ASTM A786/A786M-05(2009)

(Specification)Standard Specification for Hot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor Plates

Standard Specification for Hot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor Plates

ABSTRACT

This specification covers carbon, low-alloy, high-strength low-alloy, and alloy steel hot-rolled floor plates for flooring, stairways, transportation equipment, and general structural purposes. Steel materials shall undergo heat and product analysis. Steel specimens shall also undergo tensile tests and shall conform to the required values of yield point, yield strength, and tensile strength.

SCOPE

1.1 This specification covers carbon, low-alloy, high-strength low-alloy, and alloy steel hot-rolled floor plates for flooring, stairways, transportation equipment, and general structural purposes. While it is generally provided in the as-rolled condition, floor plate also may be provided in the heat-treated condition, depending on the material specification. Rolled floor plates have raised figures at regular intervals on one surface of the plate.

1.2 Floor plate is available in dimensions that meet the classification size limits for sheet, heavy thickness sheet coil, or plate. Maximum thickness for product delivered under this specification is 1 in. [25 mm].

1.3 When the steel is to be welded, it is presupposed that a welding procedure suitable for the grade of steel and intended use or service will be utilized. See Appendix X3 of Specification A6/A6M for information on weldability.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system is to be used independently of the other, without combining values.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A786/A786M −05(Reapproved 2009)

Standard Specification for

Hot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and

Alloy Steel Floor Plates

This standard is issued under the fixed designationA786/A786M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope A514/A514M Specification for High-Yield-Strength,

Quenched and Tempered Alloy Steel Plate, Suitable for

1.1 This specification covers carbon, low-alloy, high-

Welding

strength low-alloy, and alloy steel hot-rolled floor plates for

A568/A568M Specification for Steel, Sheet, Carbon,

flooring, stairways, transportation equipment, and general

Structural,andHigh-Strength,Low-Alloy,Hot-Rolledand

structural purposes. While it is generally provided in the

Cold-Rolled, General Requirements for

as-rolled condition, floor plate also may be provided in the

A570/A570M Specification for Structural Steel, Sheet and

heat-treated condition, depending on the material specification.

Strip, Carbon, Hot-Rolled (Withdrawn 2000)

Rolled floor plates have raised figures at regular intervals on

A572/A572M Specification for High-Strength Low-Alloy

one surface of the plate.

Columbium-Vanadium Structural Steel

1.2 Floor plate is available in dimensions that meet the

A573/A573M Specification for Structural Carbon Steel

classification size limits for sheet, heavy thickness sheet coil,

Plates of Improved Toughness

or plate. Maximum thickness for product delivered under this

A588/A588M Specification for High-Strength Low-Alloy

specification is 1 in. [25 mm].

Structural Steel, up to 50 ksi [345 MPa] Minimum Yield

1.3 When the steel is to be welded, it is presupposed that a Point, with Atmospheric Corrosion Resistance

A606/A606M Specification for Steel, Sheet and Strip, High-

welding procedure suitable for the grade of steel and intended

use or service will be utilized. See Appendix X3 of Specifica- Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, with

Improved Atmospheric Corrosion Resistance

tion A6/A6M for information on weldability.

A635/A635M Specification for Steel, Sheet and Strip,

1.4 The values stated in either inch-pound units or SI units

Heavy-Thickness Coils, Hot-Rolled, Alloy, Carbon,

are to be regarded separately as standard. The values stated in

Structural, High-Strength Low-Alloy, and High-Strength

eachsystemarenotexactequivalents;therefore,eachsystemis

Low-Alloy with Improved Formability, General Require-

to be used independently of the other, without combining

ments for

values.

A659/A659M Specification for Commercial Steel (CS),

Sheet and Strip, Carbon (0.16 Maximum to 0.25 Maxi-

2. Referenced Documents

2 mum Percent), Hot-Rolled

2.1 ASTM Standards:

A709/A709M Specification for Structural Steel for Bridges

A6/A6M Specification for General Requirements for Rolled

A829/A829M Specification forAlloy Structural Steel Plates

Structural Steel Bars, Plates, Shapes, and Sheet Piling

A830/A830M Specification for Plates, Carbon Steel, Struc-

A36/A36M Specification for Carbon Structural Steel

tural Quality, Furnished to Chemical Composition Re-

A131/A131M Specification for Structural Steel for Ships

quirements

A242/A242M Specification for High-Strength Low-Alloy

A941 TerminologyRelatingtoSteel,StainlessSteel,Related

Structural Steel

Alloys, and Ferroalloys

A1011/A1011M Specification for Steel, Sheet and Strip,

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Hot-Rolled, Carbon, Structural, High-Strength Low-

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

Alloy, High-Strength Low-Alloy with Improved

A01.02 on Structural Steel for Bridges, Buildings, Rolling Stock and Ships.

Current edition approved Oct. 1, 2009. Published December 2009. Originally

Formability, and Ultra-High Strength

approved in 1981. Last previous edition approved in 2005 as A786/A786M – 05.

A1018/A1018M Specification for Steel, Sheet and Strip,

DOI: 10.1520/A0786_A0786M-05R09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A786/A786M−05 (2009)

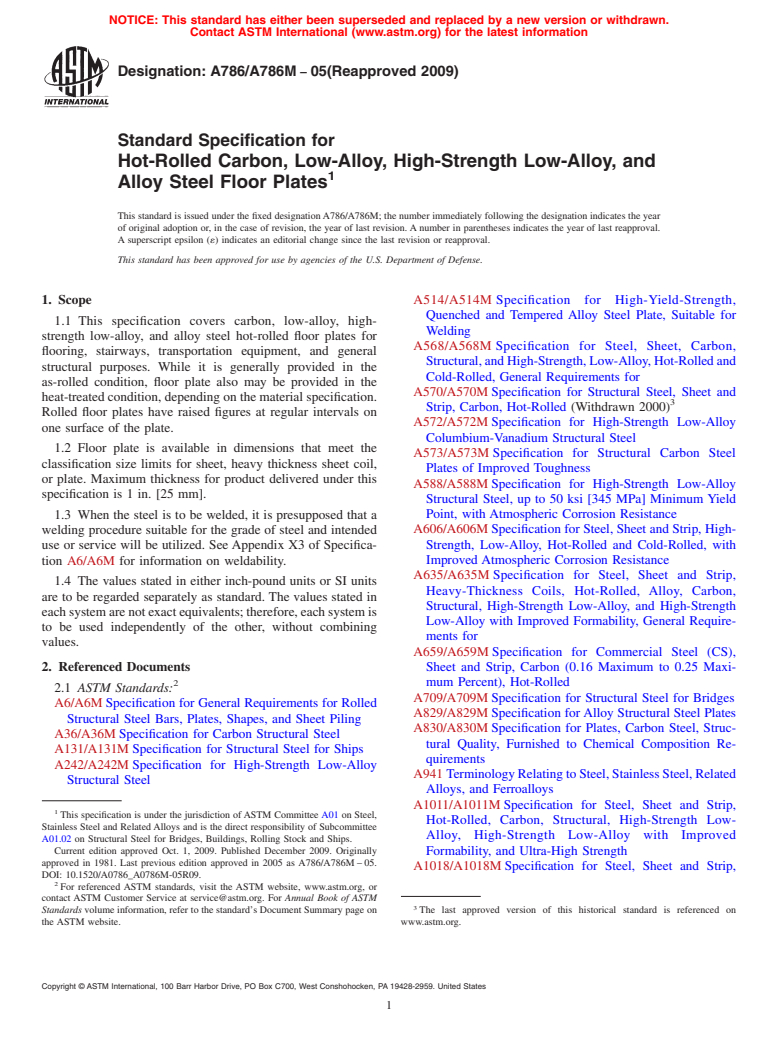

FIG. 1 Floor Plate Patterns (Full Scale)

Heavy-Thickness Coils, Hot-Rolled, Carbon, 4. Surface Pattern

Commercial, Drawing, Structural, High-Strength Low-

4.1 Individual floor plate patterns are unique to each manu-

Alloy, High-Strength Low-Alloy with Improved

facturer and are not identical in dimension or appearance to

Formability, and Ultra-High Strength

patterns manufactured by other manufacturers, although there

3. Terminology may be a close resemblance.Typical patterns are shown in Fig.

1. Manufacturers generally produce only one of the patterns

3.1 Definitions—For definitions of terms used in this

shown.

specification, refer to Terminology A941.

A786/A786M−05 (2009)

FIG. 2

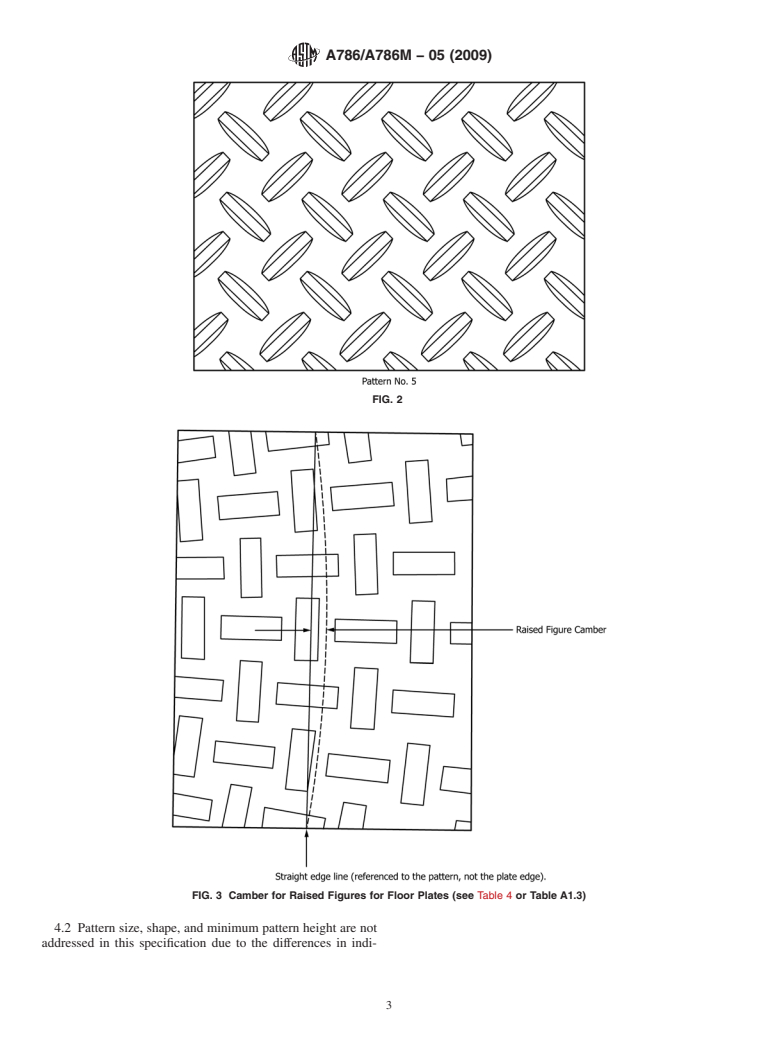

FIG. 3 Camber for Raised Figures for Floor Plates (see Table 4 or TableA1.3)

4.2 Pattern size, shape, and minimum pattern height are not

addressed in this specification due to the differences in indi-

A786/A786M−05 (2009)

FIG. 4 Camber for Rectangular Sheared Floor Plates and Gas-Cut Floor Plates (see Table 5 or TableA1.4)

vidualmanufacturer’spatternsandproductionmethods.Where 6. General Requirements

a need for these attributes exists, purchasers should consult the

6.1 Except as otherwise specified, product furnished under

manufacturer.

this specification as plate shall conform to the applicable

requirements of Specification A6/A6M.

5. Ordering Information

6.2 Except as otherwise specified, product furnished under

5.1 Information items to be considered, if appropriate, for

this specification as sheet shall conform to the applicable

inclusion in purchase orders are as follows:

requirements of Specification A568/A568M.

5.1.1 Quantity (weight [mass] or number of pieces),

5.1.2 ASTM designation and year of issue,

6.3 Except as otherwise specified, product furnished under

5.1.3 Chemical composition limits or ASTM material des-

this specification as coil shall conform to the applicable

ignation and grade (if applicable) and year of issue (if neither

requirements of Specification A635/A635M.

is specified, the product will be supplied 0.33 % maximum

6.4 In case of any conflict in requirements with this speci-

carbon, by heat analysis, and without specified mechanical

fication and a referenced material specification, the require-

properties).

ments of this specification shall prevail.

5.1.4 Dimensions (decimal thickness, width, and either cut

length of plate or coil size and weight [mass] requirements as

7. Material

applicable),

5.1.5 Condition, if other than as-rolled, 7.1 ASTM specifications that are currently available for

5.1.6 Product form (plate, sheet, or coil) and pattern from floor plate production include, but are not limited to, the

Fig.1.Asindicatedin4.2,ifspecificpatternattributes,orsome following specifications: A36/A36M, A131/A131M, A242/

alternative pattern, are desired, the purchaser will need to A242M, A514/A514M, A570/A570M, A572/A572M, A573/

consult with the manufacturer, A573M, A588/A588M, A606/A606M, A659/A659M, A709/

5.1.7 Product analysis (see 9.3), A709M, A829/A829M, A830/A830M, A1011/A1011M, and

5.1.8 Copper-bearing steel, if required (see 9.4). A1018/A1018M.

A786/A786M−05 (2009)

TABLE 1 Permitted Variations in Thickness for Floor Plates

3 3

NOTE 1—Thickness to be measured at ⁄8 to ⁄4 in. from the longitudinal edge.

NOTE 2—For thickness measured at any location other than that specified in Note 1, the permitted variations over specified thickness shall be 1 ⁄4 times

the amounts in this table, rounded to the nearest 0.010 in. for sheets, and to the nearest 0.01 in. for plates.

NOTE 3—Where “. . .” appears in this table, there is no requirement.

Permitted Variation Over

Permitted Variation Over

and Under Specified

Specified Thickness, in. Specified Thickness for

Thickness for Sheets,

B

Plates, in.

A

in.

To 0.080, incl 0.012 . . .

Over 0.080 to 0.125, incl 0.014 . . .

Over 0.125 to 0.190, incl 0.015 0.03

Over 0.190 to 0.250, incl 0.017 0.04

Over 0.250 to 0.395, incl 0.018 0.05

Over 0.395 to 1.000, incl 0.020 0.05

A

The specified thickness range captions also apply when rolled floor plate is specified to a minimum thickness, in which case the permitted variations are all over and

equal to twice the tabular values.

B

Permitted variation under specified thickness, 0.01 in.

8. Manufacture test shall be conducted on specimens with the raised figures

present.Thickness is measured at a position between the raised

8.1 The steel shall be made by any process that conforms to

figures in an area unaffected by the pattern.

the requirements of the material specification specified in the

purchase order (see 5.1.3), if any. 10.2 Percent elongation, and reduction of area where

applicable, are not required for rolled floor plate.

9. Chemical Composition Limits

11. Permitted Variations

9.1 Specified to Chemical Composition Limits Only—The

heat analysis shall conform to the chemical limits specified in

11.1 For plates and sheets, the permitted variations in

the purchase order.

dimensions shall be as given in Tables 1-3, Fig. 3, Table 4, Fig.

4, Table 5, Fig. 5, and Table 6 [Tables A1.1 toA1.6], inclusive.

9.2 Specified to an ASTM Specification—The heat analysis

shall conform to the chemical requirements listed in the

12. Certification

applicable specification.

12.1 Test Reports—Test reports shall be furnished as re-

9.3 Where specified in the purchase order, product analyses

quired by Specification A6/A6M, and shall include theASTM

shall be performed at the frequency specified in the purchase

designation and year of issue of this specification and the

order, and such analyses shall conform to the applicable

applicable ASTM material designation.

specified limits for heat analysis, subject to the permitted

variations in product analysis in Specification A6/A6M.

12.2 Identification—Identification markings shall indicate

the designation (year of issue not required) of this specification

9.4 If copper-bearing is specified in the purchase order, the

and the applicable ASTM material designation.

material shall contain at least 0.20 % copper, by heat analysis.

10. Tensile Properties 13. Keywords

10.1 The material as represented by the test specimen shall 13

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.