ASTM E2574/E2574M-17(2021)

(Test Method)Standard Test Method for Fire Testing of School Bus Seat Assemblies

Standard Test Method for Fire Testing of School Bus Seat Assemblies

SIGNIFICANCE AND USE

5.1 In this test method fire test response characteristics of a school bus seat assembly are assessed following ignition by a square gas burner.

5.2 This test method is similar in concept to a fire test currently used, and which has been in such use for many years, as the industry standard for flammability testing of school bus seats (see Appendix X1). However, in this test method the paper bag has been replaced by a gas burner as the ignition source.

5.3 The US federal government has issued a flammability test applicable to interior materials in road vehicles, FMVSS 302. FMVSS 302 remains the only regulatory test for assessing fire-test-response characteristics of school bus seats.

5.4 ASTM has issued Test Method D5132 in order to provide a more standardized way of conducting FMVSS 302.

5.5 The test method described in this document provides a significantly higher challenge to school bus seats than the FMVSS 302 federal regulatory test. Therefore, any seat assembly that performs acceptably in this test is likely to meet the requirements of FMVSS 302.

5.6 It is clear that those seat assemblies that exhibit little or no flame spread, short times to flame extinction and little mass loss in this test are likely to exhibit improved performance in an actual fire situation compared to seat assemblies that burn vigorously and have high mass loss.

5.7 This test is primarily useful to distinguish products that, when exposed to these fire conditions, will become fully involved in fire from other products that will not.

SCOPE

1.1 This is a fire-test-response standard.

1.2 This test method assesses the burning behavior of upholstered seating used in school buses by measuring specific fire-test responses when a school bus seat specimen is subjected to a specified flaming ignition source under normally ventilated conditions.

1.3 The ignition source is a gas burner.

1.4 This fire test is primarily useful to distinguish products that, when exposed to an ignition source, will become fully involved in fire from other products that will not.

1.5 Data are obtained describing the burning behavior of the seat assemblies from a specific ignition source until all burning has ceased.

1.6 This test method does not provide information on the fire performance of upholstered seating in fire conditions other than those conditions specified.

1.7 The burning behavior is visually documented by photographic or video recordings, whenever possible.

1.8 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.9 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products or assemblies under actual fire conditions.

1.10 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these tests.

1.11 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.12 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2574/E2574M − 17 (Reapproved 2021) An American National Standard

Standard Test Method for

Fire Testing of School Bus Seat Assemblies

ThisstandardisissuedunderthefixeddesignationE2574/E2574M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.11 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This is a fire-test-response standard.

responsibility of the user of this standard to establish appro-

1.2 This test method assesses the burning behavior of

priate safety, health, and environmental practices and deter-

upholstered seating used in school buses by measuring specific

mine the applicability of regulatory limitations prior to use.

fire-test responses when a school bus seat specimen is sub-

1.12 This international standard was developed in accor-

jected to a specified flaming ignition source under normally

dance with internationally recognized principles on standard-

ventilated conditions.

ization established in the Decision on Principles for the

1.3 The ignition source is a gas burner. Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

1.4 This fire test is primarily useful to distinguish products

Barriers to Trade (TBT) Committee.

that, when exposed to an ignition source, will become fully

involved in fire from other products that will not.

2. Referenced Documents

1.5 Dataareobtaineddescribingtheburningbehaviorofthe 2

2.1 ASTM Standards:

seat assemblies from a specific ignition source until all burning

D5132 Test Method for Horizontal Burning Rate of Poly-

has ceased.

meric Materials Used in Occupant Compartments of

Motor Vehicles

1.6 This test method does not provide information on the

fire performance of upholstered seating in fire conditions other E176 Terminology of Fire Standards

E1537 Test Method for Fire Testing of Upholstered Furni-

than those conditions specified.

ture

1.7 The burning behavior is visually documented by photo-

E1590 Test Method for Fire Testing of Mattresses

graphic or video recordings, whenever possible.

E2061 Guide for Fire Hazard Assessment of Rail Transpor-

1.8 The values stated in either SI units or inch-pound units

tation Vehicles

are to be regarded separately as standard. The values stated in

E2067 Practice for Full-Scale Oxygen Consumption Calo-

each system may not be exact equivalents; therefore, each

rimetry Fire Tests

system shall be used independently of the other. Combining

E2257 Test Method for Room Fire Test of Wall and Ceiling

values from the two systems may result in non-conformance

Materials and Assemblies

with the standard.

F1550 TestMethodforDeterminationofFire-Test-Response

Characteristics of Components or Composites of Mat-

1.9 This standard is used to measure and describe the

response of materials, products, or assemblies to heat and tresses or Furniture for Use in Correctional Facilities after

Exposure to Vandalism, by Employing a Bench Scale

flame under controlled conditions, but does not by itself

Oxygen Consumption Calorimeter

incorporate all factors required for fire hazard or fire risk

IEEE/ASTM SI 10 American National Standard for Metric

assessment of the materials, products or assemblies under

Practice

actual fire conditions.

2.2 National Safety Council Standard:

1.10 Fire testing is inherently hazardous. Adequate safe-

School bus seat upholstery fire block test, approved by the

guards for personnel and property shall be employed in

National Conference on School Transportation as part of

conducting these tests.

the National Standards for School Buses and National

1 2

This test method is under the jurisdiction of ASTM Committee E05 on Fire For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Standards and is the direct responsibility of Subcommittee E05.17 on Transporta- contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tion. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 1, 2021. Published April 2021. Originally the ASTM website.

approved in 2011. Last previous edition approved in 2017 as E2574/E2574M–17. Available from National Safety Council (NSC), 1121 Spring Lake Dr., Itasca,

DOI: 10.1520/E2574_E2574M-17R21. IL 60143-3201, http://www.nsc.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2574/E2574M − 17 (2021)

Standards for School Bus Operations 5.2 This test method is similar in concept to a fire test

currently used, and which has been in such use for many years,

2.3 Federal Motor Vehicle Safety Standards:

as the industry standard for flammability testing of school bus

FMVSS 222 School Bus Passenger Seating and Crash

seats (see Appendix X1). However, in this test method the

Protection, U.S. Code of Federal Regulations, Title 49,

paper bag has been replaced by a gas burner as the ignition

Transportation,SubtitleB,ChapterV,Part571,SubpartB.

source.

FMVSS302 FlammabilityofInteriorMaterial,U.S.Codeof

Federal Regulations, Title 49, Transportation, Subtitle B,

5.3 The US federal government has issued a flammability

Chapter V, Part 571, Subpart B

test applicable to interior materials in road vehicles, FM-

2.4 NFPA Standard:

VSS 302. FMVSS 302 remains the only regulatory test for

NFPA 286 Standard Method of Tests for Evaluating Contri-

assessing fire-test-response characteristics of school bus seats.

bution of Wall and Ceiling Interior Finish to Room Fire

5.4 ASTM has issued Test Method D5132 in order to

Growth

provide a more standardized way of conducting FMVSS 302.

3. Terminology

5.5 The test method described in this document provides a

3.1 For definitions of terms used in this test method asso-

significantly higher challenge to school bus seats than the

ciated with fire issues, refer to the terminology contained in FMVSS 302 federal regulatory test.Therefore, any seat assem-

Terminology E176.

bly that performs acceptably in this test is likely to meet the

requirements of FMVSS 302.

3.2 Definitions:

3.2.1 screening test, n—as related to fire,afire-responsetest

5.6 It is clear that those seat assemblies that exhibit little or

performed to determine whether a material, product, or assem-

no flame spread, short times to flame extinction and little mass

bly (a) exhibits any unusual fire-related characteristics, (b) has

loss in this test are likely to exhibit improved performance in

certain expected fire-related characteristics, or (c) is capable of

an actual fire situation compared to seat assemblies that burn

being preliminarily categorized according to the fire character-

vigorously and have high mass loss.

istic in question.

5.7 This test is primarily useful to distinguish products that,

3.3 Definitions of Terms Specific to This Standard:

when exposed to these fire conditions, will become fully

3.3.1 newspaper, n—as related to this test method, standard

involved in fire from other products that will not.

size double sheets of newsprint, with black print and no

colored ink or surface treatment.

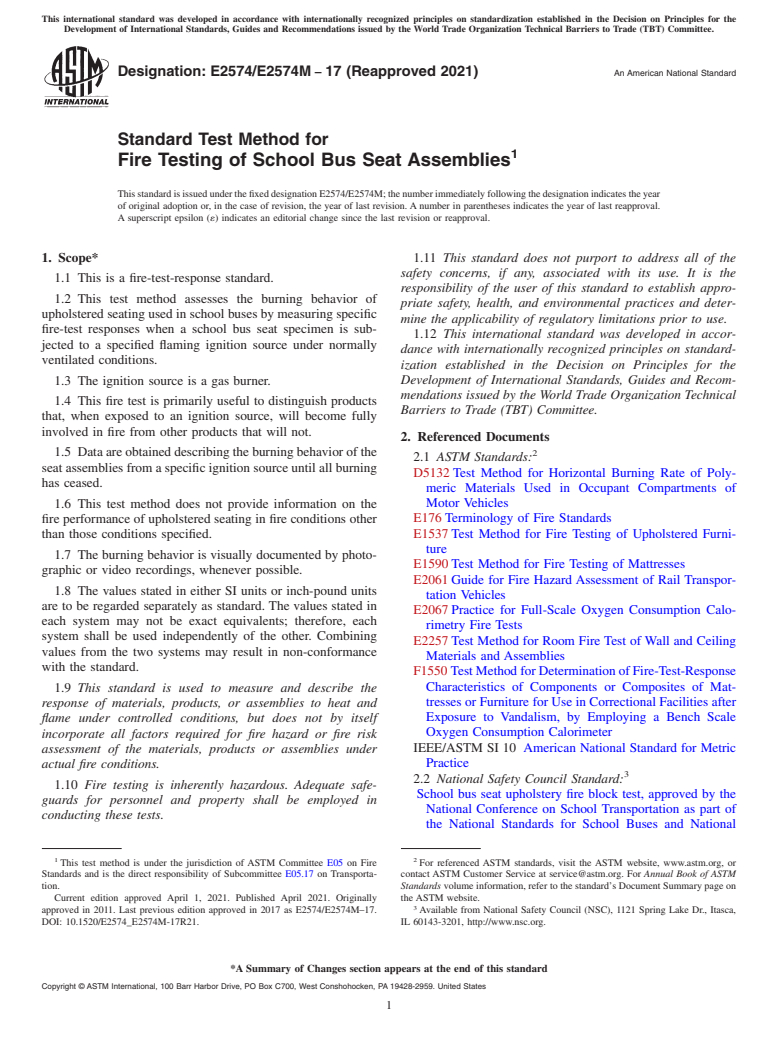

6. Apparatus: Test Chamber

3.3.2 paper bag, n—as related to this test method, a bag

6.1 General—The test chamber shall be either an actual

constructed of unbleached (brown, #30) kraft paper having

section of a school bus or it shall comply with the cross section

four sides and a bottom, with an open top, and held together

requirements of 6.2.2. Fig. 1 describes the test chamber.

with adhesive.

6.2 Cross Section:

4. Summary of Test Method

6.2.1 Use a test chamber that has the same cross section as

the body of an actual school bus, in which the seats are

4.1 A mock-up of a school bus is constructed with three

intended to be used, with a rear section on each end.

rows of actual seats.

6.2.2 Thetestchambercrosssectionshallbe2300 630mm

4.2 A gas burner ignition source is used.

[91 6 1 in.] in width by 1900 6 80 mm [75 6 3 in.] in height.

4.3 Each test consists of two trials. In each trial a gas burner

6.3 The test chamber shall have a door, which is not

ignition source is placed at a specified location to ignite the

intended for use to provide ventilation, in the center of each

middle row of seats and is ignited.

end of the test chamber. The door shall be 970 6 80 mm [38

4.4 Adifferent gas burner is used for the top of the seat and

6 3 in.] in width by 1270 6 80 mm [53 6 3 in.] in height and

for the bottom of the seat.

it shall include a latch to keep the door closed during the test.

4.5 Once flame extinction has occurred, the time to flame

See Fig. 1.

extinction, the extent of fire spread (within the seat and to the

6.4 Length—The length of the test chamber shall be such as

other seats if applicable) and the mass loss of the seat are

to allow three rows of seats at the minimum spacing recom-

assessed.

mendedbytheinstallerorasrequiredbyFMVSS222.SeeFig.

1, Detail A.

5. Significance and Use

6.4.1 In order for different types of seats to be able to be

5.1 In this test method fire test response characteristics of a

testedinthesamechamber,alengthtoleranceofplus1140mm

school bus seat assembly are assessed following ignition by a

[45 in.] shall be allowed.

square gas burner.

6.5 Ventilation—There shall be two ventilation openings in

the test chamber, one at each end. Each opening shall have an

Available from Superintendent of Documents, U.S. Government Printing 2 2

opening area of 0.210 6 0.016 m [325 6 25 in. ].The bottom

Office, Washington, DC 20402.

of the opening shall be 760 6 80 mm [30 6 3 in.] above the

Available from National Fire Protection Association (NFPA), 1 Batterymarch

Park, Quincy, MA 02169-7471, http://www.nfpa.org. chamber floor.

E2574/E2574M − 17 (2021)

FIG. 1 Test Chamber

6.5.1 There shall be no ventilation openings along the pointing straight out and spaced 13 6 1 mm [0.5 in.] apart and

length of the test chamber. four holes pointing inward at a 45° angle and spaced 50 6 2

6.5.2 Thereshallbenoforcedairventilationsystem.Baffles mm [2 in.] apart.All holes shall be of 1 6 0.05 mm [0.039 in.]

shall be used to prevent wind from blowing directly into the diameter (see Fig. 2, Fig. 3 and Fig. 4). The burner shall have

ventilation openings. an arm 288 6 10 mm [11.3 6 0.4 in.] long and welded on to

the rear of the front side (see Fig. 3) at a 30° angle. The arm

6.6 Camera ViewArea—Aviewingarea(suchasanopening

shall then include a vertical length before extending horizon-

covered with a glazing material) shall be provided at the

tallyforalengthappropriateforthestandbeingused(seeFigs.

midpoint of the chamber length for camera viewing. The

5-7). Mount the burner on an adjustable height pole at a height

opening shall allow the camera to view the seat parallel to the

of 460 6 13 mm [18 6 0.5 in.] and balance it by a

seat width. See Fig. 1.

counterweight or other appropriate mechanism (see Fig. 4).

7. Ignition Sources

NOTE 2—Warning—It is common for the burner holes to become

clogged up following a test. Inspect burner holes after each test, and clean

7.1 Top of the Seat:

thoroughly, if required. Take care not to enlarge the holes when cleaning

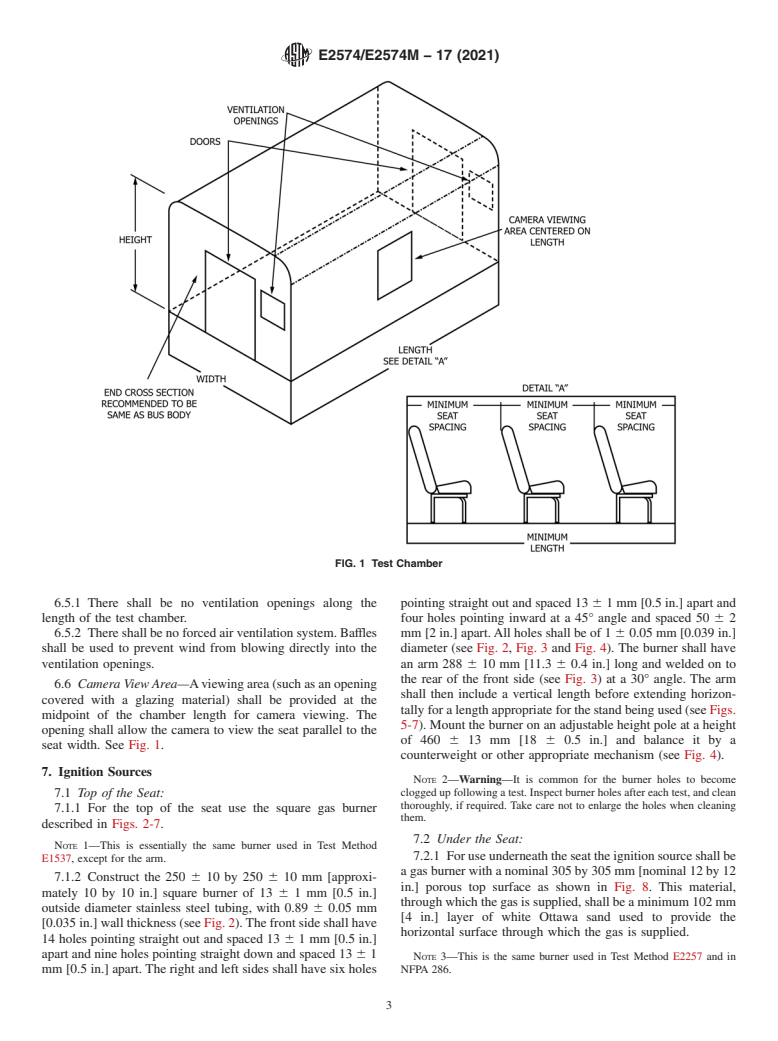

7.1.1 For the top of the seat use the square gas burner

them.

described in Figs. 2-7.

7.2 Under the Seat:

NOTE 1—This is essentially the same burner used in Test Method

7.2.1 Foruseunderneaththeseattheignitionsourceshallbe

E1537, except for the arm.

a gas burner with a nominal 305 by 305 mm [nominal 12 by 12

7.1.2 Construct the 250 6 10 by 250 6 10 mm [approxi-

in.] porous top surface as shown in Fig. 8. This material,

mately 10 by 10 in.] square burner of 13 6 1 mm [0.5 in.]

throughwhichthegasissupplied,shallbeaminimum102mm

outside diameter stainless steel tubing, with 0.89 6 0.05 mm

[4 in.] layer of white Ottawa sand used to provide the

[0.035 in.] wall thickness (see Fig. 2).The front side shall have

horizontal surface through which the gas is supplied.

14 holes pointing straight out and spaced 13 6 1 mm [0.5 in.]

apart and nine holes pointing straight down and spaced 13 6 1

NOTE 3—This is the same burner used in Test Method E2257 and in

mm [0.5 in.] apart. The right and left sides shall have six holes NFPA 286.

E2574/E2574M − 17 (2021)

FIG. 4 Cross-sectional View of Each Side of Square Gas Burner

FIG. 5 Top Burner Placement – Side View

NOTE 1—All tubing 13 mm outside diameter, stainless steel, 0.89 mm

wall thickness.

NOTE 2—All holes 1 mm in diameter.

7.2.2 The top surface of the burner through which the gas is

NOTE 3—All units are mm unless otherwise noted.

appliedshallbelocatedhorizontally300 650mm[12 62in.]

NOTE 4—See text for tolerances.

above the floor.

FIG. 2 Plan View of Square Gas Burner

7.3 Forbothignitionsourcesusepropanegas,withaknown

net heat of combustion of 2050 6 50 kJ/mol, as a fuel for this

ignition source. Meter the flow rate of propane and keep it

constant throughout the test.

7.4 For both ignition sources, use the gas burner at a flow

rate of 19.5 6 0.25 L/min for a total of 120 s. Measure the gas

flow rate at a pressure of 101 6 5 kPa (standard atmospheric

pressure,measuredattheflowgage)andatemperatureof20 6

5°C.

8. Mass Measurements

8.1 Use a balance that is capable of assessing the mass of

the test specimen and of the individual test specimen compo-

nents with a precision of 6150 g.

8.2 Calibrate the balance regularly to ensure its accuracy.

9. Test Specimens

9.1 The test specimen shall be a fully-assembled seat.

9.2 Measure the weight of all padding and upholstery prior

to assembly.

9.3 Measure the weight of the non-combustible components

FIG. 3 Side View of Square Gas Burner

of the seat (steel frame, etc.). Record this weight.

E2574/E2574M − 17 (2021)

FIG. 6 Top Burner Placement – Rear View

FIG. 7 Top Burner Placement – Front View

assembly or (b) weighing each component separately and

calculating the total weight by summing the weight of each of

the combustible and non-combustible components.

10. Preparation of Apparatus

10.1 Prior to running each trial, ensure that the test chamber

is clean and free of debris.

11. Conditioning

11.1 Condition specimens to equilibrium (constant weight)

at an ambient temperature of 23 6 3°C [73 6 5°F] and a

relative humidi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.