ASTM F1307-02(2007)

(Test Method)Standard Test Method for Oxygen Transmission Rate Through Dry Packages Using a Coulometric Sensor

Standard Test Method for Oxygen Transmission Rate Through Dry Packages Using a Coulometric Sensor

SIGNIFICANCE AND USE

Oxygen gas transmission rate is an important determinant of the protection afforded by barrier materials. It is not, however, the sole determinant, and additional tests, based on experience, must be used to correlate package performance with O2GTR. This test method is suitable as a referee method of testing, provided that the user and source have agreed on sampling procedures, standardization procedures, test conditions, and acceptance criteria.

SCOPE

1.1 This test method covers a procedure for the determination of the steady-state rate of transmission of oxygen gas into packages. More specifically, the method is applicable to packages that in normal use will enclose a dry environment.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1307 − 02(Reapproved 2007)

Standard Test Method for

Oxygen Transmission Rate Through Dry Packages Using a

Coulometric Sensor

This standard is issued under the fixed designation F1307; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3 3 −6

1. Scope cm (STP)/pkg·d,where1cm (STP)is44.62×10 mol,1atm

is 0.1013 mPa, and one day is 86 400 s.

1.1 This test method covers a procedure for the determina-

"

3.1.2 oxygen permeability coeffıcient (PO )—the product

tion of the steady-state rate of transmission of oxygen gas into

packages. More specifically, the method is applicable to of the permeance and thickness of the barrier.

packages that in normal use will enclose a dry environment. 3.1.2.1 Discussion—The permeability is meaningful only

for homogenous materials, in which case it is a property

1.2 This standard does not purport to address all of the

characteristic of the bulk material. This quantity should not be

safety concerns, if any, associated with its use. It is the

used unless the relationship between thickness and permeance

responsibility of the user of this standard to establish appro-

has been verified in tests using several thicknesses of the

priate safety and health practices and determine the applica-

material.TheSIunitofpermeabilityisthemol/m·s·Pa.Thetest

bility of regulatory limitations prior to use.

conditions must be stated.

'

2. Referenced Documents

3.1.3 oxygen permeance (PO )—the ratio of the O GTR to

2 2

the difference between the partial pressure of O on the two

2.1 ASTM Standards:

sides of the package wall.

D1434TestMethodforDeterminingGasPermeabilityChar-

3.1.3.1 Discussion—The SI unit of permeance is the mol/

acteristics of Plastic Film and Sheeting

D1898Practice for Sampling of Plastics (Withdrawn 1998) (pkg·s·Pa). The test conditions (see 4.2) must be stated.

D3985Test Method for Oxygen Gas Transmission Rate

Through Plastic Film and Sheeting Using a Coulometric 4. Summary of Test Method

Sensor

4.1 This test method employs a coulometric oxygen sensor

E691Practice for Conducting an Interlaboratory Study to

and associated equipment in an arrangement similar to that

Determine the Precision of a Test Method

describedinTestMethodD3985.Oxygengastransmissionrate

(O GTR)isdeterminedafterthepackagehasbeenmountedon

3. Terminology

a test fixture and has equilibrated in the test environment.

3.1 Definitions of Terms Specific to This Standard:

4.2 Thepackageismountedinsuchawayastoprovidethat

3.1.1 oxygen gas transmission rate (O GTR)—as applied to

the inside of the package is slowly purged by a stream of

a package, is the quantity of oxygen gas passing through the

nitrogen while the outside of the package is exposed to a

surface of the package per unit of time.

known concentration of oxygen. The package may be exposed

3.1.1.1 Discussion—The SI unit of transmission rate is the

in ambient room air which contains 20.8% oxygen, or im-

mol/pkg·s. The test conditions, including temperature, oxygen

mersed in an atmosphere of 100% oxygen.As oxygen perme-

partial pressure and humidity on both sides of the package,

ates through the package walls into the nitrogen carrier gas, it

must be stated. A commonly used unit of O GTR is the

is transported to the coulometric detector where it produces an

electricalcurrent,themagnitudeofwhichisproportionaltothe

ThistestmethodisunderthejurisdictionofASTMCommitteeF02onFlexible

amount of oxygen flowing into the detector per unit of time.

Barrier Packaging and is the direct responsibility of Subcommittee F02.10 on

Permeation.

5. Significance and Use

Current edition approved May 1, 2007. Published June 2007. Originally

approved in 1990. Last previous edition approved in 2002 as F1307–02. DOI:

5.1 Oxygen gas transmission rate is an important determi-

10.1520/F1307-02R07.

nant of the protection afforded by barrier materials. It is not,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

however, the sole determinant, and additional tests, based on

Standards volume information, refer to the standard’s Document Summary page on

experience, must be used to correlate package performance

the ASTM website.

with O GTR. This test method is suitable as a referee method

The last approved version of this historical standard is referenced on 2

www.astm.org. of testing, provided that the user and source have agreed on

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1307 − 02 (2007)

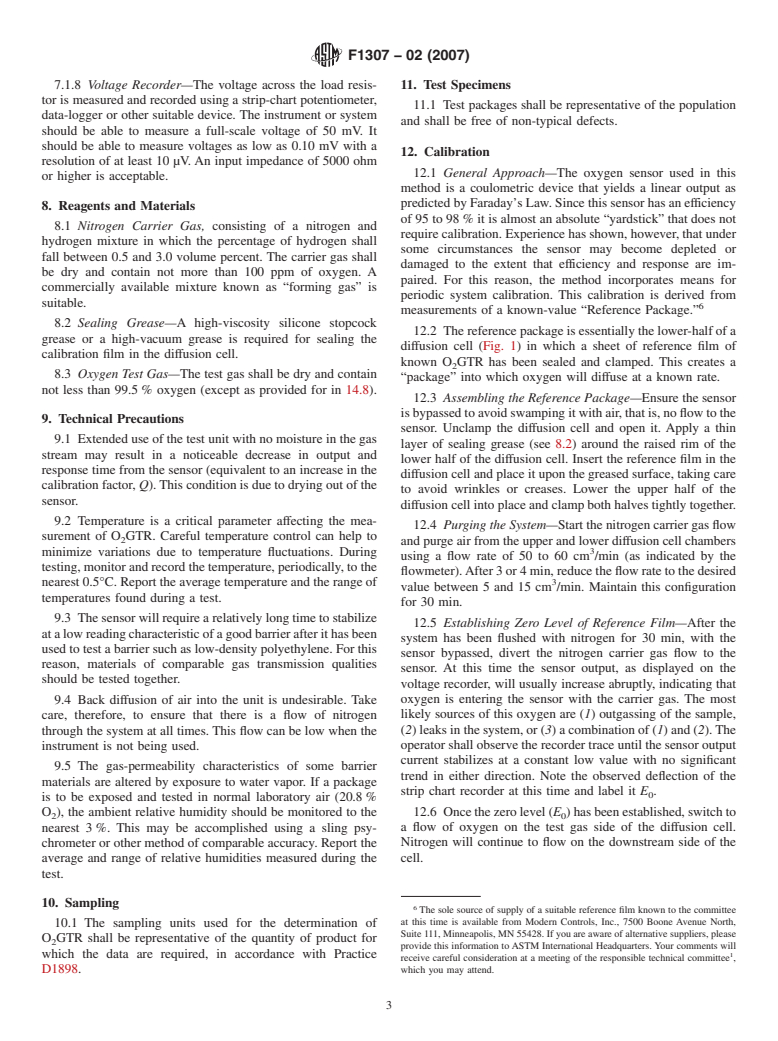

7.1.2 Diffusion Cell, consisting of two metal halves which,

when closed upon the film used for system calibration, will

accurately define a circular area of that film. Typical diffusion

2 2

cell areas are 100 cm and 30 cm .The volumes inside the cell

above and below the enclosed film are not critical; they should

be small enough to allow for rapid gas exchange, but not so

small that an unsupported film which happens to sag or bulge

will contact the top or bottom of the cell. Means shall be

provided for the measurement of cell temperature.

7.1.2.1 O-Ring—An appropriately sized groove, machined

into the oxygen (or test gas) side of the diffusion cell, retains a

neoprene O-ring. The test area is considered to be the area

established by the inside contact diameter of the compressed

O-ring when the diffusion cell is clamped shut against the test

specimen.Thearea, A,canbeobtainedbymeasuringtheinside

diameteroftheimprintleftbytheO-ringonthespecimenafter

it has been removed from the diffusion cell.

7.1.2.2 Thenitrogen(orcarriergas)sideofthediffusioncell

shallhaveaflatraisedrim.Sincethisrimisthesealingsurface

against which the test specimen is pressed, it must be smooth

and flat, without scratches which may promote leakage.

7.1.2.3 Diffusion Cell Pneumatic Fittings—Each half of the

diffusion cell shall incorporate suitable fittings for the intro-

FIG. 1 Arrangement of Components when Reference Film is

duction and exhaust of gas without significant loss or leakage.

Used to Calibrate System for Package Testing

7.1.2.4 It is desirable to thermostatically control the diffu-

sion cell. A simple resistive heater, attached to the carrier gas

sampling procedures, standardization procedures, test condi-

side of the cell in such a manner as to ensure good thermal

tions, and acceptance criteria.

contact, is adequate for this purpose. A thermistor sensor and

an appropriate control circuit will serve to regulate the cell

6. Interferences

temperature unless measurements are being made close to

6.1 The presence of certain interfering substances in the

ambient temperature. In this case, it is desirable to provide

carrier gas stream may give rise to unwanted electrical outputs

cooling coils to remove some of the heat.

and error factors. Interfering substances include free chlorine

7.1.3 Catalyst Bed, a small metal tube with fittings for

and some strong oxidizing agents. Exposure to carbon dioxide

attachment to the inlet of the nitrogen gas pneumatic fitting

should also be minimized to avoid damage to the sensor

containing 3 to5gof0.5% platinum or palladium catalyst on

through reaction with the potassium hydroxide electrolyte.

alumina to provide an essentially oxygen-free carrier gas to

the diffusion cell and to each package test station.

7. Apparatus

7.1.4 Flowmeter, a flowmeter having an operating range of

7.1 Oxygen Gas Transmission Apparatus, as diagrammed

5 to 100 mL/min is required to monitor the flow rate of

in Fig. 1 with the following:

nitrogen carrier gas through each test station.

7.1.1 Package Test Stations, providing a means for the

7.1.5 Flow Switching Valves—Two or more valves for the

introduction and exhaust of the nitrogen carrier gas stream

switching of the nitrogen and test gas flow streams.

without significant loss or leakage.

7.1.6 Oxygen-Sensitive Coulometric Sensor, operating at an

7.1.1.1 Experience has shown that arrangements using mul-

essentially constant efficiency is employed to monitor the

tiple package test stations are a practical way to increase the

quantity of oxygen transmitted.

number of measurements that can be obtained from a coulo-

7.1.7 Load Resistor—The current generated by the coulo-

metric sensor.Avalving manifold connects the carrier gas side

metric cell shall pass through a resistive load across which the

of each individual test station to the sensor in a predetermined

outputvoltageismeasured.Typicalvaluesforloadresistorsare

pattern. Carrier gas is continually purging the carrier gas sides

5.3 ohm and 53 ohm. These values yield a convenient

of those packages that are not connected to the sensor. Either

relationship between the output voltage and the oxygen trans-

test gas (100% oxygen) or normal room air (20.8% oxygen),

mission rate as expressed in terms of cm (STP)/pkg·d.

whichever is appropriate, contacts the outside of the package.

4 5

The sole source of supply of the suitable apparatus, such as that embodied in The sole source of supply of a suitable catalyst known to the committee at this

several OXTRAN models, known to the committee at this time is available from time can be obtained from Englehard Industries Division, Chemical Dept., 429

Mocon Inc., 7500 BooneAve. North, Minneapolis, MN 55428. If you are aware of DelanceyStreet,Newark,NJ07105.Ifyouareawareofalternativesuppliers,please

alternative suppliers, please provide this information to ASTM International provide this information toASTM International Headquarters.Your comments will

Headquarters.Your comments will receive careful consideration at a meeting of the receive careful consideration at a meeting of the responsible technical committee ,

responsible technical committee , which you may attend. which you may attend.

F1307 − 02 (2007)

7.1.8 Voltage Recorder—The voltage across the load resis- 11. Test Specimens

tor is measured and recorded using a strip-chart potentiometer,

11.1 Test packages shall be representative of the population

data-logger or other suitable device. The instrument or system

and shall be free of non-typical defects.

should be able to measure a full-scale voltage of 50 mV. It

should be able to measure voltages as low as 0.10 mV with a

12. Calibration

resolution of at least 10 µV.An input impedance of 5000 ohm

12.1 General Approach—The oxygen sensor used in this

or higher is acceptable.

method is a coulometric device that yields a linear output as

predictedbyFaraday’sLaw.Sincethissensorhasanefficiency

8. Reagents and Materials

of 95 to 98% it is almost an absolute “yardstick” that does not

8.1 Nitrogen Carrier Gas, consisting of a nitrogen and

requirecalibration.Experiencehasshown,however,thatunder

hydrogen mixture in which the percentage of hydrogen shall

some circumstances the sensor may become depleted or

fall between 0.5 and 3.0 volume percent. The carrier gas shall

damaged to the extent that efficiency and response are im-

be dry and contain not more than 100 ppm of oxygen. A

paired. For this reason, the method incorporates means for

commercially available mixture known as “forming gas” is

periodic system calibration. This calibration is derived from

suitable.

measurements of a known-value “Reference Package.”

8.2 Sealing Grease—A high-viscosity silicone stopcock

12.2 Thereferencepackageisessentiallythelower-halfofa

grease or a high-vacuum grease is required for sealing the

diffusion cell (Fig. 1) in which a sheet of reference film of

calibration film in the diffusion cell.

known O GTR has been sealed and clamped. This creates a

8.3 Oxygen Test Gas—The test gas shall be dry and contain

“package” into which oxygen will diffuse at a known rate.

not less than 99.5% oxygen (except as provided for in 14.8).

12.3 Assembling the Reference Package—Ensure the sensor

isbypassedtoavoidswampingitwithair,thatis,noflowtothe

9. Technical Precautions

sensor. Unclamp the diffusion cell and open it. Apply a thin

9.1 Extendeduseofthetestunitwithnomoistureinthegas

layer of sealing grease (see 8.2) around the raised rim of the

stream may result in a noticeable decrease in output and

lower half of the diffusion cell. Insert the reference film in the

response time from the sensor (equivalent to an increase in the

diffusioncellandplaceituponthegreasedsurface,takingcare

calibrationfactor, Q).Thisconditionisduetodryingoutofthe

to avoid wrinkles or creases. Lower the upper half of the

sensor.

diffusioncellintoplaceandclampbothhalvestightlytogether.

9.2 Temperature is a critical parameter affecting the mea-

12.4 Purging the System—Startthenitrogencarriergasflow

surement of O GTR. Careful temperature control can help to

andpurgeairfromtheupperandlowerdiffusioncellchambers

minimize variations due to temperature fluctuations. During

using a flow rate of 50 to 60 cm /min (as indicated by the

testing,monitorandrecordthetemperature,periodically,tothe

flowmeter).After3or4min,reducetheflowratetothedesired

nearest0.5°C.Reporttheaveragetemperatureandtherangeof

value between 5 and 15 cm /min. Maintain this configuration

temperatures found during a test.

for 30 min.

9.3 Thesensorwillrequirearelativelylongtimetostabilize

12.5 Establishing Zero Level of Reference Film—After the

atalowreadingcharacteristicofagoodbarrierafterithasbeen

system has been flushed with nitrogen for 30 min, with the

usedtotestabarriersuchaslow-densitypolyethylene.Forthis

sensor bypassed, divert the nitrogen carrier gas flow to the

reason, materials of comparable gas transmission qualities

sensor. At this time the sensor output, as displayed on the

should be tested together.

voltage recorder, will usually increase abruptly, indicating that

oxygen is entering the sensor with the carrier gas. The most

9.4 Back diffusion of air into the unit is undesirable. Take

likely sources of this oxygen are (1) outgassing of the sample,

care, therefore, to ensure that there is a flow of nitrogen

(2)leaksinthesystem,or(3)acombinationof(1)and(2).The

through the system at all times.This flow can be low when the

operatorshallobservetherecordertraceuntilthesensoroutput

instrument is not being used.

current stabilizes at a constant low value with no significant

9.5 The gas-permeability characteristics of some barrier

trend in either direction. Note the observed deflection of the

materials are altered by exposure to water vapor. If a package

strip chart recorder at this time and label it E .

is to be exposed and tested in normal laboratory air (20.8%

O ), the ambient relative humidity should be monitor

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.