ASTM D4301-05(2019)

(Test Method)Standard Test Method for Total Chlorine in Epoxy Resins and Compounds

Standard Test Method for Total Chlorine in Epoxy Resins and Compounds

SIGNIFICANCE AND USE

5.1 The presence of residual chlorine in epoxy resins is deleterious to final product properties. This test method has been found to be applicable to resins or ethers with chlorine contents ranging from 50 ppm to 35 % by weight. Other halogen compounds react with the reagent but are distinguished from chlorine by the final potentiometric titration. Epoxy and other functional groups will consume reagent but do not affect the results.

SCOPE

1.1 This test method describes a procedure for the determination of total chlorine in epoxy resins and glycidyl ethers.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 8.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

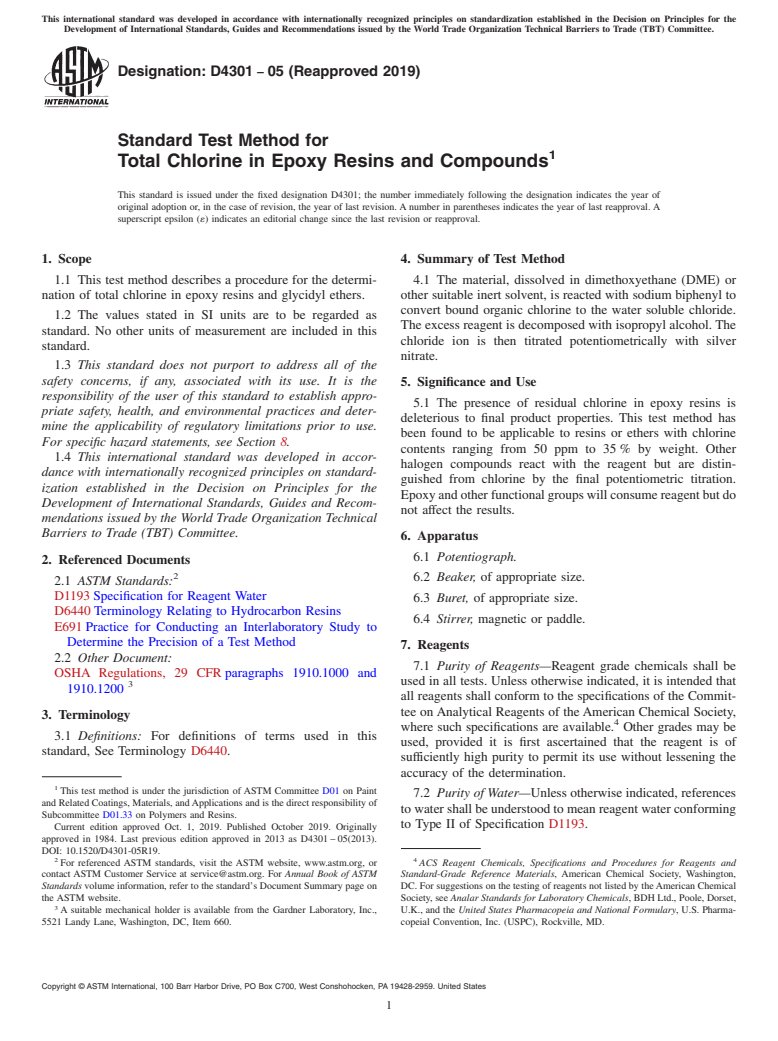

Designation: D4301 − 05 (Reapproved 2019)

Standard Test Method for

Total Chlorine in Epoxy Resins and Compounds

This standard is issued under the fixed designation D4301; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This test method describes a procedure for the determi- 4.1 The material, dissolved in dimethoxyethane (DME) or

nation of total chlorine in epoxy resins and glycidyl ethers. other suitable inert solvent, is reacted with sodium biphenyl to

convert bound organic chlorine to the water soluble chloride.

1.2 The values stated in SI units are to be regarded as

The excess reagent is decomposed with isopropyl alcohol. The

standard. No other units of measurement are included in this

chloride ion is then titrated potentiometrically with silver

standard.

nitrate.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 The presence of residual chlorine in epoxy resins is

priate safety, health, and environmental practices and deter-

deleterious to final product properties. This test method has

mine the applicability of regulatory limitations prior to use.

been found to be applicable to resins or ethers with chlorine

For specific hazard statements, see Section 8.

contents ranging from 50 ppm to 35 % by weight. Other

1.4 This international standard was developed in accor-

halogen compounds react with the reagent but are distin-

dance with internationally recognized principles on standard-

guished from chlorine by the final potentiometric titration.

ization established in the Decision on Principles for the

Epoxyandotherfunctionalgroupswillconsumereagentbutdo

Development of International Standards, Guides and Recom-

not affect the results.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

6. Apparatus

6.1 Potentiograph.

2. Referenced Documents

6.2 Beaker, of appropriate size.

2.1 ASTM Standards:

D1193 Specification for Reagent Water

6.3 Buret, of appropriate size.

D6440 Terminology Relating to Hydrocarbon Resins

6.4 Stirrer, magnetic or paddle.

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

7. Reagents

2.2 Other Document:

7.1 Purity of Reagents—Reagent grade chemicals shall be

OSHA Regulations, 29 CFR paragraphs 1910.1000 and

used in all tests. Unless otherwise indicated, it is intended that

1910.1200

all reagents shall conform to the specifications of the Commit-

tee onAnalytical Reagents of theAmerican Chemical Society,

3. Terminology

where such specifications are available. Other grades may be

3.1 Definitions: For definitions of terms used in this

used, provided it is first ascertained that the reagent is of

standard, See Terminology D6440.

sufficiently high purity to permit its use without lessening the

accuracy of the determination.

This test method is under the jurisdiction of ASTM Committee D01 on Paint

7.2 Purity of Water—Unless otherwise indicated, references

and Related Coatings, Materials, andApplications and is the direct responsibility of

towatershallbeunderstoodtomeanreagentwaterconforming

Subcommittee D01.33 on Polymers and Resins.

to Type II of Specification D1193.

Current edition approved Oct. 1, 2019. Published October 2019. Originally

approved in 1984. Last previous edition approved in 2013 as D4301 – 05(2013).

DOI: 10.1520/D4301-05R19.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or ACS Reagent Chemicals, Specifications and Procedures for Reagents and

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standard-Grade Reference Materials, American Chemical Society, Washington,

Standards volume information, refer to the standard’s Document Summary page on DC. For suggestions on the testing of reagents not listed by theAmerican Chemical

the ASTM website. Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset,

A suitable mechanical holder is available from the Gardner Laboratory, Inc., U.K., and the United States Pharmacopeia and National Formulary, U.S. Pharma-

5521 Landy Lane, Washington, DC, Item 660. copeial Convention, Inc. (USPC), Rockville, MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4301 − 05 (2019)

7.3 Sodium Biphenyl Reagent —(in ether solution). AgNO and for high chlorine

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.