ASTM D6770-02e1

(Test Method)Standard Test Method for Abrasion Resistance of Textile Webbing (Hex Bar Method)

Standard Test Method for Abrasion Resistance of Textile Webbing (Hex Bar Method)

SCOPE

1.1 This test method covers the determination of abrasion resistance of textile webbing using a hex bar abrasion tester.

1.1.1 The resistance is expressed as a percentage of retained break strength.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as the standard. Within the text, the inch-pound units are shown in parentheses. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this test method.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

e1

Designation: D 6770 – 02

Standard Test Method for

1

Abrasion Resistance of Textile Webbing (Hex Bar Method)

This standard is issued under the fixed designation D 6770; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

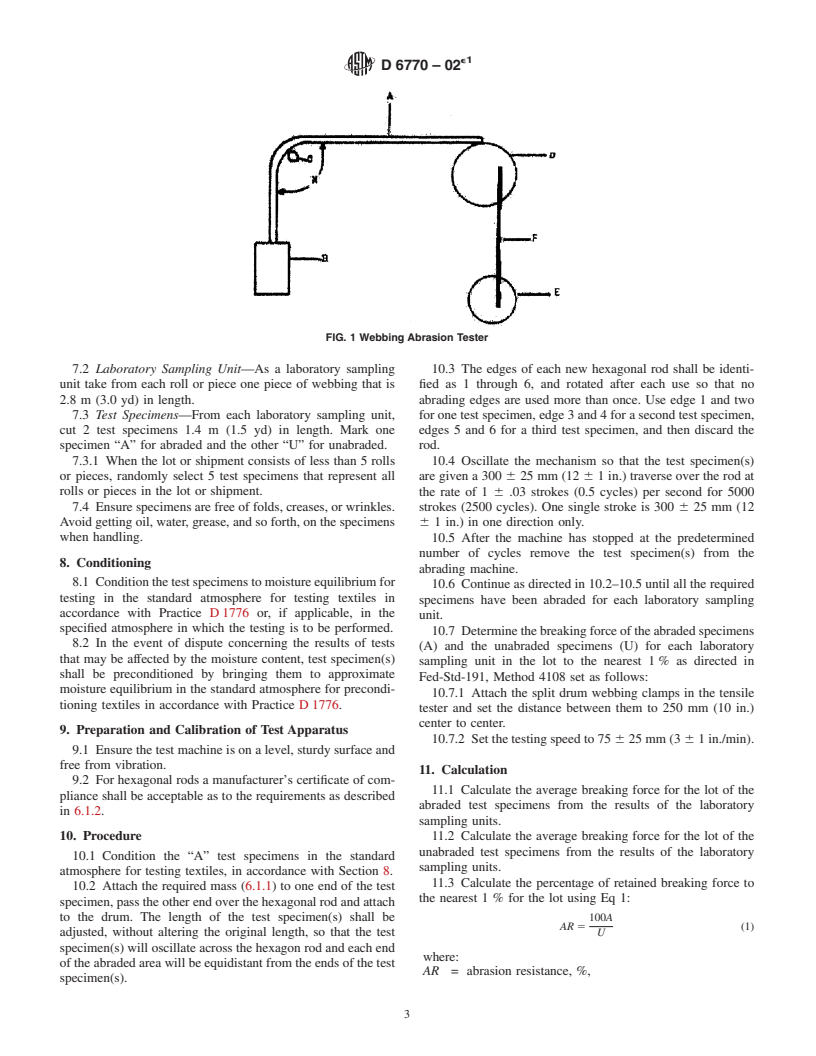

e NOTE—Figure 1 was corrected editorially in May 2002.

1. Scope 3.1.1 abrasion, n—the wearing away of any part of a

material by rubbing against another surface.

1.1 This test method covers the determination of abrasion

3.1.2 abrasion cycle, n—one or more movements of an

resistance of textile webbing using a hex bar abrasion tester.

abradant across a material surface, or the material surface

1.1.1 The resistance is expressed as a percentage of retained

acrosstheabradant,thatpermitsareturntoitsstartingposition.

break strength.

3.1.2.1 Discussion—The abrasion cycle is dependent on the

1.2 The values stated in either SI units or inch-pound units

programmed motions of the abrasion machine and the test

are to be regarded separately as the standard. Within the text,

standard used. It may consist of one back-and-forth unidirec-

the inch-pound units are shown in parentheses. The values

tional movement or one circular movement, or a combination

stated in each system may not be exact equivalents; therefore,

of both. For the hex bar abrasion method a cycle is comprised

each system shall be used independently of the other. Combin-

of two strokes.

ingvaluesfromthetwosystemsmayresultinnonconformance

3.1.3 breaking force, n—the maximum force applied to a

with this test method.

material carried to rupture. (Compare breaking point, breaking

1.3 This standard does not purport to address all of the

strength.)

safety concerns, if any, associated with its use. It is the

3.1.4 standard atmosphere for preconditioning textiles,

responsibility of the user of this standard to establish appro-

n—asetofcontrolledconditionshavingatemperaturenotover

priate safety and health practices and determine the applica-

50°C (122°F), with respective tolerance of 61°C (2°F), and a

bility of regulatory limitations prior to use.

relative humidity of 5 to 25 6 2 % for the selected humidity,

2. Referenced Documents

so that drying can be achieved prior to conditioning in the

standard atmosphere for testing textiles.

2.1 ASTM Standards:

2

3.1.5 standard atmosphere for testing textiles,

D 123 Terminology Relating to Textiles

2

n—laboratoryconditionsfortestingfibers,yarns,andfabricsin

D 1776 Practice for Conditioning and Testing Textiles

which air temperature and relative humidity are maintained at

2.2 Other Standard:

specific levels with established tolerances.

Federal Standard 191, Method 4108 “Strength and Elonga-

3.1.5.1 Discussion—Textile materials are used in a number

tion, Breaking; Textile Webbing, Tape and Braided

3

ofspecificend-useapplicationsthatfrequentlyrequiredifferent

Items”

testing temperatures and relative humidities. Specific condi-

3. Terminology

tioning and testing of textiles for end-product requirements can

be carried out as defined in Practice D 1776.

3.1 Definitions:

3.1.6 stroke, n—in hex bar abrasion testing, one-half of an

abrasion cycle that consists of one forward or one backward

1

motion.

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

and is the direct responsibility of Subcommittee D13.60 on Fabrics, Specific.

3.1.7 webbing, n—in textiles, a stout narrow fabric with a

2 2

Current edition approved Feb. 10, 2002. Published March 2002.

massperunitareaofatleast0.5kg/m (0.1lb/ft )foreach25.4

2

Annual Book of ASTM Standards, Vol 07.01.

3 mm (1 in.) of width. (Compare narrow fabric, ribbon, and

Available from Superintendent of Documents, Government Printing Office,

Washington, DC 20402. tape.)

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

e1

D6770–02

3.2 For definitions of other textile terms used in this test tive tests should be performed to determine if there is a

method, refer to Terminology D 123. statistical bias between them, using competent statistical assis-

tance. As a minimum, use samples for such comparative tests

4. Summary of Test Method

thatareashomogenousaspossible,drawnfromthesamelotof

4.1 Abrasion resistance is measured by subjecting the speci-

material as the samples that resulted in disparate results during

men to unidirectional reciprocal rubbing over a specific bar

initial testing, and randomly assigned in equal numbers to each

under specified conditions of tension, stroke length and time.

laboratory. The test results from the laboratories involved

Resistance to abrasion is evaluated by determining the percent

should be compared using a statistical test for unpaired data, as

retention of breaking

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.