ASTM E1356-23

(Test Method)Standard Test Method for Assignment of the Glass Transition Temperatures by Differential Scanning Calorimetry

Standard Test Method for Assignment of the Glass Transition Temperatures by Differential Scanning Calorimetry

SIGNIFICANCE AND USE

5.1 Differential scanning calorimetry provides a rapid test method for determining changes in specific heat capacity in a homogeneous material. The glass transition is manifested as a step change in specific heat capacity. For amorphous and semicrystalline materials the determination of the glass transition temperature may lead to important information about their thermal history, processing conditions, stability, progress of chemical reactions, and mechanical and electrical behavior.

5.2 This test method is useful for research, quality control, and specification acceptance.

SCOPE

1.1 This test method covers the assignment of the glass transition temperatures of materials using differential scanning calorimetry or differential thermal analysis.

1.2 This test method is applicable to amorphous materials or to partially crystalline materials containing amorphous regions, that are stable and do not undergo decomposition or sublimation in the glass transition region.

1.3 The normal operating temperature range is from −120 °C to 500 °C. The temperature range may be extended, depending upon the instrumentation used.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 ISO standards 11357–2 is equivalent to this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1356 − 23

Standard Test Method for Assignment of the

Glass Transition Temperatures by Differential Scanning

Calorimetry

This standard is issued under the fixed designation E1356; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ASTM Test Methods

E473 Terminology Relating to Thermal Analysis and Rhe-

1.1 This test method covers the assignment of the glass

ology

transition temperatures of materials using differential scanning

E691 Practice for Conducting an Interlaboratory Study to

calorimetry or differential thermal analysis.

Determine the Precision of a Test Method

1.2 This test method is applicable to amorphous materials or

E967 Test Method for Temperature Calibration of Differen-

to partially crystalline materials containing amorphous regions,

tial Scanning Calorimeters and Differential Thermal Ana-

that are stable and do not undergo decomposition or sublima-

lyzers

tion in the glass transition region.

E1142 Terminology Relating to Thermophysical Properties

1.3 The normal operating temperature range is from

2.2 ISO Standards:

−120 °C to 500 °C. The temperature range may be extended,

11357–2 Differential Scanning Calorimetry (DSC)-Part 2

depending upon the instrumentation used.

Determination of Glass Transition Temperature

1.4 The values stated in SI units are to be regarded as

3. Terminology

standard. No other units of measurement are included in this

3.1 Definitions:

standard.

3.1.1 Definitions—The following terms are applicable to

1.5 ISO standards 11357–2 is equivalent to this standard.

this test method and can be found in Terminologies E473 and

1.6 This standard does not purport to address all of the

E1142: differential scanning calorimetry (DSC); differential

safety concerns, if any, associated with its use. It is the

thermal analysis (DTA); glass transition; glass transition

responsibility of the user of this standard to establish appro-

temperature (T ); and specific heat capacity.

g

priate safety, health, and environmental practices and deter-

3.2 Definitions of Terms Specific to This Standard:

mine the applicability of regulatory limitations prior to use.

3.2.1 There are commonly used transition points associated

1.7 This international standard was developed in accor-

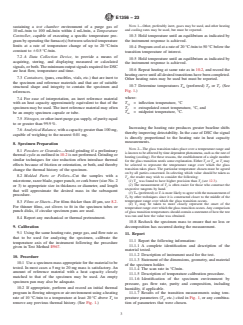

with the glass transition region—(see Fig. 1).

dance with internationally recognized principles on standard-

3.2.1.1 extrapolated end temperature, (T ), °C—the point of

e

ization established in the Decision on Principles for the

intersection of the tangent drawn at the point of greatest slope

Development of International Standards, Guides and Recom-

on the transition curve with the extrapolated baseline following

mendations issued by the World Trade Organization Technical

the transition.

Barriers to Trade (TBT) Committee.

3.2.1.2 extrapolated onset temperature, (T ), °C—the point

f

2. Referenced Documents of intersection of the tangent drawn at the point of greatest

2 slope on the transition curve with the extrapolated baseline

2.1 ASTM Standards:

prior to the transition.

E177 Practice for Use of the Terms Precision and Bias in

3.2.1.3 inflection temperature, (T ), °C—the point on the

i

thermal curve corresponding to the peak of the first derivative

This test method is under the jurisdiction of ASTM Committee E37 on Thermal (with respect to time) of the parent thermal curve. This point

Measurements and is the direct responsibility of Subcommittee E37.01 on Calo-

corresponds to the inflection point of the parent thermal curve.

rimetry and Mass Loss.

3.2.1.4 midpoint temperature, (T ), °C—the point on the

Current edition approved Aug. 1, 2023. Published August 2023. Originally

m

approved in 1991. Last previous edition approved in 2014 as E1356 – 08 (2014)

thermal curve corresponding to ⁄2 the heat flow difference

which was withdrawn March 2023 and reinstated in August 2023. DOI: 10.1520/

between the extrapolated onset and extrapolated end.

E1356-23.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1356 − 23

FIG. 1 Glass Transition Region Measured Temperatures

3.2.1.5 Discussion—Midpoint temperature is most com- 6. Interferences

monly used as the glass transition temperature (see Fig. 1).

6.1 A change in heating rates and cooling rates can affect the

3.2.2 Two additional transition points are sometimes iden-

results. The presence of impurities will affect the transition,

tified and are defined:

particularly if an impurity tends to plasticize or form solid

3.2.2.1 temperature of first deviation, (T ), °C—the point of

solutions, or is miscible in the post-transition phase. If particle

o

first detectable deviation from the extrapolated baseline prior to

size has an effect upon the detected transition temperature, the

the transition.

specimens to be compared should be of the same particle size.

3.2.2.2 temperature of return to baseline, (T ), °C—the point

r 6.2 In some cases the specimen may react with air during

of last deviation from the extrapolated baseline beyond the

the temperature program causing an incorrect transition to be

transition.

measured. Whenever this effect may be present, the test shall

be run under either vacuum or an inert gas atmosphere. Since

4. Summary of Test Method

some materials degrade near the glass transition region, care

4.1 This test method involves continuously monitoring the must be taken to distinguish between degradation and glass

difference in heat flow into, or temperature between a reference transition.

material and a test material when they are heated or cooled at

6.3 Since milligram quantities of sample are used, it is

a controlled rate through the glass transition region of the test

essential to ensure that specimens are homogeneous and

material and analyzing the resultant thermal curve to provide

representative, so that appropriate sampling techniques are

the glass transition temperature.

used.

5. Significance and Use

7. Apparatus

5.1 Differential scanning calorimetry provides a rapid test

7.1 Differential Scanning Calorimeter—The essential in-

method for determining changes in specific heat capacity in a

strumentation required to provide the minimum differential

homogeneous material. The glass transition is manifested as a

scanning calorimetric capability for this method includes a Test

step change in specific heat capacity. For amorphous and

Chamber composed of a furnace(s) to provide uniform con-

semicrystalline materials the determination of the glass transi-

trolled heating (cooling) of a specimen and reference to a

tion temperature may lead to important information about their

constant temperature or at a constant rate over the temperature

thermal history, processing conditions, stability, progress of

range from –120 °C to 500 °C, a temperature sensor to provide

chemical reactions, and mechanical and electrical behavior.

an indication of the specimen temperature to 60.1 °C, differ-

5.2 This test method is useful for research, quality control, ential sensors to detect heat flow difference between the

and specification acceptance. specimen and reference with a sensitivity of 6μW, a means of

E1356 − 23

NOTE 1—Other, preferably inert, gases may be used, and other heating

sustaining a test chamber environment of a purge gas of

and cooling rates may be used, but must be reported.

10 mL ⁄min to 100 mL/min within 4 mL/min, a Temperature

Controller, capable of executing a specific temperature pro- 10.3 Hold temperature until an equilibrium as indicated by

gram by operating the furnace(s) between selected temperature the instrument response is achieved.

limits at a rate of temp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.