ASTM C1456-13(2018)

(Test Method)Standard Test Method for Determination of Uranium or Gadolinium (or both) in Gadolinium Oxide-Uranium Oxide Pellets or by X-Ray Fluorescence (XRF)

Standard Test Method for Determination of Uranium or Gadolinium (or both) in Gadolinium Oxide-Uranium Oxide Pellets or by X-Ray Fluorescence (XRF)

SIGNIFICANCE AND USE

5.1 This test method is applicable to samples containing 1 to 10 % gadolinium oxide and 90 to 99 % uranium oxide on the “as received” basis. The method may be used to determine concentration of either uranium, gadolinium, or both.

5.2 Either wavelength-dispersive or energy-dispersive X-ray fluorescence systems may be used provided the software accompanying the system is able to accommodate the use of internal standards.

SCOPE

1.1 This test method describes the steps necessary for the preparation and analysis by X-ray fluorescence (XRF) of gadolinium or uranium (or both) in gadolinium oxide-uranium oxide pellets or powders.

1.2 This test method requires the use of appropriate internal standard(s). Care must be taken to ascertain that samples analyzed by this method do not contain the internal standard element(s) or that this contamination has been corrected for mathematically whenever present. Such corrections are not addressed in this test method.

1.3 This standard contains notes that are explanatory and are not part of the mandatory requirements of the standard.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautions are given in Section 8 and various notes throughout the method.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1456 − 13 (Reapproved 2018)

Standard Test Method for

Determination of Uranium or Gadolinium (or both) in

Gadolinium Oxide-Uranium Oxide Pellets or by X-Ray

Fluorescence (XRF)

This standard is issued under the fixed designation C1456; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method describes the steps necessary for the 2.1 ASTM Standards:

preparation and analysis by X-ray fluorescence (XRF) of D1193 Specification for Reagent Water

gadolinium or uranium (or both) in gadolinium oxide-uranium E135 Terminology Relating to Analytical Chemistry for

oxide pellets or powders. Metals, Ores, and Related Materials

2.2 Other Document

1.2 This test method requires the use of appropriate internal

ANSI/HPS N43.2-2001 Radiation Safety for X-ray Diffrac-

standard(s). Care must be taken to ascertain that samples

tion and X-ray Fluorescence Analysis Equipment

analyzed by this method do not contain the internal standard

element(s) or that this contamination has been corrected for

3. Terminology

mathematically whenever present. Such corrections are not

3.1 Definitions—For definitions of terms used in this guide,

addressed in this test method.

see Terminology E135.

1.3 Thisstandardcontainsnotesthatareexplanatoryandare

3.2 Symbol: LiTB = lithium tetraborate (see 7.4).

not part of the mandatory requirements of the standard.

1.4 The values stated in SI units are to be regarded as

4. Summary of Test Method

standard. No other units of measurement are included in this

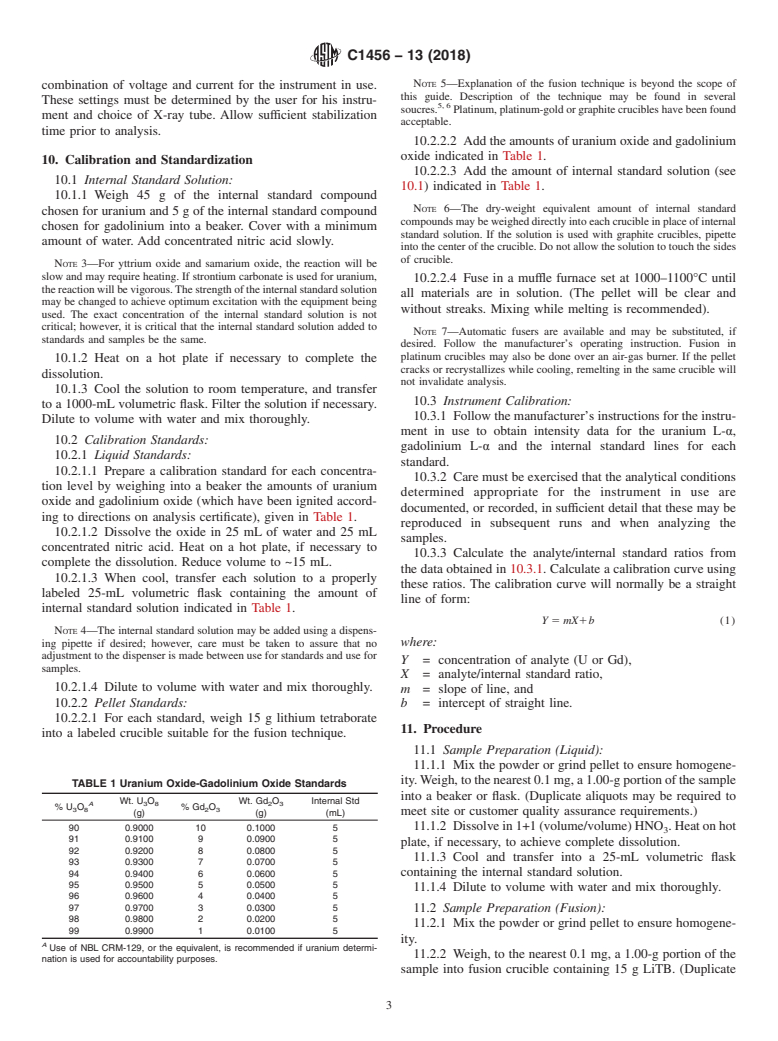

4.1 Solution or pellet standards containing the equivalent of

standard.

1–10 % gadolinium oxide and 90–99 % uranium oxide and

1.5 This standard does not purport to address all of the

appropriate internal standards are placed in the sample holder

safety concerns, if any, associated with its use. It is the

of an X-ray spectrometer and exposed to an X-ray beam

responsibility of the user of this standard to establish appro-

capable of exciting the uranium and gadolinium L-α emission

priate safety, health, and environmental practices and deter-

lines and the appropriate emission line for the internal stan-

mine the applicability of regulatory limitations prior to use.

dard. The intensities generated are measured by an appropriate

Specific precautions are given in Section 8 and various notes

detector. The intensity ratio values obtained from this data are

throughout the method.

used to calibrate the X-ray analyzer.

1.6 This international standard was developed in accor-

4.2 Samples are prepared in the same manner as the

dance with internationally recognized principles on standard-

standards and analyzed using conditions and curves generated

ization established in the Decision on Principles for the

from those standards.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical NOTE1—Yttriumandstrontiumhavebeenusedsuccessfullyasinternal

standards for uranium and samarium for gadolinium. Scatter lines also

Barriers to Trade (TBT) Committee.

1 2

This test method is under the jurisdiction ofASTM Committee C26 on Nuclear For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Fuel Cycle and is the direct responsibility of Subcommittee C26.05 on Methods of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Test. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Nov. 1, 2018. Published December 2018. Originally the ASTM website.

approved in 2000. Last previous edition approved in 2013 as C1456 – 13. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/C1456-13R18. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1456 − 13 (2018)

have been used as internal standard lines. An explanation of internal

7.2 Purity of Water—Unless otherwise indicated, references

5, 6

standard method is found in several sources.

to water shall mean reagent water conforming to Specification

D1193.

5. Significance and Use

7.3 Gadolinium Oxide, Gd O —It is recommended that the

2 3

5.1 Thistestmethodisapplicabletosamplescontaining1to

standards be prepared using same batch as in pellets/powder.

10 % gadolinium oxide and 90 to 99 % uranium oxide on the

7.4 Lithium Tetraborate, Li B O , fusion grade.

“as received” basis. The method may be used to determine 2 4 7

concentration of either uranium, gadolinium, or both.

7.5 Nitric Acid, HNO , concentrated (70 %).

5.2 Either wavelength-dispersive or energy-dispersive

7.6 Samarium Oxide, Sm O , or other suitable internal

2 3

X-ray fluorescence systems may be used provided the software

standard for gadolinium (see Note 1).

accompanying the system is able to accommodate the use of

7.7 Uranium Oxide, U O , NBLCRM-129 (or equivalent).

3 8

internal standards.

NOTE 2—High purity UO may be used if certification of uranium

analysis is not required.

6. Apparatus

7.8 Yttrium Oxide, Y O , or other suitable internal standard

2 3

6.1 X-Ray Spectrometer—See the manufacturer’s operating

for uranium (see Note 1).

manuals for the selection of the X-ray spectrometer. The

method is valid for either energy-dispersive or wavelength-

8. Technical Precautions

dispersive systems.

8.1 XRF equipment analyzes by the interaction of ionizing

6.2 Sample Cups/Holders—Prepare liquid sample cups for

radiation with the sample. Applicable safety regulations and

the X-ray spectrometer as described by the manufacturer.

standard operating procedures must be reviewed prior to the

Vented, disposable sample cups with snap-on caps are satis-

use of such equipment. All modern XRF spectrometers are

factory for most such analyses; such cups decrease the likeli-

equipped with safety interlocks to prevent accidental penetra-

hood of contamination between samples. Sample holders for

tion of the X-ray beam by the user. Do NOT override these

fused pellets should keep any pellet chips from getting into the

interlocks without proper training (See ANSI/HPS N43.2-

moving parts of the instrument.

2001).

6.3 Window Film—Polyester, polyethylene, and polypropyl-

8.2 Instrument performance may be influenced by environ-

ene films have been used successfully as the film window for

mental factors such as heat, vibration, humidity, dust, stray

cups or holders, or both. Tests should be performed to

electronic noise and line voltage stability. These factors and

determinetheserviceabilityofanyfilmchosenbeforeinsertion

performance characteristics should be reviewed prior to use of

into the instrument.

this test method.

6.4 Solution Dispenser (optional)—The dispenser for the

internal standard solution, if used, should be capable of 9. Preparation of Apparatus

reproduciblydispensingtheinternalstandardsolutiontoalevel

9.1 Chamber Environment—The liquid standards and

of 0.1 % relative standard deviation of the volume dispensed.

samples used in this method are corrosive. Some fumes will be

emittedfromthesamplecups.Thesefumesmaybedetrimental

6.5 Muffle Furnace, 1100°C capacity.

to the spectrometer chamber. It is desirable to flush this

7. Reagents and Materials chamber with an inert gas (usually helium) before and during

analysis. Some X-ray spectrometers control the change of

7.1 Purity of Materials—Reagent grade chemicals shall be

sample chamber atmosphere (air, vacuum, helium) automati-

used in all tests. Unless otherwise indicated, it is intended that

cally through the software; in others, it must be done manually.

all reagents conform to the specifications of the Committee of

Follow the instrument manufacturer’s recommendations to

Analytical Reagents of the American Chemical Society where

achieve the inert gas environment. Allow sufficient stabiliza-

such specifications are available. Other grades may be used

tion time before analysis. Fused pellet standards and samples

provided it is first ascertained that the reagent is of sufficiently

maybeanalyzedusingeitheravacuumorheliumenvironment.

high purity to permit its use without lessening the accuracy of

Line intensities will be slightly higher using a vacuum envi-

the determination.

ronment. Warning—Care must be taken to assure that a

vacuum environment is not chosen with liquid samples. Ana-

lyze standards and samples under the same environment.

Andermann, G, and Kemp, J.W., “Scattered X-Rays as Internal Standards in

X-Ray Spectroscopy,” Analytical Chemistry, Vol 20 (8), 1958.

9.2 X-Ray Power Supply—If the power to the X-ray tube is

Bertin, E.P., Introduction to X-Ray Spectrometric Analysis, Plenum Press, New

not controlled by the instrument software, set the proper

York and London, 1978.

Tertian, R. and Claisse, F., Principles of Quantitative X-Ray Fluorescence

Analysis, Heyden and Son, London, Philadelphia and Rheine, 1982.

7 8

Reagent Chemicals, American Chemical Society Specifications, American The sole source of supply of the apparatus known to the committee at this time

Chemical Society, Washington, DC. For

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.