ASTM D5018-89(2004)

(Test Method)Standard Test Method for Shear Viscosity of Coal-Tar and Petroleum Pitches

Standard Test Method for Shear Viscosity of Coal-Tar and Petroleum Pitches

SIGNIFICANCE AND USE

This test method is useful as one element in establishing the uniformity of shipments.

Viscosity is also valuable for rheological characterization of binder pitches. Binder pitch imparts consistency to carbonaceous mixes and affects their resistance to deformation. Binder pitch viscosity is important for assessing mix consistency and for evaluating the ease of mix extrusion or molding into artifacts.

SCOPE

1.1 This test method covers the determination of the apparent shear viscosity of coal-tar and petroleum-based pitches having a Mettler softening point (SP) range of approximately 95 to 120°C.

1.2 This test method is applicable only for rotational viscometers.

1.3 Since this test method is based on theoretical grounds, strict adherence to details of the procedure is necessary to comply with the theoretical requirements.

1.4 The values stated in conventional units (centipoise) are to be regarded as the standard. The SI unit is the pascal second (Pa[dot]s) and one millipascal second (mPa[dot]s) = one centipoise (cps); centipoise is in cgs units.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 5018 – 89 (Reapproved 2004)

Standard Test Method for

Shear Viscosity of Coal-Tar and Petroleum Pitches

This standard is issued under the fixed designation D5018; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope ratio of shear stress to shear rate in a unidirectional simple

shear flow field at steady state conditions. A concentric

1.1 This test method covers the determination of the appar-

cylinder viscometer is useful for measuring the apparent shear

ent shear viscosity of coal-tar and petroleum-based pitches

viscosity, provided the sample temperature is adequately con-

having a Mettler softening point (SP) range of approximately

trolled, the “end-effects” are negligible, and the gap between

95 to 120°C.

rotor/cup is small and remains constant during the test. The

1.2 This test method is applicable only for rotational vis-

extrapolated value of apparent shear viscosity at “zero” shear

cometers.

rate is called shear viscosity.

1.3 Since this test method is based on theoretical grounds,

strict adherence to details of the procedure is necessary to

4. Significance and Use

comply with the theoretical requirements.

4.1 Thistestmethodisusefulasoneelementinestablishing

1.4 The values stated in conventional units (centipoise) are

the uniformity of shipments.

to be regarded as the standard.The SI unit is the pascal second

4.2 Viscosity is also valuable for rheological characteriza-

(Pa·s) and one millipascal second (mPa·s)=one centipoise

tion of binder pitches. Binder pitch imparts consistency to

(cps); centipoise is in cgs units.

carbonaceousmixesandaffectstheirresistancetodeformation.

1.5 This standard does not purport to address all of the

Binder pitch viscosity is important for assessing mix consis-

safety concerns, if any, associated with its use. It is the

tency and for evaluating the ease of mix extrusion or molding

responsibility of the user of this standard to establish appro-

into artifacts.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific hazard

5. Apparatus

statements are given in Section 7.

5.1 Viscometer—Arotationalviscometercapableofmeasur-

2. Referenced Documents ing viscosity in the range of about 5 to 15000 cps; the

2 viscometer should be equipped with the appropriate accesso-

2.1 ASTM Standards:

ries to allow measurements up to about 230°C. Two viscom-

D4296 Practice for Sampling Pitch

eters meeting these requirements are the LVT, LVF, or

E691 Practice for Conducting an Interlaboratory Study to

equivalent, and the RV100, RV20, or equivalent.

Determine the Precision of a Test Method

5.2 Sample Temperature Control System— Any device ca-

3. Summary of Test Method pable of maintaining the sample test temperature within limits

of 61.0°C while allowing viscosity measurements. Examples

3.1 The viscosity of a pitch, over the temperature range of

3 5

are the Thermosel System and the TP 24 with heater.

about 40 to 100°C above the SPof the material, is determined

5.3 Thermometer—ASTM precision thermometer 2C, hav-

using a rotational viscometer.

ing a range of−5 to 300°C.

3.2 The recommended specifications herein are for measur-

ing the apparent shear viscosity of binder pitches via a

concentric cylinder viscometer.Apparent shear viscosity is the

The sole source of supply of the apparatus known to the committee at this time

is available from Brookfield Engineering Laboratories, Inc., 240 Cushing St.,

Stoughton, MA02072. If you are aware of alternative suppliers, please provide this

This test method is under the jurisdiction of ASTM Committee D02 on information to ASTM International Headquarters. Your comments will receive

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee careful consideration at a meeting of the responsible technical committee , which

D02.05 on Properties of Fuels, Petroleum Coke and Carbon Material. you may attend.

Current edition approved Nov. 1, 2004. Published November 2004. Originally The sole source of supply of the apparatus known to the committee at this time

e1

approved in 1989. Last previous edition approved in 1999 as D5018–89(1999) . is available from Haake Buchler Instruments, Inc., 244 Saddle River Road, Saddle

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Brook,NJ07662-6001.Ifyouareawareofalternativesuppliers,pleaseprovidethis

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM information to ASTM International Headquarters. Your comments will receive

Standards volume information, refer to the standard’s Document Summary page on careful consideration at a meeting of the responsible technical committee , which

the ASTM website. you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5018 – 89 (2004)

5.4 Hot Plate —Any hot plate with adjustable temperature 11. Viscometer Calibration

control and surface temperature indication (to prevent sample

11.1 This step, required only occasionally, is designed to

overheating).

establish that the temperature and viscosity indicated by the

5.5 Calibration Fluids —A series of calibrated fluids that

appropriate measuring devices are in agreement with known

covertheviscosityrangeofapproximately100to15000cpsat

standards.

temperatures up to 150°C.

11.2 Equipment is to be properly leveled and installed in

accordance with manufacturer’s instructions.

6. Reagents and Materials

11.3 Use theASTM thermometer (applying the appropriate

6.1 Cleaning Solvent—Any solvent capable of dissolving

stem correction) to correlate pitch temperature (in cup) to

pitch, (suitable solvents are quinoline or creosote oils).

temperaturecontroller/indicator.Testtemperatureisconsidered

6.2 Rinsing Solvents—Toluene and acetone are used for

to be the actual pitch temperature and not the temperature

final rinsing after initial cleaning.

indicated on the controller.

11.4 Calibrate viscometer using calibration fluids.

7. Safety Hazards

11.4.1 Use high- and low-temperature fluids; see 5.5.

7.1 Fumes of hot pitch or solvents, or both, should be

11.4.2 Calibrate each rotor/cup combination and use them

removedfromallworkingareasbymeansofproperhoods.The

as a paired set.

working area should be kept free of sparks and flames.

Quinoline fumes should not be inhaled, and prolonged contact

12. Procedure for Viscosity Determination

with skin should be avoided. Toluene is toxic and flammable.

12.1 The following general principles apply to all viscosity

measurements determined by rotational methods:

8. Bulk Sampling

12.1.1 Maximize rotor diameter.

8.1 Take samples from shipments in accordance with Prac-

12.1.2 Minimize gap width between rotor and cup.

tice D4296. Samples shall be free of foreign substances.

12.1.3 Minimize end effects (use longest available rotor).

Thoroughly mix the sample immediately before removing a

12.1.4 Preventviscousheating(duetoprolongedrotationof

representativeportionforthedeterminationorfordehydration.

rotor at high rpm).

9. Sample Preparation

12.2 Selecttheproperrotor/cupcombinationthatcoversthe

anticipated viscosity range. A typical viscosity-temperature

9.1 Ensure sample is dry; if there is visible moisture,

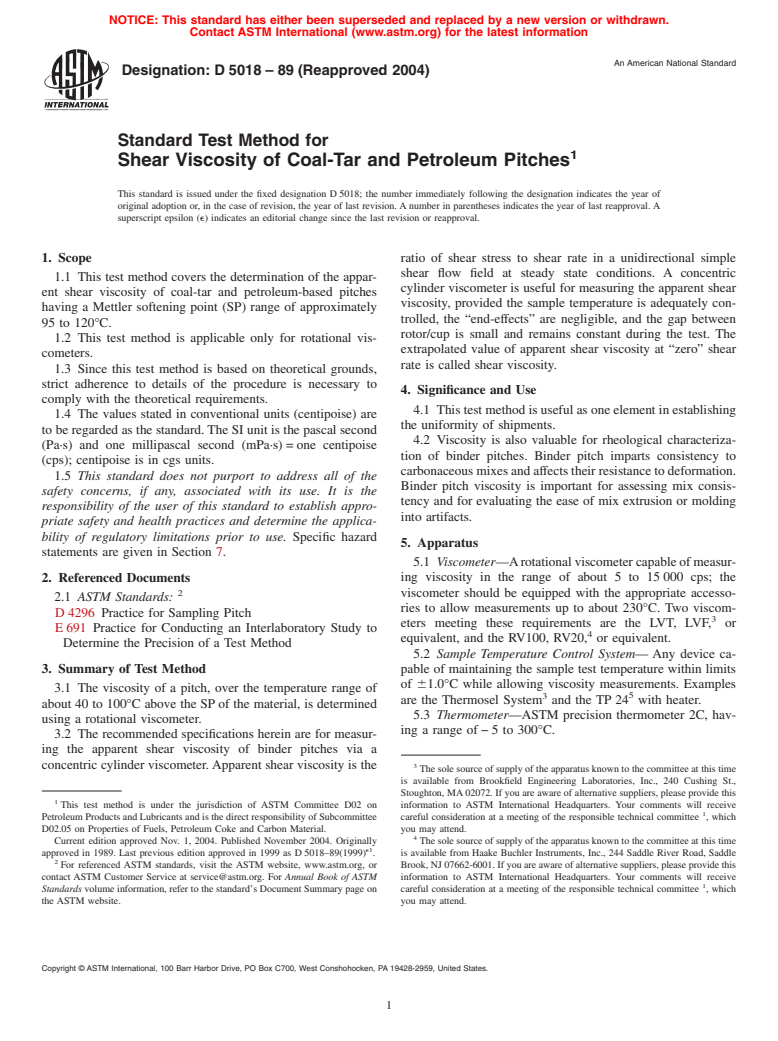

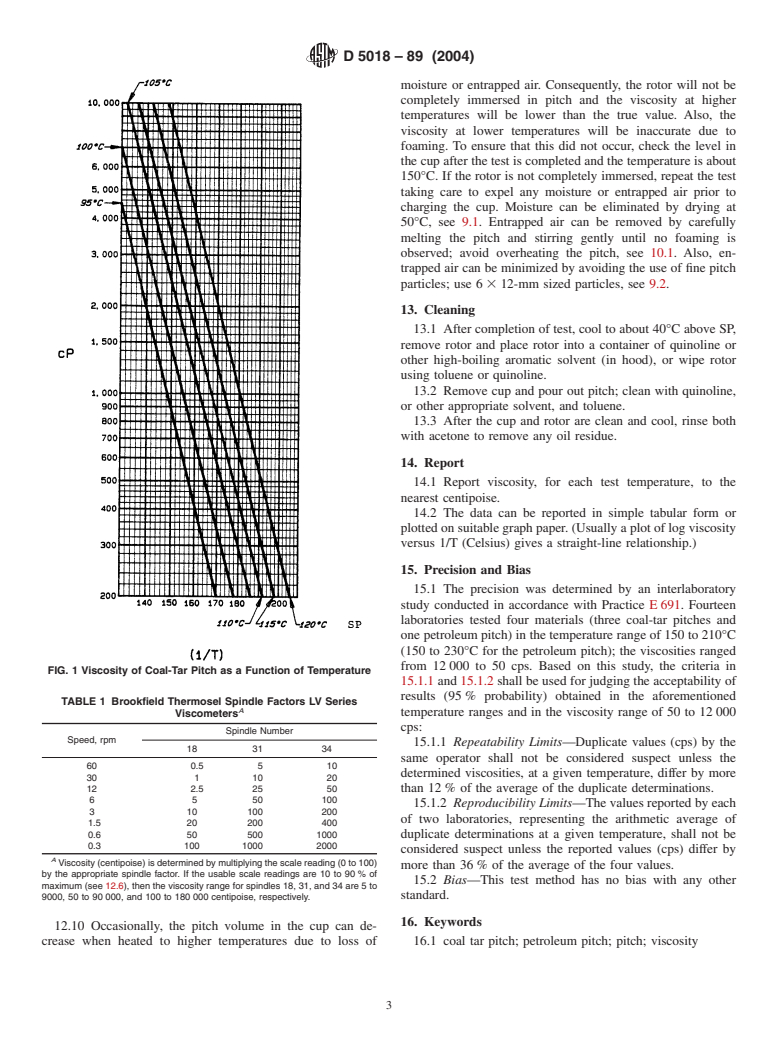

curve for various coal-tar pitches is given in Fig. 1, and a

dehydrateat50°Cinaforced-airorvacuumovenuntildry,but

typical spindle number and rpm relationship for a LV series

no longer than 2 h. (Experience has shown that drying at

Brookfield viscometer is given in Table 1. If t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.