ASTM E1556-12

(Specification)Standard Specification for Epoxy Resin System for Composite Skin, Honeycomb Sandwich Panel Repair

Standard Specification for Epoxy Resin System for Composite Skin, Honeycomb Sandwich Panel Repair

ABSTRACT

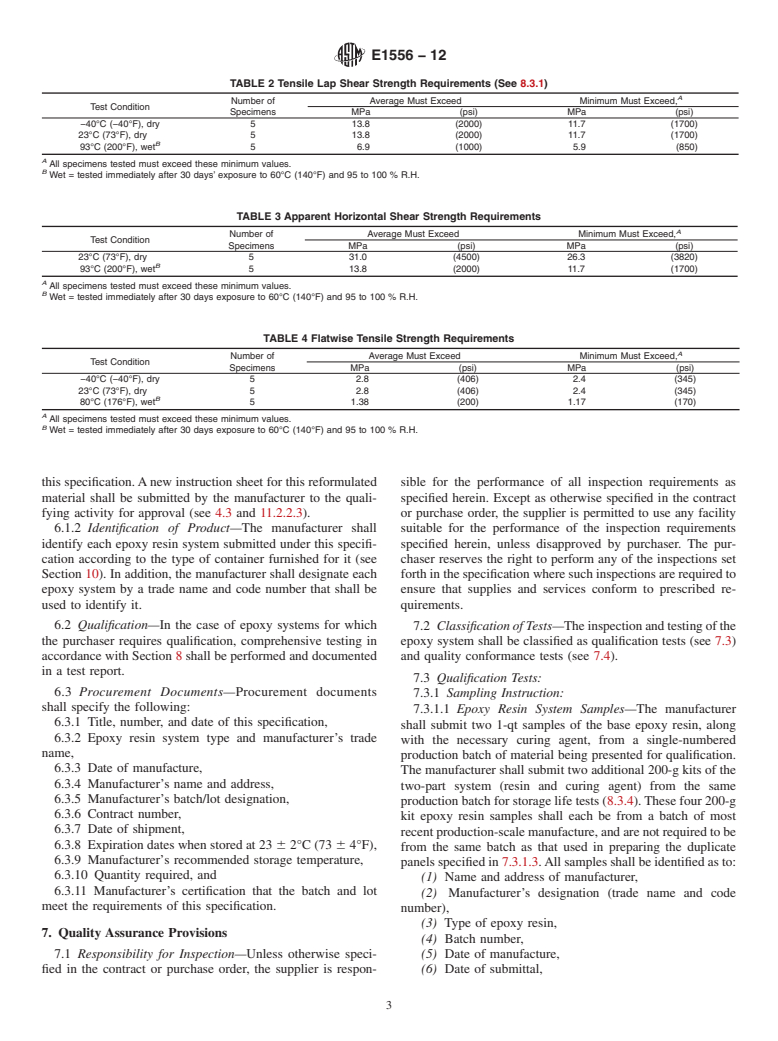

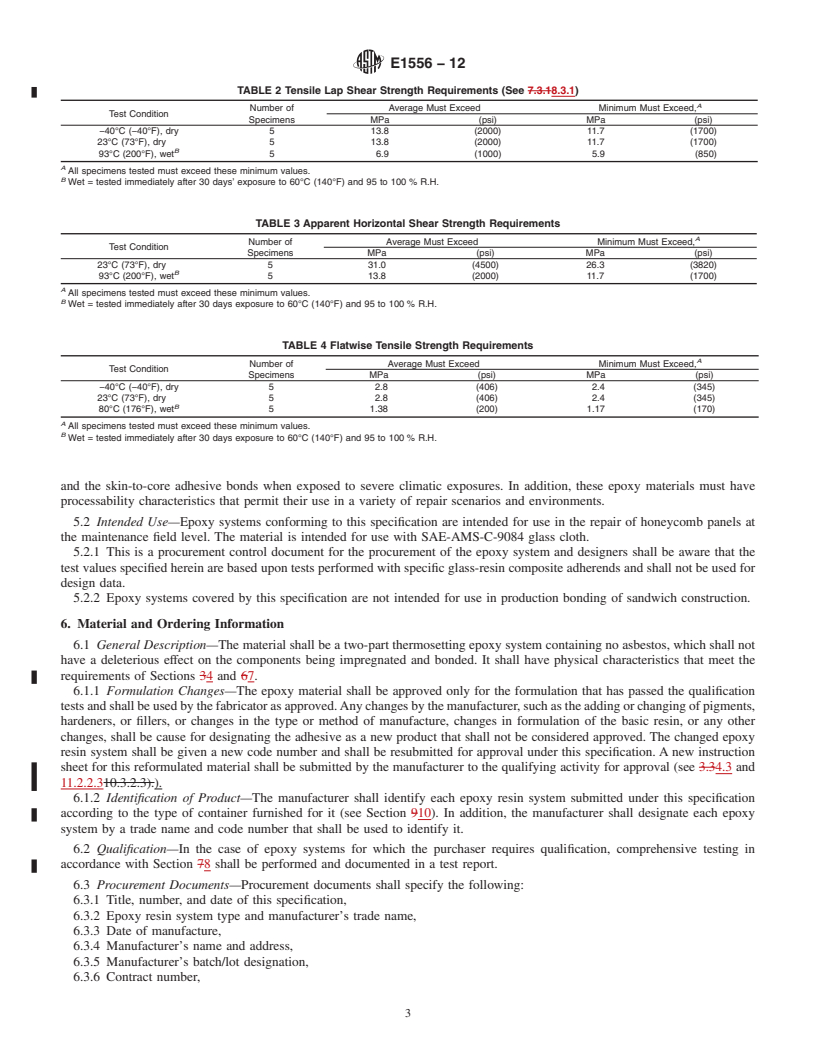

This specification covers the requirements for an epoxy resin system intended for the repair of sandwich panels for durable, rigidwall, relocatable structures. It must be usable in a field environment and shall not require the use of special equipment such as autoclaves or presses. The epoxy system covered by this specification shall be usable for simultaneous impregnation of a wet-layup composite skin and bonding of that skin to a substrate honeycomb core. The inspection and testing of the epoxy system shall be classified as qualification tests and quality conformance tests. The following test methods shall be performed to conform to the requirements specified: tensile lap shear strength; apparent horizontal shear strength; and flatwise tensile strength.

SIGNIFICANCE AND USE

5.1 Epoxy resin systems used in the repair of composite skin sandwich panels for durable, rigidwall, relocatable shelters must have a combination of mechanical property levels and environmental resistance that will assure long-term durability of the skins and the skin-to-core adhesive bonds when exposed to severe climatic exposures. In addition, these epoxy materials must have processability characteristics that permit their use in a variety of repair scenarios and environments.

5.2 Intended Use—Epoxy systems conforming to this specification are intended for use in the repair of honeycomb panels at the maintenance field level. The material is intended for use with SAE-AMS-C-9084 glass cloth.

5.2.1 This is a procurement control document for the procurement of the epoxy system and designers shall be aware that the test values specified herein are based upon tests performed with specific glass-resin composite adherends and shall not be used for design data.

5.2.2 Epoxy systems covered by this specification are not intended for use in production bonding of sandwich construction.

SCOPE

1.1 This specification covers the requirements for an epoxy resin system intended for the repair of sandwich panels for durable, rigidwall, relocatable structures. It must be usable in a field environment and shall not require the use of special equipment such as autoclaves or presses. The epoxy system covered by this specification shall be usable for simultaneous impregnation of a wet-layup composite skin and bonding of that skin to a substrate honeycomb core. The material shall withstand exposure to temperatures from −54 to 93°C (−65 to 199°F) and high relative humidity, and also the combination of stress, temperature, and relative humidity that are expected to be encountered in service.

1.2 The values stated in SI units are to be regarded as standard where only SI units are given or where SI units are given first followed by inch-pound units; where inch-pound units are given first followed by SI units, the inch-pound units are to be regarded as the standard.

1.3 The following safety hazards caveat refers only to the test methods described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1556 −12

Standard Specification for

Epoxy Resin System for Composite Skin, Honeycomb

1

Sandwich Panel Repair

This standard is issued under the fixed designation E1556; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D792Test Methods for Density and Specific Gravity (Rela-

tive Density) of Plastics by Displacement

1.1 This specification covers the requirements for an epoxy

D2344/D2344MTest Method for Short-Beam Strength of

resin system intended for the repair of sandwich panels for

PolymerMatrixCompositeMaterialsandTheirLaminates

durable,rigidwall,relocatablestructures.Itmustbeusableina

D2584Test Method for Ignition Loss of Cured Reinforced

field environment and shall not require the use of special

Resins

equipment such as autoclaves or presses. The epoxy system

D2734TestMethodsforVoidContentofReinforcedPlastics

covered by this specification shall be usable for simultaneous

D3165Test Method for Strength Properties ofAdhesives in

impregnation of a wet-layup composite skin and bonding of

Shear by Tension Loading of Single-Lap-Joint Laminated

that skin to a substrate honeycomb core. The material shall

Assemblies

withstand exposure to temperatures from −54 to 93°C (−65 to

E631Terminology of Building Constructions

199°F)andhighrelativehumidity,andalsothecombinationof

E1091Specification for Nonmetallic Honeycomb Core for

stress, temperature, and relative humidity that are expected to

Use in Shelter Panels

be encountered in service.

E1749Terminology Relating to Rigid Wall Relocatable

1.2 The values stated in SI units are to be regarded as

Shelters

3

standard where only SI units are given or where SI units are

2.2 Military Specifications:

given first followed by inch-pound units; where inch-pound

MIL-I-24768Insulation, Plastic, Laminated, Thermosetting,

units are given first followed by SI units, the inch-pound units

Glass-Cloth, Epoxy-Resin

3

are to be regarded as the standard.

2.3 Military Standards:

1.3 The following safety hazards caveat refers only to the MIL-STD-129Military Marking for Shipping and Storage

testmethodsdescribedinthisspecification. This standard does

MIL-STD-1916DOD Preferred Methods for Acceptance of

not purport to address all of the safety concerns, if any,

Product

4

associated with its use. It is the responsibility of the user of this

2.4 Commercial Standards:

standard to establish appropriate safety and health practices

SAE-AMS-C-9084Cloth, Glass, Finished for Epoxy Resin

and determine the applicability of regulatory limitations prior

Laminates

to use.

3. Terminology

2. Referenced Documents

3.1 Definitions—See Terminologies E631 and E1749 for

2

definitions of general terms used in this specification.

2.1 ASTM Standards:

C297/C297MTest Method for Flatwise Tensile Strength of

4. Physical Requirements

Sandwich Constructions

4.1 Working Characteristics:

4.1.1 Application—Thecomponentsoftheepoxyresinshall

be readily hand-mixed to a smooth consistency suitable for

1

This specification is under the jurisdiction of ASTM Committee E06 on

application. It shall be uniform and free of lumps. The resin

Performance of Buildings and is the direct responsibility of Subcommittee E06.53

on Materials and Processes for Durable Rigidwall Relocatable Structures. components, once mixed, shall not settle out. The epoxy

Current edition approved Nov. 1, 2012. Published December 2012. Originally

approved in 1993. Last previous edition approved in 2008 as E1556–08. DOI:

3

10.1520/E1556-12. Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.dodssp.daps.mil.

4

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1556−12

material shall be suitable for the wet-layup impregnation of 4.3.4 Application, impregnating, and curing instructions,

SAE-AMS-C-9084 glass cloth and for application to core including the spreading method, thickness range, and

materials over the temperature range of 16 to 38°C (60 to temperature/relative humidity working limitations.

1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1556 − 08 E1556 − 12

Standard Specification for

Epoxy Resin System for Composite Skin, Honeycomb

1

Sandwich Panel Repair

This standard is issued under the fixed designation E1556; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers the requirements for an epoxy resin system intended for the repair of sandwich panels for durable,

rigidwall, relocatable structures. It must be usable in a field environment and shall not require the use of special equipment such

as autoclaves or presses. The epoxy system covered by this specification shall be usable for simultaneous impregnation of a

wet-layup composite skin and bonding of that skin to a substrate honeycomb core. The material shall withstand exposure to

temperatures from −54 to 93°C (−65 to 199°F) and high relative humidity, and also the combination of stress, temperature, and

relative humidity that are expected to be encountered in service.

1.2 The values stated in SI units are to be regarded as standard where only SI units are given or where SI units are given first

followed by inch-pound units; where inch-pound units are given first followed by SI units, the inch-pound units are to be regarded

as the standard.

1.3 The following safety hazards caveat refers only to the test methods described in this specification.This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C297/C297M Test Method for Flatwise Tensile Strength of Sandwich Constructions

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D2344/D2344M Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates

D2584 Test Method for Ignition Loss of Cured Reinforced Resins

D2734 Test Methods for Void Content of Reinforced Plastics

E874 Practice for Adhesive Bonding of Aluminum Facings to Nonmetallic Honeycomb Core for Shelter Panels

D3165 Test Method for Strength Properties of Adhesives in Shear by Tension Loading of Single-Lap-Joint Laminated

Assemblies

E631 Terminology of Building Constructions

E1091 Specification for Nonmetallic Honeycomb Core for Use in Shelter Panels

E1749 Terminology Relating to Rigid Wall Relocatable Shelters

3

2.2 Military Specifications:

MIL-I-24768 Insulation, Plastic, Laminated, Thermosetting, Glass-Cloth, Epoxy-Resin

3

2.3 Military Standards:

MIL-STD-129 Military Marking for Shipping and Storage

MIL-STD-1916 DOD Preferred Methods for Acceptance of Product

4

2.4 Commercial Standards:

SAE-AMS-C-9084 Cloth, Glass, Finished for Epoxy Resin Laminates

1

This specification is under the jurisdiction of ASTM Committee E06 on Performance of Buildings and is the direct responsibility of Subcommittee E06.53 on Materials

and Processes for Durable Rigidwall Relocatable Structures.

Current edition approved Nov. 1, 2008Nov. 1, 2012. Published December 2008December 2012. Originally approved in 1993. Last previous edition approved in 20032008

as E1556 – 03.E1556 – 08. DOI: 10.1520/E1556-08.10.1520/E1556-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://www.dodssp.daps.mil.

4

Available from Society of Automotive Engineers (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1556 − 12

3. Terminology

3.1 Definitions—See Terminologies E631 and E1749 for definitions of general terms used in this specification.

4. Physical Requirements

4.1 Working Characteristics:

4.1.1 Application—The components of the epoxy resin shall be read

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.