ASTM D1259-06(2018)

(Test Method)Standard Test Methods for Nonvolatile Content of Resin Solutions

Standard Test Methods for Nonvolatile Content of Resin Solutions

SIGNIFICANCE AND USE

3.1 The nonvolatile content of resin solutions is useful to coatings producers and users for the determination of the total solids available for film formation and for the estimation of the volatile organic content.

SCOPE

1.1 These test methods cover the determination of nonvolatile content of solutions of resins in volatile organic solvents.

1.2 Two test methods are included as follows:

1.2.1 Test Method A—For solutions of non-heat-reactive resins. These solutions contain resins that remain stable and release the solvent under conditions of the test. Examples are ester gums and alkyds.

1.2.2 Test Method B—For two types of solutions:

1.2.2.1 Solutions of heat-reactive resins. These solutions contain resins that undergo condensation or other reactions under the influence of heat. Examples include the formaldehyde reaction products of urea, melamine, and phenols.

1.2.2.2 Solutions that release solvent slowly. Examples include epoxy resin solutions.

1.3 Test Methods A and B differ primarily in the drying times and types of oven used.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1259 − 06 (Reapproved 2018)

Standard Test Methods for

Nonvolatile Content of Resin Solutions

This standard is issued under the fixed designation D1259; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope of aluminum or tin foil. The coated foil sheets are separated

and then dried. The weight of residue is determined and the

1.1 These test methods cover the determination of nonvola-

nonvolatile content is calculated. The test method is unique in

tile content of solutions of resins in volatile organic solvents.

that it provides for drying of a very thin film of resin, thus

1.2 Two test methods are included as follows:

minimizing chances for volatiles to be trapped and held during

1.2.1 Test Method A—For solutions of non-heat-reactive

the heating operation.

resins. These solutions contain resins that remain stable and

2.2 Either a gravity-convection or a forced-ventilation oven

release the solvent under conditions of the test. Examples are

and a 30-min heating period at 105°C are used in Test Method

ester gums and alkyds.

A.

1.2.2 Test Method B—For two types of solutions:

1.2.2.1 Solutions of heat-reactive resins. These solutions 2.3 A forced-ventilation oven and a 2-h heating period at

contain resins that undergo condensation or other reactions

105°C are used in Test Method B.

under the influence of heat. Examples include the formalde-

3. Significance and Use

hyde reaction products of urea, melamine, and phenols.

1.2.2.2 Solutions that release solvent slowly. Examples

3.1 The nonvolatile content of resin solutions is useful to

include epoxy resin solutions.

coatings producers and users for the determination of the total

solids available for film formation and for the estimation of the

1.3 Test Methods A and B differ primarily in the drying

volatile organic content.

times and types of oven used.

1.4 The values stated in SI units are to be regarded as the

TEST METHOD A—NON-HEAT-REACTIVE RESIN

standard. The values given in parentheses are for information

SOLUTIONS

only.

4. Apparatus

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4.1 Ovens:

responsibility of the user of this standard to establish appro- 4.1.1 Gravity-convection type, maintained at 105 6 2°C,

priate safety, health, and environmental practices and deter- with vents open.

mine the applicability of regulatory limitations prior to use. 4.1.2 Forced-ventilation type, maintained at 105 6 2°C. For

1.6 This international standard was developed in accor- ovens with adjustable air flow rate, set the control damper at

dance with internationally recognized principles on standard- 50 %.

ization established in the Decision on Principles for the

4.2 Aluminum or Tin Foil, from 38 to 50 µm (0.0015 to

Development of International Standards, Guides and Recom-

0.0020 in.) in thickness. Either one piece 150 by 300 mm (6 by

mendations issued by the World Trade Organization Technical

12 in.), or two 150 by 150-mm (6 by 6-in.) pieces may be used.

Barriers to Trade (TBT) Committee.

The foil must be perfectly smooth; if it becomes wrinkled

during the initial handling, roll smooth as directed in 5.2.

2. Summary of Test Methods

4.3 PlateGlass—Twopiecesabout5mm( ⁄16in.)thick;one

2.1 In both test methods, a weighed specimen of resin

1 1

piece140by140mm(5 ⁄2by5 ⁄2in.)andonepiece180by180

solution is spread under pressure between two weighed sheets

mm (7 by 7 in.).

These test methods are under the jurisdiction of ASTM Committee D01 on

4.4 Device for Weighing Specimens —Apparatus that will

Paint and Related Coatings, Materials, and Applications and are the direct

prevent loss of volatile matter during the weighing operation

responsibility of Subcommittee D01.21 on Chemical Analysis of Paints and Paint

such as any of the following, or equivalent:

Materials.

Current edition approved June 1, 2018. Published June 2018. Originally

approved in 1953. Last previous edition approved in 2012 as D1259 – 06 (2012).

DOI: 10.1520/D1259-06R18. The bulb pipet is available from most scientific supply houses.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1259 − 06 (2018)

4.4.1 Syringe, Luer, 2 or 5-mL capacity, into a thin film, about 75 mm (3 in.) in diameter. The pressure

4.4.2 Weighing Buret, Smith, 10-mL capacity, or that must be exerted depends on the viscosity of the sample. In

4.4.3 Bulb Pipet, dropping, with 50-mL Erlenmeyer flask. case a specimen of low viscosity should extend beyond the

edge of the foil, repeat the determination, allowing a few

4.5 Roller, for Smoothing Foil—Use a ground and polished

minutes for a portion of the solvent to evaporate from the

cylinder, preferably stainless steel, approximately 7 in. (180

weighed specimen before covering and pressing it.

mm) long and 2 in. (50 mm) in diameter.

5.3 After pressing, open the foil to its full length and place

4.6 Foil Trays, two types as follows:

it in the foil tray. Place the tray in either a gravity-convection

4.6.1 Trays measuring 165 by 300 mm (6 ⁄2 by 12 in.) , for

or a forced-ventilation oven at 105 6 2°C for 30 min.

use with (6 by 12-in.) foil, constructed from No. 22-gauge

0.6–mmaluminumsheetinaccordancewithdimensionsshown 5.4 Remove the tray from the oven and then carefully

in Fig. 1. Several trays may be stacked in the oven to permit remove the foil sheet from the tray. Return the dried film

running several specimens simultaneously. surfaces to the face-to-face position. While the foil is still

1 1

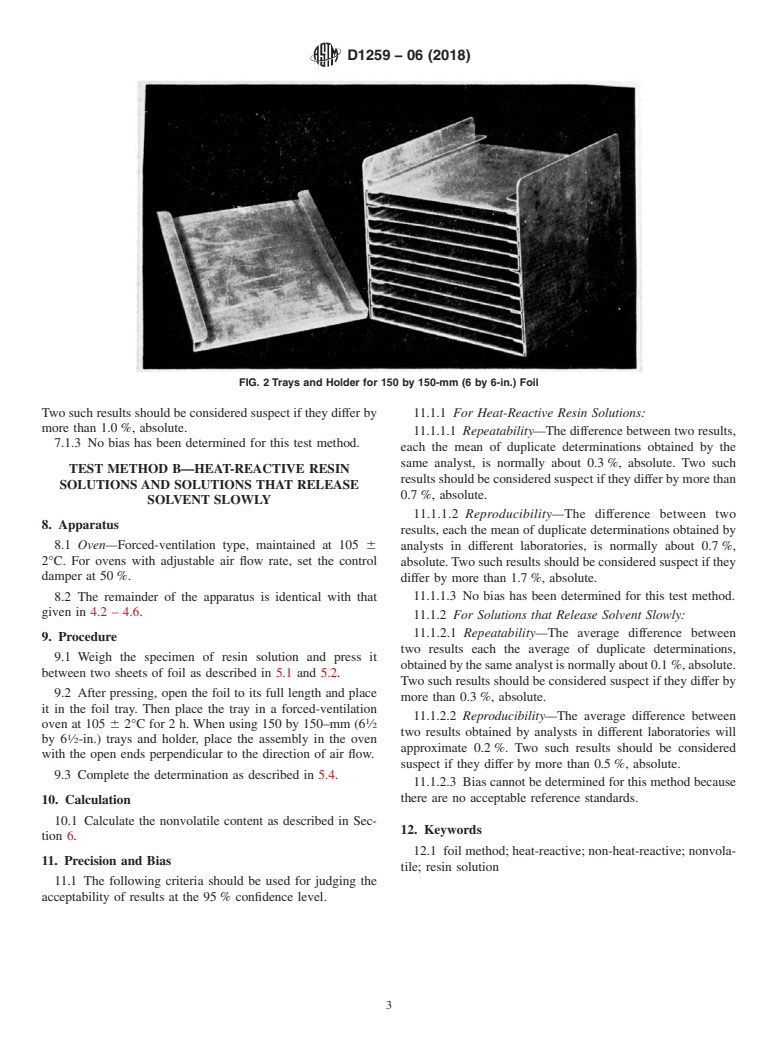

4.6.2 Trays measuring 165 by 165 mm (6 ⁄2 by 6 ⁄2 in.), for warm, fold the edges together to enclose completely the dried

usewith(6by6-in.)f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.