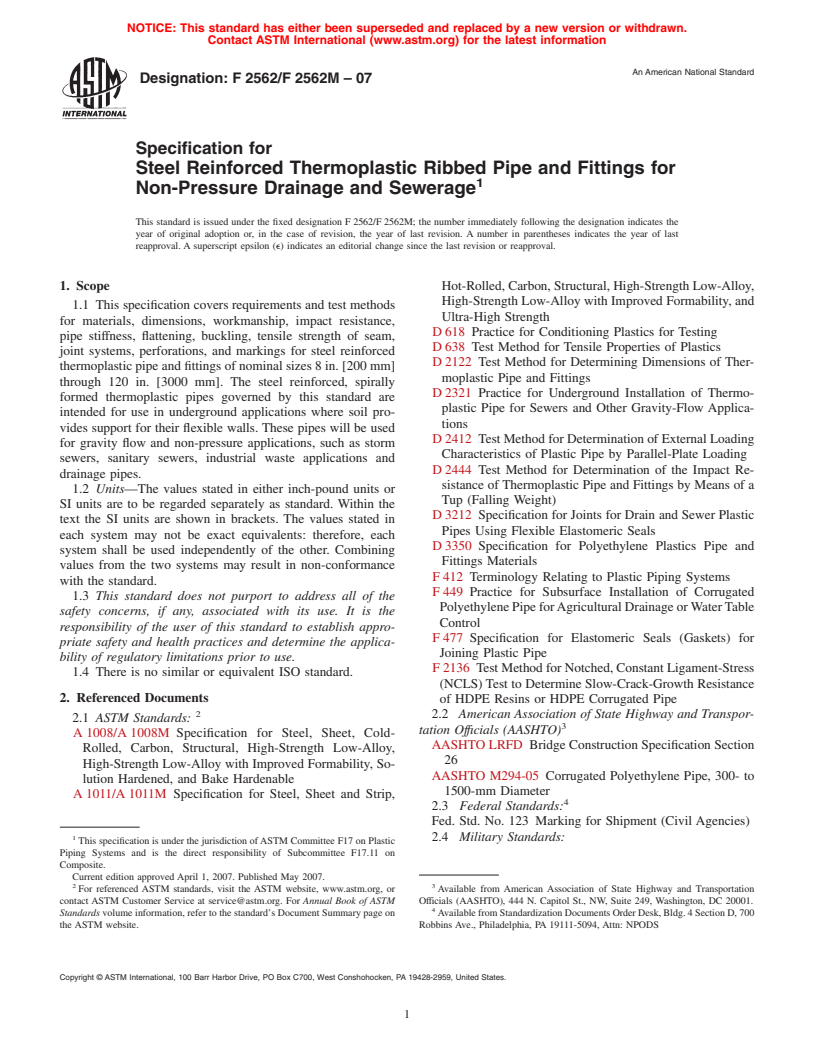

TABLE 1 Pipe Stiffness Classes and Buckling Limits

Class 1 Class 2 Class 3 Class 4 Class 5

Nominal Pipe Buckling Pipe Buckling Pipe Buckling Pipe Buckling Pipe Buckling

Inside Diameter

Pipe Size stiffness Limit stiffness Limit stiffness Limit stiffness Limit stiffness Limit

in. in. [mm] psi [kPa] % psi [kPa] % psi [kPa] % psi [kPa] % psi [kPa] %

8 8 [200] 50 [345] 20 16 [110] 20 32 [221] 20 46 [317] 20 63 [434] 20

9 9 [225] 50 [345] 20 16 [110] 20 32 [221] 20 46 [317] 20 63 [434] 20

10 10 [250] 50 [345] 20 16 [110] 20 32 [221] 20 46 [317] 20 63 [434] 20

12 12 [300] 50 [345] 20 16 [110] 20 32 [221] 20 46 [317] 20 63 [434] 20

15 15 [375] 42 [290] 20 16 [110] 20 32 [221] 20 46 [317] 20 63 [434] 15

18 18 [450] 40 [275] 20 16 [110] 20 32 [221] 20 46 [317] 20 63 [434] 15

21 21 [525] 38 [260] 20 16 [110] 20 32 [221] 20 46 [317] 15 63 [434] 10

24 24 [600] 34 [235] 20 16 [110] 20 32 [221] 20 46 [317] 15 63 [434] 10

27 27 [675] 30 [205] 20 16 [110] 20 32 [221] 20 46 [317] 12 -- --

30 30 [750] 28 [195] 20 16 [110] 20 32 [221] 20 46 [317] 12 -- --

33 33 [825] 25 [170] 20 16 [110] 20 32 [221] 15 46 [317] 10 -- --

36 36 [900] 22 [150] 20 16 [110] 20 32 [221] 15 46 [317] 10 -- --

40 40 [1000] 20 [140] 20 16 [110] 20 32 [221] 10 46 [317] 10 -- --

42 42 [1050] 20 [140] 20 16 [110] 20 32 [221] 10 46 [317] 10 -- --

48 48 [1200] 18 [125] 15 16 [110] 15 32 [221] 10 46 [317] 10 -- --

54 54 [1350] 16 [110] 15 16 [110] 15 32 [221] 10 46 [317] 10 -- --

60 60 [1500] 14 [97] 15 16 [110] 15 32 [221] 10 46 [317] 10 -- --

66 66 [1650] 14 [97] 12 16 [110] 12 32 [221] 10 46 [317] 10 -- --

72 72 [1800] 14 [97] 12 16 [110] 12 32 [221] 10 46 [317] 10 -- --

78 78 [1950] 14 [97] 10 16 [110] 10 32 [221] 10 -- -- -- --

90 90 [2250] 14 [97] 10 16 [110] 10 32 [221] 10 -- -- -- --

96 96 [2400] -- -- 16 [110] 10 -- -- -- -- -- --

100 100 [2500] -- -- 16 [110] 10 -- -- -- -- -- --

108 108 [2700] -- -- 16 [110] 10 -- -- -- -- -- --

120 120 [3000] -- -- 16 [110] 10 -- -- -- -- -- --

own pipe production provided the material and the pipe wall integrity or the encapsulation of the steel reinforcement.

produced meet all the requirements of this specification. Holes deliberately placed in perforated pipe are permitted. The

5.2 Steel Materials—The steel material shall be uncoated steel reinforcing materials shall not be exposed.

cold or hot rolled, formable steel meeting the requirements of 6.2 Pipe Dimensions and Tolerances:

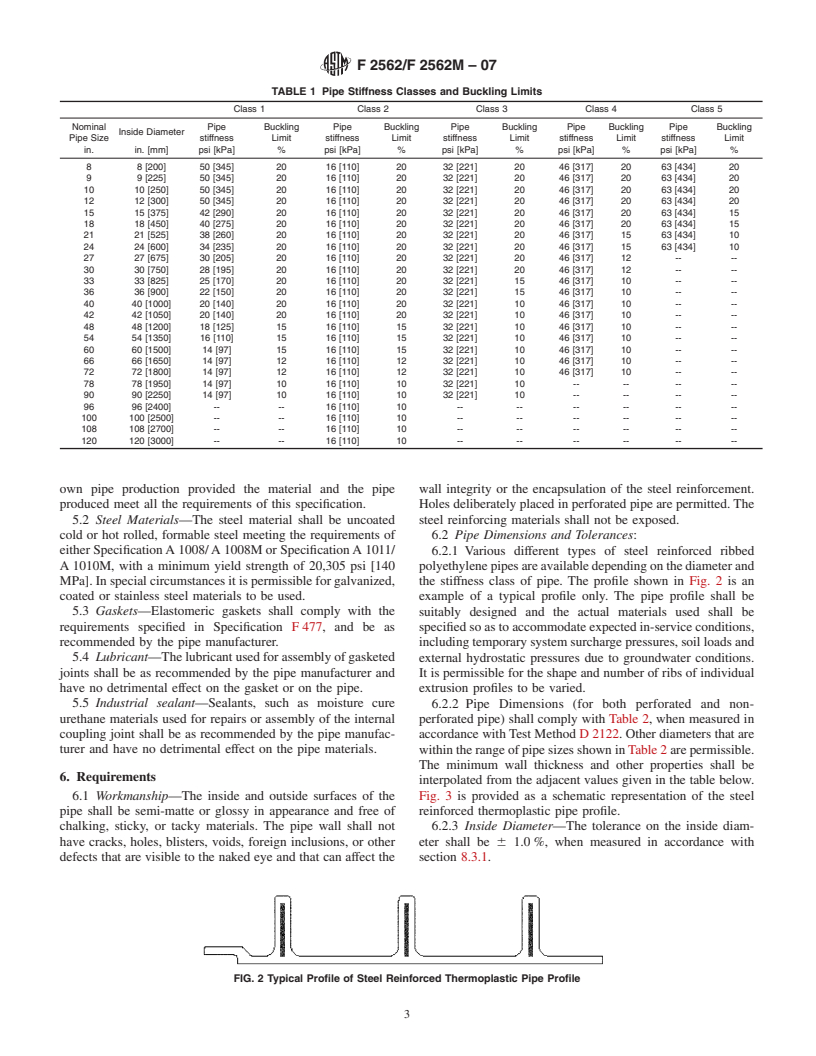

either SpecificationA 1008/A 1008M or SpecificationA 1011/ 6.2.1 Various different types of steel reinforced ribbed

A 1010M, with a minimum yield strength of 20,305 psi [140 polyethylenepipesareavailabledependingonthediameterand

MPa].Inspecialcircumstancesitispermissibleforgalvanized, the stiffness class of pipe. The profile shown in Fig. 2 is an

coated or stainless steel materials to be used. example of a typical profile only. The pipe profile shall be

5.3 Gaskets—Elastomeric gaskets shall comply with the suitably designed and the actual materials used shall be

requirements specified in Specification F 477, and be as specified so as to accommodate expected in-service conditions,

recommended by the pipe manufacturer. including temporary system surcharge pressures, soil loads and

5.4 Lubricant—Thelubricantusedforassemblyofgasketed external hydrostatic pressures due to groundwater conditions.

joints shall be as recommended by the pipe manufacturer and It is permissible for the shape and number of ribs of individual

have no detrimental effect on the gasket or on the pipe.

extrusion profiles to be varied.

5.5 Industrial sealant—Sealants, such as moisture cure 6.2.2 Pipe Dimensions (for both perforated and non-

urethane materials used for repairs or assembly of the internal

perforated pipe) shall comply with Table 2, when measured in

coupling joint shall be as recommended by the pipe manufac- accordance with Test Method D 2122. Other diameters that are

turer and have no detrimental effect on the pipe materials.

withintherangeofpipesizesshowninTable2arepermissible.

The minimum wall thickness and other properties shall be

6. Requirements

interpolated from the adjacent values given in the table below.

6.1 Workmanship—The inside and outside surfaces of the Fig. 3 is provided as a schematic representation of the steel

pipe shall be semi-matte or glossy in appearance and free of reinforced thermoplastic pipe profile.

chalking, sticky, or tacky materials. The pipe wall shall not 6.2.3 Inside Diameter—The tolerance on the inside diam-

have cracks, holes, blisters, voids, foreign inclusions, or other eter shall be 6 1.0 %, when measured in accordance with

defects that are visible to the naked eye and that can affect the section 8.3.1.

FIG. 2 Typical Profile of Steel Reinforced Thermoplastic Pipe Profile

F 2562/F 2562M – 07

TABLE 2 Nominal Pipe Sizes, Inside Diameters, and Minimum

6.3 Pipe Stiffness—The stiffness of the pipe measured at

Waterway Wall Thicknesses

5 % deflection shall be one of the classes listed in Table 1

Nominal Pipe Size Inside Diameter Minimum Waterway Minimum

(unless otherwise specified), when tested in accordance with

Wall Thickness, t Encapsulation

section 8.4.

Thickness

(Bottom), t

NOTE 3—The 5 % deflection criteria was selected for testing conve-

in. in. [mm] in. [mm[ in. [ mm]

nience and should not be considered as a limitation with respect to in-use

deflection.

8 8 [200] 0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.