ASTM E2203-14(2018)

(Specification)Standard Specification for Dense Thermoplastic Elastomers Used for Compression Seals, Gaskets, Setting Blocks, Spacers and Accessories

Standard Specification for Dense Thermoplastic Elastomers Used for Compression Seals, Gaskets, Setting Blocks, Spacers and Accessories

ABSTRACT

This specification covers the properties of products made from dense thermoplastic elastomers used for compression seals, gaskets, setting blocks, spacers, and accessories for building construction sealing and glazing applications. The products are categorized into types according to resistance to tearing and compression set, grades based on durometer hardness, classes by flame propagation requirements, and into surfaces according to the surface characteristics. All products should be a performed extrusion manufactured from a thermoplastic vulcanizate and should conform to the specified requirements for tensile strength, elongation at break, hardness, ozone resistance, compression set, heat aging, tear resistance, brittleness temperature, and water absorption.

SCOPE

1.1 This specification describes products composed of dense thermoplastic elastomers that are fabricated into gaskets and accessories (such as compression seals, setting blocks, spacers, and shims) for use in sealing and glazing applications in building construction. These products are used to seal or serve as components of compression sealing systems between mechanically restrained surfaces in building construction.

1.2 The values stated in metric (SI) units are to be regarded as the standard. The inch-pound values given in parentheses are provided for information purposes only.

1.3 Test Method C1166, as referenced in this specification, should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire risk assessment that takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2203 −14 (Reapproved 2018)

Standard Specification for

Dense Thermoplastic Elastomers Used for Compression

Seals, Gaskets, Setting Blocks, Spacers and Accessories

This standard is issued under the fixed designation E2203; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 Thisspecificationdescribesproductscomposedofdense

C717 Terminology of Building Seals and Sealants

thermoplastic elastomers that are fabricated into gaskets and

C864 SpecificationforDenseElastomericCompressionSeal

accessories (such as compression seals, setting blocks, spacers,

Gaskets, Setting Blocks, and Spacers

and shims) for use in sealing and glazing applications in

C1087 Test Method for Determining Compatibility of

building construction. These products are used to seal or serve

Liquid-Applied Sealants with Accessories Used in Struc-

as components of compression sealing systems between me-

tural Glazing Systems

chanically restrained surfaces in building construction.

C1166 Test Method for Flame Propagation of Dense and

Cellular Elastomeric Gaskets and Accessories

1.2 The values stated in metric (SI) units are to be regarded

D395 Test Methods for Rubber Property—Compression Set

asthestandard.Theinch-poundvaluesgiveninparenthesesare

D412 Test Methods forVulcanized Rubber andThermoplas-

provided for information purposes only.

tic Elastomers—Tension

1.3 Test Method C1166, as referenced in this specification,

D471 Test Method for Rubber Property—Effect of Liquids

should be used to measure and describe the properties of

D573 Test Method for Rubber—Deterioration in an Air

materials,products,orassembliesinresponsetoheatandflame

Oven

under controlled laboratory conditions and should not be used

D624 Test Method for Tear Strength of Conventional Vul-

to describe or appraise the fire hazard or fire risk of materials, canized Rubber and Thermoplastic Elastomers

products, or assemblies under actual fire conditions. However, D746 Test Method for Brittleness Temperature of Plastics

and Elastomers by Impact

results of this test may be used as elements of a fire risk

D792 Test Methods for Density and Specific Gravity (Rela-

assessment that takes into account all of the factors which are

tive Density) of Plastics by Displacement

pertinent to an assessment of the fire hazard of a particular end

D865 Test Method for Rubber—Deterioration by Heating in

use.

Air (Test Tube Enclosure)

1.4 This standard does not purport to address all of the

D925 Test Methods for Rubber Property—Staining of Sur-

safety concerns, if any, associated with its use. It is the

faces (Contact, Migration, and Diffusion)

responsibility of the user of this standard to establish appro-

D1149 Test Methods for Rubber Deterioration—Cracking in

priate safety, health, and environmental practices and deter-

an Ozone Controlled Environment

mine the applicability of regulatory limitations prior to use.

D1566 Terminology Relating to Rubber

D2000 Classification System for Rubber Products in Auto-

1.5 This international standard was developed in accor-

motive Applications

dance with internationally recognized principles on standard-

D2137 TestMethodsforRubberProperty—BrittlenessPoint

ization established in the Decision on Principles for the

of Flexible Polymers and Coated Fabrics

Development of International Standards, Guides and Recom-

D2240 Test Method for Rubber Property—Durometer Hard-

mendations issued by the World Trade Organization Technical

ness

Barriers to Trade (TBT) Committee.

D3182 PracticeforRubber—Materials,Equipment,andPro-

cedures for Mixing Standard Compounds and Preparing

This specification is under the jurisdiction of ASTM Committee C24 on

Building Seals and Sealants and is the direct responsibility of Subcommittee C24.73

on Compression Seal and Lock Strip Gaskets. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 1, 2018. Published August 2018. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2002. Last previous edition approved in 2014 as E2203-14. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E2203-14R18. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2203 − 14 (2018)

Standard Vulcanized Sheets to conditions of exposure or usage; and as setting blocks,

2.2 Other Documents: spacers, shims, or other accessories in glazing and sealing

systems.

Rubber Manufacturers Association (RMA) Standard; Rub-

ber Handbook, Fourth ed. December 1984

5.3 Grade—Each type described in 5.2 is subdivided into

Uniform Freight Classification Rules

various hardnesses, based on nominal durometer hardness as

National Motor Freight Classification Rules

shown in Tables 1 and 2. For example, Grade H3 is 30

durometer.

3. Terminology

3.1 Refer to Terminology C717 for definitions of the fol- 5.4 Class:

lowing terms used in this specification: compound, compres-

5.4.1 Flamepropagationcharacteristicsofthefinishedprod-

sion gasket, edge spacer, elastomer, elastomeric, expansion

ucts can be varied depending on the degree of exposure,

gasket, gasket, hardness, seal, setting block, shim spacer,

expected usage, and intended durability desired. Products

standard conditions, and spacer.

described by this specification shall be classified as to flame

propagation as follows:

3.2 Refer to Terminology D1566 for definitions of the

following terms used in this specification: compression set,

5.4.1.1 Class F—Resistance to flame propagation is re-

ultimate elongation, tear strength, tensile strength, and poly- quired (reference Specification C864, 4.1, Table 1).

mer.

5.4.1.2 Class designation is not needed when flame propa-

gation resistance is not required.

4. Significance and Use

5.5 Surface:

4.1 This specification describes types (based on resistance

5.5.1 Consideration of product surface requirements may be

to tearing and compression set), grades (based on durometer

necessary. During the production of these products the use of

hardness), class (based on flame propagation requirements),

various lubricants, release agents, dusting agents, and other

and surfaces (based on surface characteristics) of products as

solutionsmayberequired.Itmaybenecessarytoremovethese

listed in Section 5 for various applications. It is essential,

materials from the surfaces of the product because of appear-

therefore, that the applicable type, grade, class, and surface be

ance fabrication, or usage requirements. All products do not

specified, as well as other options stated, so that the proper

require removal of these materials or removal to the same

product is provided for the intended use.

degree of cleanliness.

5. Classification

5.5.2 Products may also be required to develop adhesion or

5.1 The products described by this specification are classi-

to not develop adhesion to sealants with which they are in

fied by type, hardness, class, and surface.

contact.

5.5.3 Products described by this specification shall be clas-

5.2 Type:

sified as to surface condition as follows:

5.2.1 TypeT,TearResistant—Ingeneraltheseproductshave

a higher level of tear resistance. This type is applicable where

5.5.3.1 Surface S1—The surface of the product shall be

finishedproductsareintendedtobridgeortocoveraspace(for

smooth,clean,freefromanyforeignmatter,andshallnotallow

example, expansion joint gaskets), or where high tear strength

adhesion of sealants (see Note 1).

is required due to conditions of exposure or usage.

5.5.3.2 Surface S2—The surface of the product shall be

5.2.2 Type C, Compression Set Resistant—In general, these

smooth, clean, free from any foreign matter, and shall allow

productshaveahigherlevelofcompressionsetresistance.This

adhesion of sealants (see Note 1).

type is applicable where finished products are used as com-

NOTE 1—Applied treatments, such as dusting or coating to the adhesion

pression gaskets, or where low compression set is required due

surface may be necessary to meet this requirement.

5.5.3.3 Surface S3—The product shall have a surface that is

Available from the Rubber Manufacturers Association, 1400 K Street, NW,

smooth, clean, and free from any foreign matter.

Washington, DC 20005.

Available from the Western Railroad Association, Department of Services and

5.5.4 Surface designation code is not needed for products

Supply, Room 1150, 222 S. Riverside Plaza, Chicago, IL 60606-5945.

not requiring special cleaning for removal of processing agents

Available from the National Motor Freight Association, 2200 Mill Road,

and materials.

Alexandria, VA 22314.

TABLE 1 Requirements for Fully Cured Elastomeric Alloy Injection Molded Plaques

Requirement

Property Test Method

Type I Type II Type III Type IV Type V Type VI

Tensile strength, min, MPa (psi) 13.8 (2000) 9.7 (1400) 7.2 (1050) 6.0 (870) 5.8 (850) 5.8 (850) D412

Elongation at break, min, % 500 460 380 350 340 340 D412

Hardness, Type A durometer, points (5 s delay) 87 ± 3 80 ± 3 73 ± 3 70 ± 3 67 ± 3 64 ± 3 D2240

Relative Density at 23°C (73°F) 0.95 ± 0.02 0.96 ± 0.02 0.97 ± 0.02 0.97 ± 0.02 0.97 ± 0.02 0.97 ± 0.02 D792

100% Modulus, min, MPa (psi) 6.1 (890) 3.8 (550) 2.8 (400) 2.2 (320) 1.9 (280) 1.9 (280) D412

Mass gain, max. %, (24 h at 121°C (250°F) ASTM No.3 60 75 80 90 95 95 D471

Oil)

E2203 − 14 (2018)

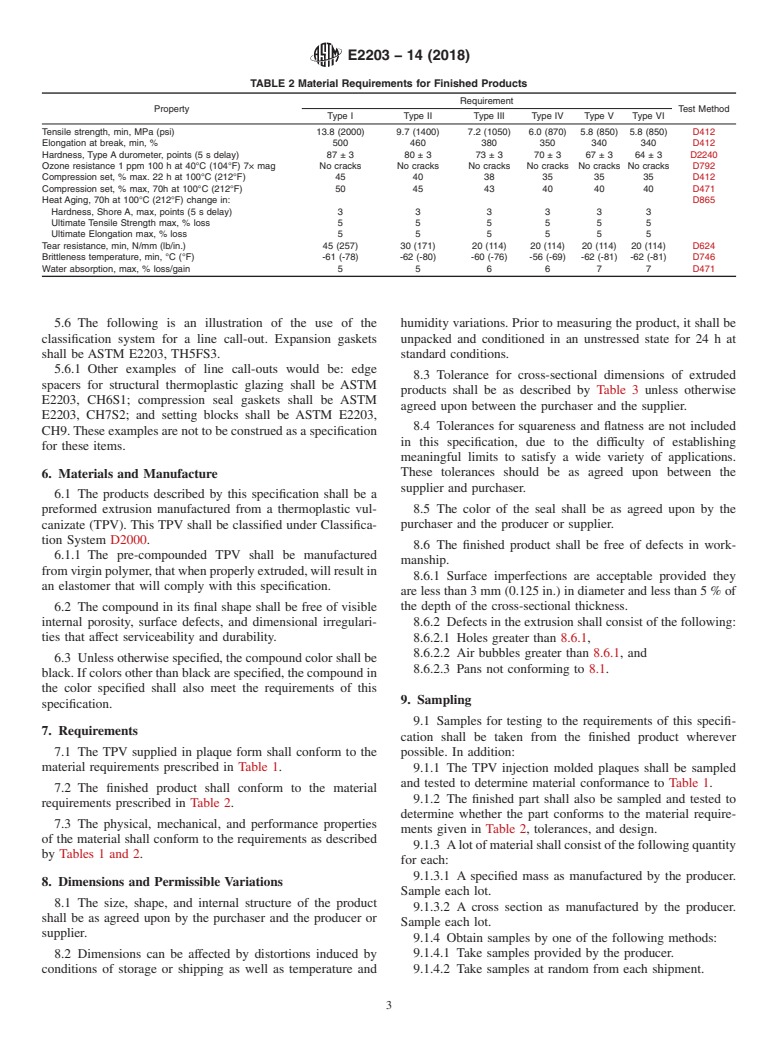

TABLE 2 Material Requirements for Finished Products

Requirement

Property Test Method

Type I Type II Type III Type IV Type V Type VI

Tensile strength, min, MPa (psi) 13.8 (2000) 9.7 (1400) 7.2 (1050) 6.0 (870) 5.8 (850) 5.8 (850) D412

Elongation at break, min, % 500 460 380 350 340 340 D412

Hardness, Type A durometer, points (5 s delay) 87 ± 3 80 ± 3 73 ± 3 70 ± 3 67 ± 3 64 ± 3 D2240

Ozone resistance 1 ppm 100 h at 40°C (104°F) 7× mag No cracks No cracks No cracks No cracks No cracks No cracks D792

Compression set, % max. 22 h at 100°C (212°F) 45 40 38 35 35 35 D412

Compression set, % max, 70h at 100°C (212°F) 50 45 43 40 40 40 D471

Heat Aging, 70h at 100°C (212°F) change in: D865

Hardness, Shore A, max, points (5 s delay) 3 3 3 3 3 3

Ultimate Tensile Strength max, % loss 5 5 5 5 5 5

Ultimate Elongation max, % loss 5 5 5 5 5 5

Tear resistance, min, N/mm (lb/in.) 45 (257) 30 (171) 20 (114) 20 (114) 20 (114) 20 (114) D624

Brittleness temperature, min, °C (°F) -61 (-78) -62 (-80) -60 (-76) -56 (-69) -62 (-81) -62 (-81) D746

Water absorption, max, % loss/gain 5 5 6 6 7 7 D471

5.6 The following is an illustration of the use of the humidity variations. Prior to measuring the product, it shall be

classification system for a line call-out. Expansion gaskets unpacked and conditioned in an unstressed state for 24 h at

shall be ASTM E2203, TH5FS3. standard conditions.

5.6.1 Other examples of line call-outs would be: edge

8.3 Tolerance for cross-sectional dimensions of extruded

spacers for structural thermoplastic glazing shall be ASTM

products shall be as described by Table 3 unless otherwise

E2203, CH6S1; compression seal gaskets shall be ASTM

agreed upon between the purchaser and the supplier.

E2203, CH7S2; and setting blocks shall be ASTM E2203,

8.4 Tolerances for squareness and flatness are not included

CH9.These examples are not to be construed as a specification

in this specification, due to the difficulty of establishing

for these items.

meaningful limits to satisfy a wide variety of applications.

These tolerances should be as agreed upon between the

6. Materials and Manufacture

supplier and purchaser.

6.1 The products described by this specification shall be a

8.5 The color of the seal shall be as agreed upon by the

preformed extrusion manufactured from a thermoplastic vul-

purchaser and the producer or supplier.

canizate (TPV). This TPV shall be classified under Classifica-

tion System D2000.

8.6 The finished product shall be free of defects in work-

6.1.1 The pre-compounded TPV shall be manufactured

manship.

fromvirginpolymer,thatwhenproperlyextruded,willresultin

8.6.1 Surface imperfections are acceptable provided they

an elastomer that will comply with this specification.

are less than 3 mm (0.125 in.) in diameter and less than 5 % of

6.2 The compound in its final shape shall be free of visible the depth of the cross-sectional thickness.

internal porosity, surface defects, and dimensional irregulari-

8.6.2 Defects in the extrusion shall consist of the following:

ties that affect serviceability and durability. 8.6.2.1 Holes greater than 8.6.1,

8.6.2.2 Air bubbles greater than 8.6.1, and

6.3 Unless otherwise specified, the compound color shall be

8.6.2.3 Pans not conforming to 8.1.

black. If colors other than black are specified, the compound in

the color specified shall also meet the requirements of this

9. Sampling

specification.

9.1 Samples for testing to the requirements of this specifi-

7. Requirements

cation shall be taken from the finished product wherever

7.1 The TPV supplied in plaque form shall conform to the possible. In addition:

material requirements prescribed in Table 1. 9.1.1 The TPV injection molded plaques shall be sampled

and tested to determine material conformance to Table 1.

7.2 The finished product shall conform to the material

9.1.2 The finished part shall also be sampled and tested to

requirements prescribed in Table 2.

determine whether the part conforms to the material require-

7.3 The physical, mechanical, and performance properties

ments given in Table 2, tolerances, and design.

of the material shall conform to the requirements as described

9.1.3 Alotofmaterialshallconsistofthefollowingquantity

by Tables 1 and 2.

for each:

9.1.3.1 A specified mass as manufactured by the producer.

8. Dimensions and Permissible Variations

Sample each lot.

8.1 The size, shape, and internal structure of the product

9.1.3.2 A cross section as manufactured by the producer.

shall be as agreed upon by the purchaser and the producer or

Sample each lot.

supplier.

9.1.4 Obtain samples by one of the following methods:

9.1.4.1 Take samples provided by the producer.

8.2 Dimensions can be affected by distortions induced by

conditions of storage or shipping as well as temperature and 9.1.4.2 Take samples at random from each shipment.

E2203 − 14 (2018)

TABLE 3 Standards for Cross Sectional Tolerance

NO

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.