ASTM D4804-09

(Test Method)Standard Test Method for Determining the Flammability Characteristics of Nonrigid Solid Plastics

Standard Test Method for Determining the Flammability Characteristics of Nonrigid Solid Plastics

SIGNIFICANCE AND USE

The test results represent the afterflame and afterglow times, in seconds, for a material under the conditions of the test.

The afterflame and afterglow times and other burning phenomena will vary with thickness. Test data shall only be compared with data for material of comparable thickness.

The effect of material thickness, colors, additives, deterioration, and possible loss of volatile components is measurable.

The results serve as a reference for comparing the relative performance of materials and can be an aid in material selection.

In this procedure, the specimens are subjected to one or more specific sets of laboratory test conditions. If different test conditions are substituted or the end-use conditions are changed, it will not always be possible by or from this test method to predict changes in the fire-test-response characteristics measured. Therefore, the results are valid only for the fire-test exposure conditions described in this test method.

SCOPE

1.1 This fire-test-response test methods describe small-scale laboratory procedures for determining the comparative burning characteristics of solid plastic materials that, due to specimen thinness and nonrigidity, distort or shrink when tested using Test Method D 3801. A flame is applied to the base of specimens held in a vertical position and the extinguishing times are determined upon removal of the test flame.

1.2 The classification system described in Appendix X1 is intended for quality assurance and the preselection of component materials for products.

1.3 This standard measures and describes the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

Note 1—This standard is equivalent to ISO 9773.

Note 2—For rate of burning of nonrigid solid plastics in a horizontal position, formerly Test Method B of this test method, see Test Method D 635, section 9.4.

1.4 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these tests.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 6.1.1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4804 − 09

StandardTest Method for

Determining the Flammability Characteristics of Nonrigid

1

Solid Plastics

This standard is issued under the fixed designation D4804; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D635 Test Method for Rate of Burning and/or Extent and

Time of Burning of Plastics in a Horizontal Position

1.1 This fire-test-response test methods describe small-scale

D3801 TestMethodforMeasuringtheComparativeBurning

laboratoryproceduresfordeterminingthecomparativeburning

Characteristics of Solid Plastics in a Vertical Position

characteristics of solid plastic materials that, due to specimen

D5025 Specification for Laboratory Burner Used for Small-

thinness and nonrigidity, distort or shrink when tested using

Scale Burning Tests on Plastic Materials

Test Method D3801. A flame is applied to the base of

D5207 Practice for Confirmation of 20–mm (50–W) and

specimens held in a vertical position and the extinguishing

125–mm (500–W) Test Flames for Small-Scale Burning

times are determined upon removal of the test flame.

Tests on Plastic Materials

1.2 The classification system described in Appendix X1 is

E176 Terminology of Fire Standards

intended for quality assurance and the preselection of compo-

E691 Practice for Conducting an Interlaboratory Study to

nent materials for products.

Determine the Precision of a Test Method

1.3 This standard measures and describes the response of 2.2 ISO Standards:

ISO 9773–98 Plastics—Determination of Burning Behav-

materials, products, or assemblies to heat and flame under

controlled conditions, but does not by itself incorporate all iour of Thin Flexible Vertical Specimens in Contact With

3

a Small Flame Ignition Source

factors required for fire hazard or fire risk assessment of the

materials, products, or assemblies under actual fire conditions.

3. Terminology

NOTE 1—This standard is equivalent to ISO 9773.

3.1 Definitions—For definitions of fire-related terms used in

NOTE 2—For rate of burning of nonrigid solid plastics in a horizontal

this test method, refer to Terminology E176.

position, formerly Test Method B of this test method, see Test Method

D635, section 9.4.

3.2 Definitions of Terms Specific to This Standard:

1.4 Fire testing is inherently hazardous. Adequate safe-

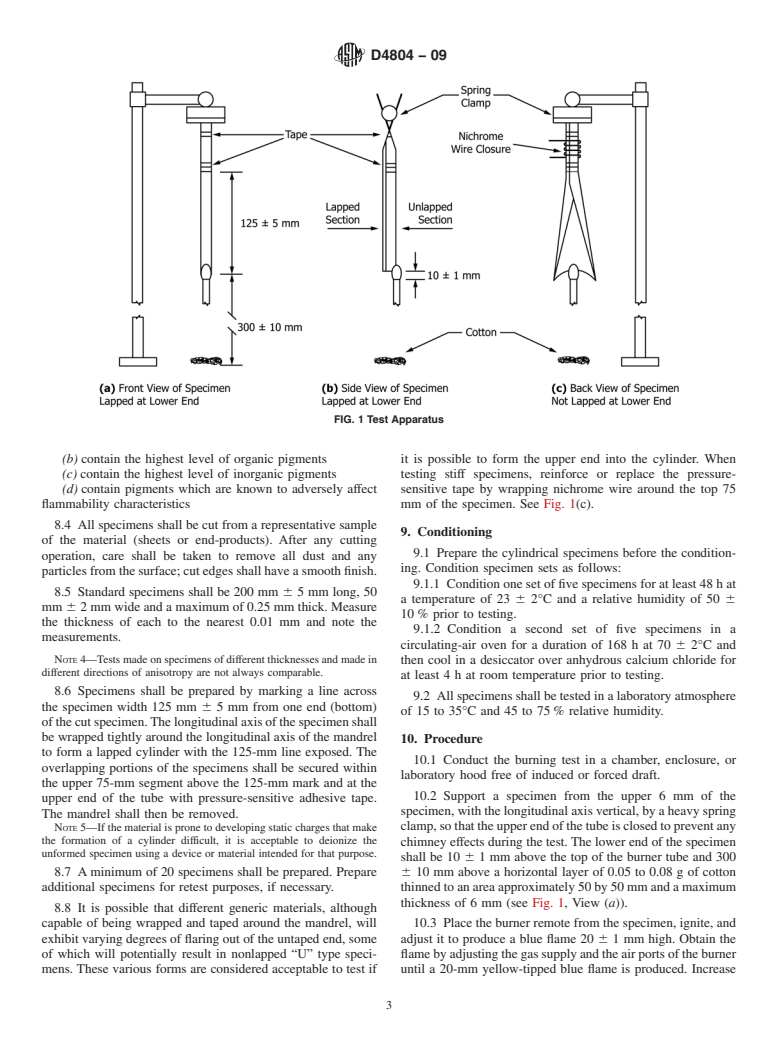

3.2.1 flame-impingement time, n—the time in seconds that

guards for personnel and property shall be employed in

the flame from the burner is in contact with the specimen.

conducting these tests.

3.2.2 flaming material, n—flaming drips or particles from

1.5 This standard does not purport to address all of the

the specimen which ignite the dry, absorbent surgical cotton

safety concerns, if any, associated with its use. It is the

placed 300 mm below the test specimen.

responsibility of the user of this standard to establish appro-

3.2.3 afterflame, n—persistence of flaming of a material,

priate safety and health practices and determine the applica-

after the ignition source has been removed.

bility of regulatory limitations prior to use. For specific hazard

3.2.4 afterflame time, n—the length of time for which a

statements, see 6.1.1.

material continues to flame, under specified conditions, after

the ignition source has been removed.

2. Referenced Documents

2

3.2.5 afterglow, n—persistence of glowing of a material,

2.1 ASTM Standards:

after cessation of flaming or, if no flaming occurs, after

removal of the ignition source.

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

3.2.6 afterglow time, n—the length of time for which a

and is the direct responsibility of Subcommittee D20.30 on Thermal Properties.

materialcontinuestoglowunderspecifiedtestconditions,after

Current edition approved Sept. 1, 2009. Published September 2009. Originally

the ignition source has been removed or cessation of flaming,

approved in 1988. Last previous edition approved in 2003 as D4804 – 03. DOI:

or both.

10.1520/D4804-09.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4804 − 09

3.2.7 flame, v—to undergo combustion in the gaseous phase 6.3 Ring Stan

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4804–03 Designation: D 4804 – 09

Standard Test Method for

Determining the Flammability Characteristics of Nonrigid

1

Solid Plastics

This standard is issued under the fixed designation D 4804; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1These1.1 This fire-test-response test methods describe small-scale laboratory procedures for determining the comparative

burning characteristics of solid plastic materials that, due to specimen thinness and nonrigidity, may distort or shrink when tested

using Test Method D 3801. A flame is applied to the base of specimens held in a vertical position and the extinguishing times are

determined upon removal of the test flame.

1.2The classification system described in

1.2 The classification system described in Appendix X1 is intended for quality assurance and the preselection of component

materials for products.

1.3 This standard measures and describes the response of materials, products, or assemblies to heat and flame under controlled

conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products,

or assemblies under actual fire conditions.

NOTE1—These test methods and ISO 9773 are technically equivalent. 1—This standard is equivalent to ISO 9773.

NOTE 2—For rate of burning of nonrigid solid plastics in a horizontal position, formerly Test Method B of thesethis test methods,method, see Test

Method D 635, section 9.4.

1.4 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these

tests.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, see Warning in 6.1For specific hazard statements, see 6.1.1.

2. Referenced Documents

2

2.1 ASTM Standards:

D 635 Test Method for Rate of Burning and/or Extent andTime of Burning of Self-Supporting Plastics in a Horizontal Position

D 3801 Test Method for Measuring the Comparative ExtinguishingBurning Characteristics of Solid Plastics in a Vertical

Position

D 5025 Specification for a Laboratory Burner Used for Small-Scale Burning Tests on Plastic Materials

D 5207 Practice for Confirmation of 20mm (50W) and 125mm (500W) Test Flames for Small-Scale Burning Tests on Plastic

Materials

E 176 Terminology of Fire Standards

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2.2 ISO Standards:

ISO 9773–98 Plastics—Determination of Burning Behaviour of Thin Flexible Vertical Specimens in Contact With a Small

3

Flame Ignition Source

3. Terminology

3.1 Definitions—For definitions of fire-related terms used in thesethis test methods,method, refer to Terminology E 176.

3.2 Definitions of Terms Specific to This Standard:

1

TheseThis test methods aremethod is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.30 on Thermal

Properties.

Current edition approved July 10, 2003.Sept. 1, 2009. Published September 2003.2009. Originally approved in 1988. Last previous edition approved in 19982003 as

D4804–98.D 4804 – 03.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4804–09

3.2.1 flame-impingement time, n—the time in seconds that the flame from the burner is in contact with the specimen.

3.2.2 flaming material, n—flaming drips or particles from the specimen which ignite the dry, absorbent surgical cotton placed

300 mm below the test specimen.

3.2.3 afterflame, n—persistence of flaming of a material, after the ignition source has been removed.

3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.