ASTM E2038-99(2004)

(Test Method)Standard Test Method for Temperature Calibration of Dielectric Analyzers (Withdrawn 2009)

Standard Test Method for Temperature Calibration of Dielectric Analyzers (Withdrawn 2009)

SIGNIFICANCE AND USE

This test method permits interlaboratory comparison and intralaboratory correlation of instrumental temperature scale data.

Dielectric analyzers are used to characterize a broad range of materials that possess dielectric moments. One of the desired values to be assigned by the measurement is the temperature at which significant changes occur in the properties of the test specimen. In order to obtain consistent results from one period of time to another and from one laboratory to another, the temperature signal from the apparatus must be calibrated accurately over the temperature range of interest.

SCOPE

1.1 This test method covers the temperature calibration of dielectric analyzers over the temperature range from -100 to 300°C and is applicable to commercial and custom-built apparatus. The calibration is performed by observing the melting transition of standard reference materials having known transition temperatures within the temperature range of use.

1.2 Electronic instrumentation or automated data analysis and data reductions systems or treatment equivalent to this test method may be used.

1.3 The values stated in SI units are to be reported as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method describes the temperature calibration of dielectric analyzers over the temperature range from –100 to 300 °C and is applicable to commercial and custom-built apparatus.

Formerly under the jurisdiction of Committee E37 on Thermal Measurements , this test method was withdrawn in September 2009 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:E2038–99 (Reapproved 2004)

Standard Test Method for

1

Temperature Calibration of Dielectric Analyzers

This standard is issued under the fixed designation E2038; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope dielectric properties is observed. The temperature observed for

the transition by the apparatus is recorded. Using a linear

1.1 This test method describes the temperature calibration

equation, for one or more transitions, the temperature scale or

of dielectric analyzers over the temperature range from –100 to

readout of the apparatus is calibrated based upon the known

300 °C and is applicable to commercial and custom-built

and observed transition temperatures.

apparatus. The calibration is performed by observing the

melting transition of standard reference materials having

5. Significance and Use

known transition temperatures within the temperature range of

5.1 This test method permits interlaboratory comparison

use.

and intralaboratory correlation of instrumental temperature

1.2 Electronic instrumentation or automated data analysis

scale data.

and data reductions systems or treatment equivalent to this test

5.2 Dielectric analyzers are used to characterize a broad

method may be used.

range of materials that possess dielectric moments. One of the

1.3 The values stated in SI units are to be reported as the

desired values to be assigned by the measurement is the

standard.

temperature at which significant changes occur in the proper-

1.4 This standard does not purport to address all of the

ties of the test specimen. In order to obtain consistent results

safety concerns, if any, associated with its use. It is the

from one period of time to another and from one laboratory to

responsibility of the user of this standard to establish appro-

another, the temperature signal from the apparatus must be

priate safety and health practices and to determine the

calibrated accurately over the temperature range of interest.

applicability of regulatory limitations prior to use.

6. Interferences

2. Referenced Documents

2

6.1 Becausethespecimensizeusuallyissmall,caremustbe

2.1 ASTM Standards:

taken to ensure that each specimen is homogeneous and

E473 Terminology Relating to Thermal Analysis and Rhe-

representative of the sample as a whole.

ology

6.2 This test method measures dielectric properties under

E1142 Terminology Relating to Thermophysical Properties

specific experimental conditions. Should those experimental

3. Terminology conditions change, there may be an effect on the calibration of

the apparatus.

3.1 Definitions—Specific technical terms used in this test

6.3 Contact or adhesion of the specimen to the sensor

method are defined in accordance with Terminologies E473

should not be lost during the course of the measurement,

and E1142.

otherwise erroneous values will be recorded.

4. Summary of Test Method

7. Apparatus

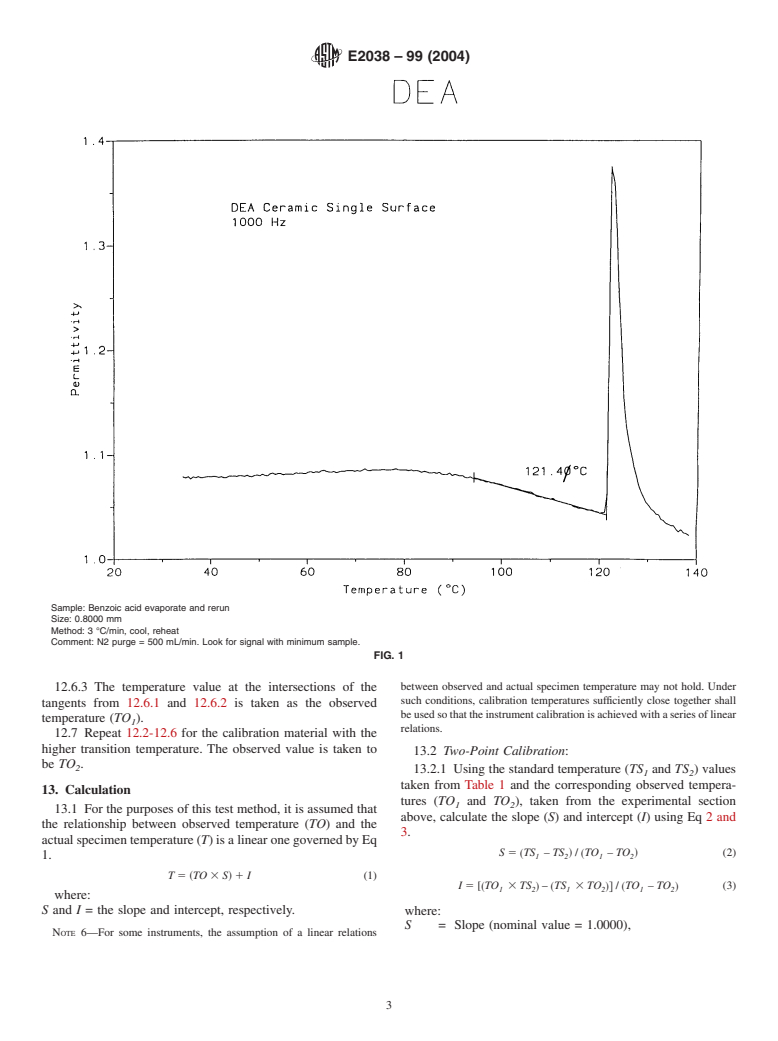

4.1 A test specimen of known solid-solid or solid-liquid

7.1 Dielectric Analyzer, consisting of the following items:

(melting) transition temperature is characterized for its dielec-

7.1.1 Sensors, electrodes for imparting the alternating elec-

tric properties in a dielectric analyzer of interest as a function

tric field and measuring the induced current and phasing in the

of temperature. At the transition, a sharp change in the

specimen. These usually are solid platforms that also serve to

hold the specimen. These may be either two parallel plate

1

This test method is under the jurisdiction ofASTM Committee E37 onThermal

electrodes or a single plate containing a series of interdigitated

Measurements and is the direct responsibility of Subcommittee E37.01 on Test

electrodes.

Methods and Recommended Practices.

Current edition approved Sept. 10, 1999. Published November 1999. DOI:

NOTE 1—When using parallel plate electrodes, provision shall be made

10.1520/E2038-99R04.

to prevent the electrodes from contacting each other upon the melting of

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the test specimen.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standardsvolume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E2038–99 (2004)

7.1.2 Temperature Sensor, for measuring the specimen tem- 10. Sampling

perature to within 6 0.1 °C.

10.1 Samples usually are analyzed on an “as received”

7.1.3 Specimen Container, for containing t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.