ASTM D5227-21

(Test Method)Standard Test Method for Measurement of Hexane Extractable Content of Polyolefins

Standard Test Method for Measurement of Hexane Extractable Content of Polyolefins

SIGNIFICANCE AND USE

5.1 FDA requirements for maximum extractables are specified for resin and uses. This test method provides a means to determine the amount of hexane-soluble low molecular weight material present in polyolefins. It is applicable to resins containing greater than 0.20 % extractables.

SCOPE

1.1 This test method describes an extraction/gravimetric procedure for determination of the amount of hexane soluble low molecular weight material present in polyethylene, polypropylene, ethylene-propylene copolymers, and ethylene-vinyl acetate copolymers. This test method is a modification of the Food and Drug Administration (FDA) procedure for determining hexane extractables of polyolefins. This test method is based upon the presumption that the weight of the residue extract present in the solvent is equal to the amount extracted from the film sample and could therefore be quantified by measuring the weight loss of the extracted film, eliminating the complex and time-consuming evaporation process described in 21 CFR 177.1520.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 The values stated in SI units are to be regarded as the standard. Units used in 21 CFR 177.1520 are also used in this test method. Units are in conformance with Federal Code 21 CFR 177.1520, from which this test method is derived.

Note 1: There is no known ISO equivalent to this standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D5227 −21

Standard Test Method for

1

Measurement of Hexane Extractable Content of Polyolefins

This standard is issued under the fixed designation D5227; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D1239 Test Method for Resistance of Plastic Films to

Extraction by Chemicals

1.1 This test method describes an extraction/gravimetric

D1600 Terminology forAbbreviatedTerms Relating to Plas-

procedure for determination of the amount of hexane soluble

tics

low molecular weight material present in polyethylene,

E131 Terminology Relating to Molecular Spectroscopy

polypropylene, ethylene-propylene copolymers, and ethylene-

E456 Terminology Relating to Quality and Statistics

vinyl acetate copolymers. This test method is a modification of

E691 Practice for Conducting an Interlaboratory Study to

the Food and Drug Administration (FDA) procedure for

Determine the Precision of a Test Method

determining hexane extractables of polyolefins. This test

E2935 Practice for Evaluating Equivalence of Two Testing

method is based upon the presumption that the weight of the

Processes

residue extract present in the solvent is equal to the amount

3

2.2 Federal Document:

extracted from the film sample and could therefore be quanti-

21 CFR 177.1520 Olefin Polymers

fied by measuring the weight loss of the extracted film,

eliminating the complex and time-consuming evaporation

3. Terminology

process described in 21 CFR 177.1520.

3.1 The definitions given in Terminology D883, D1600,

1.2 This standard does not purport to address all of the

E131, and E456 are applicable to this test method.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.2 Abbreviations:

priate safety, health, and environmental practices and deter-

3.2.1 EVA—ethylene-vinyl acetate copolymer.

mine the applicability of regulatory limitations prior to use.

3.2.2 LDPE—low-density polyethylene.

1.3 The values stated in SI units are to be regarded as the

3.2.3 HDPE—high-density polyethylene.

standard. Units used in 21 CFR 177.1520 are also used in this

3.2.4 LLDPE—linear low-density polyethylene.

test method. Units are in conformance with Federal Code 21

CFR 177.1520, from which this test method is derived.

3.2.5 FDA—Food and Drug Administration.

NOTE 1—There is no known ISO equivalent to this standard. 3.2.6 PP—polypropylene.

1.4 This international standard was developed in accor-

4. Summary of Test Method

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

4.1 Film samples are extracted with hexane for 2 h at 49.5

Development of International Standards, Guides and Recom-

6 0.5°C, dried, and weighed.

mendations issued by the World Trade Organization Technical

4.2 The loss in weight of the film is presumed to be equal to

Barriers to Trade (TBT) Committee.

the extractable content determined by solvent evaporation in

the FDA protocol.

2. Referenced Documents

2

2.1 ASTM Standards:

5. Significance and Use

D883 Terminology Relating to Plastics

5.1 FDArequirements for maximum extractables are speci-

fied for resin and uses. This test method provides a means to

1 determine the amount of hexane-soluble low molecular weight

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.70 on Analytical Methods. material present in polyolefins. It is applicable to resins

Current edition approved July 1, 2021. Published July 2021. Originally approved

containing greater than 0.20 % extractables.

in 1992. Last previous edition approved in 2013 as D5227 - 13. DOI: 10.1520/

D5227-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Standards volume information, refer to the standard’s Document Summary page on Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the ASTM website. www.dodssp.daps.mil.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

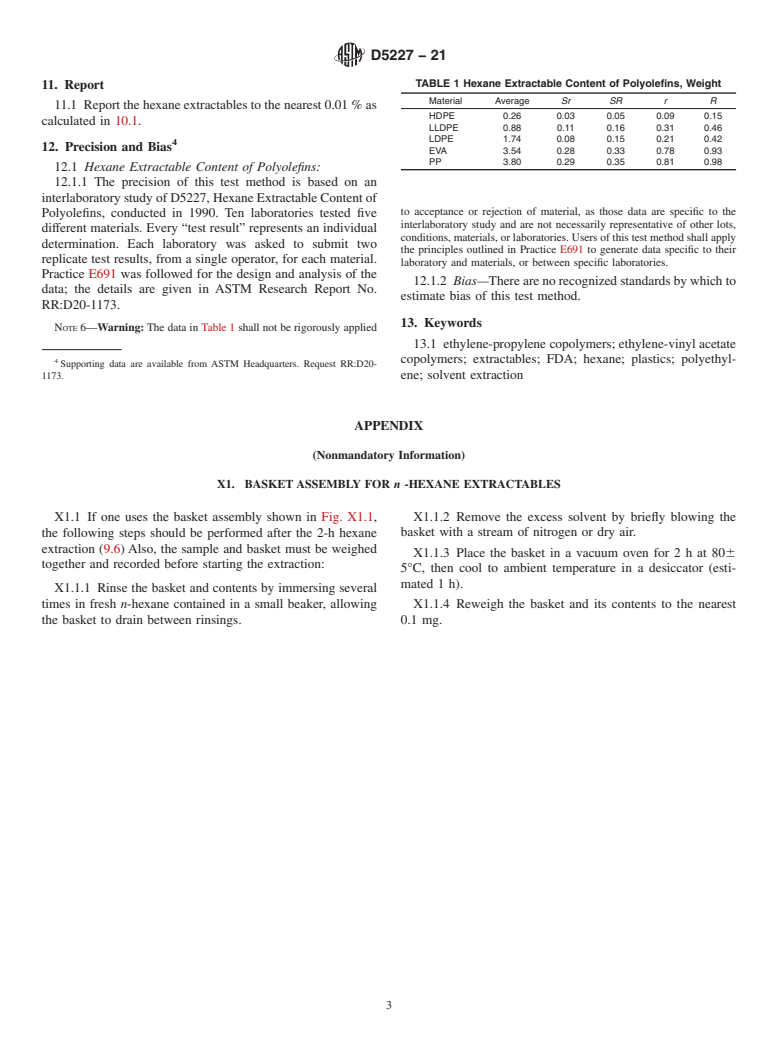

---------------------- Page: 1 ----------------------

D5227−21

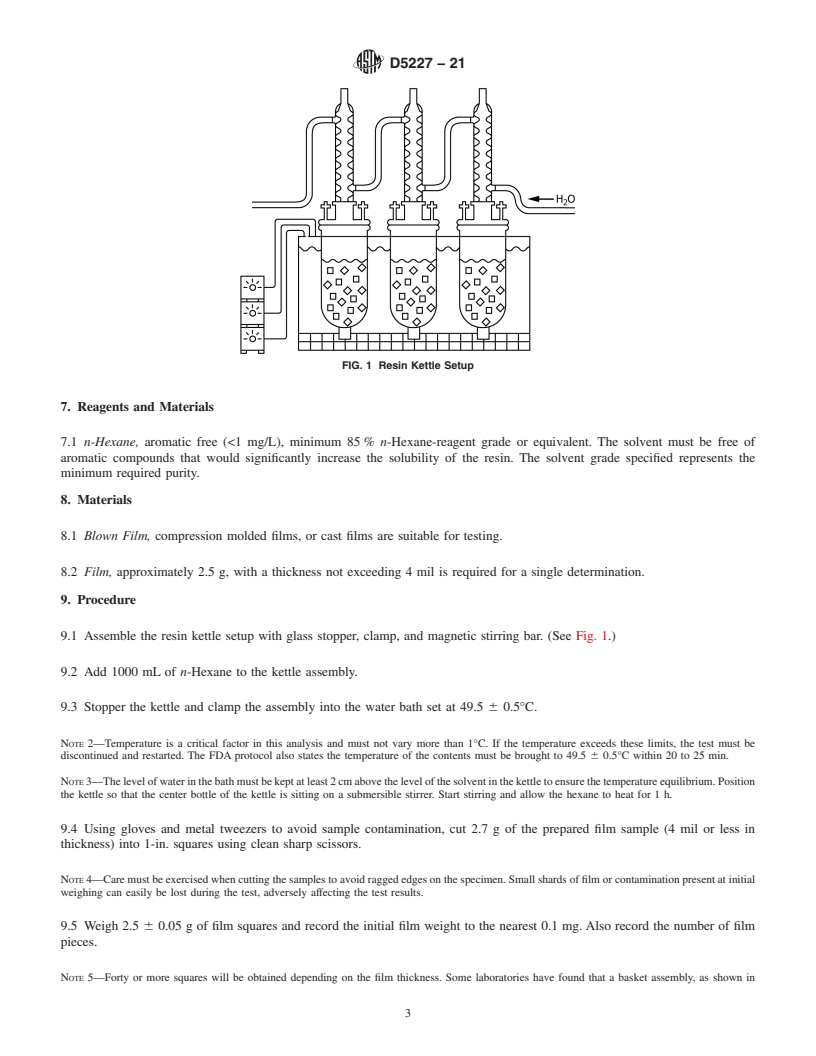

9.3 Stopperthekettleandclamptheassemblyintothewater

bath set at 49.5 6 0.5°C.

NOTE 2—Tempe

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5227 − 13 D5227 − 21

Standard Test Method for

1

Measurement of Hexane Extractable Content of Polyolefins

This standard is issued under the fixed designation D5227; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method describes an extraction/gravimetric procedure for determination of the amount of hexane soluble low

molecular weight material present in polyethylene, polypropylene, ethylene-propylene copolymers, and ethylene-vinyl acetate

copolymers. This test method is a modification of the Food and Drug Administration (FDA) procedure for determining hexane

extractables of polyolefins. This test method is based upon the presumption that the weight of the residue extract present in the

solvent is equal to the amount extracted from the film sample and could therefore be quantified by measuring the weight loss of

the extracted film, eliminating the complex and time-consuming evaporation process described in 21 CFR 177.1520.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.3 The values stated in SI units are to be regarded as the standard. Units used in 21 CFR 177.1520 are also used in this test

method. Units are in conformance with Federal Code 21 CFR 177.1520, from which this test method is derived.

NOTE 1—There is no known ISO equivalent to this standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

D1239 Test Method for Resistance of Plastic Films to Extraction by Chemicals

D1600 Terminology for Abbreviated Terms Relating to Plastics

E131 Terminology Relating to Molecular Spectroscopy

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E2935 Practice for Evaluating Equivalence of Two Testing Processes

3

2.2 Federal Document:

21 CFR 177.1520 CFR 177.1520Olefin Polymers

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.70 on Analytical Methods.

Current edition approved June 1, 2013July 1, 2021. Published July 2013July 2021. Originally approved in 1992. Last previous edition approved in 20082013 as

ε1

D5227 - 01D5227 - 13.(2008) . DOI: 10.1520/D5227-13.10.1520/D5227-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://www.dodssp.daps.mil.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5227 − 21

3. Terminology

3.1 The definitions given in Terminology D883, D1600, E131and, E131and E456 are applicable to this test method.

3.2 Abbreviations:

3.2.1 EVA—ethylene-vinyl acetate copolymer.

3.2.2 LDPE—low-density polyethylene.

3.2.3 HDPE—high-density polyethylene.

3.2.4 LLDPE—linear low-density polyethylene.

3.2.5 FDA—Food and Drug Administration.

3.2.6 PP—polypropylene.

4. Summary of Test Method

4.1 Film samples are extracted with hexane for 2 h at 49.5 6 0.5°C, dried, and weighed.

4.2 The loss in weight of the film is presumed to be equal to the extractable content determined by solvent evaporation in the FDA

protocol.

5. Significance and Use

5.1 FDA requirements for maximum extractables are specified for resin and uses. This test method provides a means to determine

the amount of hexane-solubl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.