ASTM E2203-02(2008)

(Specification)Standard Specification for Dense Thermoplastic Elastomers Used for Compression Seals, Gaskets, Setting Blocks, Spacers and Accessories

Standard Specification for Dense Thermoplastic Elastomers Used for Compression Seals, Gaskets, Setting Blocks, Spacers and Accessories

ABSTRACT

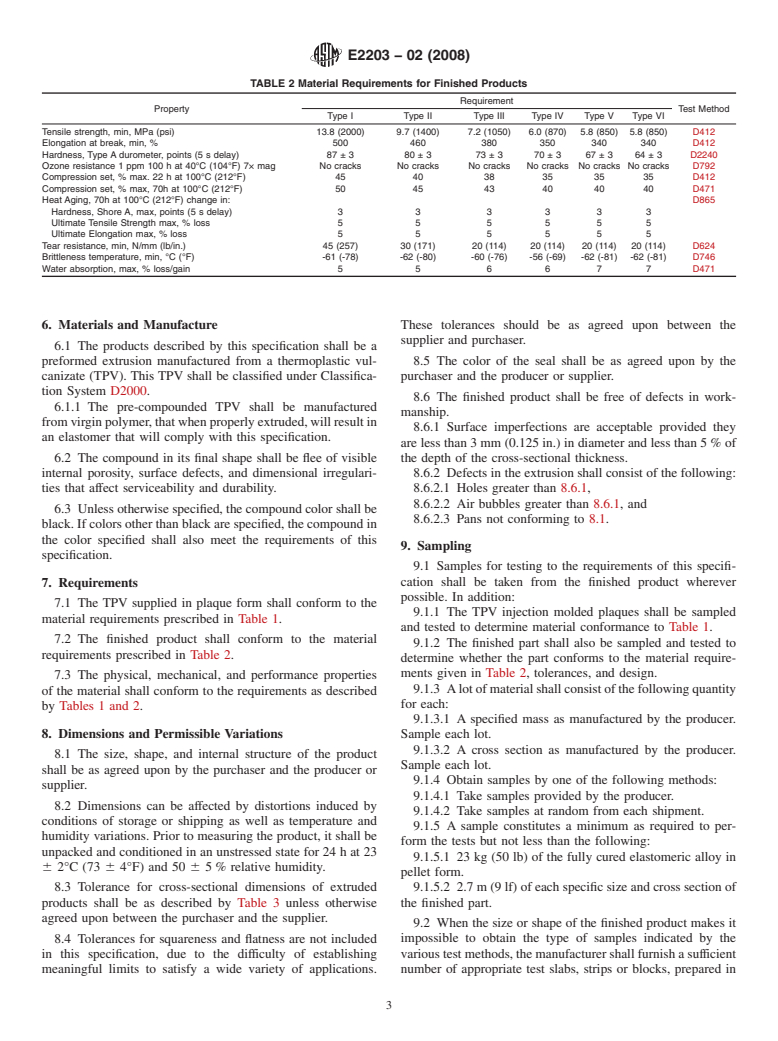

This specification covers the properties of products made from dense thermoplastic elastomers used for compression seals, gaskets, setting blocks, spacers, and accessories for building construction sealing and glazing applications. The products are categorized into types according to resistance to tearing and compression set, grades based on durometer hardness, classes by flame propagation requirements, and into surfaces according to the surface characteristics. All products should be a performed extrusion manufactured from a thermoplastic vulcanizate and should conform to the specified requirements for tensile strength, elongation at break, hardness, ozone resistance, compression set, heat aging, tear resistance, brittleness temperature, and water absorption.

SCOPE

1.1 This specification describes products composed of dense thermoplastic elastomers that are fabricated into gaskets and accessories (such as compression seals, setting blocks, spacers, and shims) for use in sealing and glazing applications in building construction. These products are used to seal or serve as components of compression sealing systems between mechanically restrained surfaces in building construction.

1.2 The values stated in metric (SI) units are to be regarded as the standard. The inch-pound values given in parentheses are provided for information purposes only.

1.3 Test Method C 1166, as referenced in this specification, should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire risk assessment that takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2203 −02(Reapproved 2008)

Standard Specification for

Dense Thermoplastic Elastomers Used for Compression

1

Seals, Gaskets, Setting Blocks, Spacers and Accessories

This standard is issued under the fixed designation E2203; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C1087 Test Method for Determining Compatibility of

Liquid-Applied Sealants with Accessories Used in Struc-

1.1 Thisspecificationdescribesproductscomposedofdense

tural Glazing Systems

thermoplastic elastomers that are fabricated into gaskets and

C1166 Test Method for Flame Propagation of Dense and

accessories (such as compression seals, setting blocks, spacers,

Cellular Elastomeric Gaskets and Accessories

and shims) for use in sealing and glazing applications in

D395 Test Methods for Rubber Property—Compression Set

building construction. These products are used to seal or serve

D412 Test Methods forVulcanized Rubber andThermoplas-

as components of compression sealing systems between me-

tic Elastomers—Tension

chanically restrained surfaces in building construction.

D471 Test Method for Rubber Property—Effect of Liquids

1.2 The values stated in metric (SI) units are to be regarded

D573 Test Method for Rubber—Deterioration in an Air

asthestandard.Theinch-poundvaluesgiveninparenthesesare

Oven

provided for information purposes only.

D624 Test Method for Tear Strength of Conventional Vul-

1.3 Test Method C1166, as referenced in this specification, canized Rubber and Thermoplastic Elastomers

D746 Test Method for Brittleness Temperature of Plastics

should be used to measure and describe the properties of

materials,products,orassembliesinresponsetoheatandflame and Elastomers by Impact

D792 Test Methods for Density and Specific Gravity (Rela-

under controlled laboratory conditions and should not be used

to describe or appraise the fire hazard or fire risk of materials, tive Density) of Plastics by Displacement

D865 Test Method for Rubber—Deterioration by Heating in

products, or assemblies under actual fire conditions. However,

results of this test may be used as elements of a fire risk Air (Test Tube Enclosure)

D925 Test Methods for Rubber Property—Staining of Sur-

assessment that takes into account all of the factors which are

pertinent to an assessment of the fire hazard of a particular end faces (Contact, Migration, and Diffusion)

use. D1149 Test Methods for Rubber Deterioration—Cracking in

an Ozone Controlled Environment

1.4 This standard does not purport to address all of the

D1566 Terminology Relating to Rubber

safety concerns, if any, associated with its use. It is the

D2000 Classification System for Rubber Products in Auto-

responsibility of the user of this standard to establish appro-

motive Applications

priate safety and health practices and determine the applica-

D2137 TestMethodsforRubberProperty—BrittlenessPoint

bility of regulatory requirements prior to use.

of Flexible Polymers and Coated Fabrics

D2240 Test Method for Rubber Property—Durometer Hard-

2. Referenced Documents

2 ness

2.1 ASTM Standards:

D3182 PracticeforRubber—Materials,Equipment,andPro-

C717 Terminology of Building Seals and Sealants

cedures for Mixing Standard Compounds and Preparing

C864 SpecificationforDenseElastomericCompressionSeal

Standard Vulcanized Sheets

Gaskets, Setting Blocks, and Spacers

2.2 Other Documents:

Rubber Manufacturers Association (RMA) Standard; Rub-

1

This specification is under the jurisdiction of ASTM Committee C24 on

3

ber Handbook, Fourth ed. December 1984

Building Seals and Sealants and is the direct responsibility of Subcommittee C24.73

4

Uniform Freight Classification Rules

on Compression Seal and Lock Strip Gaskets.

Current edition approved March 15, 2008. Published April 2008. Originally

approved in 2002. Last previous edition approved in 2002 as E2203-02. DOI:

10.1520/E2203-02R08.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from the Rubber Manufacturers Association, 1400 K Street, NW,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Washington, DC 20005.

4

Standards volume information, refer to the standard’s Document Summary page on Available from the Western Railroad Association, Department of Services and

the ASTM website. Supply, Room 1150, 222 S. Riverside Plaza, Chicago, IL 60606-5945.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2203−02 (2008)

5

National Motor Freight Classification Rules 5.4 Class:

5.4.1 Flamepropagatio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.