ASTM B21/B21M-18(2019)

(Specification)Standard Specification for Naval Brass Rod, Bar, and Shapes

Standard Specification for Naval Brass Rod, Bar, and Shapes

ABSTRACT

This specification establishes the requirements for rods, bars, and shapes of naval brass with Copper Alloy UNS Nos. C46200, C46400, C47940, C48200, and C48500. Tempers available under this specification are M30 (as-hot extruded), O60 (soft annealed), O50 (light annealed), H60 (cold headed and formed), H02 (½ hard), and H04 (hard). Products shall be tested and shall adhere to dimensional (diameter, shape, length, straightness, and edge contour), mechanical (tensile and yield strength, Rockwell hardness, and elongation), and chemical composition requirements. Products shall also meet piston-finish rod and shafting, and U.S. Government purchase requirements.

SCOPE

1.1 This specification establishes the requirements for naval brass rod, bar, and shapes produced from Copper Alloy UNS Nos. C46200, C46400, C46750, C47940, C48200, C48500, or C48640.

1.1.1 For piston-finish rod or shafting refer to the Other Requirements Section.

1.1.2 For hot forging material, refer to Specification B124/B124M.

1.2 Units—The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, SI units are shown in brackets. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other and values from the two systems shall not be combined.

1.3 Warning—Mercury is a definite health hazard in use and disposal (see Performance Requirements).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B21/B21M −18 (Reapproved 2019)

Standard Specification for

Naval Brass Rod, Bar, and Shapes

This standard is issued under the fixed designation B21/B21M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* B124/B124M Specification for Copper and Copper Alloy

Forging Rod, Bar, and Shapes

1.1 This specification establishes the requirements for naval

B154 Test Method for Mercurous Nitrate Test for Copper

brass rod, bar, and shapes produced from Copper Alloy UNS

Alloys

Nos. C46200, C46400, C46750, C47940, C48200, C48500, or

B249/B249M Specification for General Requirements for

C48640.

Wrought Copper and Copper-Alloy Rod, Bar, Shapes and

1.1.1 For piston-finish rod or shafting refer to the Other

Forgings

Requirements Section.

B601 Classification forTemper Designations for Copper and

1.1.2 For hot forging material, refer to Specification B124/

Copper Alloys—Wrought and Cast

B124M.

B858 Test Method forAmmoniaVaporTest for Determining

1.2 Units—The values stated in either inch-pound units or

Susceptibility to Stress Corrosion Cracking in Copper

SI units are to be regarded separately as standard. Within the

Alloys

text, SI units are shown in brackets. The values stated in each

E8/E8M Test Methods for Tension Testing of Metallic Ma-

system are not necessarily exact equivalents; therefore, to

terials

ensure conformance with the standard, each system shall be

E18 Test Methods for Rockwell Hardness of Metallic Ma-

used independently of the other and values from the two

terials

systems shall not be combined.

E62 Test Methods for Chemical Analysis of Copper and

CopperAlloys (Photometric Methods) (Withdrawn 2010)

1.3 Warning—Mercury is a definite health hazard in use

and disposal (see Performance Requirements). E478 Test Methods for ChemicalAnalysis of CopperAlloys

1.4 This standard does not purport to address all of the

3. General Requirements

safety concerns, if any, associated with its use. It is the

3.1 The following sections of Specification B249/B249M

responsibility of the user of this standard to establish appro-

constitute a part of this specification:

priate safety, health, and environmental practices and deter-

3.1.1 Terminology;

mine the applicability of regulatory limitations prior to use.

3.1.2 Materials and Manufacture;

1.5 This international standard was developed in accor-

3.1.3 Workmanship, Finish, and Appearance;

dance with internationally recognized principles on standard-

3.1.4 Sampling;

ization established in the Decision on Principles for the

3.1.5 Number of Tests and Retests;

Development of International Standards, Guides and Recom-

3.1.6 Specimen Preparation;

mendations issued by the World Trade Organization Technical

3.1.7 Test Methods;

Barriers to Trade (TBT) Committee.

3.1.8 Significance of Numerical Limits;

2. Referenced Documents

3.1.9 Inspection;

3.1.10 Rejection and Rehearing;

2.1 ASTM Standards:

3.1.11 Certification;

3.1.12 Mill Test Report;

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

3.1.13 Packaging and Product Marking; and

and CopperAlloys and is the direct responsibility of Subcommittee B05.02 on Rod,

3.1.14 Supplementary Requirements.

Bar, Wire, Shapes and Forgings.

Current edition approved April 1, 2019. Published April 2019. Originally

3.2 In addition, when a section with a title identical to that

approved in 1918. Last previous edition approved in 2018 as B21/B21M–18. DOI:

referenced in 3.1, above, appears in this specification, it

10.1520/B0021_B0021M–18R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B21/B21M − 18 (2019)

contains additional requirements which supplement those ap- 5.3 For alloys in which zinc is listed as the “remainder,”

pearing in Specification B249/B249M. either copper or zinc may be taken as the difference between

the sum of the results of all other elements determined and

4. Ordering Information

100 %. When copper is so determined, that difference value

shall conform to the requirements given in Table 1.

4.1 Include the following specified choices when placing

orders for product under this specification, as applicable:

5.4 When all the elements listed in Table 1 for the Copper

4.1.1 ASTM designation and year of issue;

Alloy No. are determined, the sum of the results shall be

4.1.2 Copper Alloy UNS No. designation (Scope);

99.6 % minimum except for C46750 and C48640, which shall

4.1.3 Temper (Temper Section and related Tables);

be 99.5 % minimum.

4.1.4 Form—cross-section such as round, hexagonal,

6. Temper

square, and so forth;

4.1.5 Diameter or distance between parallel surfaces, width 6.1 The standard tempers for products described in this

and thickness (Dimensions and Permissible Variations);

specification, as defined in Classification B601, are shown in

4.1.6 Length (Dimensions and Permissible Variations);

Tables 2 and 3.

4.1.7 Edge contours (Dimensions and Permissible Varia-

7. Mechanical Property Requirements

tions);

4.1.8 Quantity—number of pieces or total weight, for each 7.1 Product furnished under this specification shall conform

size and form; and to the mechanical property requirements prescribed in Tables

4.1.9 Intended application. 2-4.

7.1.1 Rockwell Hardness Requirements—For the alloys and

4.2 The following options are available, but may not be

tempers listed, the product ⁄2 in. [12 mm] and over in diameter

included, unless specified at the time of placing of the order

or distance between parallel surfaces should conform with the

when required:

requirements prescribed in Table 4, when tested in accordance

4.2.1 Tensile test for product ⁄2 in. [12 mm] and over, for

with Test Methods E18.

the alloys and tempers listed in Table 4;

7.1.1.1 For the alloys, tempers, and sizes listed in Table 4,

4.2.2 Residual stress test (Performance Requirements sec-

Rockwell hardness may be used as the basis of acceptance or

tion);

rejection for mechanical properties except when the tensile test

4.2.3 Piston finish rod or shafting (Other Requirements

is specified in the contract or purchase order.

section);

7.1.1.2 Hardness test results outside the ranges of Table 4

4.2.4 Certification (Specification B249/B249M);

shall not be cause for rejection if the tensile property require-

4.2.5 Mill test report (Specification B249/B249M);

ments of Tables 2 and 3 are met.

4.2.6 Heat identification or traceability details (Specifica-

7.1.2 Tensile Strength Requirements—The product shall

tion B249/B249M); and

conform with the requirements of Tables 2 and 3, when tested

4.2.7 If product is purchased for agencies of the U.S.

in accordance with Test Methods E8/E8M. Whenever tensile

Government (Other Requirements—Purchases for U.S. Gov-

test results are obtained from both full-size and from machined

ernment).

test specimens and they differ, the results obtained from

full-size test specimens shall be used to determine confor-

5. Chemical Composition

mance to the requirements of this specification.

5.1 The material shall conform to the chemical composition

requirements specified in Table 1 for the Copper Alloy UNS 8. Performance Requirements

No. designation specified in the ordering information.

8.1 Residual Stress Test:

5.2 These composition limits do not preclude the presence 8.1.1 When specified in the contract or purchase order,

of other elements. Limits may be established and analysis product in drawn tempers shall be tested for residual stress

required for unnamed elements by agreement between the according to the requirements of Test Method B154 or Test

manufacturer or supplier and purchaser. Method B858 and show no signs of cracking.

TABLE 1 Chemical Requirements

Copper Alloy UNS No.

Element,

%

C46200 C46400 C46750 C47940 C48200 C48500 C48640

Copper 62.0–65.0 59.0–62.0 59.2–62.5 63.0–66.0 59.0–62.0 59.0–62.0 59.0–62.0

Tin 0.50–1.0 0.50–1.0 1.00–1.80 1.2–2.0 0.50–1.0 0.50–1.0 0.50–2.0

Lead 0.20 max 0.20 max 0.25 max 1.0–2.0 0.40–1.0 1.3–2.2 1.0–3.0

Zinc remainder remainder remainder remainder remainder remainder remainder

Iron 0.10 max 0.10 max 0.10 max 0.10–1.0 0.10 max 0.10 max 0.40 max

A B

Nickel . . 0.50 max 0.10–0.50 . . 0.30 max

Antimony . . 0.05–0.15 . . . .

Phosphorus . . 0.05–0.15 . . . 0.05–0.25

A

Including cobalt.

B

Not including Co.

B21/B21M − 18 (2019)

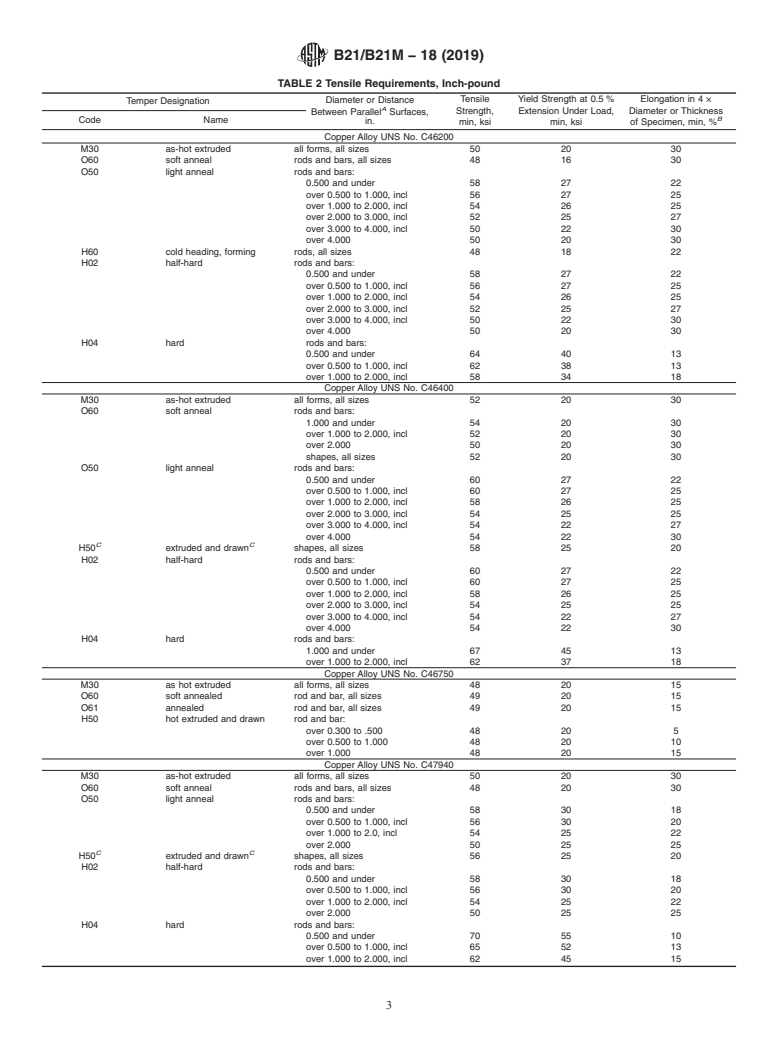

TABLE 2 Tensile Requirements, Inch-pound

Diameter or Distance Tensile Yield Strength at 0.5 % Elongation in 4 ×

Temper Designation

A

Strength, Extension Under Load, Diameter or Thickness

Between Parallel Surfaces,

B

Code Name

in.

min, ksi min, ksi of Specimen, min, %

Copper Alloy UNS No. C46200

M30 as-hot extruded all forms, all sizes 50 20 30

O60 soft anneal rods and bars, all sizes 48 16 30

O50 light anneal rods and bars:

0.500 and under 58 27 22

over 0.500 to 1.000, incl 56 27 25

over 1.000 to 2.000, incl 54 26 25

over 2.000 to 3.000, incl 52 25 27

over 3.000 to 4.000, incl 50 22 30

over 4.000 50 20 30

H60 cold heading, forming rods, all sizes 48 18 22

H02 half-hard rods and bars:

0.500 and under 58 27 22

over 0.500 to 1.000, incl 56 27 25

over 1.000 to 2.000, incl 54 26 25

over 2.000 to 3.000, incl 52 25 27

over 3.000 to 4.000, incl 50 22 30

over 4.000 50 20 30

H04 hard rods and bars:

0.500 and under 64 40 13

over 0.500 to 1.000, incl 62 38 13

over 1.000 to 2.000, incl 58 34 18

Copper Alloy UNS No. C46400

M30 as-hot extruded all forms, all sizes 52 20 30

O60 soft anneal rods and bars:

1.000 and under 54 20 30

over 1.000 to 2.000, incl 52 20 30

over 2.000 50 20 30

shapes, all sizes 52 20 30

O50 light anneal rods and bars:

0.500 and under 60 27 22

over 0.500 to 1.000, incl 60 27 25

over 1.000 to 2.000, incl 58 26 25

over 2.000 to 3.000, incl 54 25 25

over 3.000 to 4.000, incl 54 22 27

over 4.000 54 22 30

C C

H50 extruded and drawn shapes, all sizes 58 25 20

H02 half-hard rods and bars:

0.500 and under 60 27 22

over 0.500 to 1.000, incl 60 27 25

over 1.000 to 2.000, incl 58 26 25

over 2.000 to 3.000, incl 54 25 25

over 3.000 to 4.000, incl 54 22 27

over 4.000 54 22 30

H04 hard rods and bars:

1.000 and under 67 45 13

over 1.000 to 2.000, incl 62 37 18

Copper Alloy UNS No. C46750

M30 as hot extruded all forms, all sizes 48 20 15

O60 soft annealed rod and bar, all sizes 49 20 15

O61 annealed rod and bar, all sizes 49 20 15

H50 hot extruded and drawn rod and bar:

over 0.300 to .500 48 20 5

over 0.500 to 1.000 48 20 10

over 1.000 48 20 15

Copper Alloy UNS No. C47940

M30 as-hot extruded all forms, all sizes 50 20 30

O60 soft anneal rods and bars, all sizes 48 20 30

O50 light anneal rods and bars:

0.500 and under 58 30 18

over 0.500 to 1.000, incl 56 30 20

over 1.000 to 2.0, incl 54 25 22

over 2.000 50 25 25

C C

H50 extruded and drawn shapes, all sizes 56 25 20

H02 half-hard rods and bars:

0.500 and under 58 30 18

over 0.500 to 1.000, incl 56 30 20

over 1.000 to 2.000, incl 54 25 22

over 2.000 50 25 25

H04 hard rods and bars:

0.500 and under 70 55 10

over 0.500 to 1.000, incl 65 52 13

over 1.000 to 2.000, incl 62 45 15

B21/B21M − 18 (2019)

TABLE 2 Continued

Tensile Yield Strength at 0.5 % Elongation in 4 ×

Diameter or Distance

Temper Designation

A

Strength, Extension Under Load, Diameter or Thickness

Between Parallel Surfaces,

B

Code Name

in. min, ksi min, ksi of Specimen, min, %

Copper Alloy UNS No. C48200

M30 as-hot extruded all forms, all sizes 52 20 25

O60 soft anneal rods and bars:

1.000 and under 54 20 25

over 1.000 to 2.000, incl 52 20 25

over 2.000 50 20 25

shapes, all sizes 52 20 25

O50 light anneal rods and bars:

1.000 and under 60 27 18

over 1.000 to 2.000, incl 58 26 20

over 2.000 to 3.000, incl 54 25 20

over 3.000 to 4.000, incl 54 22 20

over 4.000 54 22 25

C C

H50 extruded and drawn shapes, all sizes 58 25 15

H02 half-hard rods and bars:

1.000 and under 60 27 18

over 1.000 to 2.000, incl 58 26 20

over 2.000 to 3.000, incl 54 25 20

over 3.000 to 4.000, incl 54 22 20

over 4.000 54 22 25

H04 hard rods and bars:

1.000 and under 67 45 11

over 1.000 to 2.000, incl 62 37 15

Copper Alloy UNS No. C48500

M30 as-hot extruded all forms, all sizes 52 20 20

O60 soft anneal rods and bars:

1.000 and under 54 20 20

over 1.000 to 2.000, incl 52 20 20

over 2.000 50 20 20

shapes, all sizes 52 20 20

O50 light anneal rods and bars:

1.000 and under 60 27 12

over 1.000 to 2.000, incl 58 26 20

over 2.000 to 3.000, incl 54 25 20

over 3.000 to 4.000, incl 54 22 20

over 4.000 54 22 20

C C

H50 extruded and drawn shapes, all sizes 58 25 15

H02 half-hard rods and bars:

1.000 and under 60 27 12

over 1.000 to 2.000, incl 58 26 20

over 2.000 to 3.000, incl 54 25 20

over 3.000 to 4.000, incl 54 22 20

over 4.000 54 22 20

H04 hard rods and bars:

1.000 and under 67 45 10

over 1.000 to 2.000, incl 62 37 13

Copper Alloy UNS No. C48640

M30 as hot-extruded all forms, all sizes 45.7 18 15

H02 half-hard rod and bar:

0.300 to 0.500, incl 45.7 18 5

over 0.500 to 1.00, incl 45.7 18 10

over 1.000 45.7 18 15

A

For rectangular bar, the Distance Between Parallel Surfaces refers to thickness.

B

In any case, a minimum gage length of 1 in. shall be used.

C

This temper does not apply to hollow shapes.

8.1.2 Unless otherwise agreed upon between the manufac- plicable product Safety Data Sheet (SDS) for additional

turer or supplier and the purchaser, the manufacturer shall have

information. The potential exists that selling mercury or

the option of using either the Mercurous Nitrate Test or the mercury-containing products, or both, is prohibited by local or

Ammonia Vapor Test. When the Ammonia Vapor Test is used,

national law. Users must determine legality of sales in their

the test pH value appropriate for the intended application shall

location.)

be 10 unless otherwise specified by the purchaser. (Warning—

NOTE 1—Aresidual stress test provides information about the adequacy

Mercury has been designated by many regulatory agencies as

of the stress relief of the material. Bar straightening is a method of

a hazardous substance that can cause serious medical issues. mechanical stress relief. Str

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B21/B21M − 18 B21/B21M − 18 (Reapproved 2019)

Standard Specification for

Naval Brass Rod, Bar, and Shapes

This standard is issued under the fixed designation B21/B21M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification establishes the requirements for naval brass rod, bar, and shapes produced from Copper Alloy UNS Nos.

C46200, C46400, C46750, C47940, C48200, C48500, or C48640.

1.1.1 For piston-finish rod or shafting refer to the Other Requirements Section.

1.1.2 For hot forging material, refer to Specification B124/B124M.

1.2 Units—The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text,

SI units are shown in brackets. The values stated in each system mayare not benecessarily exact equivalents; therefore, to ensure

conformance with the standard, each system shall be used independently of the other. Combiningother and values from the two

systems may result in nonconformance with the specification.shall not be combined.

1.3 Warning—Mercury is a definite health hazard in use and disposal (see Performance Requirements).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

B124/B124M Specification for Copper and Copper Alloy Forging Rod, Bar, and Shapes

B154 Test Method for Mercurous Nitrate Test for Copper Alloys

B249/B249M Specification for General Requirements for Wrought Copper and Copper-Alloy Rod, Bar, Shapes and Forgings

B601 Classification for Temper Designations for Copper and Copper Alloys—Wrought and Cast

B858 Test Method for Ammonia Vapor Test for Determining Susceptibility to Stress Corrosion Cracking in Copper Alloys

E8/E8M Test Methods for Tension Testing of Metallic Materials

E18 Test Methods for Rockwell Hardness of Metallic Materials

E62 Test Methods for Chemical Analysis of Copper and Copper Alloys (Photometric Methods) (Withdrawn 2010)

E478 Test Methods for Chemical Analysis of Copper Alloys

3. General Requirements

3.1 The following sections of Specification B249/B249M constitute a part of this specification:

3.1.1 Terminology,Terminology;

3.1.2 Materials and Manufacture,Manufacture;

3.1.3 Workmanship, Finish, and Appearance,Appearance;

3.1.4 Sampling,Sampling;

This specification is under the jurisdiction of ASTM Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.02 on Rod, Bar,

Wire, Shapes and Forgings.

Current edition approved Oct. 1, 2018April 1, 2019. Published October 2018April 2019. Originally approved in 1918. Last previous edition approved in 20142018 as

B21/B21M–14.–18. DOI: 10.1520/B0021_B0021M–18.10.1520/B0021_B0021M–18R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B21/B21M − 18 (2019)

3.1.5 Number of Tests and Retests,Retests;

3.1.6 Specimen Preparation,Preparation;

3.1.7 Test Methods,Methods;

3.1.8 Significance of Numerical Limits,Limits;

3.1.9 Inspection,Inspection;

3.1.10 Rejection and Rehearing,Rehearing;

3.1.11 Certification,Certification;

3.1.12 Mill Test Report,Report;

3.1.13 Packaging and Product Marking,Marking; and

3.1.14 Supplementary Requirements.

3.2 In addition, when a section with a title identical to that referenced in 3.1, above, appears in this specification, it contains

additional requirements which supplement those appearing in Specification B249/B249M.

4. Ordering Information

4.1 Include the following specified choices when placing orders for product under this specification, as applicable:

4.1.1 ASTM designation and year of issue,issue;

4.1.2 Copper Alloy UNS No. designation (Scope),(Scope);

4.1.3 Temper (Temper Section and related Tables),Tables);

4.1.4 Form—cross-section such as round, hexagonal, square, and so forth,forth;

4.1.5 Diameter or distance between parallel surfaces, width and thickness (Dimensions and Permissible Variations),Variations);

4.1.6 Length (Dimensions and Permissible Variations),Variations);

4.1.7 Edge contours (Dimensions and Permissible Variations),Variations);

4.1.8 Quantity—number of pieces or total weight, for each size and form,form; and

4.1.9 Intended application.

4.2 The following options are available, but may not be included, unless specified at the time of placing of the order when

required:

4.2.1 Tensile test for product ⁄2 in. [12 mm] and over, for the alloys and tempers listed in Table 4.;

4.2.2 Residual stress test (Performance Requirements section),section);

4.2.3 Piston finish rod or shafting (Other Requirements section),section);

4.2.4 Certification (Specification B249/B249M),);

4.2.5 Mill test report (Specification B249/B249M),);

4.2.6 Heat identification or traceability details (Specification B249/B249M),); and

4.2.7 If product is purchased for agencies of the U.S. governmentGovernment (Other Requirements—Purchases for U.S.

Government).

5. Chemical Composition

5.1 The material shall conform to the chemical composition requirements specified in Table 1 for the Copper Alloy UNS No.

designation specified in the ordering information.

5.2 These composition limits do not preclude the presence of other elements. Limits may be established and analysis required

for unnamed elements by agreement between the manufacturer or supplier,supplier and purchaser.

5.3 For alloys in which zinc is listed as the “remainder,” either copper or zinc may be taken as the difference between the sum

of the results of all other elements determined and 100 %. When copper is so determined, that difference value shall conform to

the requirements given in Table 1.

TABLE 1 Chemical Requirements

Copper Alloy UNS No.

Element,

%

C46200 C46400 C46750 C47940 C48200 C48500 C48640

Copper 62.0–65.0 59.0–62.0 59.2–62.5 63.0–66.0 59.0–62.0 59.0–62.0 59.0–62.0

Tin 0.50–1.0 0.50–1.0 1.00–1.80 1.2–2.0 0.50–1.0 0.50–1.0 0.50–2.0

Lead 0.20 max 0.20 max 0.25 max 1.0–2.0 0.40–1.0 1.3–2.2 1.0–3.0

Zinc remainder remainder remainder remainder remainder remainder remainder

Iron 0.10 max 0.10 max 0.10 max 0.10–1.0 0.10 max 0.10 max 0.40 max

A B

Nickel . . 0.50 max 0.10–0.50 . . 0.30 max

Antimony . . 0.05–0.15 . . . .

Phosphorus . . 0.05–0.15 . . . 0.05–0.25

A

Including cobalt.

B

Not including Co.

B21/B21M − 18 (2019)

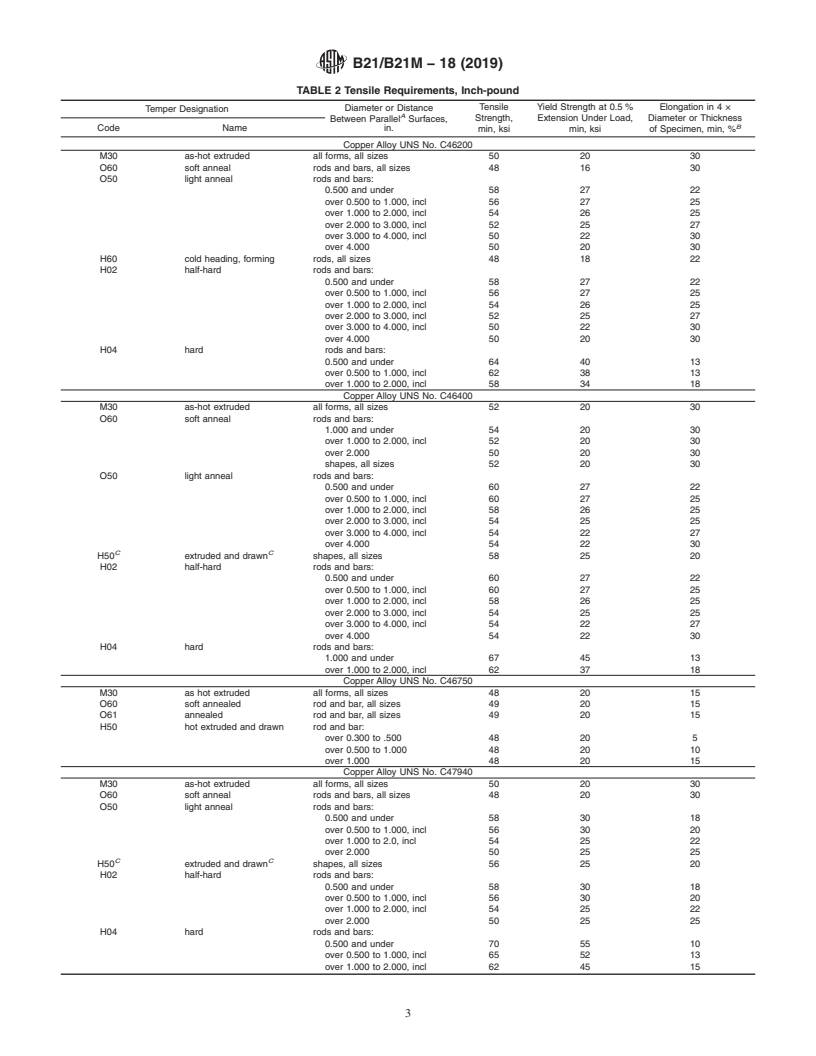

TABLE 2 Tensile Requirements, Inch-pound

Tensile Yield Strength at 0.5 % Elongation in 4 ×

Temper Designation Diameter or Distance

A

Strength, Extension Under Load, Diameter or Thickness

Between Parallel Surfaces,

B

Code Name

in.

min, ksi min, ksi of Specimen, min, %

Copper Alloy UNS No. C46200

M30 as-hot extruded all forms, all sizes 50 20 30

O60 soft anneal rods and bars, all sizes 48 16 30

O50 light anneal rods and bars:

0.500 and under 58 27 22

over 0.500 to 1.000, incl 56 27 25

over 1.000 to 2.000, incl 54 26 25

over 2.000 to 3.000, incl 52 25 27

over 3.000 to 4.000, incl 50 22 30

over 4.000 50 20 30

H60 cold heading, forming rods, all sizes 48 18 22

H02 half-hard rods and bars:

0.500 and under 58 27 22

over 0.500 to 1.000, incl 56 27 25

over 1.000 to 2.000, incl 54 26 25

over 2.000 to 3.000, incl 52 25 27

over 3.000 to 4.000, incl 50 22 30

over 4.000 50 20 30

H04 hard rods and bars:

0.500 and under 64 40 13

over 0.500 to 1.000, incl 62 38 13

over 1.000 to 2.000, incl 58 34 18

Copper Alloy UNS No. C46400

M30 as-hot extruded all forms, all sizes 52 20 30

O60 soft anneal rods and bars:

1.000 and under 54 20 30

over 1.000 to 2.000, incl 52 20 30

over 2.000 50 20 30

shapes, all sizes 52 20 30

O50 light anneal rods and bars:

0.500 and under 60 27 22

over 0.500 to 1.000, incl 60 27 25

over 1.000 to 2.000, incl 58 26 25

over 2.000 to 3.000, incl 54 25 25

over 3.000 to 4.000, incl 54 22 27

over 4.000 54 22 30

C C

H50 extruded and drawn shapes, all sizes 58 25 20

H02 half-hard rods and bars:

0.500 and under 60 27 22

over 0.500 to 1.000, incl 60 27 25

over 1.000 to 2.000, incl 58 26 25

over 2.000 to 3.000, incl 54 25 25

over 3.000 to 4.000, incl 54 22 27

over 4.000 54 22 30

H04 hard rods and bars:

1.000 and under 67 45 13

over 1.000 to 2.000, incl 62 37 18

Copper Alloy UNS No. C46750

M30 as hot extruded all forms, all sizes 48 20 15

O60 soft annealed rod and bar, all sizes 49 20 15

O61 annealed rod and bar, all sizes 49 20 15

H50 hot extruded and drawn rod and bar:

over 0.300 to .500 48 20 5

over 0.500 to 1.000 48 20 10

over 1.000 48 20 15

Copper Alloy UNS No. C47940

M30 as-hot extruded all forms, all sizes 50 20 30

O60 soft anneal rods and bars, all sizes 48 20 30

O50 light anneal rods and bars:

0.500 and under 58 30 18

over 0.500 to 1.000, incl 56 30 20

over 1.000 to 2.0, incl 54 25 22

over 2.000 50 25 25

C C

H50 extruded and drawn shapes, all sizes 56 25 20

H02 half-hard rods and bars:

0.500 and under 58 30 18

over 0.500 to 1.000, incl 56 30 20

over 1.000 to 2.000, incl 54 25 22

over 2.000 50 25 25

H04 hard rods and bars:

0.500 and under 70 55 10

over 0.500 to 1.000, incl 65 52 13

over 1.000 to 2.000, incl 62 45 15

B21/B21M − 18 (2019)

TABLE 2 Continued

Diameter or Distance Tensile Yield Strength at 0.5 % Elongation in 4 ×

Temper Designation

A

Strength, Extension Under Load, Diameter or Thickness

Between Parallel Surfaces,

B

Code Name

in. min, ksi min, ksi of Specimen, min, %

Copper Alloy UNS No. C48200

M30 as-hot extruded all forms, all sizes 52 20 25

O60 soft anneal rods and bars:

1.000 and under 54 20 25

over 1.000 to 2.000, incl 52 20 25

over 2.000 50 20 25

shapes, all sizes 52 20 25

O50 light anneal rods and bars:

1.000 and under 60 27 18

over 1.000 to 2.000, incl 58 26 20

over 2.000 to 3.000, incl 54 25 20

over 3.000 to 4.000, incl 54 22 20

over 4.000 54 22 25

C C

H50 extruded and drawn shapes, all sizes 58 25 15

H02 half-hard rods and bars:

1.000 and under 60 27 18

over 1.000 to 2.000, incl 58 26 20

over 2.000 to 3.000, incl 54 25 20

over 3.000 to 4.000, incl 54 22 20

over 4.000 54 22 25

H04 hard rods and bars:

1.000 and under 67 45 11

over 1.000 to 2.000, incl 62 37 15

Copper Alloy UNS No. C48500

M30 as-hot extruded all forms, all sizes 52 20 20

O60 soft anneal rods and bars:

1.000 and under 54 20 20

over 1.000 to 2.000, incl 52 20 20

over 2.000 50 20 20

shapes, all sizes 52 20 20

O50 light anneal rods and bars:

1.000 and under 60 27 12

over 1.000 to 2.000, incl 58 26 20

over 2.000 to 3.000, incl 54 25 20

over 3.000 to 4.000, incl 54 22 20

over 4.000 54 22 20

C C

H50 extruded and drawn shapes, all sizes 58 25 15

H02 half-hard rods and bars:

1.000 and under 60 27 12

over 1.000 to 2.000, incl 58 26 20

over 2.000 to 3.000, incl 54 25 20

over 3.000 to 4.000, incl 54 22 20

over 4.000 54 22 20

H04 hard rods and bars:

1.000 and under 67 45 10

over 1.000 to 2.000, incl 62 37 13

Copper Alloy UNS No. C48640

M30 as hot-extruded all forms, all sizes 45.7 18 15

H02 half-hard rod and bar:

0.300 to 0.500, incl 45.7 18 5

over 0.500 to 1.00, incl 45.7 18 10

over 1.000 45.7 18 15

A

For rectangular bar, the Distance Between Parallel Surfaces refers to thickness.

B

In any case, a minimum gage length of 1 in. shall be used.

C

This temper does not apply to hollow shapes.

5.4 When all the elements listed in Table 1 for the Copper Alloy No. are determined, the sum of the results shall be 99.6 %

minimum except for C46750 and C48640, which shall be 99.5 % minimum.

6. Temper

6.1 The standard tempers for products described in this specification, as defined in Classification B601, are shown in Tables 2

and 3.

7. Mechanical Property Requirements

7.1 Product furnished under this specification shall conform to the mechanical property requirements prescribed in Tables 2-4.

7.1.1 Rockwell Hardness Requirements—For the alloys and tempers listed, the product ⁄2 in. [12 mm] and over in diameter or

distance between parallel surfaces should conform with the requirements prescribed in Table 4, when tested in accordance with

Test Methods E18.

B21/B21M − 18 (2019)

TABLE 3 Tensile Requirements, SI

Tensile Yield Strength at 0.5 % Elongation in 4×

Temper Designation Diameter or Distance

A

Strength, Extension Under Load, Diameter or Thickness

Between Parallel Surfaces,

B

Code Name

mm

min, MPa min, MPa of Specimen, min, %

Copper Alloy UNS No. C46200

M30 as-hot extruded all forms, all sizes 345 140 30

O60 soft anneal rods and bars, all sizes 330 110 30

O50 light anneal rods and bars:

12 and under 400 185 22

over 12 to 25, incl 385 185 25

over 25 to 50, incl 370 180 25

over 50 to 75, incl 360 170 27

over 75 to 100, incl 345 150 30

over 100 345 140 30

H60 cold heading, forming rods, all sizes 330 125 22

H02 half-hard rods and bars:

12 and under 400 185 22

over 12 to 25, incl 385 185 25

over 25 to 50, incl 370 180 25

over 50 to 75, incl 360 170 27

over 75 to 100, incl 345 150 30

over 100 345 140 30

H04 hard rods and bars:

12 and under 440 275 13

over 12 to 25, incl 425 260 13

over 25 to 50, incl 400 235 18

Copper Alloy UNS No. C46400

M30 as-hot extruded all forms, all sizes 360 140 30

O60 soft anneal rods and bars:

25 and under 370 140 30

over 25 to 50, incl 360 140 30

over 50 345 140 30

shapes, all sizes 360 140 30

O50 light anneal rods and bars:

12 and under 415 185 22

over 12 to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.