ASTM F838-05(2013)

(Test Method)Standard Test Method for Determining Bacterial Retention of Membrane Filters Utilized for Liquid Filtration

Standard Test Method for Determining Bacterial Retention of Membrane Filters Utilized for Liquid Filtration

SIGNIFICANCE AND USE

5.1 Since all sterilizing filtration processes are performed under positive pressure, this test method is designed to assess the retentivity of a sterilizing filter under process conditions.

5.1.1 A challenge of 107 bacteria per cm2 of effective filtration area is orders of magnitude higher than one would expect to encounter in a sterilizing filtration process. This level was selected in order to provide a high degree of assurance that the filter would quantitatively retain large numbers of organisms. This concept is important, in view of the requirement to provide a quantitative assessment in validating a sterilization process.

5.1.2 The analytical procedure utilized in this test method provides a method to assign a numerical value to the filtration efficiency of the filter being evaluated. This value, coupled with a knowledge of the number and types of organisms (bioburden) indigenous to the process, may then be utilized to determine the probability of obtaining a sterile filtrate. Conversely, the numerical value of the filtration efficiency may be used when one must meet a specified probability of sterility assurance to calculate the volume of fluid that may be filtered in order to maintain that level of assurance.

SCOPE

1.1 This test method determines the bacterial retention characteristics of membrane filters for liquid filtration using Pseudomonas diminuta as the challenge organism. This test method may be employed to evaluate any membrane filter system used for liquid sterilization.

1.2 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F838 − 05(Reapproved 2013)

Standard Test Method for

Determining Bacterial Retention of Membrane Filters

Utilized for Liquid Filtration

ThisstandardisissuedunderthefixeddesignationF838;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope filer disc which is subsequently incubated on a solidified

growth medium. Organisms that are not retained by the filter

1.1 This test method determines the bacterial retention

being tested will develop into visible colonies on the analysis

characteristics of membrane filters for liquid filtration using

membrane and can then be enumerated.

Pseudomonas diminuta as the challenge organism. This test

method may be employed to evaluate any membrane filter

5. Significance and Use

system used for liquid sterilization.

5.1 Since all sterilizing filtration processes are performed

1.2 This standard may involve hazardous materials,

under positive pressure, this test method is designed to assess

operations, and equipment. This standard does not purport to

the retentivity of a sterilizing filter under process conditions.

address all of the safety concerns, if any, associated with its 7 2

5.1.1 A challenge of 10 bacteria per cm of effective

use. It is the responsibility of the user of this standard to

filtration area is orders of magnitude higher than one would

establish appropriate safety and health practices and deter-

expecttoencounterinasterilizingfiltrationprocess.Thislevel

mine the applicability of regulatory limitations prior to use.

wasselectedinordertoprovideahighdegreeofassurancethat

the filter would quantitatively retain large numbers of organ-

2. Referenced Documents

isms. This concept is important, in view of the requirement to

2.1 ASTM Standards:

provide a quantitative assessment in validating a sterilization

D1193Specification for Reagent Water

process.

5.1.2 The analytical procedure utilized in this test method

3. Terminology

provides a method to assign a numerical value to the filtration

3.1 Definitions:

efficiency of the filter being evaluated. This value, coupled

3.1.1 log reduction value—the logarithm to the base 10 of

with a knowledge of the number and types of organisms

the ratio of the number of microorganisms in the challenge to

(bioburden) indigenous to the process, may then be utilized to

the number of organisms in the filtrate.

determine the probability of obtaining a sterile filtrate.

Conversely,thenumericalvalueofthefiltrationefficiencymay

4. Summary of Test Method

be used when one must meet a specified probability of sterility

4.1 After sterilization, the test filter is challenged with a

assurance to calculate the volume of fluid that may be filtered

suspension of Pseudomonas diminuta (ATCC 19146) at a

in order to maintain that level of assurance.

7 2

concentration of 10 organisms per cm of effective filtration

6. Apparatus

area (EFA) at a maximum differential pressure across the test

filterof30psig(206kPa)andaflowrateof0.5to1.0GPMper

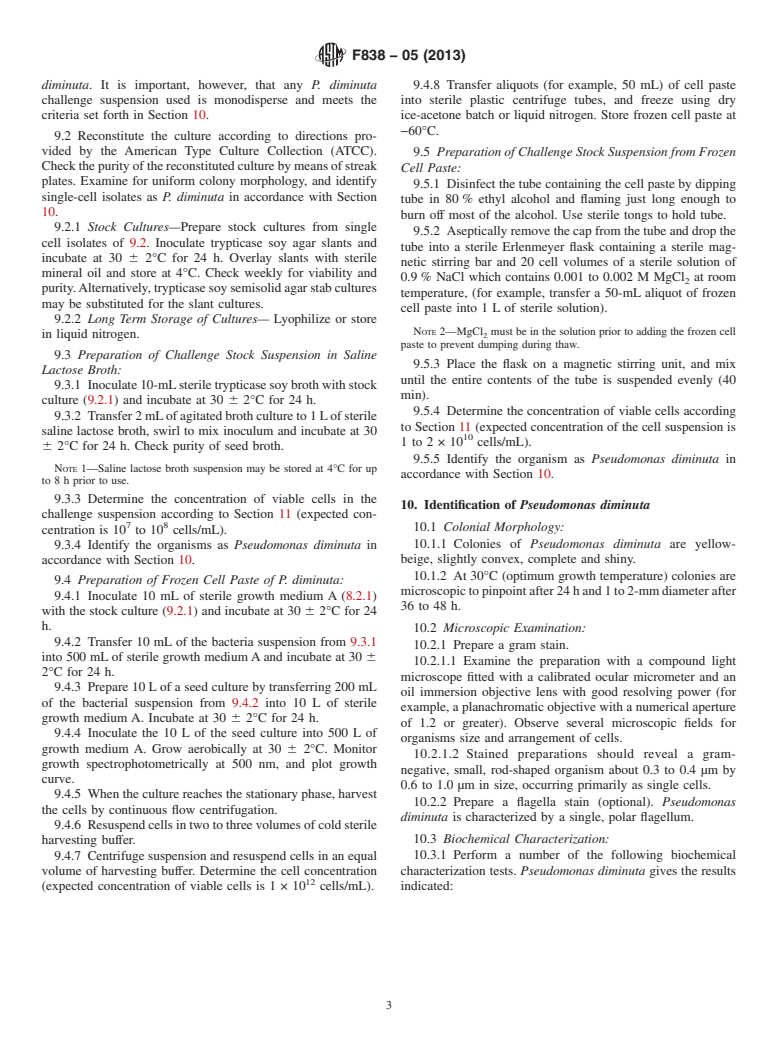

6.1 Assemble the apparatus described below as in Fig. 1:

2 -3 2

ft of effective filtration area (2 to4×10 LPM per cm ).The

6.1.1 Stainless Steel Pressure Vessel, 12-L capacity (or

entire filtrate is then filtered through an analytical membrane

larger), fitted witha0to 50-psi (0 to 350-kPa) pressure gage.

6.1.2 Air Regulator.

6.1.3 142-mm Disc Filter Assemblies, two or more, with

This test method is under the jurisdiction of ASTM Committee E55 on

hose connections.

ManufactureofPharmaceuticalProductsandisthedirectresponsibilityofSubcom-

mittee E55.03 on General Pharmaceutical Standards.

6.1.4 Diaphragm-Protected 0 to 50-psi Pressure Gage (0 to

Current edition approved June 1, 2013. Published June 2013. Originally

350-kPa), for upstream pressure reading. A second equivalent

approved in 1983. Last previous edition published in 2005 as F838–05. DOI:

gauge for downstream pressure reading is optional.

10.1520/F0838-05R13.

6.1.5 Manifold,withvalves(autoclavable)andhoseconnec-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tions.

Standards volume information, refer to the standard’s Document Summary page on

6.1.6 Autoclavable Tubing, (must be able to withstand a

the ASTM website.

pressure of 50 psi (350 kPa)).

Available from American Type Culture Collection (ATCC), 10801 University

Boulevard, Manassas, VA 20110, http://www.atcc.org. 6.1.7 Filter Housing, with hose connections.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F838 − 05 (2013)

FIG. 1 Test Set-Up for Bacteria Retention Testing

6.1.8 Hose Clamps. 8.2.1 Growth Medium A—Dissolve in water and dilute to 1

6.1.9 Incubator, 30 6 2°C. L. Autoclave at 121°C for 15 min (pH 6.8 to 7.0).

6.1.10 Laminar Flow Bench.

Trypticase Peptone (or Casitone) 7.5 g

6.1.11 Smooth-Tip Forceps. Yeast Extract 2.5 g

Sodium Chloride (NaCl) 0.5 g

Magnesium Sulfate (MgSO ·3H O) 0.35 g

4 2

7. Purity of Reagents and Materials

8.2.2 Harvesting Buffer—Dissolve 0.790 g of monobasic

7.1 Purity of Reagents—Reagent grade chemicals shall be

potassium phosphate (KH PO)and1.0gofK HPO in 100

2 4 2 4

used. Unless otherwise indicated, all reagents shall conform to

mL of glycerol (C H O ). Adjust to pH 7.2 with 0.1 N

3 8 3

the specifications of the American Chemical Society, where

potassium hydroxide solution. Dilute to 1 L with water and

such specifications are available.

sterilize at 121°C for 15 min.

7.2 Purity of Water—Unless otherwise indicated, references

8.2.3 Potassium Hydroxide Solution (0.1 N)—Dissolve 5.61

to water shall mean reagent water, Type IV as defined in

g of potassium hydroxide (KOH) in water and dilute to 1 Lin

Specification D1193.

a volumetric flask.

7.2.1 Additionally, any water used in this test method must

8.2.4 Trypticase Soy Agar—Prepare according to manufac-

conformtotherequirementsfornon-bacteriostaticwaterspeci-

turer’s instructions.

fied in the current edition of Standard Methods for the

8.2.5 Trypticase Soy Broth—Prepare according to manufac-

Examination of Water and Wastewater.

turer’s instructions.

8.3 Analytical Reagents and Materials:

8. Reagents and Materials

8.3.1 M-Plate Count Agar—Prepare according to manufac-

8.1 Saline Lactose Broth Medium:

turer’s instructions.

8.1.1 Lactose Broth—Dissolve 1.3 g of dehydrated lactose

8.3.2 Peptone Water (1 g/L)—Dissolvethepeptoneinwater.

broth medium in 100 mL of water.

Dispense suitable volumes, for preparing decimal dilutions,

8.1.2 Sodium Chloride Solution—Dissolve 7.6 g of sodium

into screw-cap containers. Autoclave at 121°C for 15 min.

chloride (NaCl) in 970 mL of water in a 2-L flask with an

appropriate closure.

8.4 Pseudomonas diminuta (ATCC 19146).

8.1.3 Add 30 mL of lactose broth (8.1.1) to 970 mL of

8.5 Analytical Membrane Filters, 142-mm diameter, 0.45

sodium chloride solution. Autoclave at 121°C for 15 min.

µm pore size, 130 to 160 µm thick.

8.2 Frozen Cell Paste Method:

8.6 Petri Dishes, 150-mm diameter.

Reagent Chemicals, American Chemical Society Specifications, American

9. Methods for Preparation of Bacterial Challenge Stock

Chemical Society, Washington, DC, www.chemistry.org. For suggestions on the

Suspension

testing of reagents not listed by the American Chemical Society, see Analar

Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the

9.1 General—The following two methods have been used

United States Pharmacopeia and National Formulary, U.S. Pharmacopeial

extensively for the preparation of P. diminuta challenge sus-

Convention, Inc. (USPC), Rockville, MD, http://www.usp.org.

pensions. The presentation of these methods is not meant to

Available from theAmerican Public HealthAssociation (APHA), 800 I Street,

NW, Washington, DC 20001-3710, http://www.apha.org. exclude other equally valid methods for the preparation of P.

F838 − 05 (2013)

diminuta. It is important, however, that any P. diminuta 9.4.8 Transfer aliquots (for example, 50 mL) of cell paste

challenge suspension used is monodisperse and meets the into sterile plastic centrifuge tubes, and freeze using dry

criteria set forth in Section 10. ice-acetone batch or liquid nitrogen. Store frozen cell paste at

−60°C.

9.2 Reconstitute the culture according to directions pro-

vided by the American Type Culture Collection (ATCC).

9.5 Preparation of Challenge Stock Suspension from Frozen

Checkthepurityofthereconstitutedculturebymeansofstreak

Cell Paste:

plates. Examine for uniform colony morphology, and identify

9.5.1 Disinfect the tube containing the cell paste by dipping

single-cell isolates as P. diminuta in accordance with Section

tube in 80% ethyl alcohol and flaming just long enough to

10.

burn off most of the alcohol. Use sterile tongs to hold tube.

9.2.1 Stock Cultures—Prepare stock cultures from single

9.5.2 Asepticallyremovethecapfromthetubeanddropthe

cell isolates of 9.2. Inoculate trypticase soy agar slants and

tube into a sterile Erlenmeyer flask containing a sterile mag-

incubate at 30 6 2°C for 24 h. Overlay slants with sterile

netic stirring bar and 20 cell volumes of a sterile solution of

mineral oil and store at 4°C. Check weekly for viability and

0.9% NaCl which contains 0.001 to 0.002 M MgCl at room

purity.Alternatively,trypticasesoysemisolidagarstabcultures

temperature, (for example, transfer a 50-mL aliquot of frozen

may be substituted for the slant cultures.

cell paste into 1 L of sterile solution).

9.2.2 Long Term Storage of Cultures— Lyophilize or store

NOTE 2—MgCl must be in the solution prior to adding the frozen cell

in liquid nitrogen.

paste to prevent dumping during thaw.

9.3 Preparation of Challenge Stock Suspension in Saline

9.5.3 Place the flask on a magnetic stirring unit, and mix

Lactose Broth:

until the entire contents of the tube is suspended evenly (40

9.3.1 Inoculate10-mLsteriletrypticasesoybrothwithstock

min).

culture (9.2.1) and incubate at 30 6 2°C for 24 h.

9.5.4 Determine the concentration of viable cells according

9.3.2 Transfer2mLofagitatedbrothcultureto1Lofsterile

to Section 11 (expected concentration of the cell suspension is

saline lactose broth, swirl to mix inoculum and incubate at 30

1to2×10 cells/mL).

6 2°C for 24 h. Check purity of seed broth.

9.5.5 Identify the organism as Pseudomonas diminuta in

NOTE 1—Saline lactose broth suspension may be stored at 4°C for up

accordance with Section 10.

to 8 h prior to use.

9.3.3 Determine the concentration of viable cells in the

10. Identification of Pseudomonas diminuta

challenge suspension according to Section 11 (expected con-

7 8

10.1 Colonial Morphology:

centration is 10 to 10 cells/mL).

10.1.1 Colonies of Pseudomonas diminuta are yellow-

9.3.4 Identify the organisms as Pseudomonas diminuta in

beige, slightly convex, complete and shiny.

accordance with Section 10.

10.1.2 At 30°C (optimum growth temperature) colonies are

9.4 Preparation of Frozen Cell Paste of P. diminuta:

microscopictopinpointafter24hand1to2-mmdiameterafter

9.4.1 Inoculate 10 mL of sterile growth medium A (8.2.1)

36 to 48 h.

with the stock culture (9.2.1) and incubate at 30 6 2°C for 24

h.

10.2 Microscopic Examination:

9.4.2 Transfer 10 mL of the bacteria suspension from 9.3.1

10.2.1 Prepare a gram stain.

into 500 mLof sterile growth mediumAand incubate at 30 6

10.2.1.1 Examine the preparation with a compound light

2°C for 24 h.

microscope fitted with a calibrated ocular micrometer and an

9.4.3 Prepare 10 Lof a seed culture by transferring 200 mL

oil immersion objective lens with good resolving power (for

of the bacterial suspension from 9.4.2 into 10 L of sterile

example,aplanachromaticobjectivewithanumericalaperture

growth medium A. Incubate at 30 6 2°C for 24 h.

of 1.2 or greater). Observe several microscopic fields for

9.4.4 Inoculate the 10 L of the seed culture into 500 L of

organisms size and arrangement of cells.

growth medium A. Grow aerobically at 30 6 2°C. Monitor

10.2.1.2 Stained preparations should reveal a gram-

growth spectrophotometrically at 500 nm, and plot growth

negative, small, rod-shaped organism about 0.3 to 0.4 µm by

curve.

0.6 to 1.0 µm in size, occurring primarily as single cells.

9.4.5 Whentheculturereachesthestationaryphase,harvest

10.2.2 Prepare a flagella stain (optional). Pseudomonas

the cells by continuous flow centrifugation.

diminuta is characterized by a single, polar flagellum.

9.4.6 Resuspendcellsintwotothreevolumesofcoldsterile

10.3 Biochemical Characterization:

harvesting buffer.

9.4.7 Centrifuge suspension and resuspend cells in an equal 10.3.1 Perform a number of the following biochemical

volume of harvesting buffer. Determine the cell concentration characterization tests. Pseudomonas diminuta gives the results

(expected concentration of viable cells is1×10 cells/mL). indicated:

F838 − 05 (2013)

12. Equipment Preparation

P. diminuta

Test

(ATCC 19146)

12.1 Install the filter to be tested in the housing. Wrap the

Spore formation – inlet and outlet connections with autoclave paper, and auto-

OF glucose medium, open –

clave according to manufacturer’s instruction. Alternatively,

OF glucose medium, sealed –

the test filter may be in-situ steam sterilized according to

OF ethanol (3 %) medium, open +

OF ethanol (3 %) medium, sealed –

manufacturer’sinstructions.Thesterilizationprocedureshould

Indole –

be validated using biological indicators or thermocouples.

Methyl red –

12.1.1 Aseptically perform an integrity test on the filter

Acetylmethylcarbionol –

Gelatinase –

using an appropriate procedure recommended by the filter

Aerobe +

manufacturer.

Catalase +

Cytochrome (Indophenol) oxidase +

12.2 Assemble analysis filter membranes in filter assem-

Growth on MacConkey agar +

blies.Attachautoclavabletubing(1to2ft)toinletsandoutlets.

Dentrification +

Wrap hose ends with single layer of autoclavable paper.

DNAase (BBL DNase Test agar or –

equivalent)

Autoclave in accordance with manufacturer’s instructions

Centrimide tolerance –

usually 30 to 45 min at 15 psi (103 kPa) and 121°C.

12.3 Wrapmanifoldandconnectinghose(valvesmustbein

11. Preparation of Bacterial Challenge Suspension

open position) in autoclave paper and autoclave.Alternatively,

11.1 Determine by direct microscopic count the bacterial

themanifoldmaybeconnectedtothetestfilterassemblyoutlet

titre of the suspension. This will determine the total number,

and autoclaved or in-situ steam sterilized simultaneously. This

viable and nonviable, cells present.

will eliminate one aseptic connection downstream prior to

t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.