ASTM D2852-95(2002)

(Specification)Standard Specification for Styrene-Rubber (SR) Plastic Drain Pipe and Fittings

Standard Specification for Styrene-Rubber (SR) Plastic Drain Pipe and Fittings

SCOPE

1.1 This specification covers requirements and test methods for materials, dimensions, workmanship, impact resistance, load-deflection properties, dimensional stability, and joint tightness of plain-end or bell-end styrene-rubber (SR) plastic drain pipe and fittings in sizes 2 through 6 in.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following safety hazards caveat pertains only to the test methods portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 2852 – 95 (Reapproved 2002)

Standard Specification for

Styrene-Rubber (SR) Plastic Drain Pipe and Fittings

This standard is issued under the fixed designation D 2852; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope tic Pipe and Fittings by Means of a Tup (Falling Weight)

D3122 Specification for Solvent Cements for Styrene-

1.1 This specification covers requirements and test methods

Rubber Plastic Pipe and Fittings

for materials, dimensions, workmanship, impact resistance,

F412 Terminology Relating to Plastic Piping Systems

load-deflection properties, dimensional stability, and joint

2.2 Federal Standard:

tightness of plain-end or bell-end styrene-rubber (SR) plastic

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

drain pipe and fittings in sizes 2 through 6 in.

2.3 Military Standard:

1.2 The values stated in inch-pound units are to be regarded

MIL-STD-129 Marking for Shipment and Storage

as the standard. The values given in parentheses are for

information only.

3. Terminology

1.3 The following safety hazards caveat pertains only to the

3.1 Definitions—Definitions are in accordance with Termi-

test methods portion, Section 8, of this specification: This

nology F412, and abbreviations are in accordance with Ter-

standard does not purport to address all of the safety concerns,

minologyD1600,unlessotherwisespecified.Theabbreviation

if any, associated with its use. It is the responsibility of the user

for styrene-rubber plastics is SR.

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

4. Significance and Use

tions prior to use.

4.1 The requirements for this specification are intended to

provide pipe and fittings suitable for nonpressure underground

2. Referenced Documents

drainage of sewage and certain other liquid wastes, in appli-

2.1 ASTM Standards:

cationsoutsidethebuildinglimits,wheredimensionalstability,

D256 Test Methods for Determining the Izod Pendulum

2 resistance to aging, and strong eight joints are required. The

Impact Resistance of Plastics

2 plasticdrainpipeandfittingsdescribedinthisspecificationare

D618 Practice for Conditioning Plastics for Testing

2 intended for use in the following applications:

D638 Test Method for Tensile Properties of Plastics

4.1.1 House connections to septic tanks.

D648 Test Method for Deflection Temperature of Plastics

2 4.1.2 Footing drains (foundation drains).

Under Flexural Load in the Edgewise Position

4.1.3 Storm drainage.

D1600 Terminology for Abbreviated Terms Relating to

2 4.2 ThepipeshouldbeinstalledinaccordancewithPractice

Plastics

D2321.

D2122 Test Method for Determining Dimensions of Ther-

moplastic Pipe and Fittings

5. Materials and Manufacture

D2321 Practice for Underground Installation of Thermo-

5.1 Materials—The pipe and fittings shall be made of

plastic Pipe for Sewers and Other Gravity-Flow Applica-

3 styrene-rubber (SR) plastics meeting the following require-

tions

ments:

D2412 TestMethodforDeterminationofExternalLoading

3 5.1.1 The SR plastics compound shall contain at least 50%

Characteristics of Plastic Pipe by Parallel-Plate Loading

styrene plastics, combined with rubbers to a minimum rubber

D2444 Test Method for Impact Resistance of Thermoplas-

content of 5%, and compounding materials such as antioxi-

dants and lubricants, and may contain up to 15% acrylonitrile

combined in the styrene plastics or rubbers, or both. The

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

rubbers shall be of the polybutadiene or butadiene-styrene

Piping Systems and is the direct responsibility of Subcommittee F17.65 on Land

Drainage.

Current edition approved Sept. 10, 1995. Published November 1995. Originally

published as D2852–69T. Last previous edition D2852–93.

2 4

Annual Book of ASTM Standards, Vol 08.01. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Annual Book of ASTM Standards, Vol 08.04. Robbins Ave., Philadelphia, PA 19111-5098, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 2852 – 95 (2002)

type, or both, with a maximum styrene content of 25% or satisfactory if the bell was formed from pipe meeting the

nitrile type. The combined styrene plastics and rubber content requirements of Table 1.

shall be not less than 90%. No fillers may be used. 6.3.2.2 For molded fittings, the wall thickness of the water-

5.1.2 The SR plastic compound shall meet the following way and socket or bell shall be no less than the respective

minimumrequirementswhentestedinaccordancewithSection minimum thickness listed for the equivalent pipe wall in Table

8: 2. For reducing fittings or those with smaller inlets, the

minimum wall thickness of each inlet shall be no less than the

Tensile strength at rupture, 3800 psi (26.2 MPa)

Elongation at rupture, %, 15

minimum wall thickness for that size pipe.

Modulus of elasticity in tension, 300 000 psi (2068 MPa)

6.3.3 Socket Depth—Thesocketdepthshallbenotlessthan

Izod impact strength, notched 0.8 ft·lbf/in. (42.5 J/m)

Deflection temperature at 264 psi (1.82 149 (65) thatshowninTable2whenmeasuredinaccordancewith8.7.3.

MPa),° F (°C)

6.3.4 Laying Length—The laying length shall meet the

requirements shown in Table 3. All dimensions are minimum

5.1.3 Rework Material—Clean rework material, generated

with a negative tolerance of zero.

from the manufacturer’s own pipe or fittings production, may

6.4 Impact Strength—The impact strength of the pipe and

be used by the same manufacturer, provided that the pipe and

fittings shall not be less than the values given in Table 4 when

fittings produced meet all of the requirements of this specifi-

tested in accordance with 8.9.

cation.

NOTE 1—This test is intended only as a quality control test, not as a

6. Workmanship, Finish, and Appearance

simulated service test.

6.1 Workmanship—The pipe shall be homogeneous

6.5 Pipe Stiffness—Thepipestiffnessat5%deflectionshall

throughout and essentially uniform in color, opacity, density,

be not less than the values given in Table 5 when tested in

and other properties. The inside and outside surfaces shall be

accordance with 8.10. This requirement does not apply to

semimatte or glossy in appearance and free of chalking, sticky,

fittings.

or tacky material.The pipe walls shall be free of cracks, holes,

NOTE 2—The 5% deflection criterion, which was arbitrarily selected

blisters, voids, foreign inclusion, or other defects that are

for testing convenience, should not be considered as a limitation with

visible to the naked eye and that may affect the wall integrity.

respect to in-use deflection. The engineer is responsible for establishing

Holes deliberately placed in perforated pipe are acceptable.

the acceptable deflection limit.

The surfaces shall be free of excessive bloom. Bloom or

NOTE 3—The strength and load-carrying capabilities of plastic drain

chalking may develop in pipe exposed to direct rays of the sun

and sewer pipe are measured and reported as Pipe Stiffness, which is

(ultraviolet radiant energy) for extended periods and conse-

determined in accordance with Test Method D2412. The term “crush

strength”isnotapplicabletoplasticpipingbecause(a)thevaluesobtained

quently these requirements do not apply to pipe after extended

can be significantly different, depending on the bedding, loading, or

exposure to direct rays of the sun.

testing technique used; and (b) the term derives from rigid pipe and refers

6.2 Pipe Dimensions:

to its ultimate strength at rupture.

6.2.1 Pipe Diameters—The outside and inside diameters of

6.6 Flattening—The pipe shall show no evidence of split-

the pipe shall be within the tolerances given in Table 1 when

ting, cracking, or breaking at 20% deflection when tested in

tested in accordance with 8.6.1.

accordance with 8.8.

6.2.2 Wall Thickness—Pipe wall thickness shall meet the

6.7 Dimensional Stability—The average decrease in inside

requirements of Table 1 when measured in accordance with

diameterofpipeandfittingsshallnotexceed10%whentested

8.6.2.

in accordance with 8.11.

6.2.3 Laying Length—The laying length shall be 10 ft with

1 6.8 Solvent Cement—Solvent cements shall meet the re-

atoleranceof−0+ ⁄2in.,unlessotherwisespecified.Thelaying

quirements of Specification D3122.

length shall be determined in accordance with 8.6.3.

6.9 Joint Tightness—Jointsmadewithpipeandfittingsshall

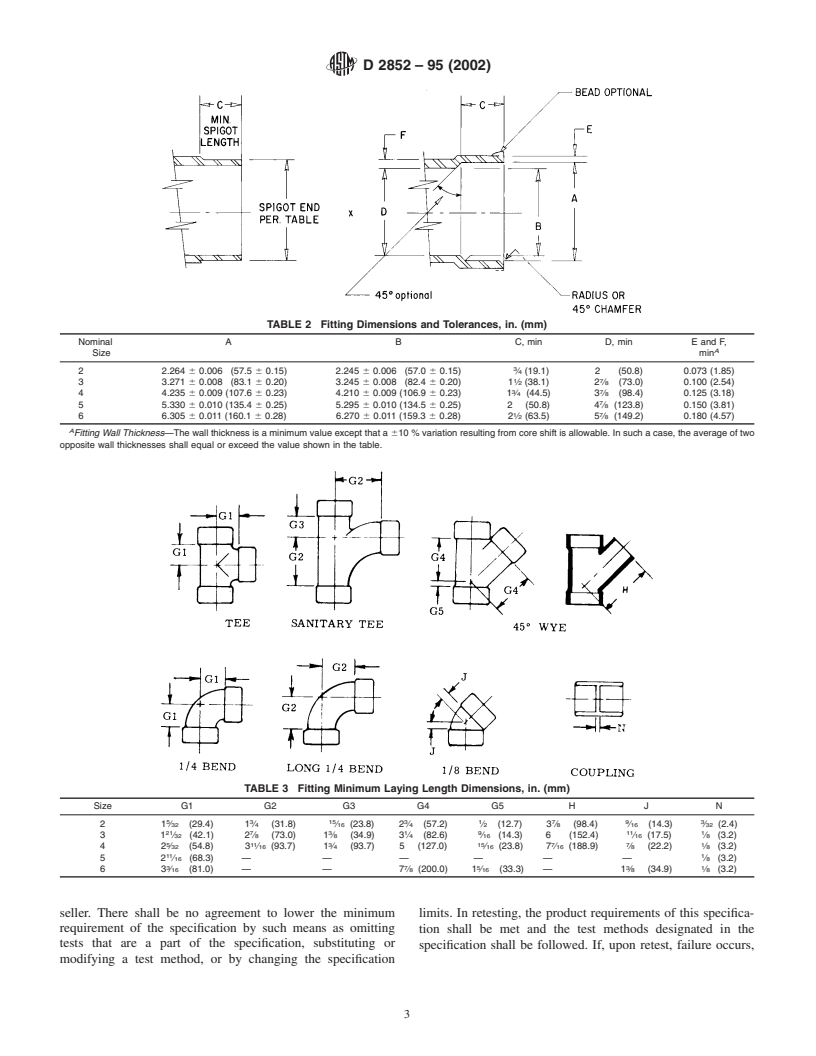

6.3 Fitting and Bell-End Dimensions:

not leak when tested in accordance with 8.12.

6.3.1 Socket Diameters—The inside diameters of the sock-

ets shall comply with the dimensions in Table 2 when deter-

7. Retest and Rejection

mined in accordance with 8.7.1.

7.1 If the results of any test(s) do not meet the requirements

6.3.2 Wall Thickness:

6.3.2.1 For belled pipe and fittings fabricated from pipe of this specification, the test(s) may be conducted again in

accordance with an agreement between the purchaser and the

sections,thethicknessofthebelledsectionshallbeconsidered

TABLE 1 Dimensions and Tolerances for SR Plastic Drain Pipe, in. (mm)

Permissible Deviations of

the Diameter from Mea- Minimum Average Minimum Wall

Nominal Size Average Outside Diameter

sured Average (Out-of- Inside Diameter Thickness

roundness)

2 2.250 6 0.006 (57.2 6 0.15) 60.030 (60.76) 2.000 (50.8) 0.073 (1.85)

3 3.250 6 0.008 (82.6 6 0.20) 60.040 (61.02) 2.875 (73.0) 0.100 (2.54)

4 4.215 6 0.009 (104.8 6 0.23) 60.050 (61.27) 3.875 (98.4) 0.125 (3.18)

5 5.300 6 0.010 (134.6 6 0.25) 60.060 (61.52) 4.875 (123.8) 0.150 (3.81)

6 6.275 6 0.011 (159.4 6 0.28) 60.070 (61.78) 5.875 (149.2) 0.180 (4.57)

D 2852 – 95 (2002)

TABLE 2 Fitting Dimensions and Tolerances, in. (mm)

Nominal A B C, min D, min E and F,

A

Size min

2 2.264 6 0.006 (57.5 6 0.15) 2.245 6 0.006 (57.0 6 0.15) ⁄4 (19.1) 2 (50.8) 0.073 (1.85)

1 7

3 3.271 6 0.008 (83.1 6 0.20) 3.245 6 0.008 (82.4 6 0.20) 1 ⁄2 (38.1) 2 ⁄8 (73.0) 0.100 (2.54)

3 7

4 4.235 6 0.009 (107.6 6 0.23) 4.210 6 0.009 (106.9 6 0.23) 1 ⁄4 (44.5) 3 ⁄8 (98.4) 0.125 (3.18)

5 5.330 6 0.010 (135.4 6 0.25) 5.295 6 0.010 (134.5 6 0.25) 2 (50.8) 4 ⁄8 (123.8) 0.150 (3.81)

1 7

6 6.305 6 0.011 (160.1 6 0.28) 6.270 6 0.011 (159.3 6 0.28) 2 ⁄2 (63.5) 5 ⁄8 (149.2) 0.180 (4.57)

A

Fitting Wall Thickness—The wall thickness is a minimum value except that a 610 % variation resulting from core shift is allowable. In such a case, the average of two

opposite wall thicknesses shall equal or exceed the value shown in the table.

TABLE 3 Fitting Minimum Laying Length Dimensions, in. (mm)

Size G1 G2 G3 G4 G5 H J N

5 3 15 3 1 7 9 3

21 ⁄32 (29.4) 1 ⁄4 (31.8) ⁄16 (23.8) 2 ⁄4 (57.2) ⁄2 (12.7) 3 ⁄8 (98.4) ⁄16 (14.3) ⁄32 (2.4)

21 7 3 1 9 11 1

31 ⁄32 (42.1) 2 ⁄8 (73.0) 1 ⁄8 (34.9) 3 ⁄4 (82.6) ⁄16 (14.3) 6 (152.4) ⁄16 (17.5) ⁄8 (3.2)

5 11 3 15 7 7 1

42 ⁄32 (54.8) 3 ⁄16 (93.7) 1 ⁄4 (93.7) 5 (127.0) ⁄16 (23.8) 7 ⁄16 (188.9) ⁄8 (22.2) ⁄8 (3.2)

11 1

52 ⁄16 (68.3) — — — — — — ⁄8 (3.2)

3 7 5 3 1

63 ⁄16 (81.0) — — 7 ⁄8 (200.0) 1 ⁄16 (33.3) — 1 ⁄8 (34.9) ⁄8 (3.2)

seller. There shall be no agreement to lower the minimum limits. In retesting, the product requirements of this specifica-

requirement of the specification by such means as omitting tion shall be met and the test methods designated in the

tests that are a part of the specification, substituting or

specification shall be followed. If, upon retest, failure occurs,

modifying a test method, or by changing the specification

D 2852 – 95 (2002)

TABLE 4 Minimum Impact Strength Requirements of Pipe and

8.6.1.2 Measure the average inside diameter of the pipe in

Fittings at 73°F (23°C)

accordance with Test Method D2122.

Minimum Impact

8.6.2 Wall Thickness—Measure the wall thickness in accor-

Nominal Size, in.

ft·lbf m·kg

dance with Test Method D2122. Make sufficient readings, a

minimum of six, to ensure that the minimum thickness has

210 1.4

310 1.4

been determined. Use a cylindrical anvil tubing micrometer

415 2.1

accurate to 60.001 in. (60.02 mm).

515 2.1

8.6.3 Length—Determine the over-all length of the pipe in

615 2.1

accordance withTest Method D2122 using a steel tape with at

least ⁄16-in. (1-mm) graduations. For belled or coupled pipe,

TABLE 5 Minimum Pipe Stiffness for Pipe

determine the laying length by measuring the bell or coupling

Minimum Pipe Stiffness at 5 % socket depth with a steel rule with at least ⁄16-in. graduations

Deflection

and subtracting this dimension from the overall length.

Nominal Size, in. Original and Water Immersion

8.7 Fitting and Bell-End Socket Dimensions:

Specimens

8.7.1 Socket Diameters—Measure the inside diameters of

psi MPa

the sockets at the socket entrance and bottom, using an inside

2 50 0.35

micrometer accurate to 60.001 in. (60.02 mm) or a telescop-

3 42 0.29

ing pin gage in conjunction with an outside micrometer

4 38 0.26

accurate to 60.001 in. Determine the average inside diameters

5 37 0.26

6 34 0.23

attheentranceandthebottomofthesocketbytakingsufficient

readingsateachposition.Calculatetheaverageinsidediameter

at each position by taking the mean of the minimum and

thequantityofproductrepresentedbythetest(s)doesnotmeet

maximum values.

the requirements of this specification.

8.7.2 Wall Thickness—Measure the wall thickness in accor-

dance with Test Method D2122. Make sufficent readings, a

8. Test Methods

minimum of six, to ensure that the minimum thickness has

8.1 Conditioning—Condition the specimens prior to test at

been determined. Use a cylindrical anvil tubing micrometer

73.4 6 3.6°F (23 6 2°C) and 50 6 5% relative humidity for

accurate to 60.001 in. (60.02 mm).

not less than 40 h in accordance with Procedure A of Practice

8.7.3 Socket Depth—Measure the socket depth using a steel

D618, for those tests where conditioning is required and in all

rule with at least ⁄16-in. (1-mm) graduations. Make sufficient

cases of disagreement.

readings to ensure that the minimum depth has been deter-

8.2 Test Conditions—Conduct tests in the standard labora-

mined.

tory atmosphere of 73.4 6 3.6°F (23 6 2°C) and 50 65%

8.8 Flattening—Flatten three specimens of pipe, 6 in. long,

relative humidity, unless otherwise specified.

between parallel plates in a suitable press, until the distance

8.3 Deflection Temperature—Determine the deflection tem-

between the plates is 80% of the original outside diameter of

peratureinaccordancewithTestMethodD648.Inj

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.