ASTM A882/A882M-96e1

(Specification)Standard Specification for Epoxy-Coated Seven-Wire Prestressing Steel Strand

Standard Specification for Epoxy-Coated Seven-Wire Prestressing Steel Strand

SCOPE

1.1 This specification covers ASTM Specification A 416 low-relaxation Grade 250 and Grade 270 seven-wire prestressing steel strand with protective fusion-bonded epoxy coating applied by the electrostatic deposition method or other method that will meet the coating requirements in Section 7.

Note 1—The manufacturer as identified throughout this specification is the coating applicator.

1.2 Supplementary Requirements S1 contains requirements for epoxy-coated and filled strand. Epoxy-coated and filled strand shall not be furnished unless ordered, or by arrangement between purchaser and manufacturer.

Note 2—This standard is a product specification and it does not delineate requirements regarding the use of epoxy-coated strand. Proper use of epoxy-coated strand includes design considerations, handling, installing, and stressing of strands, permissible concrete curing temperature, and procedures for repairing damaged coating and protection of the ends of strands. Information and procedures for such items are presented in a report by the PCI Ad Hoc Committee on Epoxy-Coated Strand.

1.3 This specification is applicable for orders in either inch-pound units (as Specification A 882) or SI units [as Specification A 882M].

1.4 The values stated in either inch-pound or SI units are to be regarded as standard. Within the test, the SI units are shown in brackets. The values stated in each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: A 882/A882M – 96

Standard Specification for

Epoxy-Coated Seven-Wire Prestressing Steel Strand

This standard is issued under the fixed designation A 882/A882M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial corrections were made in June 2001.

1. Scope Seven-Wire for Prestressed Concrete

B 117 Practice for Operating Salt Spray (Fog) Apparatus

1.1 This specification covers ASTM Specification A 416

D 968 Test Methods for Abrasion Resistance of Organic

low-relaxation Grade 250 and Grade 270 seven-wire prestress-

Coatings by Falling Abrasive

ing steel strand with protective fusion-bonded epoxy coating

G 14 Test Method for Impact Resistance of Pipeline Coat-

applied by the electrostatic deposition method or other method

ings (Falling Weight Test)

that will meet the coating requirements in Section 7.

G 20 Test Method for Chemical Resistance of Pipeline

NOTE 1—The manufacturer as identified throughout this specification is 7

Coatings

the coating applicator.

2.2 Federal Highway Administration Report:

1.2 Supplementary Requirements S1 contains requirements

FHWA-RD-74-18 Nonmetallic Coatings for Concrete Rein-

for epoxy-coated and filled strand. Epoxy-coated and filled

forcing Bars (February 1974)

strand shall not be furnished unless ordered, or by arrangement

3. Ordering Information

between purchaser and manufacturer.

3.1 The purchaser should specify:

NOTE 2—This standard is a product specification and it does not

3.1.1 Diameter, grade, and type of uncoated strand in

delineate requirements regarding the use of epoxy-coated strand. Proper

accordance with Specification A 416/A 416M (latest edition).

use of epoxy-coated strand includes design considerations, handling,

installing, and stressing of strands, permissible concrete curing tempera-

3.1.2 Smooth or grit impregnated coating (see 6.3).

ture, and procedures for repairing damaged coating and protection of the

3.1.3 Quantity (in feet [metres]).

ends of strands. Information and procedures for such items are presented

3.1.4 Requirements for certification (see Section A1.2.3).

in a report by the PCI Ad Hoc Committee on Epoxy-Coated Strand.

3.1.5 Requirements for material samples (see 4.3).

1.3 This specification is applicable for orders in either

3.1.6 Requirements for patching material (see 4.4).

inch-pound units (as Specification A 882) or SI units [as

NOTE 3—A typical ordering description for epoxy-coated strand is as

Specification A 882M].

follows: 84 000 feet [2560 m] of grit-impregnated epoxy-coated strand,

1.4 The values stated in either inch-pound or SI units are to

⁄2-in. [12.7-mm] diameter, Grade 270 K low-relaxation on wooden reels

be regarded as standard. Within the test, the SI units are shown

to ASTM Specification A 882 – [A 882M – ].

in brackets. The values stated in each system must be used

4. Materials

independently of the other. Combining values from the two

systems may result in nonconformance with this specification.

4.1 Prestressing steel strand to be coated shall meet the

requirements of Specification A 416/A 416M as specified by

2. Referenced Documents

the purchaser and shall be free of contaminants such as oil,

2.1 ASTM Standards:

grease, or paint.

A 370 Test Methods and Definitions for Mechanical Testing

4.1.1 Epoxy-coated strand shall have relaxation losses of

of Steel Products

not more than 4 % when initially loaded to 70 % of specified

A 416/A 416M Specification for Steel Strand, Uncoated

minimum breaking strength of the strand after 1000 h when

tested under conditions of Specification A 416/A 416M.

4.2 The coating material shall meet the requirements listed

in Annex A1 of this specification. The coating material shall be

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

A01.05 on Steel Reinforcement.

Annual Book of ASTM Standards, Vol 01.04.

Current edition approved March 10, 1996. Published May 1996. Originally

Annual Book of ASTM Standards, Vol 03.02.

published as A 882/A 882M – 91. Last previous edition A 882/A 882M – 95.

Annual Book of ASTM Standards, Vol 06.01.

“Guidelines for the Use of Epoxy-Coated Strand,” PCI Journal, Precast/

Annual Book of ASTM Standards, Vol 06.02.

Prestressed Concrete Institute, Vol. 38, No. 4, July-August 1993, pp. 26–32.

Available from the National Technical Information Service, 5285 Port Royal

Annual Book of ASTM Standards, Vol 01.03.

Rd., Springfield, VA 22161.

Copyright © ASTM International, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 882/A882M

of organic composition except for the pigment, or grit if the crown of the wires, on a straight length of the strand. The

applicable, which may be inorganic if used. magnetic gage shall be placed at one point in the strand and

4.2.1 If specified in the order, a written certification shall be readings shall be taken at the crown of each outer wire.

furnished to the purchaser that properly identifies the number

7.1.4 For each reel of strand, thickness measurements shall

of each batch of coating material used in the order, material,

be conducted at five locations spaced approximately even

quantity represented, date of manufacture, name and address of

along the manufactured length of the strand. Records of

manufacturer, a statement that the supplied coating material

inspection during manufacturing shall be available when re-

meets the requirements of Annex A1, and a statement that the

quested.

coating material used in each batch is the same material as that

7.2 Continuity of Coating:

which was qualified under the requirements of Annex A1.

7.2.1 After curing, the coating shall be free of holes, voids,

4.3 If specified in the order, a representative 8-oz. [0.23-kg]

cracks, and damaged areas discernible to the unaided eye.

sample of coating material shall be packaged in an airtight

7.2.2 During the coating process, a continuous holiday

container and identified by batch number, and supplied to the

detection procedure shall be employed using an appropriate

purchaser.

holiday detector that uses water as the conductor and follows

4.4 If specified in the order, patching material compatible

the procedure furnished by the manufacturer of the holiday

with the coating material and inert in concrete, and meeting the

detector. (A holiday is a pinhole in the coating not discernible

requirements of Annex A1 shall be supplied to the purchaser.

to the unaided eye.)

7.2.3 During the continuous holiday detection procedure, if

5. Surface Preparation

more than two holidays per hundred feet [30 m] are detected,

5.1 The surface of the steel strand to be coated shall be

the strand shall be rejected and corrective action shall be

cleaned chemically or by another method that will impart the

instituted. Coated strand with two holidays or less per hundred

same cleanliness to ensure that the coated strand meets the

feet [30 m] shall be patched in accordance with the patching

requirements of Section 7.

material manufacturer’s recommendation.

7.3 Adhesion of Coating:

6. Application of Coating

7.3.1 The adhesion and shear strength of the coating shall be

6.1 The coating shall be applied to the cleaned surface as

evaluated by bending a sample from a finished reel of coated

soon as possible after cleaning and before reoxidation of the

strand 180° around a mandrel diameter equal to 32 times the

surface discernible to the unaided eye occurs. However, in no

nominal diameter of the strand. Test specimens shall be at

case shall application of the coating be delayed more than 10

thermal equilibrium between 68 and 86°F [20 and 30°C].

minutes after cleaning, unless otherwise permitted by the

7.3.2 No cracking or disbonding of the coating shall be

purchaser.

visible to the unaided eye on the outside radius of the bent

6.2 The coating shall be applied by the electrostatic depo-

strand. Evidence of cracking or disbonding of the coating shall

sition method, or other method that will meet the coating

be considered cause for rejection of the coated strand repre-

requirements in Section 7, and fully cured in accordance with

sented by the bend test sample. Retests shall be conducted in

the recommendations of the manufacturer of the coating

accordance with 9.1.

material.

7.3.3 Fracture of the steel wire or strand in the bend test for

6.3 The coating may be smooth or grit-impregnated.

adhesion of coating shall not be considered as an adhesion

6.3.1 Inert particles (grit) shall be impregnated into the

failure of the coating, and another specimen from the same

surface of the coating when grit-impregnated strand is ordered.

production shift may be substituted.

Such particles shall not cause the coating to fail the require-

7.3.4 The adhesion of coating shall also be evaluated by a

ments of Section 7. The particles shall be inert in concrete and

tension test in accordance with Section 6 of Specification

non-reactive with concrete additives and soluble salts.

A 416. The coated strand shall satisfy the requirements for

6.3.2 The epoxy on the surface of grit-impregnated strand

breaking strength, yield strength (1 % extension), and ultimate

shall be capable of reaching a temperature of 150°F [66°C]

elongation described in Specification A 416/A 416M. No

without reducing the transfer of prestress by bond from the

cracks visible to the unaided eye shall occur in the coating up

strand to the surrounding concrete.

to an elongation of 1 % (yield strength).

NOTE 4—Warning: At temperatures above 165°F [74°C], currently

7.3.5 Sample length for the bend test shall be at least 5 ft, 0

available epoxy begins to soften and lose its ability to transfer load from

in. long [1500 mm]. Sample length for the tension test shall

strand to concrete by bond. At 200°F [93°C] practically all transfer

follow the requirements of Test Methods and Definitions

capacity will be lost.

A 370.

7. Requirements for Coated Strands

7.4 Bond with Concrete or Grout:

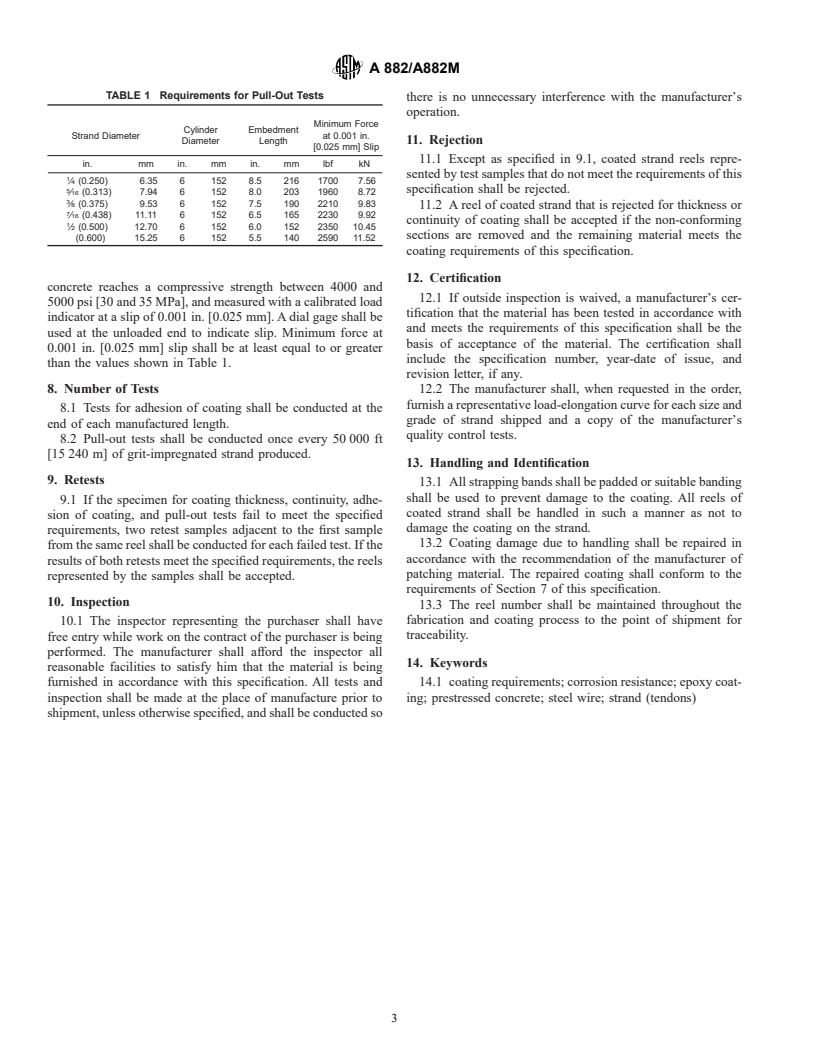

7.1 Thickness of Coating: 7.4.1 Pull-out tests shall be conducted on grit-impregnated

7.1.1 The film thickness of the coating after curing shall be coated strand to ensure proper bond properties. Pull-out speci-

25 to 45 mils [0.64 to 1.14 mm]. mens shall be cast in concrete cylinders with dimensions

7.1.2 The thickness of the coating film shall be determined shown in Table 1. The untensioned strand shall be embedded

with a magnetic gauge or other method, with 65 % allowable concentrically along the longitudinal axis of the specimen. The

error, capable of measuring along a curved surface. minimum force at 0.001 in. [0.025 mm] slip shall be applied as

7.1.3 The thickness of the coating film shall be measured on shown in Fig. 1, by a hydraulic or mechanical jack when

A 882/A882M

TABLE 1 Requirements for Pull-Out Tests

there is no unnecessary interference with the manufacturer’s

operation.

Minimum Force

Cylinder Embedment

Strand Diameter at 0.001 in.

11. Rejection

Diameter Length

[0.025 mm] Slip

11.1 Except as specified in 9.1, coated strand reels repre-

in. mm in. mm in. mm lbf kN

sented by test samples that do not meet the requirements of this

⁄4 (0.250) 6.35 6 152 8.5 216 1700 7.56

specification shall be rejected.

⁄16 (0.313) 7.94 6 152 8.0 203 1960 8.72

⁄8 (0.375) 9.53 6 152 7.5 190 2210 9.83

11.2 A reel of coated strand that is rejected for thickness or

⁄16 (0.438) 11.11 6 152 6.5 165 2230 9.92

continuity of coating shall be accepted if the non-conforming

⁄2 (0.500) 12.70 6 152 6.0 152 2350 10.45

sections are removed and the remaining material meets the

(0.600) 15.25 6 152 5.5 140 2590 11.52

coating requirements of this specification.

12. Certification

concrete reaches a compressive strength between 4000 and

12.1 If outside inspection is waived, a manufacturer’s cer-

5000 psi [30 and 35 MPa], and measured with a calibrated load

tification that the material has been tested in accordance with

indicator at a slip of 0.001 in. [0.025 mm]. A dial gage shall be

and meets the requirements of this specification shall be the

used at the unloaded end to indicate slip. Minimum force at

basis of acceptance of the material. The certification shall

0.001 in. [0.025 mm] slip shall be at least equal to or greater

include the specification number, year-date of issue, and

than the values shown in Table 1.

revision letter, if any.

8. Number of Tests

12.2 The manufacturer shall, when requested in the order,

furnish a representative load-elongation curve for each size and

8.1 Tests for adhesion of coating shall be conducted at the

grade of strand shipped and a copy of the manufacturer’s

end of each manufactured length.

quality control tests.

8.2 Pull-out tests shall be conducted once every 50 000 ft

[15 240 m] of grit-impregnated strand produced.

13. Handling and Identification

9. Retests

13.1 All strapping bands shall be padded or suitable banding

shall be used to prevent damage to the coating. All reels of

9.1 If the specimen for coating thickness, continuity, adhe-

coated strand shall be handled in such a manner as not to

sion of coating, and pull-out tests fail to meet the specified

damage the coating on the strand.

requirements, two retest samples adjacent to the first sample

13.2 Coating damage due to handling shall be repaired in

from the same reel shall be conducted for each failed test. If the

accordance with the recommendation of the manufacturer of

results of both retests meet the specified requirements, the reels

patching material. The repaired coating shall conform to the

represented by the samples shall be accepted.

requirements of Section 7 of this specification.

10. Inspection

13.3 The reel number shall be maintained throughout the

fabrication and coating process to the point of shipment for

10.1 The inspector representing the purchaser shall have

traceability.

free entry while work on the contract of the purchaser is being

performed. The manufacturer shall afford the inspector all

14. Keywords

reasonable facilities to satisfy him that the material is being

furnished in accordance with this specification. All tests and 14.1 coating requirements; corrosion resistance; epoxy coat-

inspection shall be made at the place of manufacture prior to ing; prestressed concrete; steel wire; strand (tendons)

shipment, unless otherwise specified, and shall be conducted so

A 882/A882M

FIG. 1 Recommended Arrangement for Pull-Out Testing

SUPPLEMENTARY REQUIREMENTS

I. EPOXY–COATE

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.