ASTM D4854-95(2001)

(Guide)Standard Guide for Estimating the Magnitude of Variability from Expected Sources in Sampling Plans (Withdrawn 2009)

Standard Guide for Estimating the Magnitude of Variability from Expected Sources in Sampling Plans (Withdrawn 2009)

SIGNIFICANCE AND USE

This guide is useful in estimating the variation due to lot sampling units, laboratory sampling units, and specimen selection and testing during the sampling and testing of a lot of material.

Estimates of variation from the several sources will make it possible to write sampling plans which balance the cost of sampling and testing with the desired precision of the plan.

This guide is useful in: (1) designing process controls and (2) developing sampling plans as parts of product specifications.

This guide can be used for designing new sampling plans or for improving old plans.

This guide is concerned with the process of sampling. This is unlike Practice D 2904 or Practice D 4467 which are concerned with the process of testing.

Studies based on this guide are applicable only to the material(s) on which the studies are made. If the conclusions are to be used for a specification, then separate studies should be made on three or more kinds of materials of the type on which the test method may be used and which produce test results covering the range of interest.

SCOPE

1.1 This guide serves as an aid to subcommittees in writing specifications and sampling procedures.

1.2 The guide explains how to estimate the contributions of the variability of lot sampling units, laboratory sampling units, and specimens to the variation of the test result of a sampling plan.

1.3 The guide explains how to combine the estimates of the variability from the three sources to obtain an estimate of the variability of the sampling plan results.

1.4 The guide is applicable to all sampling plans that produce variables data (Note 1). It is not applicable to plans that produce attribute data, since such plans do not take specimens in stages, but require that specimens be taken at random from all of the individual items in the lot. Note 0This guide is applicable to all sampling plans that produce variables data regardless of the kind of frequency distribution of these data, because no estimates are made of any probabilities.

1.5 This guide includes the following topics:Topic TitleSectionNumberScope1Referenced Documents2Terminology3Significance and Use4Sampling Plans Producing Variables Data5Reducing Variability of Sampling Results6Keywords 7Analysis of Data Using ANOVAAnnex A1A Numerical ExampleAnnex A2

WITHDRAWN RATIONALE

This guide serves as an aid to subcommittees in writing specifications and sampling procedures.

Formerly under the jurisdiction of Committee D13 on Textiles, this guide was withdrawn in March 2009 because D13 no longer has the expertise to maintain and statistical standards are being maintained by committee E11.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4854 – 95 (Reapproved 2001)

Standard Guide for

Estimating the Magnitude of Variability from Expected

Sources in Sampling Plans

This standard is issued under the fixed designation D4854; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D4271 PracticeforWritingStatementsonSamplinginTest

Methods for Textiles

1.1 This guide serves as an aid to subcommittees in writing

D4467 Practice for InterlaboratoryTesting of aTextileTest

specifications and sampling procedures.

Method that Produces Non-Normally Distributed Data

1.2 The guide explains how to estimate the contributions of

E456 Terminology Relating to Quality and Statistics

the variability of lot sampling units, laboratory sampling units,

2.2 ASTM Adjuncts:

and specimens to the variation of the test result of a sampling

TEX-PAC

plan.

1.3 The guide explains how to combine the estimates of the

NOTE 2—Tex-Pac is a group of PC programs on floppy disks, available

variability from the three sources to obtain an estimate of the throughASTM Headquarters, 100 Barr Harbor Drive, Conshohocken, PA

19428, USA. The calculations described in the annexes of this guide,

variability of the sampling plan results.

including the cost comparisons of various sampling plans, can be

1.4 The guide is applicable to all sampling plans that

conducted using one of these programs.

produce variables data (Note 1). It is not applicable to plans

that produce attribute data, since such plans do not take

3. Terminology

specimens in stages, but require that specimens be taken at

3.1 Definitions:

random from all of the individual items in the lot.

3.1.1 analysis of variance (ANOVA), n—a procedure for

NOTE 1—This guide is applicable to all sampling plans that produce

dividing the total variation of a set of data into two or more

variables data regardless of the kind of frequency distribution of these

parts, one of which estimates the error due to selecting and

data, because no estimates are made of any probabilities.

testing specimens and the other part(s) possible sources of

1.5 This guide includes the following topics:

additional variation.

Section 3.1.2 attribute data, n—observed values or determinations

Topic Title

Number

which indicate the presence or absence of specific character-

Scope 1

istics.

Referenced Documents 2

Terminology 3 3.1.3 component of variance, n—a part of a total variance

Significance and Use 4

identified with a specific source of variability.

Sampling Plans Producing Variables Data 5

3.1.4 degrees of freedom, n—for a set,thenumberofvalues

Reducing Variability of Sampling Results 6

Keywords 7 that can be assigned arbitrarily and still get the same value for

Analysis of Data Using ANOVA Annex A1

each of one or more statistics calculated from the set of data.

A Numerical Example Annex A2

3.1.4.1 Discussion— For example, if only an average is

2. Referenced Documents specifiedforasetoffiveobservations,therearefourdegreesof

freedom since the same average can be obtained with any

2.1 ASTM Standards:

values substituted for four of the observations as long as the

D123 Terminology Relating to Textiles

fifth value is set to give the correct total. If both the average

D2904 Practice for InterlaboratoryTesting of aTextileTest

andstandarddeviationhavebeenspecified,thereareonlythree

Method that Produces Normally Distributed Data

degrees of freedom left.

This guide is under the jurisdiction of ASTM Committee D13 on Textiles and

is the direct responsibility of Subcommittee D13.93 on Statistics. Annual Book of ASTM Standards, Vol 07.02.

Current edition approved May 15, 1995. Published July 1995. Originally Annual Book of ASTM Standards, Vol 14.02.

published as D4854–88. Last previous edition D4854–91. PC programs on floppy disks are available throughASTM. For a 3 ⁄2 inch disk

Annual Book of ASTM Standards, Vol 07.01. request PCN:12-429040-18, for a 5 ⁄4 inch disk request PCN:12-429041-18.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4854

3.1.5 determination value, n—the numerical quantity calcu- 3.1.20 variance, s , n—of a population, a measure of the

lated by means of the test method equation from the measure- dispersion of members of the population expressed as a

ment values obtained as directed in a test method. (Syn. function of the sum of the squared deviations from the

determination) (See also observation.) population mean.

3.1.21 variance, s , n—of a sample, a measure of the

3.1.6 laboratory sample, n—a portion of material taken to

represent the lot sample, or the original material, and used in dispersion of variates observed in a sample expressed as a

function of the squared deviations from the sample average.

the laboratory as a source of test specimens.

3.1.22 For definitions of textile terms, refer to Terminology

3.1.7 lot sample, n—one or more shipping units taken to

represent an acceptance sampling lot and used as a source of D123.Fordefinitionsofstatisticalterms,refertoTerminology

D123 or Terminology E456, or appropriate textbooks on

laboratory samples.

statistics.

3.1.8 mean square—in analysis of variance,acontractionof

the expression “mean of the squared deviations from the

4. Significance and Use

appropriate average(s)” where the divisor of each sum of

squares is the appropriate degrees of freedom.

4.1 Thisguideisusefulinestimatingthevariationduetolot

3.1.9 observation, n—(1) the process of determining the

sampling units, laboratory sampling units, and specimen selec-

presence or absence of attributes or making measurements of a

tion and testing during the sampling and testing of a lot of

variable,(2)aresultoftheprocessofdeterminingthepresence

material.

or absence of an attribute or making a measurement of a

4.2 Estimates of variation from the several sources will

variable. (Compare measurement value, determination value,

makeitpossibletowritesamplingplanswhichbalancethecost

and test result.)

of sampling and testing with the desired precision of the plan.

3.1.10 precision, n—thedegreeofagreementwithinasetof

4.3 This guide is useful in: (1) designing process controls

observations or test results obtained as directed in a method.

and (2) developing sampling plans as parts of product specifi-

3.1.10.1 Discussion—The term “precision,” delimited in

cations.

various ways, is used to describe different aspects of precision.

4.4 This guide can be used for designing new sampling

This usage was chosen in preference to the use of “repeatabil-

plans or for improving old plans.

ity” and “reproducibility” which have been assigned conflict-

4.5 This guide is concerned with the process of sampling.

ing meanings by various authors and standardizing bodies.

This is unlike Practice D2904 or Practice D4467 which are

3.1.11 random sampling, n—the process of selecting units

concerned with the process of testing.

for a sample of size n in such a manner that all combinations

4.6 Studies based on this guide are applicable only to the

of n units under consideration have an equal or ascertainable

material(s) on which the studies are made. If the conclusions

chance of being selected as the sample. (Syn. simple random

are to be used for a specification, then separate studies should

sampling and sampling at random.)

be made on three or more kinds of materials of the type on

3.1.12 sample, n—(1) a portion of a lot of material which is

which the test method may be used and which produce test

taken for testing or record purposes; (2) a group of specimens results covering the range of interest.

used, or observations made, which provide information that

can be used for making statistical inferences about the popu- 5. Sampling Plans Producing Variables Data

lation(s) from which they were drawn. (See also lot sample,

5.1 Fortheresultsofusingthisguidetobecompletelyvalid,

laboratory sample, and specimen.)

it is necessary that all of the sampling units at every stage be

3.1.13 sampling plan, n—a procedure for obtaining a

taken randomly. It is not always practical to achieve complete

sample.

randomness, but every reasonable effort should be made to do

3.1.14 sampling plan result, n—thenumberobtainedforuse

so.

in judging the acceptability of a lot when applying a sampling

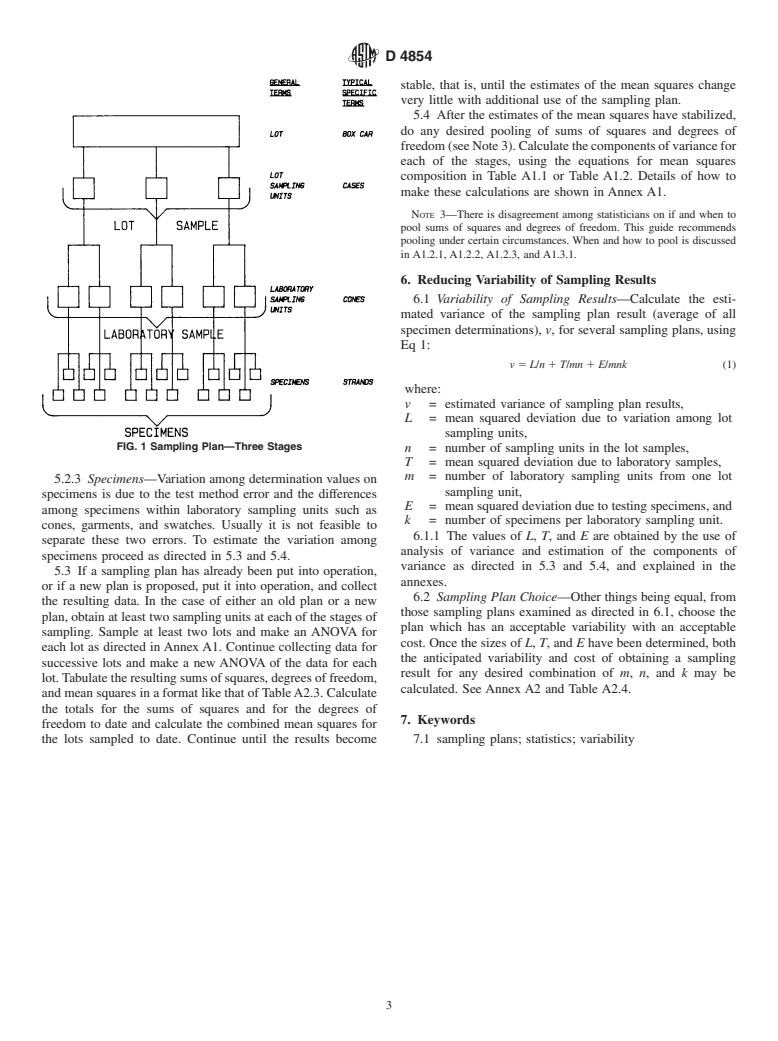

5.2 In sampling plans which produce variables data, there

plan.

are three stages in which variation can occur. For a schematic

3.1.15 sampling unit, n—an identifiable, discrete unit or

representationofthesethreestagesseeFig.1(seealsoPractice

subunit of material that could be taken as part of a sample.

D4271):

3.1.16 specimen, n—a specific portion of a material or

5.2.1 Lot Sample—Variation among the averages of the

laboratory sample upon which a test is performed or which is

sampling units within a lot sample is due to differences

taken for that purpose. (Syn. test specimen.)

between such items as cases, cartons, and bolts, variation

3.1.17 sum of squares—in analysis of variance, a contrac-

among laboratory samples plus test method error and differ-

tion of the expression “sum of the squared deviations from the

ences among specimens. To estimate variation due to lot

appropriateaverage(s)”wheretheaverage(s)ofinterestmaybe

sampling units alone, proceed as directed in 5.3 and 5.4.

the average(s) of a specific subset(s) of data or of the entire set

5.2.2 Laboratory Sample—Within the lot sampling units,

of data.

variation among the averages of the laboratory sampling units

3.1.18 test result, n—a value obtained by applying a test is due to differences among such items as cones within cases,

method, expressed either as a single determination or a

garments within cartons, and swatches within bolts, plus test

specified combination of a number of determinations.

method error and differences among specimens. To estimate

3.1.19 variables data, n—measurements which vary and variation due to laboratory sampling units alone, proceed as

may take any of a specified set of numerical values. directed in 5.3 and 5.4.

D 4854

stable, that is, until the estimates of the mean squares change

very little with additional use of the sampling plan.

5.4 After the estimates of the mean squares have stabilized,

do any desired pooling of sums of squares and degrees of

freedom(seeNote3).Calculatethecomponentsofvariancefor

each of the stages, using the equations for mean squares

composition in Table A1.1 or Table A1.2. Details of how to

make these calculations are shown in Annex A1.

NOTE 3—There is disagreement among statisticians on if and when to

pool sums of squares and degrees of freedom. This guide recommends

pooling under certain circumstances. When and how to pool is discussed

in A1.2.1, A1.2.2, A1.2.3, and A1.3.1.

6. Reducing Variability of Sampling Results

6.1 Variability of Sampling Results—Calculate the esti-

mated variance of the sampling plan result (average of all

specimen determinations), v, for several sampling plans, using

Eq 1:

v 5 L/n 1 T/mn 1 E/mnk (1)

where:

v = estimated variance of sampling plan results,

L = mean squared deviation due to variation among lot

sampling units,

FIG. 1 Sampling Plan—Three Stages

n = number of sampling units in the lot samples,

T = mean squared deviation due to laboratory samples,

m = number of laboratory sampling units from one lot

5.2.3 Specimens—Variation among determination values on

sampling unit,

specimens is due to the test method error and the differences

E = mean squared deviation due to testing specimens, and

among specimens within laboratory sampling units such as

k = number of specimens per laboratory sampling unit.

cones, garments, and swatches. Usually it is not feasible to

6.1.1 The values of L, T, and E are obtained by the use of

separate these two errors. To estimate the variation among

analysis of variance and estimation of the components of

specimens proceed as directed in 5.3 and 5.4.

variance as directed in 5.3 and 5.4, and explained in the

5.3 If a sampling plan has already been put into operation,

annexes.

or if a new plan is proposed, put it into operation, and collect

6.2 Sampling Plan Choice—Other things being equal, from

the resulting data. In the case of either an old plan or a new

those sampling plans examined as directed in 6.1, choose the

plan, obtain at least two sampling units at each of the stages of

plan which has an acceptable variability with an acceptable

sampling. Sample at least two lots and make an ANOVA for

cost. Once the sizes of L, T, and E have been determined, both

each lot as directed inAnnexA1. Continue collecting data for

the anticipated variability and cost of obtaining a sampling

successive lots and make a new ANOVA of the data for each

result for any desired combination of m, n, and k may be

lot.Tabulatetheresultingsumsofsquares,degreesoffreedom,

calculated. See Annex A2 and Table A2.4.

andmeansquaresinaformatlikethatofTableA2.3.Calculate

the totals for the sums of squares and for the degrees of

7. Keywords

freedom to date and calculate the combined mean squares for

the lots sampled to date. Continue until the results become 7.1 sampling plans; statistics; variability

D 4854

ANNEXES

(Mandatory Information)

A1. ANALYSIS OF DATA USING ANOVA

sampling units within the lot sample, laboratory sampling units within the

A1.1 Sampling Stages—Data taken as directed in 5.3 will

laboratory samples within lot samples, and specimens within the labora-

be in three, two, or one stage as follows:

tory sampling units within laboratory samples within lot samples.

A1.1.1 Three-Stage Sampling—For a sampling plan having

A1.2.1 If the estimate of the mean square for lot samples is

distinct sampling units in the lot sample, laboratory samples,

less than or equal to that for laboratory samples, it means that

and specimens, the ANOVA takes the form of lot sampling

all of the variation in lot samples may be explained by the

units with two stages of subsampling (laboratory sampling

variation in laboratory samples. In this case, set L =0, and

units within lot samples and specimens within laboratory

pool the mean squares for lot and laboratory samples to give a

sampling units). See A1.2.

new estimate of the mean square for laboratory samples:

A1.1.2 Two-Stage Sampling—For a sampling plan having

[(2)–(4)]/(mn − 1). Rewrite theANOVAtable, omitting the lot

distinct sampling units in the lot sample, but the laboratory

sample line, replacing the sum of squares for laboratory

sampling units serve as test specimens, the ANOVA takes the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.