ASTM E2067-23

(Practice)Standard Practice for Full-Scale Oxygen Consumption Calorimetry Fire Tests

Standard Practice for Full-Scale Oxygen Consumption Calorimetry Fire Tests

SIGNIFICANCE AND USE

4.1 The oxygen consumption principle, used for the measurements described here, is based on the observation that, generally, the net heat of combustion is directly related to the amount of oxygen required for combustion (1).7 Approximately 13.1 MJ of heat are released per 1 kg of oxygen consumed. Test specimens in the test are burned in ambient air conditions, while being subjected to a prescribed external heating source.

4.1.1 This technique is not appropriate for use on its own when the combustible fuel is an oxidizer or an explosive agent, which release oxygen. Further analysis is required in such cases (see Appendix X2).

4.2 The heat release is determined by the measurement of the oxygen consumption, as determined by the oxygen concentration and the flow rate in the combustion product stream, in a full scale environment.

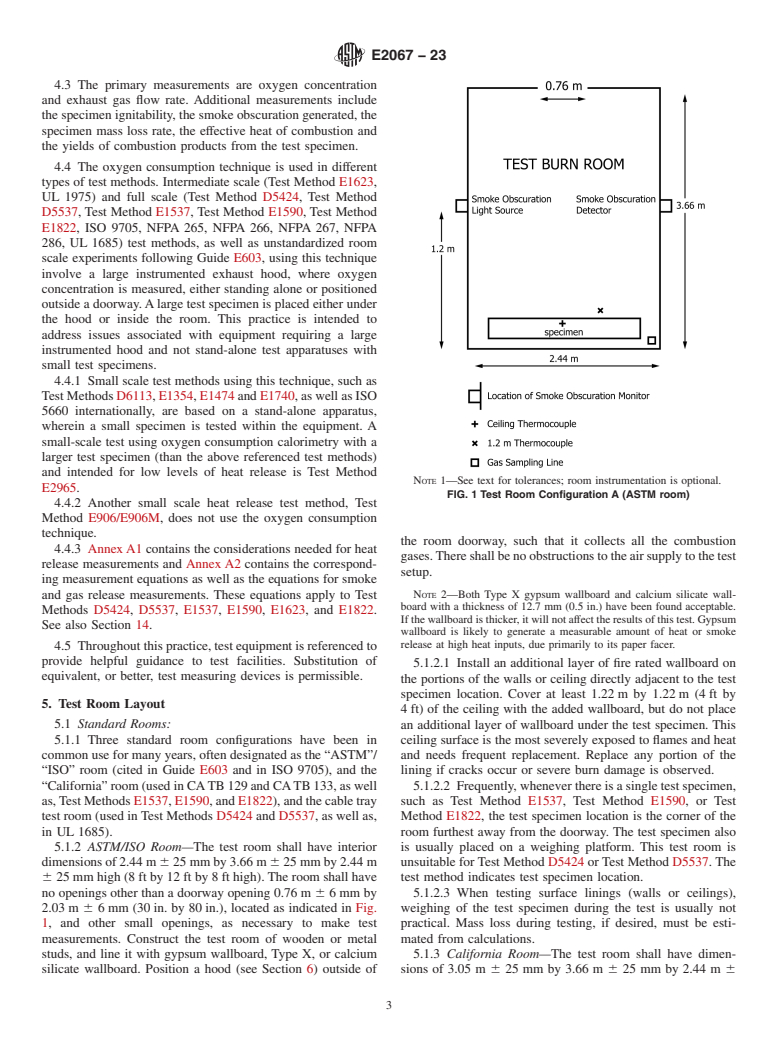

4.3 The primary measurements are oxygen concentration and exhaust gas flow rate. Additional measurements include the specimen ignitability, the smoke obscuration generated, the specimen mass loss rate, the effective heat of combustion and the yields of combustion products from the test specimen.

4.4 The oxygen consumption technique is used in different types of test methods. Intermediate scale (Test Method E1623, UL 1975) and full scale (Test Method D5424, Test Method D5537, Test Method E1537, Test Method E1590, Test Method E1822, ISO 9705, NFPA 265, NFPA 266, NFPA 267, NFPA 286, UL 1685) test methods, as well as unstandardized room scale experiments following Guide E603, using this technique involve a large instrumented exhaust hood, where oxygen concentration is measured, either standing alone or positioned outside a doorway. A large test specimen is placed either under the hood or inside the room. This practice is intended to address issues associated with equipment requiring a large instrumented hood and not stand-alone test apparatuses with small test specimens.

4.4.1 Small scale test methods using this technique, such as Tes...

SCOPE

1.1 This practice deals with methods to construct, calibrate, and use full scale oxygen consumption calorimeters to help minimize testing result discrepancies between laboratories.

1.2 The methodology described herein is used in a number of ASTM test methods, in a variety of unstandardized test methods, and for research purposes. This practice will facilitate coordination of generic requirements, which are not specific to the item under test.

1.3 The principal fire-test-response characteristics obtained from the test methods using this technique are those associated with heat release from the specimens tested, as a function of time. Other fire-test-response characteristics also are determined.

1.4 This practice is intended to apply to the conduction of different types of tests, including both some in which the objective is to assess the comparative fire performance of products releasing low amounts of heat or smoke and some in which the objective is to assess whether flashover will occur.

1.5 This practice does not provide pass/fail criteria that can be used as a regulatory tool, nor does it describe a test method for any material or product.

1.6 For use of the SI system of units in referee decisions, see IEEE/ASTM SI-10. The units given in parentheses are provided for information only.

1.7 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

Note 1: This is the standard caveat described in section F2.2.2.1 of the Form and Style for ASTM Standards manual for fire-test-response standards. In actual fact, this practice does not provide quantitative measures.

1.8 Fire testing of products and materials is inherently hazardous, and adequate safeguar...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2067 − 23 An American National Standard

Standard Practice for

1

Full-Scale Oxygen Consumption Calorimetry Fire Tests

This standard is issued under the fixed designation E2067; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.8 Fire testing of products and materials is inherently

hazardous, and adequate safeguards for personnel and property

1.1 This practice deals with methods to construct, calibrate,

shall be employed in conducting these tests. Fire testing

and use full scale oxygen consumption calorimeters to help

involves hazardous materials, operations, and equipment. See

minimize testing result discrepancies between laboratories.

also Section 7.

1.2 The methodology described herein is used in a number

1.9 This standard does not purport to address all of the

of ASTM test methods, in a variety of unstandardized test

safety concerns, if any, associated with its use. It is the

methods, and for research purposes. This practice will facilitate

responsibility of the user of this standard to establish appro-

coordination of generic requirements, which are not specific to

priate safety, health, and environmental practices and deter-

the item under test.

mine the applicability of regulatory limitations prior to use.

1.10 This international standard was developed in accor-

1.3 The principal fire-test-response characteristics obtained

dance with internationally recognized principles on standard-

from the test methods using this technique are those associated

ization established in the Decision on Principles for the

with heat release from the specimens tested, as a function of

Development of International Standards, Guides and Recom-

time. Other fire-test-response characteristics also are deter-

mined. mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.4 This practice is intended to apply to the conduction of

different types of tests, including both some in which the

2. Referenced Documents

objective is to assess the comparative fire performance of

2

2.1 ASTM Standards:

products releasing low amounts of heat or smoke and some in

D5424 Test Method for Smoke Obscuration of Insulating

which the objective is to assess whether flashover will occur.

Materials Contained in Electrical or Optical Fiber Cables

1.5 This practice does not provide pass/fail criteria that can

When Burning in a Vertical Cable Tray Configuration

be used as a regulatory tool, nor does it describe a test method

D5537 Test Method for Heat Release, Flame Spread, Smoke

for any material or product.

Obscuration, and Mass Loss Testing of Insulating Mate-

rials Contained in Electrical or Optical Fiber Cables When

1.6 For use of the SI system of units in referee decisions, see

Burning in a Vertical Cable Tray Configuration

IEEE/ASTM SI-10. The units given in parentheses are pro-

D6113 Test Method for Using Cone Calorimeter to Deter-

vided for information only.

mine Fire-Test-Response Characteristics of Insulating Ma-

1.7 This standard is used to measure and describe the

terials Contained in Electrical or Optical Fiber Cables

response of materials, products, or assemblies to heat and flame

E84 Test Method for Surface Burning Characteristics of

under controlled conditions, but does not by itself incorporate

Building Materials

all factors required for fire hazard or fire risk assessment of the

E176 Terminology of Fire Standards

materials, products, or assemblies under actual fire conditions.

E603 Guide for Room Fire Experiments

E906/E906M Test Method for Heat and Visible Smoke

NOTE 1—This is the standard caveat described in section F2.2.2.1 of the

Form and Style for ASTM Standards manual for fire-test-response Release Rates for Materials and Products Using a Ther-

standards. In actual fact, this practice does not provide quantitative

mopile Method

measures.

E1354 Test Method for Heat and Visible Smoke Release

Rates for Materials and Products Using an Oxygen Con-

sumption Calorimeter

1

This practice is under the jurisdiction of ASTM Committee E05 on Fire

Standards and is the direct responsibility of Subcommittee E05.21 on Smoke and

2

Combustion Products. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2023. Published November 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2000. Last previous edition approved in 2022 as E2067 – 22

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2067 − 22 E2067 − 23 An American National Standard

Standard Practice for

1

Full-Scale Oxygen Consumption Calorimetry Fire Tests

This standard is issued under the fixed designation E2067; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice deals with methods to construct, calibrate, and use full scale oxygen consumption calorimeters to help minimize

testing result discrepancies between laboratories.

1.2 The methodology described herein is used in a number of ASTM test methods, in a variety of unstandardized test methods,

and for research purposes. This practice will facilitate coordination of generic requirements, which are not specific to the item

under test.

1.3 The principal fire-test-response characteristics obtained from the test methods using this technique are those associated with

heat release from the specimens tested, as a function of time. Other fire-test-response characteristics also are determined.

1.4 This practice is intended to apply to the conduction of different types of tests, including both some in which the objective is

to assess the comparative fire performance of products releasing low amounts of heat or smoke and some in which the objective

is to assess whether flashover will occur.

1.5 This practice does not provide pass/fail criteria that can be used as a regulatory tool, nor does it describe a test method for

any material or product.

1.6 For use of the SI system of units in referee decisions, see IEEE/ASTM SI-10. The units given in parentheses are provided for

information only.

1.7 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under

controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials,

products, or assemblies under actual fire conditions.

NOTE 1—This is the standard caveat described in section F2.2.2.1 of the Form and Style for ASTM Standards manual for fire-test-response standards.

In actual fact, this practice does not provide quantitative measures.

1.8 Fire testing of products and materials is inherently hazardous, and adequate safeguards for personnel and property shall be

employed in conducting these tests. Fire testing involves hazardous materials, operations, and equipment. See also Section 7.

1

This practice is under the jurisdiction of ASTM Committee E05 on Fire Standards and is the direct responsibility of Subcommittee E05.21 on Smoke and Combustion

Products.

Current edition approved July 1, 2022Nov. 1, 2023. Published August 2022November 2023. Originally approved in 2000. Last previous edition approved in 20202022

as E2067 – 20.E2067 – 22. DOI: 10.1520/E2067-22.10.1520/E2067-23.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2067 − 23

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.10 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D5424 Test Method for Smoke Obscuration of Insulating Materials Contained in Electrical or Optical Fiber Cables When

Burning in a Vertical Cable Tray Configuration

D5537 Test Method for Heat Release, Flame Spread, Smoke Obscuration, and Mass Loss Testing of Insulating Materials

Contained in Electrical or Optical Fiber Cables When Burning in a Vertical Cable Tray Configuration

D6113 Test Method for Using Cone Calorimeter to Determine Fire-Test-Response Characteristics of Insulating Materials

Contained in Electrical or Optical Fiber Cables

E84 Test Method for Surface Burning Characteristics of Building Materials

E176 Terminology of Fi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.