ASTM D5228-92(2015)

(Test Method)Standard Test Method for Determination of Butane Working Capacity of Activated Carbon

Standard Test Method for Determination of Butane Working Capacity of Activated Carbon

SIGNIFICANCE AND USE

5.1 The BWC, as determined by this test method, is a measure of the ability of an activated carbon to adsorb and desorb butane from dry air under specified conditions. It is useful for quality control and evaluation of granular activated carbons that are used in applications where the adsorption of butane and desorption with dry air are of interest. The BWC can also provide a relative measure of the effectiveness of the tested activated carbons on other adsorbates.

5.2 The butane activity and retentivity can also be determined under the conditions of the test. The butane activity is an indication of the micropore volume of the activated carbon sample. The butane retentivity is an indication of the pore structure of the activated carbon sample.

SCOPE

1.1 This test method covers the determination of the butane working capacity (BWC) of new granular activated carbon. The BWC is defined as the difference between the butane adsorbed at saturation and the butane retained per unit volume of carbon after a specified purge. The test method also produces a butane activity value that is defined as the total amount of butane adsorbed on the carbon sample and is expressed as a mass of butane per unit weight or volume of carbon.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement, see 7.1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5228 − 92(Reapproved 2015)

Standard Test Method for

Determination of Butane Working Capacity of Activated

Carbon

This standard is issued under the fixed designation D5228; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the determination of the butane 3.1 Definitions— For definitions of terms used in this test

working capacity (BWC) of new granular activated carbon. method, refer to Terminology D2652.

The BWC is defined as the difference between the butane

adsorbed at saturation and the butane retained per unit volume 4. Summary of Test Method

of carbon after a specified purge. The test method also

4.1 An activated carbon bed of known volume and mass is

produces a butane activity value that is defined as the total

saturatedwithbutanevapor.Themassadsorbedatsaturationis

amount of butane adsorbed on the carbon sample and is

noted. The carbon bed is then purged under prescribed condi-

expressed as a mass of butane per unit weight or volume of

tions with dry hydrocarbon free air. The loss of mass is the

carbon.

BWC and is expressed as mass of butane per unit volume of

1.2 The values stated in SI units are to be regarded as carbon.

standard. No other units of measurement are included in this

standard.

5. Significance and Use

1.3 This standard does not purport to address all of the

5.1 The BWC, as determined by this test method, is a

safety concerns, if any, associated with its use. It is the

measure of the ability of an activated carbon to adsorb and

responsibility of the user of this standard to establish appro-

desorb butane from dry air under specified conditions. It is

priate safety and health practices and determine the applica-

useful for quality control and evaluation of granular activated

bility of regulatory limitations prior to use. For a specific

carbons that are used in applications where the adsorption of

hazard statement, see 7.1.

butane and desorption with dry air are of interest. The BWC

can also provide a relative measure of the effectiveness of the

2. Referenced Documents

tested activated carbons on other adsorbates.

2.1 ASTM Standards:

5.2 The butane activity and retentivity can also be deter-

D2652Terminology Relating to Activated Carbon

minedundertheconditionsofthetest.Thebutaneactivityisan

D2854Test Method for Apparent Density of Activated

indication of the micropore volume of the activated carbon

Carbon

sample. The butane retentivity is an indication of the pore

D2867Test Methods for Moisture in Activated Carbon

structure of the activated carbon sample.

D3195Practice for Rotameter Calibration

E177Practice for Use of the Terms Precision and Bias in

6. Apparatus

ASTM Test Methods

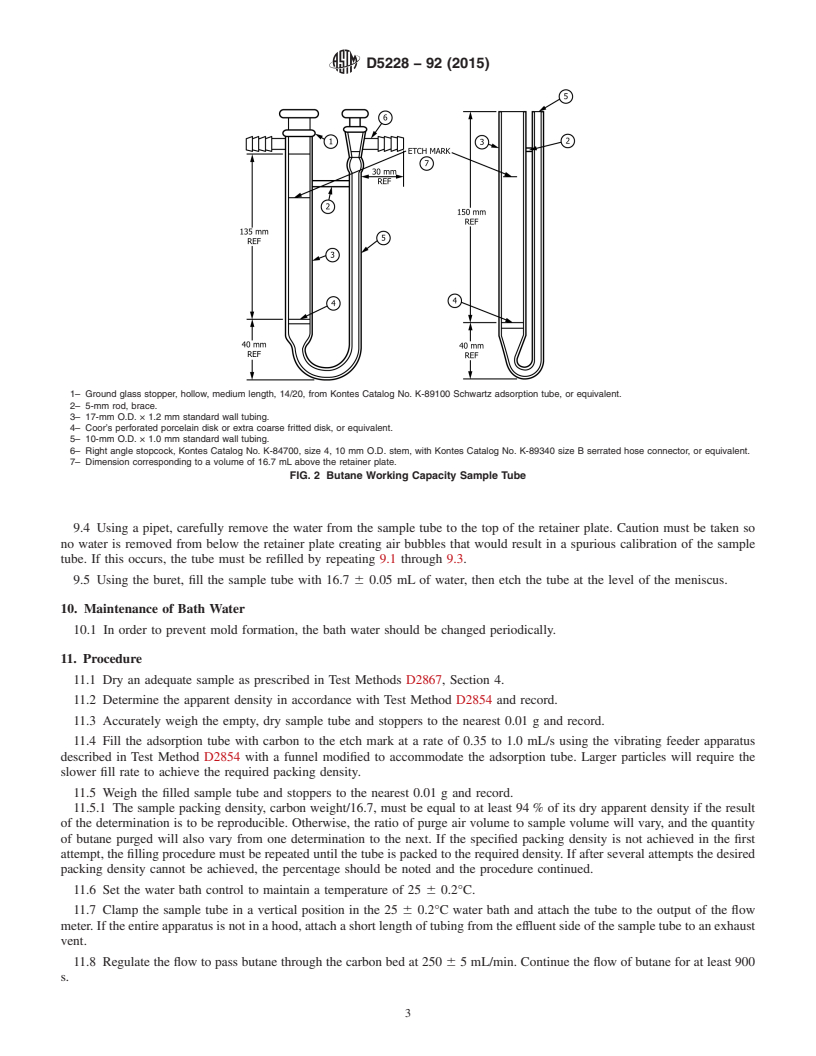

6.1 Water Bath, capable of maintaining a temperature of 25

E300Practice for Sampling Industrial Chemicals

6 0.2°C and of sufficient depth so the entire carbon bed in the

E691Practice for Conducting an Interlaboratory Study to

sampletubeisimmersedinthewater.A6-mmODcoppertube

Determine the Precision of a Test Method

with an immersed length of 1.9 m (Fig. 1) provides adequate

heat transfer for gas temperature control.

This test method is under the jurisdiction of ASTM Committee D28 on

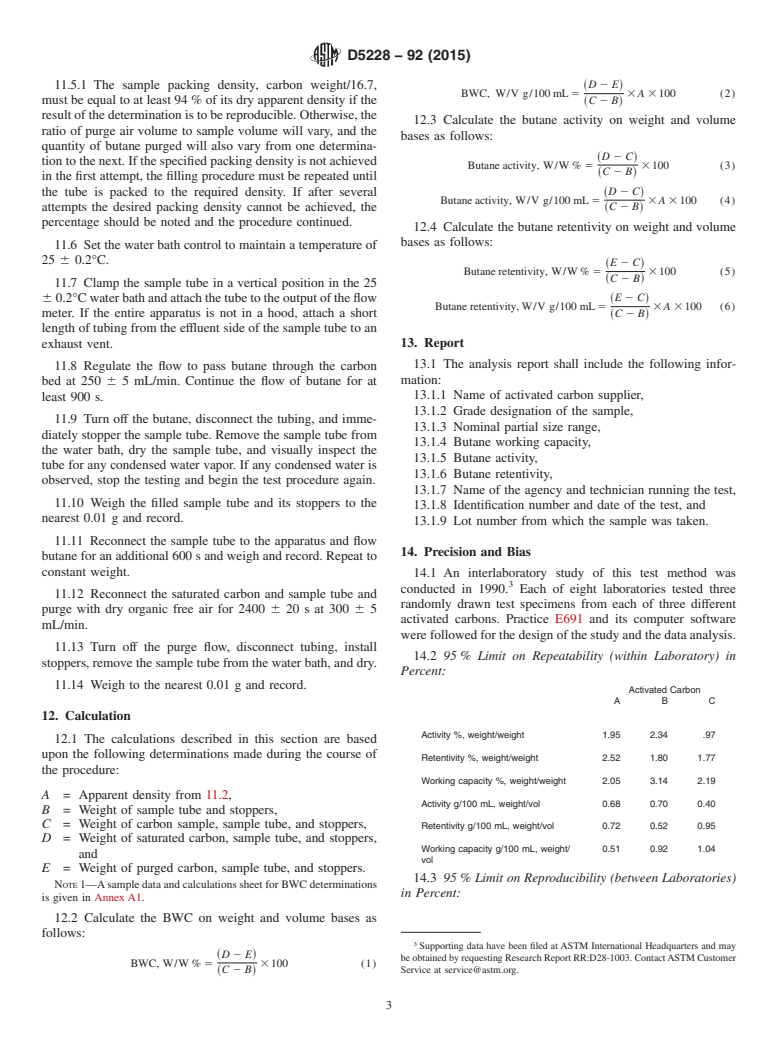

6.2 Sample Tube, as shown in Fig. 2. The glass plate with

Activated Carbon and is the direct responsibility of Subcommittee D28.04 on Gas

holes is preferred to a fritted disk to support the carbon, since

Phase Evaluation Tests.

Current edition approved Oct. 1, 2015. Published October 2015. Originally fritted disks can vary widely in pressure drop.

approved in 1992. Last previous edition approved in 2010 as D5228–92 (2010).

6.3 Flow Meters, one capable of delivering air at 0 to 500

DOI: 10.1520/D5228-92R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or mL/min, and one capable of delivering butane at 0 to 500

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

mL/min, both calibrated in accordance with Practice D3195.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 6.4 Balance, capable of weighing to within 60.01 g.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5228 − 92 (2015)

6.7 Apparatus Assembly shown in Fig. 1.

7. Reagents

7.1 n-Butane, C. P. Grade. (Warning—Butane is a flam-

mable gas with a flash point of −138°C and a boiling point of

0.5°C. Its specific gravity is 2.046 relative to air. Butane may

be narcotic in high concentrations and is considered a simple

asphyxiant.Iftheentireapparatusisnotsetupinafumehood,

provision must be made to vent the gas coming from the

discharge stem of the sample tube.)

7.2 Dry Air, free of organics, with a dew point no higher

than −32°C.

8. Sampling

8.1 For guidance in sampling granular activated carbon,

refer to Practice E300.

9. Calibration of a Sample Tube

9.1 Clean and dry the sample tube to prevent any water

droplets from adhering to the inner surface of the tube.

9.2 Using distilled water, carefully fill the sample tube

throughthenarrowsidestemtopreventtheintroductionofany

FIG. 1 Butane Working Capacity Apparatus Schematic

air bubbles.

9.2.1 Holdthesampletubeuprightwhileslowlyintroducing

thedistilledwater.Airbubbleshaveatendencytoformdirectly

below the retainer plate of the tube.

9.3 Clamp the filled sample tube in an upright position to a

ring stand and stopper the narrow side stem.

9.4 Using a pipet, carefully remove the water from the

sample tube to the top of the retainer plate. Caution must be

taken so no water is removed from below the retainer plate

creating air bubbles that would result in a spurious calibration

of the sample tube. If this occurs, the tube must be refilled by

repeating 9.1 through 9.3.

9.5 Using the buret, fill the sample tube with 16.7 6 0.05

mL of water, then etch the tube at the level of the meniscus.

10. Maintenance of Bath Water

10.1 In order to prevent mold formation, the bath water

should be changed periodically.

11. Procedure

11.1 Dry an adequate sample as prescribed in Test Methods

1– Ground glass stopper, hollow, medium length, 14/20, from Kontes Catalog

No. K-89100 Schwartz adsorption tube, or equivalent.

D2867, Section 4.

2– 5-mm rod, brace.

3– 17-mm O.D. × 1.2 mm standard wall tubing.

11.2 DeterminetheapparentdensityinaccordancewithTest

4– Coor’s perforated porcelain disk or extra coarse fritted disk, or equivalent.

Method D2854 and record.

5– 10-mm O.D. × 1.0 mm standard wall tubing.

6– Right angle stopcock, Kontes Catalog No. K-84700, size 4, 10 mm O.D.

11.3 Accurately weigh the empty, dry sample tube and

stem, with Kontes Catalog No. K-89340 size B serrated hose connector, or

stoppers to the nearest 0.01 g and record.

equivalent.

7– Dimension corresponding to a volu

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5228 − 92 (Reapproved 2010) D5228 − 92 (Reapproved 2015)

Standard Test Method for

Determination of Butane Working Capacity of Activated

Carbon

This standard is issued under the fixed designation D5228; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the butane working capacity (BWC) of new granular activated carbon. The

BWC is defined as the difference between the butane adsorbed at saturation and the butane retained per unit volume of carbon after

a specified purge. The test method also produces a butane activity value that is defined as the total amount of butane adsorbed on

the carbon sample and is expressed as a mass of butane per unit weight or volume of carbon.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For a specific hazard statement, see 7.1.

2. Referenced Documents

2.1 ASTM Standards:

D2652 Terminology Relating to Activated Carbon

D2854 Test Method for Apparent Density of Activated Carbon

D2867 Test Methods for Moisture in Activated Carbon

D3195 Practice for Rotameter Calibration

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E300 Practice for Sampling Industrial Chemicals

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions— For definitions of terms used in this test method, refer to Terminology D2652.

4. Summary of Test Method

4.1 An activated carbon bed of known volume and mass is saturated with butane vapor. The mass adsorbed at saturation is

noted. The carbon bed is then purged under prescribed conditions with dry hydrocarbon free air. The loss of mass is the BWC and

is expressed as mass of butane per unit volume of carbon.

5. Significance and Use

5.1 The BWC, as determined by this test method, is a measure of the ability of an activated carbon to adsorb and desorb butane

from dry air under specified conditions. It is useful for quality control and evaluation of granular activated carbons that are used

in applications where the adsorption of butane and desorption with dry air are of interest. The BWC can also provide a relative

measure of the effectiveness of the tested activated carbons on other adsorbates.

5.2 The butane activity and retentivity can also be determined under the conditions of the test. The butane activity is an

indication of the micropore volume of the activated carbon sample. The butane retentivity is an indication of the pore structure

of the activated carbon sample.

This test method is under the jurisdiction of ASTM Committee D28 on Activated Carbon and is the direct responsibility of Subcommittee D28.04 on Gas Phase

Evaluation Tests.

Current edition approved April 1, 2010Oct. 1, 2015. Published May 2010October 2015. Originally approved in 1992. Last previous edition approved in 20052010 as

D5228 – 92 (2005).(2010). DOI: 10.1520/D5228-92R10.10.1520/D5228-92R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5228 − 92 (2015)

6. Apparatus

6.1 Water Bath, capable of maintaining a temperature of 25 6 0.2°C and of sufficient depth so the entire carbon bed in the

sample tube is immersed in the water. A 6-mm OD copper tube with an immersed length of 1.9 m (Fig. 1) provides adequate heat

transfer for gas temperature control.

6.2 Sample Tube, as shown in Fig. 2. The glass plate with holes is preferred to a fritted disk to support the carbon, since fritted

disks can vary widely in pressure drop.

6.3 Flow Meters, one capable of delivering air at 0 to 500 mL/min, and one capable of delivering butane at 0 to 500 mL/min,

both calibrated in accordance with Practice D3195.

6.4 Balance, capable of weighing to within 60.01 g.

6.5 Fill Device—The vibration feed device used in Test Method D2854, Figs. 1 through 4, is preferred.

6.6 Buret, Class A, 25 mL capacity.

6.7 Apparatus Assembly shown in Fig. 1.

7. Reagents

7.1 n-Butane, C. P. Grade. (Warning—Butane is a flammable gas with a flash point of −138°C and a boiling point of 0.5°C.

Its specific gravity is 2.046 relative to air. Butane may be narcotic in high concentrations and is considered a simple asphyxiant.

If the entire apparatus is not set up in a fume hood, provision must be made to vent the gas coming from the discharge stem of

the sample tube.)

7.2 Dry Air, free of organics, with a dew point no higher than −32°C.

8. Sampling

8.1 For guidance in sampling granular activated carbon, refer to Practice E300.

9. Calibration of a Sample Tube

9.1 Clean and dry the sample tube to prevent any water droplets from adhering to the inner surface of the tube.

9.2 Using distilled water, carefully fill the sample tube through the narrow side stem to prevent the introduction of any air

bubbles.

9.2.1 Hold the sample tube upright while slowly introducing the distilled water. Air bubbles have a tendency to form directly

below the retainer plate of the tube.

9.3 Clamp the filled sample tube in an upright position to a ring stand and stopper the narrow side stem.

FIG. 1 Butane Working Capacity Apparatus Schematic

D5228 − 92 (2015)

1– Ground glass stopper, hollow, medium length, 14/20, from Kontes Catalog No. K-89100 Schwartz adsorption tube, or equivalent.

2– 5-mm rod, brace.

3– 17-mm O.D. × 1.2 mm standard wall tubing.

4– Coor’s perforated porcelain disk or extra coarse fritted disk, or equivalent.

5– 10-mm O.D. × 1.0 mm standard wall tubing.

6– Right angle stopcock, Kontes Catalog No. K-84700, size 4, 10 mm O.D. stem, with Kontes Catalog No. K-89340 size B serrated hose connector, or equivalent.

7– Dimension corresponding to a volume of 16.7 mL above the retainer plate.

FIG. 2 Butane Working Capacity Sample Tube

9.4 Using a pipet, carefully remove the water from the sample tube to the top of the retainer plate. Caution must be taken so

no water is removed from below the retainer plate creating air bubbles that would result in a spurious calibration of the sample

tube. If this occurs, the tube must be refilled by repeating 9.1 through 9.3.

9.5 Using the buret, fill the sample tube with 16.7 6 0.05 mL of water, then etch the tube at the level of the meniscus.

10. Maintenanc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.