ASTM A805-93(1998)

(Specification)Standard Specification for Steel, Flat Wire, Carbon, Cold-Rolled

Standard Specification for Steel, Flat Wire, Carbon, Cold-Rolled

SCOPE

1.1 This specification covers carbon steel flat wire in coils or cut lengths. Flat wire is classified as a cold-rolled section, rectangular in shape, 0.500 in. (12.7 mm) or less in width and under 0.250 in. (6.35 mm) in thickness.

1.2 Low-carbon steel flat wire is produced from steel compositions with a maximum carbon content of 0.25% by cast or heat analysis.

1.3 Carbon spring steel flat wire is produced to a carbon range in which the specified or required maximum is over 0.25% by cast or heat analysis.

1.3.1 Two types of carbon spring steel flat wire are produced:

1.3.1.1 Untempered cold-rolled carbon spring steel flat wire, produced to several desirable combinations of properties and

1.3.1.2 Hardened and tempered carbon spring steel wire.

1.4 Definite application flat wire is a product developed for a specific application and may be specified only by size and descriptive name.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact

ASTM International (www.astm.org) for the latest information.

Designation: A 805 – 93 (Reapproved 1998)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Steel, Flat Wire, Carbon, Cold-Rolled

This standard is issued under the fixed designation A 805; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.3 Federal Standard:

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

1.1 This specification covers carbon steel flat wire in coils

2.4 SAE Standard:

or cut lengths. Flat wire is classified as a cold-rolled section,

Recommended Practice SAEJ 419 Methods of Measuring

rectangular in shape, 0.500 in. (12.7 mm) or less in width and

Decarburization

under 0.250 in. (6.35 mm) in thickness.

1.2 Low-carbon steel flat wire is produced from steel

3. Terminology

compositions with a maximum carbon content of 0.25 % by

3.1 Definitions of Terms Specific to This Standard: Descrip-

cast or heat analysis.

tions of Terms Specific to This Standard:

1.3 Carbon spring steel flat wire is produced to a carbon

3.1.1 annealing—the process of heating to and holding at a

range in which the specified or required maximum is over

suitable temperature and then cooling at a suitable rate, for

0.25 % by cast or heat analysis.

such purposes as reducing hardness, facilitating cold working,

1.3.1 Two types of carbon spring steel flat wire are pro-

producing a desired microstructure, or obtaining desired me-

duced:

chanical, physical, or other properties.

1.3.1.1 Untempered cold-rolled carbon spring steel flat

3.1.2 batch annealing—annealing that is generally per-

wire, produced to several desirable combinations of properties

formed in large cylindrical bell type or large rectangular box or

and

car-type furnaces. The product is protected from scaling and

1.3.1.2 Hardened and tempered carbon spring steel wire.

decarburization by the use of a controlled atmosphere that

1.4 Definite application flat wire is a product developed for

envelops the charge in an inner chamber sealed to prevent the

a specific application and may be specified only by size and

influx of air or products of combustion. The coils

descriptive name.

or bundles are heated to a temperature in the vicinity of the

2. Referenced Documents lower critical temperature for the grade of steel, and held at that

temperature for a definite length of time; after which the steel

2.1 ASTM Standards:

is allowed to cool slowly to room temperature. The time of

A 370 Test Methods and Definitions for Mechanical Testing

holding at the annealing temperature varies with the grade of

of Steel Products

the steel and the desired degree of softness.

A 510 Specification for General Requirements for Wire

3.1.3 continuous or strand annealing—annealing that con-

Rods and Coarse Round Wire, Carbon Steel

sists of passing a number of individual strands of flat wire

A 751 Test Methods, Practices and Terminology for Chemi-

continuously through either a muffle furnace or a bath of

cal Analysis of Steel Products

molten lead or salt, thus heating the flat wire to the desired

E 45 Practice for Determining the Inclusion Content of

temperature for a definite time. The hardness obtained by this

Steel

3 type of annealing, as measured by Rockwell hardness number,

E 112 Test Methods for Determining Average Grain Size

is normally somewhat higher than is secured by batch-type

E 140 Hardness Conversion Tables for Metals

annealing. Other characteristics peculiar to strand–annealed

2.2 Military Standards:

steel require this type of annealing for some flat wire products.

MIL-STD-129 Marking for Shipment and Storage

3.1.4 salt annealing—annealing that is accomplished by

MIL-STD-163 Steel Mill Products, Preparation for Ship-

immersing bundles or coils of flat wire in a molten salt bath at

ment and Storage

a desired temperature for a definite time. Following the

annealing, the coils are permitted to cool slowly, after which

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

they are immersed in hot water to remove any adhering salts.

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

3.1.5 spheroidize annealing—an operation consisting of

A01.19 on Sheet Steel and Strip.

prolonged heating and prolonged cooling cycles to produce a

Current edition approved June 15, 1993. Published August 1993. Originally

published as A 805 – 82. Last previous edition A 805 – 91.

Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 03.01.

4 5

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 Available from Society of Automotive Engineers, 400 Commonwealth Drive,

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS Warrendale, PA 15096.

NOTICE:¬This¬standard¬has¬either¬been¬superceded¬and¬replaced¬by¬a¬new¬version¬or¬discontinued.¬

Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

A 805

NOTE 1—A typical ordering description is as follows: 18 000 lb

globular or spheroidal condition of the carbide for maximum

Low-Carbon Cold-Rolled Carbon Steel Flat Wire, Temper 4, Edge 4,

softness.

Finish 2, 0.125 by 0.450-in. vibrated coils, 2000 lb max, coil weight, 16

3.1.6 cold reduction—the process of reducing the thickness

to 20 in. ID, 36 in. max OD, Face dimension 6 to 10 in., ASTM A 805

of the strip at room temperature. The amount of reduction is

dated , for Stove Frames.

greater than that used in skin-rolling (see section 3.3).

3.1.7 finish—the degree of smoothness or lustre of the flat 5. Materials and Manufacture

wire. The production of specific finishes requires special

5.1 Low-carbon steel flat wire is normally produced from

preparation and control of the roll surfaces employed.

rimmed, capped, or semi-killed steel. When required, killed

3.1.8 hardening and tempering—a heat treatment for steel

steel may be specified, with silicon or aluminum as the

over 0.25 % carbon by cast or heat analysis involving continu-

deoxidizer.

ous strand heating at finish size to an appropriate temperature

5.2 Untempered-carbon spring steel flat wire is commonly

above the critical temperature range, followed by quenching in

produced from killed steel, although semi-killed steel is some-

oil and finally passing the strands through a tempering bath.

times used.

This heat treatment is used in the production of such commodi-

5.3 Hardened and tempered carbon spring steel flat wire

ties as oil–tempered spring wire for use in certain types of

customarily has a carbon content over 0.60 %.

mechanical springs that are not subjected to a final heat

5.4 Flat wire is generally produced from hot-rolled rods or

treatment after forming. Oil-tempered wire is intended prima-

round wire, by one or more cold-rolling operations, primarily

rily for the manufacture of products that are required to

for the purpose of obtaining the size and section desired and for

withstand high stresses. The mechanical properties and resil-

improving surface finish, dimensional accuracy, and varying

iency of oil-tempered wire provide resistance to permanent set

mechanical properties. Flat wire can also be produced from

under repeated and continuous stress applications.

slitting hot- or cold-rolled flat steel to the desired width. The

3.1.9 patenting—a thermal treatment usually confined to

hot-rolled slit flat steel is subsequently cold reduced. The width

steel over 0.25 % carbon. In this process individual strands of

to thickness ratio and the specified type of edge generally

rods or wire are heated well above the upper critical tempera-

determine the process that is necessary to produce a specific

ture followed by comparatively rapid cooling in air, molten

flat-wire item.

salt, or molten lead. This treatment is generally employed to

5.5 The production of good surface quality flat wire is

prepare the material for subsequent processing.

dependent upon scale-free and clean wire, rod, or hot-rolled

3.1.10 skin-rolled—a term denoting a relatively light cold-

steel prior to cold-rolling. Scale removal can be accomplished

rolling operation following annealing. It serves to reduce the

by chemical or mechanical cleaning.

tendency of the steel to flute or stretcher strain during fabrica-

5.6 Edge rolls, machined with contour grooves, may be used

tion. It is also used to impart surface finish, or affect hardness

in conjunction with flat-rolling passes to produce the desired

or other mechanical properties.

edge shape.

3.1.11 temper—a designation by number to indicate the

5.7 Straightness in flat wire may be controlled by the use of

hardness as a minimum, as a maximum, or as a range. The

roll straighteners alone or in conjunction with cold-rolling

tempers are obtained by the selection and control of chemical

passes.

composition, by amounts of cold reduction, and by thermal

5.8 Edges of flat wire produced by slitting wider flat-rolled

treatment.

steel can be dressed, depending upon requirements by:

5.8.1 Deburring—A process by which burrs are removed by

4. Ordering Information

rolling or filing to obtain an approximate square edge;

5.8.2 Rolling—A process by which the slit edge is dressed

4.1 Orders for material to this specification shall include the

by edge rolling to the desired contour; and

following information, as necessary, to describe adequately the

5.8.3 Filing—A process by which the slit edge is filed to a

desired product:

specific contour and dimension by passing one or more times

4.1.1 Quantity,

against a series of files mounted at various angles.

4.1.2 Name of material (flat wire identified by type),

4.1.3 Analysis or grade, if required (Section 6),

6. Chemical Composition

4.1.4 Temper of low carbon or type of spring steel (Sections

6.1 Limits:

9, 10, and 11),

6.1.1 When carbon steel flat wire is specified to chemical

4.1.5 Edge (Section 7),

composition, the compositions are commonly prepared using

4.1.6 Finish or coating (Sections 14and 12),

the ranges and limits shown in Table 1. The elements compris-

4.1.7 Dimensions,

ing the desired chemical composition are specified in one of

4.1.8 Coil type and size requirements (Section 17),

three ways:

4.1.9 Packaging (17.1),

6.1.1.1 By a maximum limit,Tables 2-5

4.1.10 Condition (oiled or not oiled) (14.4),

6.1.1.2 By a minimum limit, or

4.1.11 ASTM designation and date of issue,

6.1.1.3 By minimum and maximum limits, termed the

4.1.12 Copper-bearing steel, if required,

“range.” By common usage, the range is the arithmetical

4.1.13 Application (part identification or description), difference between the two limits (for example, 0.60 to 0.71 is

4.1.14 Case or heat analysis (request, if desired), and

0.11 range).

4.1.15 Exceptions to the specification, if required. 6.1.2 When carbon steel flat wire is produced from round

NOTICE:¬This¬standard¬has¬either¬been¬superceded¬and¬replaced¬by¬a¬new¬version¬or¬discontinued.¬

Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

A 805

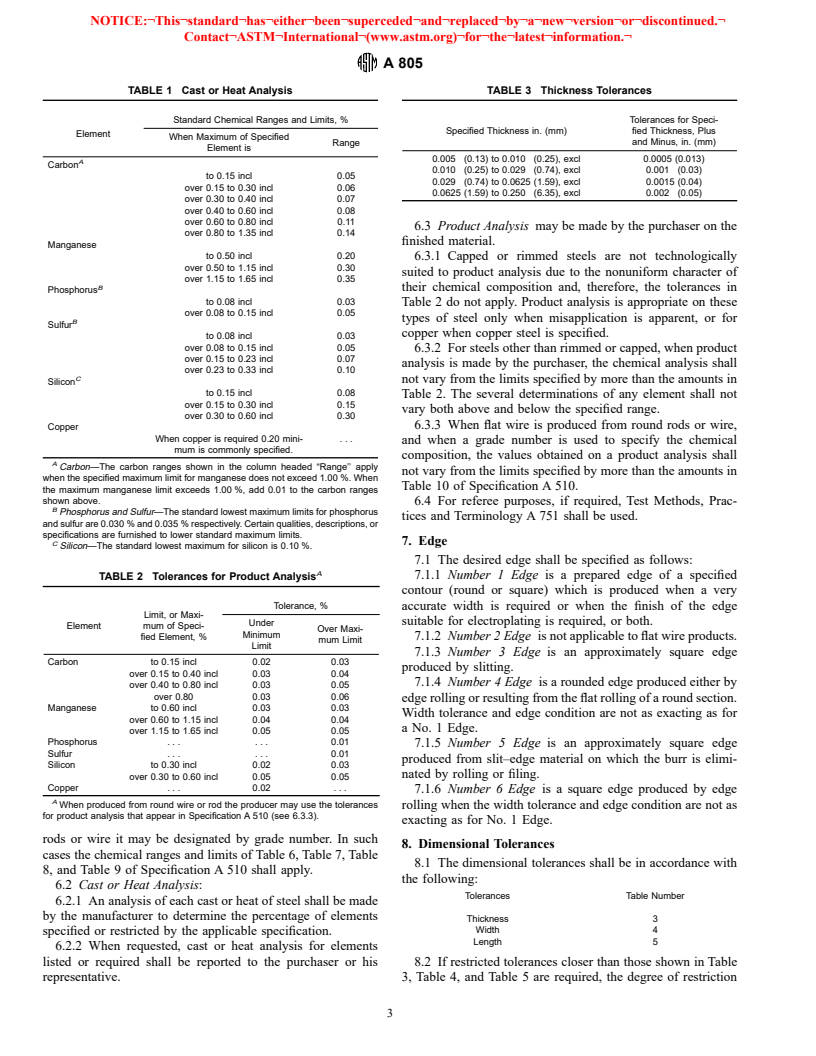

TABLE 1 Cast or Heat Analysis TABLE 3 Thickness Tolerances

Standard Chemical Ranges and Limits, % Tolerances for Speci-

Specified Thickness in. (mm) fied Thickness, Plus

Element

When Maximum of Specified

and Minus, in. (mm)

Range

Element is

0.005 (0.13) to 0.010 (0.25), excl 0.0005 (0.013)

A

Carbon

0.010 (0.25) to 0.029 (0.74), excl 0.001 (0.03)

to 0.15 incl 0.05

0.029 (0.74) to 0.0625 (1.59), excl 0.0015 (0.04)

over 0.15 to 0.30 incl 0.06

0.0625 (1.59) to 0.250 (6.35), excl 0.002 (0.05)

over 0.30 to 0.40 incl 0.07

over 0.40 to 0.60 incl 0.08

over 0.60 to 0.80 incl 0.11

6.3 Product Analysis may be made by the purchaser on the

over 0.80 to 1.35 incl 0.14

finished material.

Manganese

to 0.50 incl 0.20

6.3.1 Capped or rimmed steels are not technologically

over 0.50 to 1.15 incl 0.30

suited to product analysis due to the nonuniform character of

over 1.15 to 1.65 incl 0.35

B

their chemical composition and, therefore, the tolerances in

Phosphorus

to 0.08 incl 0.03

Table 2 do not apply. Product analysis is appropriate on these

over 0.08 to 0.15 incl 0.05

types of steel only when misapplication is apparent, or for

B

Sulfur

copper when copper steel is specified.

to 0.08 incl 0.03

over 0.08 to 0.15 incl 0.05

6.3.2 For steels other than rimmed or capped, when product

over 0.15 to 0.23 incl 0.07

analysis is made by the purchaser, the chemical analysis shall

over 0.23 to 0.33 incl 0.10

C

not vary from the limits specified by more than the amounts in

Silicon

to 0.15 incl 0.08

Table 2. The several determinations of any element shall not

over 0.15 to 0.30 incl 0.15

vary both above and below the specified range.

over 0.30 to 0.60 incl 0.30

6.3.3 When flat wire is produced from round rods or wire,

Copper

When copper is required 0.20 mini- .

and when a grade number is used to specify the chemical

mum is commonly specified.

composition, the values obtained on a product analysis shall

A

Carbon—The carbon ranges shown in the column headed “Range’’ apply

not vary from the limits specified by more than the amounts in

when the specified maximum limit for manganese does not exceed 1.00 %. When

Table 10 of Specification A 510.

the maximum manganese limit exceeds 1.00 %, add 0.01 to the carbon ranges

shown above. 6.4 For referee purposes, if required, Test Methods, Prac-

B

Phosphorus and Sulfur—The standard lowest maximum limits for phosphorus

tices and Terminology A 751 shall be used.

and sulfur are 0.030 % and 0.035 % respectively. Certain qualities, descriptions, or

specifications are furnished to lower standard maximum limits.

7. Edge

C

Silicon—The standard lowest maximum for silicon is 0.10 %.

7.1 The desired edge shall be specified as follows:

A

7.1.1 Number 1 Edge is a prepared edge of a specified

TABLE 2 Tolerances for Product Analysis

contour (round or square) which is produced when a very

Tolerance, %

accurate width is required or when the finish of the edge

Limit, or Maxi-

suitable for electroplating is required, or both.

Under

Element mum of Speci-

Over Maxi-

Minimum

fied Element, % 7.1.2 Number 2 Edge is not applicable to flat wire products.

mum Limit

Limit

7.1.3 Number 3 Edge is an approximately square edge

Carbon to 0.15 incl 0.02 0.03

produced by slitting.

over 0.15 to 0.40 incl 0.03 0.04

7.1.4 Number 4 Edge is a rounded edge produced either by

over 0.40 to 0.80 incl 0.03 0.05

over 0.80 0.03 0.06

edge rolling or resulting from the flat rolling of a round section.

Manganese to 0.60 incl 0.03 0.03

Width tolerance and edge condition are not as exacting as for

over 0.60 to 1.15 incl 0.04 0.04

a No. 1 Edge.

over 1.15 to 1.65 inc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.