ASTM D5001-90a(2000)e1

(Test Method)Standard Test Method for Measurement of Lubricity of Aviation Turbine Fuels by the Ball-on-Cylinder Lubricity Evaluator (BOCLE)

Standard Test Method for Measurement of Lubricity of Aviation Turbine Fuels by the Ball-on-Cylinder Lubricity Evaluator (BOCLE)

SCOPE

1.1 This test method assesses the wear aspects of the boundary lubrication properties of aviation turbine fuels on rubbing steel surfaces.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 7 and Annex A1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation: D 5001 – 90a (Reapproved 2000)

Standard Test Method for

Measurement of Lubricity of Aviation Turbine Fuels by the

Ball-on-Cylinder Lubricity Evaluator (BOCLE)

This standard is issued under the fixed designation D 5001; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Warning notes were placed in the text editorially in December 2000.

1. Scope ANSI B3.12, Metal Balls

2.5 Society of Automotive Engineers Standard:

1.1 This test method assesses the wear aspects of the

SAE 8720 Steel

boundary lubrication properties of aviation turbine fuels on

rubbing steel surfaces.

3. Terminology

1.2 The values stated in SI units are to be regarded as the

3.1 Definitions of Terms Specific to This Standard:

standard.

3.1.1 cylinder—the test ring and mandrel assembly.

1.3 This standard does not purport to address the safety

3.1.2 lubricity—a general term used to describe the bound-

concerns, if any, associated with its use. It is the responsibility

ary lubrication properties of a fluid. In this test method, the

of the user of this standard to establish appropriate safety and

lubricity of a fluid is defined in terms of a wear scar, in

health practices and determine the applicability of regulatory

millimeters, produced on a stationary ball from contact with

limitations prior to use. Specific hazard statements are given in

the fluid wetted rotating cylinder operating under closely

Section 7 and Annex A1.

defined and controlled conditions.

2. Referenced Documents

4. Summary of Test Method

2.1 ASTM Standards:

2 4.1 The fluid under test is placed in a test reservoir in which

D 329 Specification for Acetone

atmospheric air is maintained at 10 % relative humidity. A

D 770 Specification for Isopropyl Alcohol

non-rotating steel ball is held in a vertically mounted chuck and

D 1016 Test Method for Purity of Hydrocarbons from

3 forced against an axially mounted steel ring with an applied

Freezing Points

load. The test cylinder is rotated at a fixed speed while being

D 4306 Practice for Aviation Fuel Sample Containers for

4 partially immersed in the fluid reservoir. This maintains the

Tests Affected by Trace Contamination

cylinder in a wet condition and continuously transports the test

2.2 Military Specification:

fluid to the ball/cylinder interface. The wear scar generated on

MIL-I-25017, Inhibitor, Corrosion/Lubricity Improver, Fuel

5 the test ball is a measure of the fluid lubricating properties.

Soluble

2.3 American Iron and Steel Institute Standard:

5. Significance and Use

AISI E-52100 Chromium Alloy Steel

5.1 Wear due to excessive friction resulting in shortened life

2.4 American National Standards Institute Standard:

of engine components such as fuel pumps and fuel controls has

sometimes been ascribed to lack of lubricity in an aviation fuel.

5.2 The relationship of test results to aviation fuel system

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

component distress due to wear has been demonstrated for

D02.J0 on Aviation Fuels.

some fuel/hardware combinations where boundary lubrication

Current edition approved Sept. 28, 1990. Published November 1990. Originally

is a factor in the operation of the component.

published as D 5001 – 89. Last previous edition D 5001 – 90.

This test method was developed by the Coordinating Research Council and is a 5.3 The wear scar generated in the ball-on-cylinder lubricity

part of their report No. 560.

evaluator (BOCLE) test is sensitive to contamination of the

Annual Book of ASTM Standards, Vol 06.04.

Annual Book of ASTM Standards, Vol 05.01.

Annual Book of ASTM Standards, Vol 05.02.

5 7

Available from Standardization Documents Order Desk, Bldg 4 Section D, 700 Available from American National Standards Institute, 11 West 42nd Street,

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. 13th Floor, New York, NY 10036.

6 8

Available from American Iron and Steel Institute, 1000 16th Street, NW, Available from Society of Automotive Engineers, Inc., 400 Commonwealth

Washington, DC 20036. Ave., Warrendale, PA 15096.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D 5001 – 90a (2000)

fluids and test materials, the presence of oxygen and water in

the atmosphere, and the temperature of the test. Lubricity

measurements are also sensitive to trace materials acquired

during sampling and storage. Containers specified in Practice

D 4306 shall be used.

5.4 The BOCLE test method may not directly reflect oper-

ating conditions of engine hardware. For example, some fuels

that contain a high content of certain sulfur compounds may

give anomalous test results.

6. Apparatus

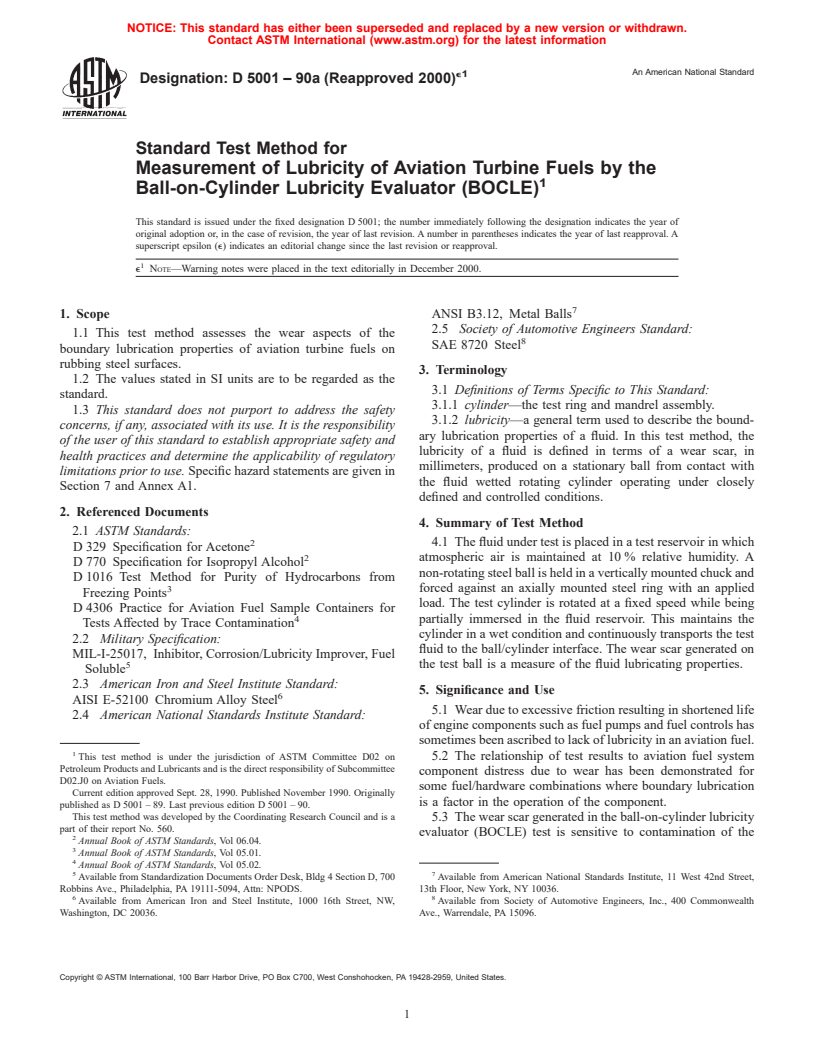

6.1 Ball-On-Cylinder Lubricity Evaluator (BOCLE), illus-

trated in Fig. 1 and Fig. 2. The test requirements are listed in

Table 1.

FIG. 2 Ring Mandrel Assembly

6.2 Constant Temperature Bath-Circulator, capable of

maintaining the fluid sample at 25 6 1°C when circulating

TABLE 1 Standard Operating Conditions

coolant through the base of the sample reservoir.

6.3 Microscope, capable of 100 3 magnification in gradua-

Fluid Volume 50 6 1.0 mL

Fluid Temperature 25 6 1°C

tions of 0.1 mm and incremented in divisions of 0.01 mm.

Conditioned Air 10 6 0.2 % relative humidity

at 25 6 1°C

Fluid pretreatment 0.50 L/min flowing through and 3.3 L/min

over the fluid for 15 min.

9 Fluid test conditions 3.8 L/min flowing over the fluid.

BOCLE units, BOC 100, made by InterAv, Inc., P.O. Box 792228, San Antonio,

Applied Load 1000 g (500 g weight)

TX 78279 have been found satisfactory. Other units built to the drawings available

Cylinder Rotational Speed 240 6 1 r/min

from ASTM, 100 Barr Harbor Drive, West Conshohocken, PA, meeting the test

Test Duration 30 6 0.1 min

requirements of Table 1 in accordance with the procedure of 3.2 of Guidelines for

Equipment Supply, Listing, and Replacement in ASTM Committee D-2 methods

and practices are considered acceptable. These units can have different operating

procedures.

6.3.1 Glass Slide Micrometer, with a scale ruled in 0.01 mm

divisions.

6.4 Cleaning Bath—Ultrasonic seamless stainless steel tank

with a capacity of 1.9 L ( ⁄2 gal) and a cleaning power of 40 W.

7. Reagents and Materials

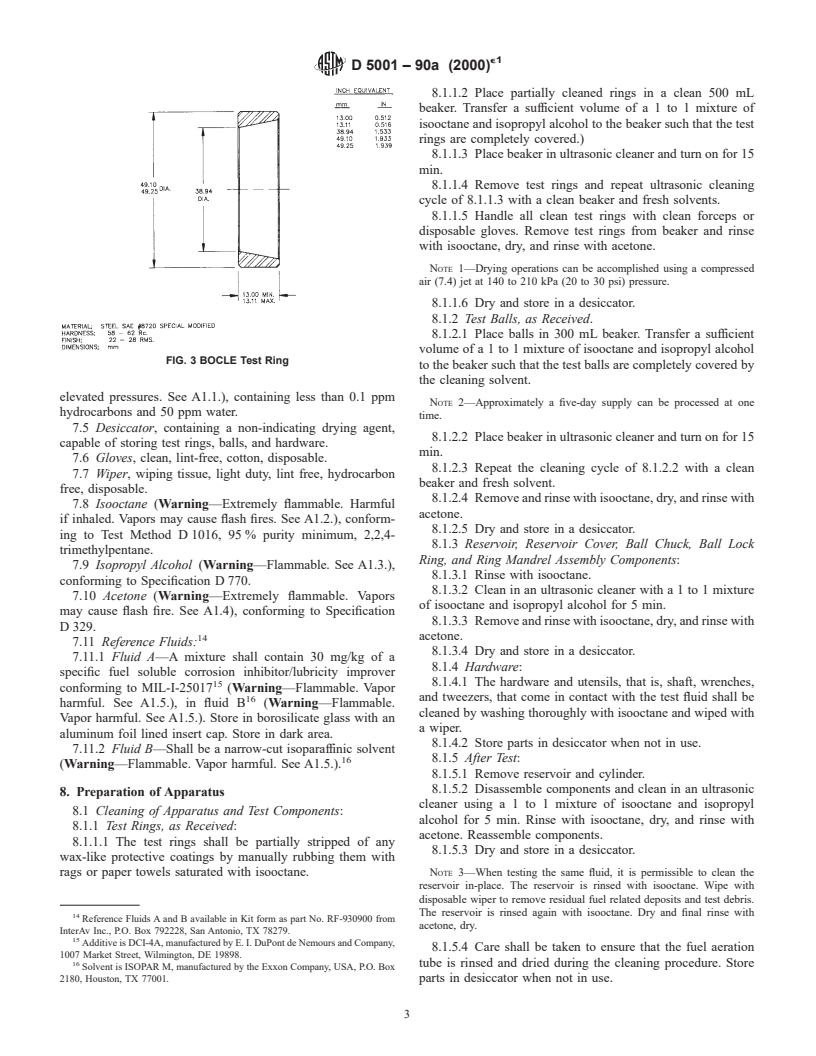

7.1 Test Ring, of SAE 8720 steel, having a Rockwell

hardness “C” scale, (HRC) number of 58 to 62 and a surface

finish of 0.56 to 0.71 μm (22 to 28 μin.) root mean square. The

dimensions are given in Fig. 3.

7.2 Mandrel, a 10° tapered short cylindrical section used for

holding test ring. See Fig. 2.

7.3 Test Ball, chrome alloy steel, made from AISI standard

steel No. E-52100, with a diameter of 12.7 mm (0.5 in.) grade

5 to 10 EP finish. The balls are described in ANSI Specifica-

tions B 3.12. The extra-polish finish is not described in that

specification. The HRC shall be 64 to 66, a closer limit than is

found in the ANSI requirement.

7.4 Compressed Air (Warning—Compressed gas under

high pressure. Use with extreme caution in the presence of

combustible material, since the autoignition temperatures of

most organic compounds in air are drastically reduced at

Catalog No. 31-16-99 from Bausch and Lomb, Inc. has been found satisfac-

tory. A certificate of traceability from the National Institute of Standards and

Technology is available.

Test Rings, Part No. F25061 from Falex Corp., 2055 Comprehensive Drive,

Aurora, IL 60505, have been found satisfactory.

Mandrel, part No. M-O from Falex Corp., or P/N BOC-2101 from InterAv,

Inc. P.O. Box 792228, San Antonio, TX 78279, have been found satisfactory.

Test Balls, SKF Swedish, part No. 310995A, RB 12.7, grade 5 to 10 EP Finish,

AISI 52100 Alloy from SKF Industries, Component Systems, 1690 East Race

FIG. 1 Ball-on-Cylinder Lubricity Evaluator Street, Allentown, PA 90653, have been found satisfactory.

e1

D 5001 – 90a (2000)

8.1.1.2 Place partially cleaned rings in a clean 500 mL

beaker. Transfer a sufficient volume ofa1to1 mixture of

isooctane and isopropyl alcohol to the beaker such that the test

rings are completely covered.)

8.1.1.3 Place beaker in ultrasonic cleaner and turn on for 15

min.

8.1.1.4 Remove test rings and repeat ultrasonic cleaning

cycle of 8.1.1.3 with a clean beaker and fresh solvents.

8.1.1.5 Handle all clean test rings with clean forceps or

disposable gloves. Remove test rings from beaker and rinse

with isooctane, dry, and rinse with acetone.

NOTE 1—Drying operations can be accomplished using a compressed

air (7.4) jet at 140 to 210 kPa (20 to 30 psi) pressure.

8.1.1.6 Dry and store in a desiccator.

8.1.2 Test Balls, as Received.

8.1.2.1 Place balls in 300 mL beaker. Transfer a sufficient

volume ofa1to1 mixture of isooctane and isopropyl alcohol

FIG. 3 BOCLE Test Ring

to the beaker such that the test balls are completely covered by

the cleaning solvent.

elevated pressures. See A1.1.), containing less than 0.1 ppm

NOTE 2—Approximately a five-day supply can be processed at one

hydrocarbons and 50 ppm water.

time.

7.5 Desiccator, containing a non-indicating drying agent,

8.1.2.2 Place beaker in ultrasonic cleaner and turn on for 15

capable of storing test rings, balls, and hardware.

min.

7.6 Gloves, clean, lint-free, cotton, disposable.

8.1.2.3 Repeat the cleaning cycle of 8.1.2.2 with a clean

7.7 Wiper, wiping tissue, light duty, lint free, hydrocarbon

beaker and fresh solvent.

free, disposable.

8.1.2.4 Remove and rinse with isooctane, dry, and rinse with

7.8 Isooctane (Warning—Extremely flammable. Harmful

acetone.

if inhaled. Vapors may cause flash fires. See A1.2.), conform-

8.1.2.5 Dry and store in a desiccator.

ing to Test Method D 1016, 95 % purity minimum, 2,2,4-

8.1.3 Reservoir, Reservoir Cover, Ball Chuck, Ball Lock

trimethylpentane.

Ring, and Ring Mandrel Assembly Components:

7.9 Isopropyl Alcohol (Warning—Flammable. See A1.3.),

8.1.3.1 Rinse with isooctane.

conforming to Specification D 770.

8.1.3.2 Clean in an ultrasonic cleaner witha1to1 mixture

7.10 Acetone (Warning—Extremely flammable. Vapors

of isooctane and isopropyl alcohol for 5 min.

may cause flash fire. See A1.4), conforming to Specification

8.1.3.3 Remove and rinse with isooctane, dry, and rinse with

D 329.

14 acetone.

7.11 Reference Fluids:

8.1.3.4 Dry and store in a desiccator.

7.11.1 Fluid A—A mixture shall contain 30 mg/kg of a

8.1.4 Hardware:

specific fuel soluble corrosion inhibitor/lubricity improver

8.1.4.1 The hardware and utensils, that is, shaft, wrenches,

conforming to MIL-I-25017 (Warning—Flammable. Vapor

and tweezers, that come in contact with the test fluid shall be

harmful. See A1.5.), in fluid B (Warning—Flammable.

cleaned by washing thoroughly with isooctane and wiped with

Vapor harmful. See A1.5.). Store in borosilicate glass with an

a wiper.

aluminum foil lined insert cap. Store in dark area.

8.1.4.2 Store parts in desiccator when not in use.

7.11.2 Fluid B—Shall be a narrow-cut isoparaffinic solvent

8.1.5 After Test:

(Warning—Flammable. Vapor harmful. See A1.5.).

8.1.5.1 Remove reservoir and cylinder.

8.1.5.2 Disassemble components and clean in an ultrasonic

8. Preparation of Apparatus

cleaner usinga1to1 mixture of isooctane and isopropyl

8.1 Cleaning of Apparatus and Test Components:

alcohol for 5 min. Rinse with isooctane, dry, and rinse with

8.1.1 Test Rings, as Received:

acetone. Reassemble components.

8.1.1.1 The test rings shall be partially stripped of any

8.1.5.3 Dry and store in a desiccator.

wax-like protective coatings by manually rubbing them with

rags or paper towels saturated with isooctane. NOTE 3—When testing the same fluid, it is permissible to clean the

reservoir in-place. The reservoir is rinsed with isooctane. Wipe with

disposable wiper to remove residual fuel related deposits and test debris.

The reservoir is rinsed again with isooctane. Dry and final rinse with

Reference Fluids A and B available in Kit form as part No. RF-930900 from

acetone, dry.

InterAv Inc., P.O. Box 792228, San Antonio, TX 78279.

Additive is DCI-4A, manufactured by E. I. DuPont de Nemours and Company,

8.1.5.4 Care shall be taken to ensure that the fuel aeration

1007 Market Street, Wilmington, DE 19898.

tube is rinsed and dried during the cleaning procedure. Store

Solvent is ISOPAR M, manufactured by the Exxon Company, USA, P.O. Box

2180, Houston, TX 77001. parts in desiccator when not in use.

e1

D 5001 – 90a (2000)

9. Calibration and Standardization 9.4.4 Check level on top of load arm. The indicator bubble

shall be centered in the middle of the two lines. If required,

9.1 Visually inspect test balls before each test. Discard balls

adjust the retaining nut screw to achieve a level load arm.

that exhibit pits, corrosion, or surface abnormalities.

9.5 Assembly of Cylinder:

9.2 Reference Fluids:

9.5.1 Place a clean test ring on the mandrel and bolt the back

9.2.1 Conduct three tests on each new batch of the reference

plate to the mandrel as shown in Fig. 2.

fluids in accordance with Section 10 using a cylinder previ-

ously standardized by reference fluid testing.

10. Procedure

9.2.2 Repeat the three tests if the wear scar diameters differ

10.1 The summary of test conditions is included in Table 1.

by more than 0.04 mm for Reference Fluid A or by more than

10.2 Installation of Cleaned Test Cylinder:

0.08 mm for Reference Fluid B.

9.2.3 Reject the Reference Batch concerned if the wear scar

NOTE 4—The BOCLE is very sensitive to contamination problems.

diameters for the repeat tests again differ by more than the

10.2.1 The greatest care shall be taken to adhere strictly to

values obtained in 9.2.1.

cleanliness requirements and to the specified cleaning proce-

9.2.4 Calculate the average wear scar for the three results

dures. During handling and installation procedures, protect

that are within the values of 9.2.2 for the appropriate Reference

cleaned test parts (cylinder, balls, reservoir, and reservoir

Fluid.

cover) from contamination by wearing clean cotton gloves.

9.2.5 Compare the average results with the following Ref-

10.2.2 Rinse shaft with isooctane and wipe with disposable

erence Fluid values:

wiper.

Reference Fluid A 0.56 mm average WSD

10.2.3 Push the shaft through the left hand bearing and

Reference Fluid B 0.85 mm average WSD

support bracket.

9.2.6 Reject the new Reference Fluid batch if the average

10.2.4 Hold the cylinder with the set screw hub facing left.

results obtained at 9

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.