ASTM F37-00

(Test Method)Standard Test Methods for Sealability of Gasket Materials

Standard Test Methods for Sealability of Gasket Materials

SCOPE

1.1 These test methods provide a means of evaluating the sealing properties of sheet and solid form-in-place gasket materials at room temperature. Test Method A is restricted to liquid leakage measurements, whereas Test Method B may be used for both liquid and gas leakage measurements.

1.2 These test methods are suitable for evaluating the sealing characteristics of a gasket material under different compressive flange loads. The test method may be used as an acceptance test when the supplier and the purchaser have agreed to specific test conditions for the following parameters: test medium, internal pressure on medium, and flange load on gasket specimens.

1.3 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (For specific hazard statements, see Section 6, Note 3, and Note 8.)

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F37–00

Standard Test Methods for

Sealability of Gasket Materials

ThisstandardisissuedunderthefixeddesignationF 37;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2.2 ANSI Standard:

B57.1 Compressed Gas Cylinder Valve Outlet and Inlet

1.1 These test methods provide a means of evaluating the

Connections

sealing properties of sheet and solid form-in-place gasket

materials at room temperature. Test Method A is restricted to

3. Summary of Test Methods

liquid leakage measurements, whereas Test Method B may be

3.1 Both test methods utilize a test specimen compressed

used for both liquid and gas leakage measurements.

betweenthesurfacesoftwosmoothsteelflangefaces.Afterthe

1.2 These test methods are suitable for evaluating the

specified flange load is applied, the test medium is introduced

sealing characteristics of a gasket material under different

into the center of the annular gasket compressed between the

compressive flange loads. The test method may be used as an

flangesandthespecifiedpressureisappliedtothemedium.For

acceptance test when the producer and user have agreed to

liquid sealability tests (Test MethodsAand B), Reference Fuel

specific test conditions for the following parameters: test

A (see Test Method D 471, Motor Fuel Section of Annex) is

medium, internal pressure on medium, and flange load on

recommended and the leakage rate is measured by a change in

gasket specimens.

the level of a sight-glass located in the line upstream from the

1.3 The values stated in SI units are to be regarded as the

gasket testing fixture. Nitrogen is the recommended gas for the

standard. The values in parentheses are for information only.

gas sealability test (Test Method B) and the leakage rate is

1.4 This standard does not purport to address all of the

measured by a change in the level of a water manometer

safety concerns, if any, associated with its use. It is the

located in the line upstream from the gasket testing fixture.

responsibility of the user of this standard to establish appro-

3.1.1 Test MethodAuses a test fixture (Fig. 1) by which an

priate safety and health practices and determine the applica-

external load is transferred into the fixture to produce a

bility of regulatory limitations prior to use.(Forspecifichazard

compressive force on the gasket specimen.

statements, see Section 6, Note 3, and Note 8.)

3.1.2 Test Method B uses a test fixture (Fig. 2 and Fig. 3) in

2. Referenced Documents which the flanges are held within a four-bolt cage that permits

loading the flanges at various force levels. The flange load is

2.1 ASTM Standards:

measured by a transducer held within the cage.

D 471 Test Method for Rubber Property—Effect of Liq-

2 3.2 Resultsofthesealabilitytestsareexpressedasaleakage

uids

rate in millilitres per hour for the test specimen under the

D 2000 Classification System for Rubber Products inAuto-

3 specific conditions of the test.

motive Applications

E 691 Practice for Conducting an Interlaboratory Study to

4. Significance and Use

Determine the Precision of a Test Method

4.1 These test methods are designed to compare gasket

F 38 Test Methods for Creep Relaxation of a Gasket Mate-

3 materials under controlled conditions and to provide a precise

rial

measure of leakage rate.

F 104 Classification System for Nonmetallic Gasket Mate-

4.2 These test methods are suitable for measuring leakage

rials

rates as high as 6 L/h and as low as 0.3 mL/h. In many cases,

“zero” leakage may not be attainable.

4.3 These test methods evaluate leakage rates after time

These test methods are under the jurisdiction of ASTM Committee F03 on

periods that are typically 5 to 30 min under load. Holding a

Gaskets and are the direct responsibility of Subcommittee F 03.40 on Composite

Gaskets. gasket material under load for extended time periods may give

Current edition approved Apr. 10, 2000. Published May 2000. Originally

different results.

designated as D 2025. Redesignated in 1963 as F 37 – 62T. Last previous edition

e1

F37–95 .

Annual Book of ASTM Standards, Vol 09.01.

3 5

Annual Book of ASTM Standards, Vol 09.02. Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 14.02. Floor, New York, NY 10036.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

F37

FIG. 1 Test Assembly for Determining Sealability of Gasket Materials by Liquid Leakage Measurements—Test Method A

FIG. 2 Test Assembly for Determining Sealability of Gasket Materials by Liquid Leakage Measurements—Test Method B

4.4 Ifthefluidbeingusedinthetestcauseschanges,suchas 5.1.1 Compressed Air Supply and Regulator—A source of

swelling, in the gasket material, then unpredictable results may compressed air with a suitable regulator to control the pressure

be obtained. at a point between 0 and 760 mm (30 in.) of mercury.

5.1.2 Mercury Manometer or Pressure Gage—A 760-mm

5. Apparatus

(30-in.) mercury manometer or suitable pressure gage to read

5.1 Test Method A: the pressure to the nearest 5 mm (0.2 in.).

F37

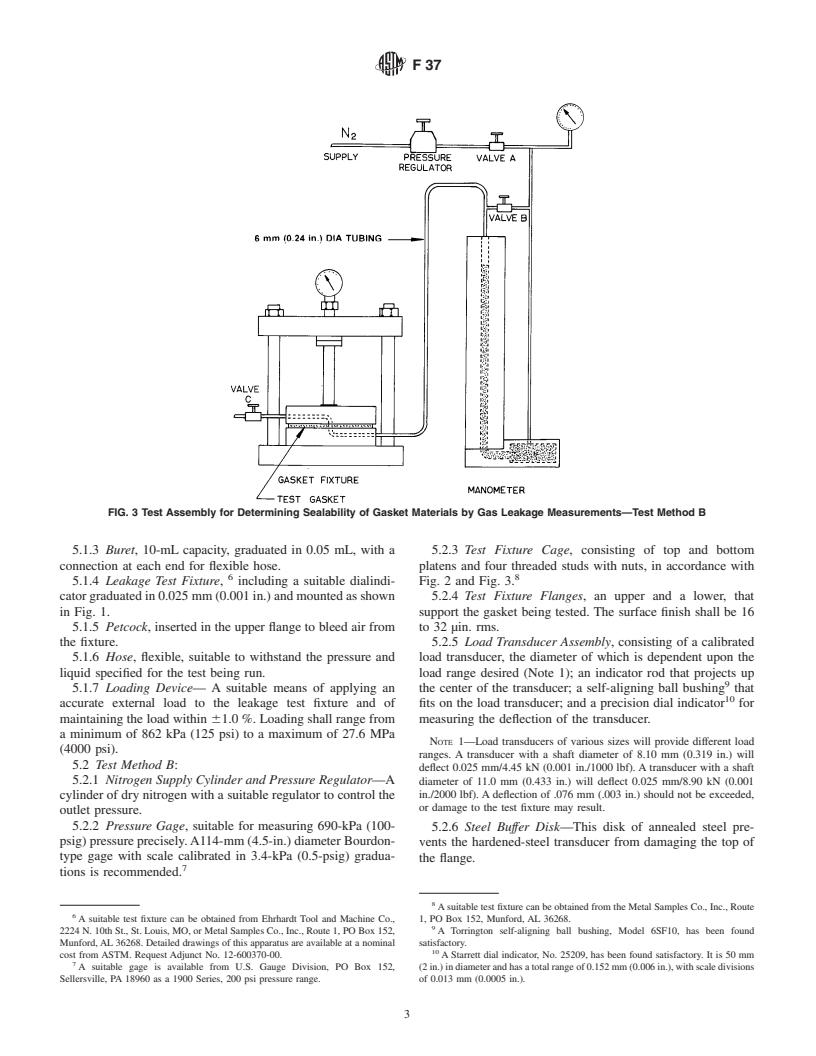

FIG. 3 Test Assembly for Determining Sealability of Gasket Materials by Gas Leakage Measurements—Test Method B

5.1.3 Buret, 10-mL capacity, graduated in 0.05 mL, with a 5.2.3 Test Fixture Cage, consisting of top and bottom

connection at each end for flexible hose. platens and four threaded studs with nuts, in accordance with

6 8

5.1.4 Leakage Test Fixture, including a suitable dialindi- Fig. 2 and Fig. 3.

catorgraduatedin0.025mm(0.001in.)andmountedasshown 5.2.4 Test Fixture Flanges, an upper and a lower, that

in Fig. 1. support the gasket being tested. The surface finish shall be 16

5.1.5 Petcock, inserted in the upper flange to bleed air from to 32 µin. rms.

the fixture. 5.2.5 Load Transducer Assembly, consisting of a calibrated

5.1.6 Hose, flexible, suitable to withstand the pressure and load transducer, the diameter of which is dependent upon the

liquid specified for the test being run. load range desired (Note 1); an indicator rod that projects up

5.1.7 Loading Device— A suitable means of applying an the center of the transducer; a self-aligning ball bushing that

accurate external load to the leakage test fixture and of fits on the load transducer; and a precision dial indicator for

maintaining the load within 61.0 %. Loading shall range from measuring the deflection of the transducer.

a minimum of 862 kPa (125 psi) to a maximum of 27.6 MPa

NOTE 1—Load transducers of various sizes will provide different load

(4000 psi).

ranges. A transducer with a shaft diameter of 8.10 mm (0.319 in.) will

5.2 Test Method B:

deflect 0.025 mm/4.45 kN (0.001 in./1000 lbf). A transducer with a shaft

5.2.1 Nitrogen Supply Cylinder and Pressure Regulator—A

diameter of 11.0 mm (0.433 in.) will deflect 0.025 mm/8.90 kN (0.001

in./2000 lbf). A deflection of .076 mm (.003 in.) should not be exceeded,

cylinder of dry nitrogen with a suitable regulator to control the

or damage to the test fixture may result.

outlet pressure.

5.2.2 Pressure Gage, suitable for measuring 690-kPa (100-

5.2.6 Steel Buffer Disk—This disk of annealed steel pre-

psig) pressure precisely.A114-mm (4.5-in.) diameter Bourdon-

vents the hardened-steel transducer from damaging the top of

type gage with scale calibrated in 3.4-kPa (0.5-psig) gradua-

the flange.

tions is recommended.

Asuitable test fixture can be obtained from the Metal Samples Co., Inc., Route

A suitable test fixture can be obtained from Ehrhardt Tool and Machine Co., 1, PO Box 152, Munford, AL 36268.

2224 N. 10th St., St. Louis, MO, or Metal Samples Co., Inc., Route 1, PO Box 152, A Torrington self-aligning ball bushing, Model 6SF10, has been found

Munford,AL 36268. Detailed drawings of this apparatus are available at a nominal satisfactory.

cost from ASTM. Request Adjunct No. 12-600370-00. A Starrett dial indicator, No. 25209, has been found satisfactory. It is 50 mm

A suitable gage is available from U.S. Gauge Division, PO Box 152, (2in.)indiameterandhasatotalrangeof0.152mm(0.006in.),withscaledivisions

Sellersville, PA 18960 as a 1900 Series, 200 psi pressure range. of 0.013 mm (0.0005 in.).

F37

5.2.7 Adapter Collet— The adapter collet is used to attach ating pressure control in accordance with ANSI Standard

the dial indicator to the threaded end of the load transducer. B 57.1. Full details are also included in the Handbook of

When attached properly, the indicating member on the load Compressed Gases.

transducer contacts the actuating button on the dial indicator.

7. Test Specimens

NOTE 2—Depending on the exact equipment used, sometimes the

7.1 Preparation of Test Specimens for Test Method A:

adapter collet used inTest Methods F 38,Test Method B, can be used with

7.1.1 When sheet gasket material (see Classification F 104)

this fixture.

is to be tested, test specimens shall be die-cut so that the edges

5.2.8 Manometer—A standard Meriam-type 760-mm (30-

are flat, clean, and free of burrs. The size shall be 32.26 to

in.) manometer suitable for use with water and suitable for

32.31 mm (1.270 to 1.272 in.) in inside diameter and 44.20 to

2.07-MPa (300-psig) pressure. The scale shall be calibrated

44.32 mm (1.740 to 1.745 in.) in outside diameter. The

with 1.0-mm (0.04-in.) graduations.

thickness shall be approximately 0.76 mm (0.030 in.) unless

5.2.9 Sight Glass and Reservoir—The liquid testing proce-

otherwise agreed upon between the producer and user. The

durerequiresaliquidreservoirthatmaybeanymetalcontainer

assumed average area of this test specimen is 719.35 mm

3 3

of approximately 1500-cm (100-in. ) capacity that can be

(1.115 in. ).

piped into the system and conveniently filled. A sightglass

7.1.2 For reporting purposes, measure the thickness of the

made from 2.07-MPa (300-psig) boiler-gage glass tubing is

gasket test specimens with a dial-type micrometer in accor-

usedforobservingthefluidlevel.Apieceof16-mm(0.625-in.)

dance with Classification F 104.

outside diameter glass tubing approximately 280- mm (11-in.)

7.1.3 The test specimens shall be inspected and rejected for

long has proven satisfactory. This glass gage shall be as-

surface irregularities, such as scratches, tears, and clumps of

sembled with appropriate fittings and a stand. The scale used

fibers.

with the gage shall be calibrated with 1.0-mm (0.04-in.)

7.2 Preparation of Test Specimens for Test Method B:

graduations. If desired, the manometer described in 5.2.8 can

7.2.1 Sheet Gasket Material (see Classification F 104):

be used as a sightglass (see 9.2).

7.2.1.1 Test specimens shall be die-cut so that the edges are

flat, clean, and free of burrs. They shall be of circular

5.2.10 Tubing, Fittings, and Valves—Suitable high-pressure

flexible tubing and either flare or compression adapter fittings construction having concentric inside and outside diameters

such that they fit the sealability test cell. The thickness shall be

shall be used. Small hand valves shall be used where indicated.

The tubing connecting the manometer or sightglass to the test approximately 0.76 mm (0.030 in.) unless otherwise agreed

upon between the producer and user.

fixture shall be of small bore to reduce the internal volume.

Capillary tubing with a 1.6-mm (0.0625-in.) inside diameter is 7.2.1.2 For reporting purposes, measure the thickness of the

gasket specimens with a dial-type micrometer in accordance

suggested.

with Classification F 104.

5.2.11 Laboratory Stress-Strain Equipment—Suitable ten-

7.2.2 Types 4 and 5 Form-In-Place Gasket Material (see

sion equipment with calibrated load cell to produce and

Classification F 104)—A 122-mm (4.8-in.) long piece of

measure a force required for a given deflection of the trans-

standard size material, between 4.76 and 6.35-mm (0.1875 and

ducer tube. The tension equipment shall have an accuracy of

0.250-in.) nominal size or width, shall be formed into a circle

65 % of the load value read (see Note 3).

of 38-mm (1.5-in.) mean diameter. The ends of the Type 4

5.2.12 Prepare some type of holding fixture to hold the

material shall be so laid as to have a 6.35 6 1.59-mm (0.25 6

bottom platen of the test fixture cage when the nuts at the top

0.0625-in.) overlap to complete the seal. The Type 5 material

are tightened.

shallhaveanoverlapof1.59 60.79mm(0.0625 60.0313in.)

to complete the seal.

6. Hazards

7.2.3 The test specimens shall be inspected, and surface

6.1 Normal safety practices required for operating pressure

irregularities such as scratches and tears shall be cause for

equipment shall be observed by the personnel conducting the

rejection.

tests.

8. Preparation of Apparatus

6.2 A suitably mounted, transparent safety shield shall be

usedasabarrierbetweentheoperatorandthepressurizedglass

8.1 Test Method A:

tubing.

8.1.1 Prior to running any tests, check the setup for leaks.

For Test Method A, this is accomplished by inserting in the

6.3 All components of the system must be designed to

fixture a rubber gasket cut from an approximately 3.2-mm

safely accommodate a maximum working pressure of 1.03

(0.12-in.)thickrubbercompoundconformingtoGradeBG515

MPa (150 psig), in order to satisfy the requirements of the user

in accordance with Classification D 2000. Adjust the external

and ensure the safety of the operator (see Note 3).

flange pressure to 862 kPa (125 psi) and the internal pressure

6.4 Care shall be exercised to ensure proper support of

of the test liquid to 760 mm (30 in.) of mercury. The system

nitrogen gas cylinders and pressure regulators used for oper-

shall be free of leaks for 15 min under these conditions.

Available from the Compressed Gas Association, Inc., 500 Fifth Ave., New

York, NY 10110.

F37

8.2 Test Method B: 10. Conditioning

8.2.1 Maintain a light film of oil on the various parts of the

10.1 Test Methods A and B:

apparatus, including the cage nuts and washers, and the

10.1.1 Condition all types of the test specimens, except

transducer self-aligning ball bushing.

Type4,inanatmosphereof50to55 %relativehumidityfor24

8.2.2 Clean the exposed surfaces of the top and bottom

h prior to use. If a humidity cabinet with gentle air circulation

flanges of the test fixture so that all residue from previous tests

is not available, then place a tray containing a saturated

is removed. Before each test, inspect the flange for nicks or

solution of magnes

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.