ASTM F468M-06(2012)

(Specification)Standard Specification for Nonferrous Bolts, Hex Cap Screws, and Studs for General Use (Metric)

Standard Specification for Nonferrous Bolts, Hex Cap Screws, and Studs for General Use (Metric)

ABSTRACT

This specification covers the requirements for commercial wrought nonferrous bolts, hex cap screws, and studs manufactured from a number of alloys in common use and intended for general service applications. The bolts, cap screws, and studs shall be manufactured from material having a chemical composition conforming to the requirements specified. The fasteners shall be cold formed, hot formed, or machined from suitable material. Different tests shall be conducted in order to determine the following mechanical properties of fasteners: hardness, tensile strength, yield strength, and elongation.

SIGNIFICANCE AND USE

For purposes of determining compliance with the specified limits for requirements of the properties listed in this specification, an observed value or calculated value shall be rounded in accordance with Practice E29.

SCOPE

1.1 This specification covers the requirements for commercial wrought nonferrous bolts, hex cap screws, and studs in nominal thread diameters M6 to M36 inclusive manufactured from a number of alloys in common use and intended for general service applications.

1.2 Unless otherwise specified, nuts used on these bolts, cap screws, and studs shall conform to the requirements of Specification F467M. Nuts shall be of the same alloy group as the fastener on which they are used and shall have a specified minimum proof stress equal to or greater than the specified minimum tensile strength stress of the fastener on which they are used.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

Note 1—This specification is the metric companion of Specification F468.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F468M −06 (Reapproved 2012)

Standard Specification for

Nonferrous Bolts, Hex Cap Screws, and Studs for General

Use (Metric)

This standard is issued under the fixed designation F468M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* B574 Specification for Low-Carbon Nickel-Chromium-

Molybdenum, Low-Carbon Nickel-Molybdenum-

1.1 This specification covers the requirements for commer-

Chromium, Low-Carbon Nickel-Molybdenum-

cial wrought nonferrous bolts, hex cap screws, and studs in

Chromium-Tantalum, Low-Carbon Nickel-Chromium-

nominal thread diameters M6 to M36 inclusive manufactured

Molybdenum-Copper, and Low-Carbon Nickel-

from a number of alloys in common use and intended for

Chromium-Molybdenum-Tungsten Alloy Rod

general service applications.

D3951Practice for Commercial Packaging

1.2 Unlessotherwisespecified,nutsusedonthesebolts,cap

E8MTestMethodsforTensionTestingofMetallicMaterials

screws, and studs shall conform to the requirements of Speci- 3

[Metric] (Withdrawn 2008)

fication F467M. Nuts shall be of the same alloy group as the

E18Test Methods for Rockwell Hardness of Metallic Ma-

fastener on which they are used and shall have a specified

terials

minimum proof stress equal to or greater than the specified

E29Practice for Using Significant Digits in Test Data to

minimum tensile strength stress of the fastener on which they

Determine Conformance with Specifications

are used.

E34Test Methods for Chemical Analysis of Aluminum and

1.3 The values stated in SI units are to be regarded as Aluminum-Base Alloys

E38Methods for Chemical Analysis of Nickel-Chromium

standard. No other units of measurement are included in this

standard. and Nickel-Chromium-Iron Alloys (Withdrawn 1989)

E53Test Method for Determination of Copper in Unalloyed

NOTE 1—This specification is the metric companion of Specification

Copper by Gravimetry

F468.

E54Test Methods for ChemicalAnalysis of Special Brasses

and Bronzes (Withdrawn 2002)

2. Referenced Documents

E55Practice for Sampling Wrought Nonferrous Metals and

2.1 ASTM Standards:

Alloys for Determination of Chemical Composition

B154Test Method for Mercurous Nitrate Test for Copper

E62Test Methods for Chemical Analysis of Copper and

Alloys

CopperAlloys(PhotometricMethods)(Withdrawn2010)

B193Test Method for Resistivity of Electrical Conductor

E75Test Methods for Chemical Analysis of Copper-Nickel

Materials

and Copper-Nickel-Zinc Alloys (Withdrawn 2010)

B211MSpecification for Aluminum and Aluminum-Alloy

E76Test Methods for Chemical Analysis of Nickel-Copper

Rolled or Cold-Finished Bar, Rod, and Wire (Metric)

Alloys (Withdrawn 2003)

B565Test Method for Shear Testing of Aluminum and

E92Test Methods for Vickers Hardness and Knoop Hard-

Aluminum-Alloy Rivets and Cold-Heading Wire and

ness of Metallic Materials

Rods

E101TestMethodforSpectrographicAnalysisofAluminum

and Aluminum Alloys by the Point-to-Plane Technique

(Withdrawn 1996)

This specification is under the jurisdiction of ASTM Committee F16 on

E120Test Methods for Chemical Analysis of Titanium and

Fasteners and is the direct responsibility of Subcommittee F16.04 on Nonferrous

Titanium Alloys (Withdrawn 2003)

Fasteners.

Current edition approved April 1, 2012. Published May 2012. Originally

E165Practice for Liquid Penetrant Examination for General

ε1

approved in 1979. Last previous edition approved in 2006 as F468M–06 . DOI:

Industry

10.1520/F0468M-12.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F468M−06 (2012)

E227 Test Method for Optical Emission Spectrometric 4.1.2 The starting condition of the raw material shall be at

Analysis of Aluminum and Aluminum Alloys by the the discretion of the fastener manufacturer but shall be such

Point-to-Plane Technique (Withdrawn 2002) that the finished products conform to all of the specified

E354 Test Methods for Chemical Analysis of High- requirements.

Temperature,Electrical,Magnetic,andOtherSimilarIron,

4.2 Manufacture:

Nickel, and Cobalt Alloys

4.2.1 Forming—Unless otherwise specified, the fasteners

E478Test Methods for ChemicalAnalysis of CopperAlloys

shall be cold formed, hot formed, or machined from suitable

E1409TestMethodforDeterminationofOxygenandNitro-

material, at the option of the manufacturer.

gen in Titanium and TitaniumAlloys by Inert Gas Fusion

4.2.2 Condition—Except as provided in 4.2.3, the fasteners

F467MSpecification for Nonferrous Nuts for General Use

shall be furnished in the following conditions:

(Metric)

Alloy Condition

F606MTest Methods for Determining the Mechanical Prop-

Copper (all alloys): As formed or stress relieved at manufacturer’s option

erties of Externally and Internally Threaded Fasteners,

Nickel alloys:

Washers, and Rivets (Metric) 400 and 405 As formed or stress relieved at manufacturer’s option

500 Solution annealed and aged

F1470Practice for Fastener Sampling for Specified Me-

625 Annealed

chanical Properties and Performance Inspection

Aluminum alloys:

2024-T4 Solution treated and naturally aged

2.2 ASME Standards:

6061-T6 Solution treated and artificially aged

B1.13MMetric Screw Threads

7075-T73 Solution treated and stabilized

B18.2.3.1M Metric Hex Cap Screws Titanium As formed

B18.2.3.5MMetric Hex Bolts

4.2.3 Stress Relieving—Whenrequired,stressrelievingshall

H35.1 Alloy and Temper Designation Systems for Alumi-

bespecifiedbythepurchaserfornickelalloys400and405and

num

all copper alloys.

4.2.4 Threads—Unlessotherwisespecified,thethreadsshall

3. Ordering Information

be rolled or cut at the option of the manufacturer.

3.1 Orders for fasteners under this specification shall in-

clude the following information:

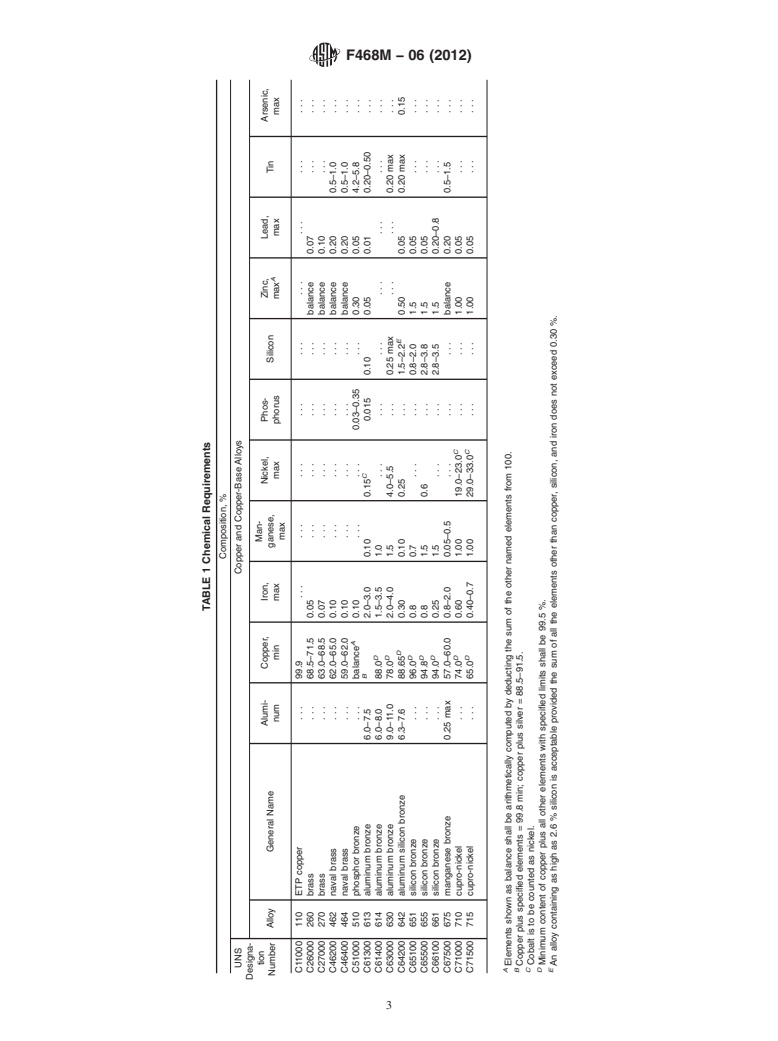

5. Chemical Composition

3.1.1 Quantity (number of pieces of each item and size);

5.1 Chemical Composition—The fasteners shall conform to

3.1.2 Name of item. For silicon bronze alloy 651, state if

the requirements as to chemical composition prescribed in

hex cap screw dimensions or roll thread body diameter are

Table 1 for the specified alloy.

required (see 7.1.2);

3.1.3 Dimensions including nominal diameter, thread pitch, 5.2 Manufacturer’s Analysis:

and length; 5.2.1 When test reports are required on the inquiry or

3.1.4 Alloynumber(Table1).ForTi5,stateClassAorClass

purchase order (see 3.1.8), the manufacturer shall make indi-

B(Table 2, 6.5, and 6.5.1); vidual analyses of randomly selected finished fasteners from

3.1.5 Stress relieving, if required (see 4.2.3),

the product to be shipped and report the results to the

3.1.6 Shipment lot testing, as required (see Section 10); purchaser, except as provided in 5.2.2. Alternatively, if heat

3.1.7 Source inspection, if required (see Section 14);

andlotidentitieshavebeenmaintained,theanalysisoftheraw

3.1.8 Certificate of compliance or test report, if required materialfromwhichthefastenershavebeenmanufacturedmay

(see Section 16);

be reported instead of product analysis.

3.1.9 Additional requirements, if any, to be specified on the

5.2.2 Foraluminumfasteners,themanufacturermayfurnish

purchase order (see 4.2.1, 4.2.4, 7.3.1, 8.2, 11.1, and 12.1);

insteadacertificateofconformancecertifyingcompliancewith

3.1.10 Supplementary Requirements, if any; and

the chemical composition specified in Table 1.

3.1.11 ASTM specification and year of issue.

5.3 Product Analysis:

NOTE 2—A typical ordering description is as follows: 10000 pieces,

5.3.1 Product analyses may be made by the purchaser from

Hex Cap Screw, M6×1×80, Alloy 270. Furnish Certificate of

finished products representing each lot. The chemical compo-

Compliance, Supplementary Requirement S1, ASTM F468M-XX.

sition thus determined shall conform to the requirements in

Table 1.

4. Materials and Manufacture

5.3.2 In the event of disagreement, a referee chemical

4.1 Materials:

analysis of samples from each lot shall be made in accordance

4.1.1 Thebolts,capscrews,andstudsshallbemanufactured

with 11.1 and 12.1.

from material having a chemical composition conforming to

the requirements in Table 1 and capable of developing the

6. Mechanical Properties

required mechanical properties for the specified alloy in the

6.1 The fasteners shall be tested in accordance with the

finished fastener. See Specification B574 for nickel alloys.

mechanicaltestingrequirementsfortheapplicabletype,length

of product, and minimum tensile strength and shall meet the

mechanical properties in Table 2 and Table 3 for the specified

Available from Global Engineering Documents, 15 Inverness Way, East

Englewood, CO 80112-5704. alloy.

F468M−06 (2012)

TABLE 1 Chemical Requirements

Composition, %

UNS Copper and Copper-Base Alloys

Designa-

Man-

tion

Alumi- Copper, Iron, Nickel, Phos- Zinc, Lead, Arsenic,

Alloy General Name ganese, Silicon Tin

Number A

num min max max phorus max max max

max

C11000 110 ETP copper . . . 99.9 . . . . . . . . . . . . . . . . . . . . . . . . . . .

C26000 260 brass . . . 68.5–71.5 0.05 . . . . . . . . . . . . balance 0.07 . . . . . .

C27000 270 brass . . . 63.0–68.5 0.07 . . . . . . . . . . . . balance 0.10 . . . . . .

C46200 462 naval brass . . . 62.0–65.0 0.10 . . . . . . . . . . . . balance 0.20 0.5–1.0 . . .

C46400 464 naval brass . . . 59.0–62.0 0.10 . . . . . . . . . . . . balance 0.20 0.5–1.0 . . .

A

C51000 510 phosphor bronze . . . balance 0.10 . . . . . . 0.03–0.35 . . . 0.30 0.05 4.2–5.8 . . .

B C

C61300 613 aluminum bronze 6.0–7.5 2.0–3.0 0.10 0.15 0.015 0.10 0.05 0.01 0.20–0.50 . . .

D

C61400 614 aluminum bronze 6.0–8.0 88.0 1.5–3.5 1.0 . . . . . . . . . . . . . . . . . . . . .

D

C63000 630 aluminum bronze 9.0–11.0 78.0 2.0–4.0 1.5 4.0–5.5 . . . 0.25 max . . . . . . 0.20 max . . .

D E

C64200 642 aluminum silicon bronze 6.3–7.6 88.65 0.30 0.10 0.25 . . . 1.5–2.2 0.50 0.05 0.20 max 0.15

D

C65100 651 silicon bronze . . . 96.0 0.8 0.7 . . . . . . 0.8–2.0 1.5 0.05 . . . . . .

D

C65500 655 silicon bronze . . . 94.8 0.8 1.5 0.6 . . . 2.8–3.8 1.5 0.05 . . . . . .

D

C66100 661 silicon bronze . . . 94.0 0.25 1.5 . . . . . . 2.8–3.5 1.5 0.20–0.8 . . . . . .

C67500 675 manganese bronze 0.25 max 57.0–60.0 0.8–2.0 0.05–0.5 . . . . . . . . . balance 0.20 0.5–1.5 . . .

D C

C71000 710 cupro-nickel . . . 74.0 0.60 1.00 19.0–23.0 . . 1.00 0.05 . . .

D C

C71500 715 cupro-nickel . . . 65.0 0.40–0.7 1.00 29.0–33.0 . . 1.00 0.05 . . .

A

Elements shown as balance shall be arithmetically computed by deducting the sum of the other named elements from 100.

B

Copper plus specified elements = 99.8 min; copper plus silver = 88.5–91.5.

C

Cobalt is to be counted as nickel.

D

Minimum content of copper plus all other elements with specified limits shall be 99.5 %.

E

An alloy containing as high as 2.6 % silicon is acceptable provided the sum of all the elements other than copper, silicon, and iron does not exceed 0.30 %.

F468M−06 (2012)

TABLE 1 Continued

Nickel and Nickel-Base Alloys

Man-

UNS Car- Phos- Sili- Co-

Alumi- Chro- Iron, gan- Molybde- Sulfur, Tung-

A A

Designation Alloy General Name bon, Copper Nickel phorus, con, Titanium balt, Vanadium Niobium

num mium max ese, num max sten

Number max max max max

max

N10001 335 Ni-Mo 0.05 1.0 4.0– 1.0 balance 0.025 1.00 2.50 26.0– 0.030 0.2– . .

max 6.0 30.0 0.4

N10276 276 Ni-Mo-Cr . . . 0.02 14.5– 4.0– 1.00 balance 0.040 0.08 2.50 15.0– 0.030 0.35 3.0– .

16.5 7.0 17.0 max 4.5

B

N04400 400 Ni-Cu Class A . . . 0.3 . . . balance 2.5 2.0 63.0– . 0.5 . . 0.024 . . .

70.0

B

N04405 405 Ni-Cu Class B . . . 0.3 . . . balance 2.5 2.0 63.0– . 0.5 . . . . 0.025– . . .

70.0 0.060

B

N05500 500 Ni-Cu-Al 2.30– 0.25 . . . balance 2.0 1.5 63.0– . . . 0.5 0.35– . 0.01 . . .

3.15 70.0 0.85

N06059 59 Ni-Cr-Mo 0.1– 0.010 22.0– 0.5 1.5 0.5 balance 0.015 0.10 . 0.3 15.0– 0.010 . . .

0.4 max 24.0 max max max max max max 16.5 max

C

N06625 625 Ni-Cr-Mo-Cb 0.40 max 0.10 20.0– . 5.0 0.50 58.0 0.015 0.50 0.40 1.00 8.0– 0.015 . . . . . . 3.2–

23.0 max min max max max 10.0 4.2

N06686 686 Ni-Cr-Mo-W . . . 0.010 19.0– . 5.0 0.75 balance 0.04 0.08 0.02– . . . 15.0– 0.02 . . . 3.0– .

max 23.0 max max max max 0.25 17.0 max 4.4

A

Elements shown as balance shall be arithmetically computed by deducting the sum of the other named elements from 100.

B

Cobalt is to be counted as nickel.

C

Alloy 625 material shall be refined using the electroslag remelting process (ESR), or the vacuum arc remelting process (VAR).

F468M−06 (2012)

TABLE 1 Continued

Composition, %

A

Aluminum-Base Alloys

Other Elements,

UNS Desig-

General Alumi- Chro- Iron, Manganese, Silicon, Titanium, Zinc, Magne-

max

nation Alloy Copper

B

Name num mium max max max max max sium

Number

Each Total

C

A92024 2024 Aluminum 2024 balance 0.10 max 3.8–4.9 0.50 0.30–0.9 0.50 0.15 0.25 1.2–1.8 0.05 0.15

A96061 6061 Aluminum 6061 balance 0.04–0.35 0.15–0.40 0.7 0.15 0.40–0.8 0.15 0.25 0.8–1.2 0.05 0.15

D

A97075 7075 Aluminum 7075 balance 0.18–0.35 1.2–2.0 0.50 0.30 0.40 0.20 5.1–6.1 2.1–2.9 0.05 0.15

A

Analysis shall regularly be made only for the elements specified in this table. If, however, the presence of other elements is suspected or indicated in amounts greater than the specified limits, further analysis shall be

made to determine that these elements are not present in excess of the specified limits.

B

Elements shown as balance shall be arithmetically computed by deducting the sum of the other named elements from 100.

C

Titanium + zirconium 0.20 %, max.

D

Lead 0.4–0.7 %; bismuth 0.4–0.7 %.

F468M−06 (2012)

TABLE 1 Continued

A

Titanium and Titanium-Base Alloys

B

Residuals

UNS Des- Car- Nitro- Oxy- Molyb- Ruthe-

General Alumi- Iron, Tita- Hydro- Palla- Vana- Chro- Zirco- Tin, Sili-

ignation Alloy bon, gen, gen, denum, nium,

each, total,

Name num, Al Fe nium, Ti gen, H dium, Pd dium, V mium, Cr nium, Zr Sn con, Si

Number C N O Mo Ru

max max

R50250 1 Titanium Gr 1 . . . 0.10 0.20 balance 0.0125 0.05 0.18 . . . . . . . . . . . . . .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.