ASTM A882/A882M-04a

(Specification)Standard Specification for Filled Epoxy-Coated Seven-Wire Prestressing Steel Strand

Standard Specification for Filled Epoxy-Coated Seven-Wire Prestressing Steel Strand

ABSTRACT

This specification covers filled epoxy-coated seven-wire prestressing steel strands with protective fusion-bonded epoxy coating applied by the electrostatic deposition method. This specification also covers relaxation loss limits for filled epoxy coated strands. Prestressing steel strands shall be free of contaminants such as oil, grease, or paint. Steel strand surfaces shall be cleaned to meet coating requirements, such as coating thickness, coating continuity, coating adhesion, coating composition, and coating bond with concrete or grout. Smooth or grit-impregnated coating shall be applied by the electrostatic deposition method or other method that will meet the coating requirements. Pullout tests shall be performed three times annually or maybe repeated if the coating failed to meet the requirements.

SCOPE

1.1 This specification covers ASTM Specification A 416 low-relaxation Grade 250 and Grade 270 seven-wire prestressing steel strand with protective fusion-bonded epoxy coating applied by the electrostatic deposition method or other method that will meet the coating requirements in Section 8, and, except as allowed by 1.2, with the interstices of the seven wires filled with epoxy to minimize migration of corrosive media, either by capillary action or other hydrostatic forces.

Note 1—The manufacturer as identified throughout this specification is the coating applicator.

1.2 Upon special request by the purchaser, the interstices are left unfilled.

Note 2—Unfilled strand can corrode from the inside and its application for prestressing tendons in concrete or for rock and soil anchors is not recommended.

1.3 This specification is applicable for orders in either inch-pound units (as Specification A 882) or SI units [as Specification A 882M].

1.4 The values stated in either inch-pound or SI units are to be regarded as standard. Within the test, the SI units are shown in brackets. The values stated in each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A882/A882M – 04a

Standard Specification for

1

Filled Epoxy-Coated Seven-Wire Prestressing Steel Strand

This standard is issued under the fixed designationA882/A882M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Coatings by Falling Abrasive

G12 Test Method for Nondestructive Measurement of Film

1.1 This specification covers ASTM Specification A416/

Thickness of Pipeline Coatings on Steel

A416M low-relaxation Grade 250 and Grade 270 seven-wire

G14 Test Method for Impact Resistance of Pipeline Coat-

prestressing steel strand with protective fusion-bonded epoxy

ings (Falling Weight Test)

coating applied by the electrostatic deposition method or other

G20 Test Method for Chemical Resistance of Pipeline

method that will meet the coating requirements in Section 8,

Coatings

and, except as allowed by 1.2, with the interstices of the seven

2.2 Federal Highway Administration Report:

wires filled with epoxy to minimize migration of corrosive

FHWA-RD-74-18 Nonmetallic Coatings for Concrete Rein-

media, either by capillary action or other hydrostatic forces.

3

forcing Bars (February 1974)

NOTE 1—Themanufacturerasidentifiedthroughoutthisspecificationis

the coating applicator.

3. Terminology

1.2 Uponspecialrequestbythepurchaser,theintersticesare

3.1 Definitions of Terms Specific to This Standard:

left unfilled.

3.1.1 disbonding—loss of adhesion between the fusion-

bonded epoxy coating and the steel strand wires.

NOTE 2—Unfilledstrandcancorrodefromtheinsideanditsapplication

3.1.2 fusion-bonded epoxy coating—a product containing

for prestressing tendons in concrete or for rock and soil anchors is not

pigments, thermo-setting epoxy resins, cross-linking agents,

recommended.

and other substances, which is applied in the form of powder

1.3 This specification is applicable for orders in either

onto a clean, heated metallic substrate and fuses to form a

inch-pound units (as Specification A882) or SI units [as

continuous barrier coating.

Specification A882M].

3.1.3 grit—inert particles impregnated on the outer surface

1.4 The values stated in either inch-pound or SI units are to

of the epoxy coating for improving bond with cement grout.

be regarded as standard.Within the test, the SI units are shown

3.1.4 holiday—a discontinuity in the coating that is not

in brackets. The values stated in each system must be used

discernible to a person with normal or corrected vision.

independently of the other. Combining values from the two

3.1.5 patching material—a liquid coating used to repair

systems may result in nonconformance with this specification.

damaged or uncoated areas.

2. Referenced Documents

4. Ordering Information

2

2.1 ASTM Standards:

4.1 The purchaser should specify:

A370 Test Methods and Definitions for Mechanical Testing

4.1.1 Diameter, grade, and type of uncoated strand in

of Steel Products

accordance with Specification A416/A416M (latest edition).

A416/A416M Specification for Steel Strand, Uncoated

4.1.2 Smooth or grit impregnated coating (see 7.3).

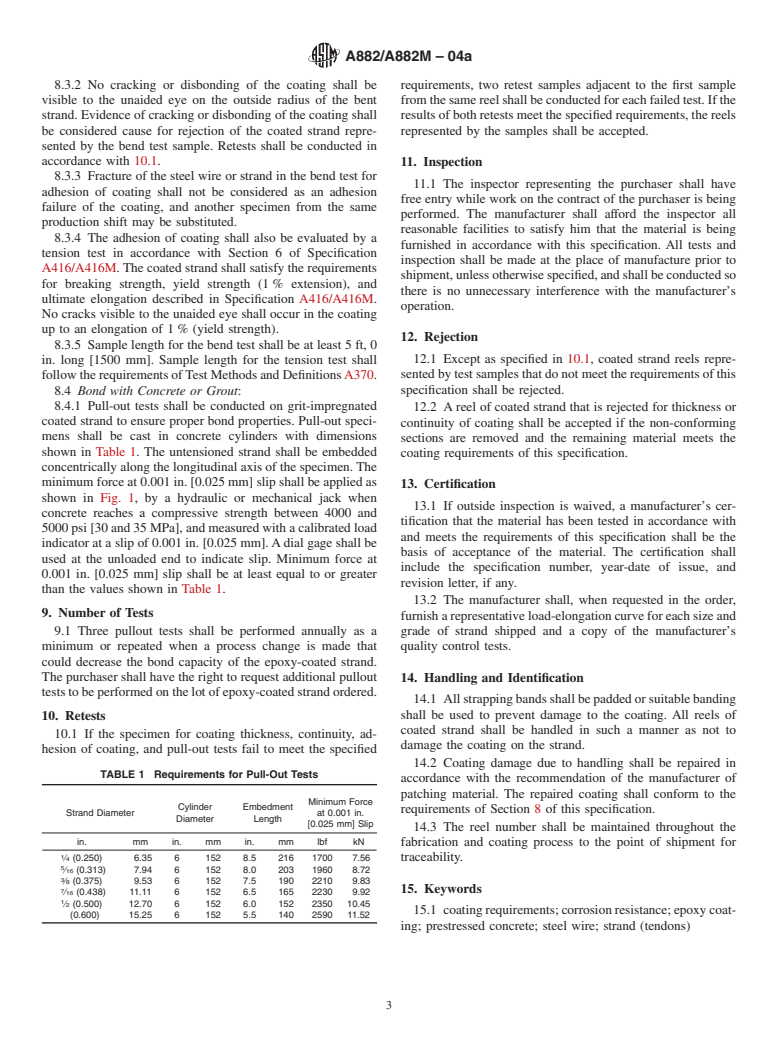

Seven-Wire for Prestressed Concrete

4.1.3 Quantity (in feet [metres]).

B117 Practice for Operating Salt Spray (Fog) Apparatus

4.1.4 Requirements for certification (see Section A1.2.3).

D968 Test Methods for Abrasion Resistance of Organic

4.1.5 Requirements for material samples (see 5.3).

4.1.6 Requirements for patching material (see 5.4).

1

4.1.7 Number of pullout tests to be performed, if any.

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

NOTE 3—A typical ordering description for epoxy-coated strand is as

A01.05 on Steel Reinforcement.

follows: 84000 feet [2560 m] of grit-impregnated epoxy-coated strand,

Current edition approved March 1, 2004. Published April 2004. Originally

1

approved in 1991. Last previous edition approved in 2004 as A882/A882M–04. ⁄2-in. [12.7-mm] diameter, Grade 270 K low-relaxation on wooden reels

DOI: 10.1520/A0882_A0882M-04A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from the National Technical Information Service, 5285 Port Royal

the ASTM website. Rd., Springfield, VA 22161.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A882/A882M – 04a

to A

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.