ASTM D1238-10

(Test Method)Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer

Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer

SIGNIFICANCE AND USE

This test method is particularly useful for quality control tests on thermoplastics.

The data produced by this test method serves to indicate the uniformity of the flow rate of the polymer as made by an individual process. It is not to be used as an indication of uniformity of other properties without valid correlation with data from other tests.

The flow rate obtained with the extrusion plastometer is not a fundamental polymer property. It is an empirically defined parameter critically influenced by the physical properties and molecular structure of the polymer and the conditions of measurement. The rheological characteristics of polymer melts depend on a number of variables. It is possible that the values of these variables occurring in this test will differ substantially from those in large-scale processes, which would result in data that does not correlate directly with processing behavior.

Measure the flow rate of a material using any of the conditions listed for the material in 8.2. For many materials, there are specifications that require the use of this test method, but with some procedural modifications that take precedence when adhering to the specification. Therefore, it is advisable to refer to that material specification before using this test method. Table 1 in Classification D4000 lists the ASTM materials standards that currently exist. An alternative test method for poly (vinyl chloride) (PVC) compounds is found in D3364.

Additional characterization of a material can be obtained if more than one condition is used. In the case that two or more conditions are employed, a Flow Rate Ratio (FRR) is obtained by dividing the flow rate at one condition by the flow rate at another condition. Procedure D provides one method to measure more than one condition in a single charge.

Frequently, variations in test technique, apparatus geometry, or test conditions, which defy all but the most careful scrutiny, exist, causing discrepancies in flow rate det...

SCOPE

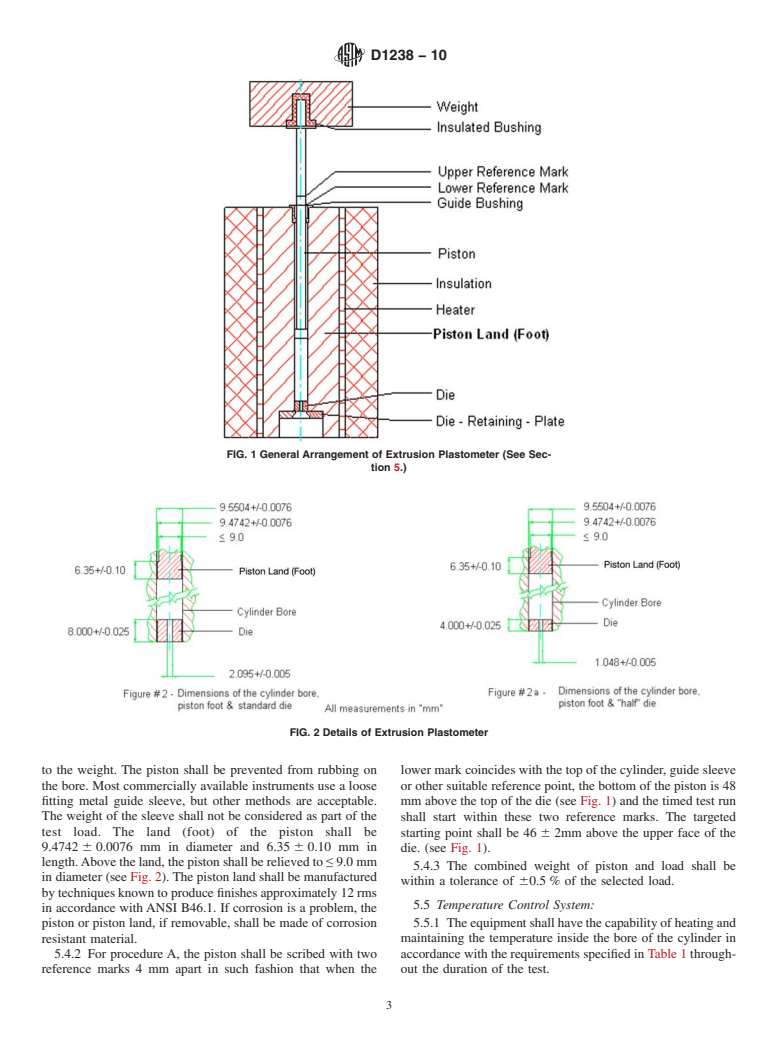

1.1 This test method covers the determination of the rate of extrusion of molten thermoplastic resins using an extrusion plastometer. After a specified preheating time, resin is extruded through a die with a specified length and orifice diameter under prescribed conditions of temperature, load, and piston position in the barrel. Four procedures are described. Comparable results have been obtained by these procedures in interlaboratory round-robin measurements of several materials and are described in Section 15.

1.2 Procedure A is used to determine the melt flow rate (MFR) of a thermoplastic material. The units of measure are grams of material/10 minutes (g/10 min). It is based on the measurement of the mass of material that extrudes from the die over a given period of time. It is generally used for materials having melt flow rates that fall between 0.15 and 50 g/10 min (see Note 1).

1.3 Procedure B is an automatically timed measurement used to determine the melt flow rate (MFR) as well as the melt volume rate (MVR) of thermoplastic materials. MFR measurements made with Procedure B are reported in g/10 minutes. MVR measurements are reported in cubic centimetres/ten minutes (cm3/10 min). Procedure B measurements are based on the determination of the volume of material extruded from the die over a given period of time. The volume is converted to a mass measurement by multiplying the result by the melt density value for the material (see Note 2). Procedure B is generally used with materials having melt flow rates from 0.50 to 1500 g/10 min.

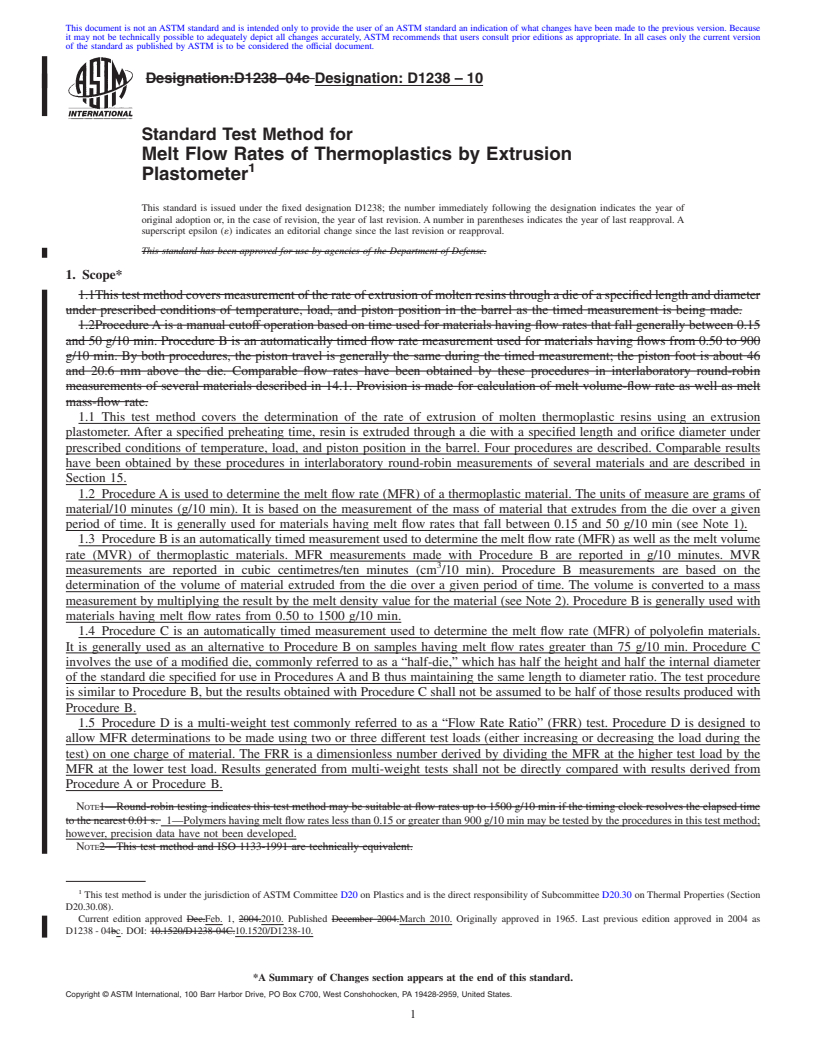

1.4 Procedure C is an automatically timed measurement used to determine the melt flow rate (MFR) of polyolefin materials. It is generally used as an alternative to Procedure B on samples having melt flow rates greater than 75 g/10 min. Procedure C involves the use of a modified die, commonly referred to as a “half-die,” which has half the height and half the internal diameter of th...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1238 − 10

StandardTest Method for

Melt Flow Rates of Thermoplastics by Extrusion

1

Plastometer

This standard is issued under the fixed designation D1238; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* the internal diameter of the standard die specified for use in

Procedures A and B thus maintaining the same length to

1.1 This test method covers the determination of the rate of

diameterratio.ThetestprocedureissimilartoProcedureB,but

extrusion of molten thermoplastic resins using an extrusion

the results obtained with Procedure C shall not be assumed to

plastometer.Afteraspecifiedpreheatingtime,resinisextruded

be half of those results produced with Procedure B.

throughadiewithaspecifiedlengthandorificediameterunder

prescribed conditions of temperature, load, and piston position 1.5 ProcedureDisamulti-weighttestcommonlyreferredto

in the barrel. Four procedures are described. Comparable as a “Flow Rate Ratio” (FRR) test. Procedure D is designed to

results have been obtained by these procedures in interlabora- allow MFR determinations to be made using two or three

tory round-robin measurements of several materials and are different test loads (either increasing or decreasing the load

described in Section 15. during the test) on one charge of material. The FRR is a

dimensionless number derived by dividing the MFR at the

1.2 Procedure A is used to determine the melt flow rate

higher test load by the MFR at the lower test load. Results

(MFR) of a thermoplastic material. The units of measure are

generated from multi-weight tests shall not be directly com-

grams of material/10 minutes (g/10 min). It is based on the

pared with results derived from Procedure A or Procedure B.

measurementofthemassofmaterialthatextrudesfromthedie

NOTE1—Polymershavingmeltflowrateslessthan0.15orgreaterthan

over a given period of time. It is generally used for materials

900 g/10 min may be tested by the procedures in this test method;

having melt flow rates that fall between 0.15 and 50 g/10 min

however, precision data have not been developed.

(see Note 1). NOTE 2—Melt density is the density of the material in it molten state.

Itisnottobeconfusedwiththestandarddensityvalueofthematerial.See

1.3 Procedure B is an automatically timed measurement

Table 3.

usedtodeterminethemeltflowrate(MFR)aswellasthemelt

NOTE 3—This test method and ISO1133 address the same subject

volumerate(MVR)ofthermoplasticmaterials.MFRmeasure- matter, but differ in technical content.

ments made with Procedure B are reported in g/10 minutes.

1.6 This standard does not purport to address the safety

MVR measurements are reported in cubic centimetres/ten

concerns, if any, associated with its use. It is the responsibility

3

minutes (cm /10 min). Procedure B measurements are based

of the user of this standard to establish appropriate safety and

on the determination of the volume of material extruded from

health practices and determine the applicability of regulatory

thedieoveragivenperiodoftime.Thevolumeisconvertedto

limitations prior to use.

a mass measurement by multiplying the result by the melt

2. Referenced Documents

density value for the material (see Note 2). Procedure B is

2

generallyusedwithmaterialshavingmeltflowratesfrom0.50

2.1 ASTM Standards:

to 1500 g/10 min.

D618Practice for Conditioning Plastics for Testing

D883Terminology Relating to Plastics

1.4 Procedure C is an automatically timed measurement

D3364TestMethodforFlowRatesforPoly(VinylChloride)

used to determine the melt flow rate (MFR) of polyolefin

with Molecular Structural Implications

materials. It is generally used as an alternative to Procedure B

D4000Classification System for Specifying Plastic Materi-

on samples having melt flow rates greater than 75 g/10 min.

als

Procedure C involves the use of a modified die, commonly

E691Practice for Conducting an Interlaboratory Study to

referred to as a “half-die,” which has half the height and half

Determine the Precision of a Test Method

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

and is the direct responsibility of Subcommittee D20.30 on Thermal Properties

2

(Section D20.30.08). For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 1, 2010. Published March 2010. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1965. Last previous edition approved in 2004 as D1238-04c. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D1238-10. the ASTM website.

*A Summary of Changes section appears at t

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D1238–04c Designation: D1238 – 10

Standard Test Method for

Melt Flow Rates of Thermoplastics by Extrusion

1

Plastometer

This standard is issued under the fixed designation D1238; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1Thistestmethodcoversmeasurementoftherateofextrusionofmoltenresinsthroughadieofaspecifiedlengthanddiameter

under prescribed conditions of temperature, load, and piston position in the barrel as the timed measurement is being made.

1.2ProcedureAis a manual cutoff operation based on time used for materials having flow rates that fall generally between 0.15

and 50 g/10 min. Procedure B is an automatically timed flow rate measurement used for materials having flows from 0.50 to 900

g/10 min. By both procedures, the piston travel is generally the same during the timed measurement; the piston foot is about 46

and 20.6 mm above the die. Comparable flow rates have been obtained by these procedures in interlaboratory round-robin

measurements of several materials described in 14.1. Provision is made for calculation of melt volume-flow rate as well as melt

mass-flow rate.

1.1 This test method covers the determination of the rate of extrusion of molten thermoplastic resins using an extrusion

plastometer. After a specified preheating time, resin is extruded through a die with a specified length and orifice diameter under

prescribed conditions of temperature, load, and piston position in the barrel. Four procedures are described. Comparable results

have been obtained by these procedures in interlaboratory round-robin measurements of several materials and are described in

Section 15.

1.2 ProcedureAis used to determine the melt flow rate (MFR) of a thermoplastic material. The units of measure are grams of

material/10 minutes (g/10 min). It is based on the measurement of the mass of material that extrudes from the die over a given

period of time. It is generally used for materials having melt flow rates that fall between 0.15 and 50 g/10 min (see Note 1).

1.3 ProcedureBisanautomaticallytimedmeasurementusedtodeterminethemeltflowrate(MFR)aswellasthemeltvolume

rate (MVR) of thermoplastic materials. MFR measurements made with Procedure B are reported in g/10 minutes. MVR

3

measurements are reported in cubic centimetres/ten minutes (cm /10 min). Procedure B measurements are based on the

determination of the volume of material extruded from the die over a given period of time. The volume is converted to a mass

measurement by multiplying the result by the melt density value for the material (see Note 2). Procedure B is generally used with

materials having melt flow rates from 0.50 to 1500 g/10 min.

1.4 Procedure C is an automatically timed measurement used to determine the melt flow rate (MFR) of polyolefin materials.

It is generally used as an alternative to Procedure B on samples having melt flow rates greater than 75 g/10 min. Procedure C

involves the use of a modified die, commonly referred to as a “half-die,” which has half the height and half the internal diameter

of the standard die specified for use in ProceduresAand B thus maintaining the same length to diameter ratio.The test procedure

is similar to Procedure B, but the results obtained with Procedure C shall not be assumed to be half of those results produced with

Procedure B.

1.5 Procedure D is a multi-weight test commonly referred to as a “Flow Rate Ratio” (FRR) test. Procedure D is designed to

allow MFR determinations to be made using two or three different test loads (either increasing or decreasing the load during the

test) on one charge of material. The FRR is a dimensionless number derived by dividing the MFR at the higher test load by the

MFR at the lower test load. Results generated from multi-weight tests shall not be directly compared with results derived from

Procedure A or Procedure B.

NOTE1—Round-robin testing indicates this test method may be suitable at flow rates up to 1500 g/10 min if the timing clock resolves the elapsed time

tothenearest0.01s. 1—Polymershavingmeltflowrateslessthan0.15orgreaterthan900g/10minmaybetestedbytheproceduresinthistestmethod;

however, precision data have not been developed.

NOTE2—This test method and ISO 1133-1991 are technically equivalent.

1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.