ASTM G100-89(1999)

(Test Method)Standard Test Method for Conducting Cyclic Galvanostaircase Polarization

Standard Test Method for Conducting Cyclic Galvanostaircase Polarization

SCOPE

1.1 This test method gives a procedure for conducting cyclic galvanostaircase polarization (GSCP) to determine relative susceptibility to localized corrosion (pitting and crevice corrosion) for aluminum alloy 3003-H14 (UNS A93003) (1). It may serve as guide for examination of other alloys (2-5). This test method also describes a procedure that can be used as a check for one's experimental technique and instrumentation.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G 100 – 89 (Reapproved 1999)

Standard Test Method for

Conducting Cyclic Galvanostaircase Polarization

This standard is issued under the fixed designation G 100; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope are not intended to correlate in a quantitative manner with the

rate of propagation of localized corrosion that one might

1.1 This test method gives a procedure for conducting cyclic

observe in service.

galvanostaircase polarization (GSCP) to determine relative

3.2 The breakdown (E ), and protection potentials (E )

susceptibility to localized corrosion (pitting and crevice corro- b prot

determined by the cyclic GSCP method correlate with the

sion) for aluminum alloy 3003-H14 (UNS A93003) (1). It

constant potential corrosion test (immersion-glassware) result

may serve as guide for examination of other alloys (2–5). This

for aluminum (1, 6, 8). When the applied potential was more

test method also describes a procedure that can be used as a

negative than the GSCP E , no pit initiation was observed.

check for one’s experimental technique and instrumentation. prot

When the applied potential was more positive than the GSCP

1.2 This standard does not purport to address all of the

E , pitting occurred even when the applied potential was less

safety concerns, if any, associated with its use. It is the prot

negative than E .

b

responsibility of the user of this standard to establish appro-

3.2.1 Severe crevice corrosion occurred when the separation

priate safety and health practices and determine the applica-

of E and E was 500 mV or greater and E was less

b prot prot

bility of regulatory limitations prior to use.

than −400 mV Vs. SCE (in 100 ppm NaCl) (1, 6, 7). For

2. Referenced Documents

aluminum, E determined by cyclic GSCP agrees with the

prot

repassivation potential determined by the scratch potentiostatic

2.1 ASTM Standards:

method (1, 10). Both the scratch potentiostatic method and the

D 1193 Specification for Reagent Water

constant potential technique for determination of E require

prot

G 1 Practice for Preparing, Cleaning, and Evaluating Cor-

much longer test times and are more involved techniques than

rosion Test Specimens

the GSCP method.

G 5 Reference Test Method for Making Potentiostatic and

3.3 DeBerry and Viebeck (3–5) found that the breakdown

Potentiodynamic Anodic Polarization Measurements

potentials (E ) (galvanodynamic polarization, similar to GSCP

G 59 Practice for Conducting Potentiodynamic Polarization b

but no kinetic information) had a good correlation with the

Resistance Measurements

inhibition of localized corrosion of 304L stainless steel by

G 69 Practice for Measurement of Corrosion Potentials of

surface active compounds. They attained accuracy and preci-

Aluminum Alloys

sion by avoiding the strong induction effect which they

3. Significance and Use

observed by the potentiodynamic technique.

3.4 If this test method is followed using the specific alloy

3.1 In this test method, susceptibility to localized corrosion

discussed it will provide (GSCP) measurements that will

of aluminum is indicated by a protection potential (E )

prot

reproduce data developed at other times in other laboratories.

determined by cyclic galvanostaircase polarization (1). The

3.5 E and E obtained are based on the results from eight

more noble this potential, the less susceptible is the alloy to

b prot

different laboratories that followed the standard procedure

initiation of localized corrosion. The results of this test method

using aluminum alloy 3003-H14 (UNS A93003). E and E

b prot

are included with statistical analysis to indicate the acceptable

range.

This test method is under the jurisdiction of ASTM Committee G-1 on

Corrosion of Metals and is the direct responsibility of Subcommittee G1.11 on

4. Apparatus

Electrochemical Measurements in Corrosion Testing.

Current edition approved Feb. 24, 1989. Published April 1989.

4.1 Cell—The cell should be constructed of inert materials

The boldface numbers in parentheses refer to the list of references at the end of

such as borosilicate glass and PTFE fluorocarbon. It should

this test method.

3 have ports for the insertion of a working electrode (1 cm flat

Annual Book of ASTM Standards, Vol 11.01.

Annual Book of ASTM Standards, Vol 03.02. specimen holder (Note 1) is very convenient), two auxiliary

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G 100

electrodes, salt bridge for reference electrode, and a thermom- 4.3.2 Auxiliary Electrodes—Graphite, (ultrafine grade)

eter or a thermostat probe for temperature control. The figure in (Note 3).

Test Method G 5 would be satisfactory, but a flat bottom cell is

NOTE 3—Coarse grades of graphite should be avoided because they

also satisfactory provided that all of the essential ports are

absorb solute impurities. Ultrafine grades are available from spectro-

provided. (See Ref (9) for details.)

graphic supply companies.

NOTE 1—These specific recommendations and conditions were fol- 4.3.3 Reference Electrode—Saturated calomel (Note 1). It

lowed to improve the inter-laboratory precision during the round robin for

should be checked against another reference which has not

galvanostaircase polarization.

been exposed to test solutions and they should be within 3 mV

4.2 Current Staircase Generator and Recorder—The sche- of each other. Practice G 69 round robin test conducted by

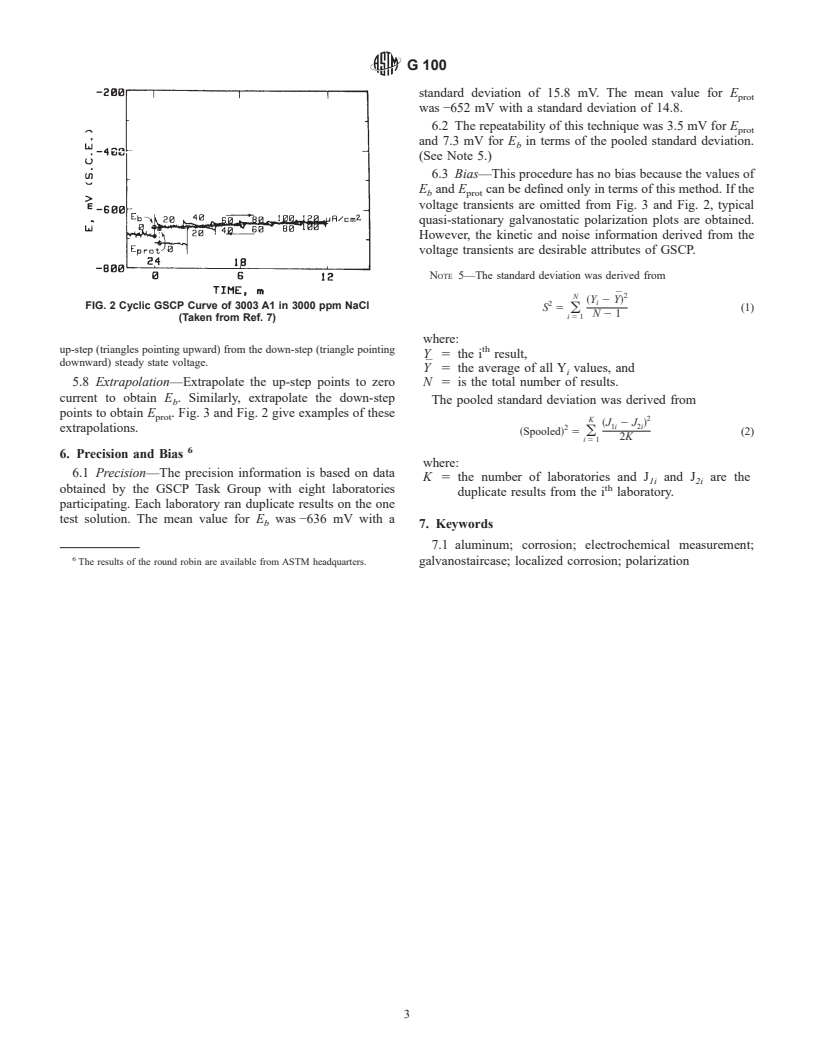

matic diagram of the apparatus is given in Fig. 1. The recorder G01.11 (unpublished results) indicate that potential difference

may be replaced by a plotter if the current staircase signal is should not exceed 2 or 3 mV. The reference electrode is

generated with the aid of a computer. The current staircase may connected to the test bridge solution which consists of 75 %

be generated manually (Note 2) but this is not recommended. saturated KCl, prepared by adding 1 part (by volume) of

The most convenient current staircase generators are found in distilled water to 3 parts saturated KCl. When the bridge is in

recent commercial potentiostats where the software is avail- active use, the bridge solution should be replaced once each

able. The electrical equipment may be checked in accordance day and the bridge tip immersed in this solution when not in

with the procedure in Practice G 59. use. Any test solution that does not deposit films may also be

used in the bridge. (The VYCOR tip should not be allowed to

NOTE 2—The current staircase signal was generated manually in the

go to dryness.)

round robin because automated system or software was not available when

4.4 Magnetic Stirrer.

this project was started.

4.3 Electrodes:

5. Procedure

4.3.1 Working Electrode—For generating data to be com-

5.1 Test solution, 3000 6 30 ppm (0.0513 M) NaCl. For

pared to the reference data included herein, use type 3003-H14

example, transfer 6.000 g reagent grade

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.