ASTM F3204-16(2024)

(Guide)Standard Guide for Design and Construction of Welded Wire Fence Systems for Security Purposes

Standard Guide for Design and Construction of Welded Wire Fence Systems for Security Purposes

SCOPE

1.1 This guide provides assistance for the site security engineer to select the proper components required to design a site-specific, welded-wire physical security perimeter barrier.

1.2 This standard does not purport to address all of the physical protection security concerns, if any, associated with its use. It is the responsibility of the user of the standard to establish the appropriate design level of physical protection required and determine the applicability of regulatory requirements or limitations.

1.3 Specification F2453 is to be used in conjunction with this guide.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Some specific hazards statements are given in Section 7 on Hazards.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3204 − 16 (Reapproved 2024)

Standard Guide for

Design and Construction of Welded Wire Fence Systems for

Security Purposes

This standard is issued under the fixed designation F3204; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This guide provides assistance for the site security

A121 Specification for Metallic-Coated Carbon Steel

engineer to select the proper components required to design a

Barbed Wire

site-specific, welded-wire physical security perimeter barrier.

A307 Specification for Carbon Steel Bolts, Studs, and

1.2 This standard does not purport to address all of the

Threaded Rod 60 000 PSI Tensile Strength

physical protection security concerns, if any, associated with its

F934 Specification for Standard Colors for Polymer-Coated

use. It is the responsibility of the user of the standard to

Chain Link Fence Materials

establish the appropriate design level of physical protection

F1043 Specification for Strength and Protective Coatings on

required and determine the applicability of regulatory require- Steel Industrial Fence Framework

ments or limitations. F1083 Specification for Pipe, Steel, Hot-Dipped Zinc-

Coated (Galvanized) Welded, for Fence Structures

1.3 Specification F2453 is to be used in conjunction with

F1665 Specification for Poly(Vinyl Chloride) (PVC) and

this guide.

Other Conforming Organic Polymer-Coated Steel Barbed

Wire Used With Chain-Link Fence

1.4 The values stated in inch-pound units are to be regarded

F1910 Specification for Long Barbed Tape Obstacles

as standard. The values given in parentheses are mathematical

F1911 Practice for Installation of Barbed Tape

conversions to SI units that are provided for information only

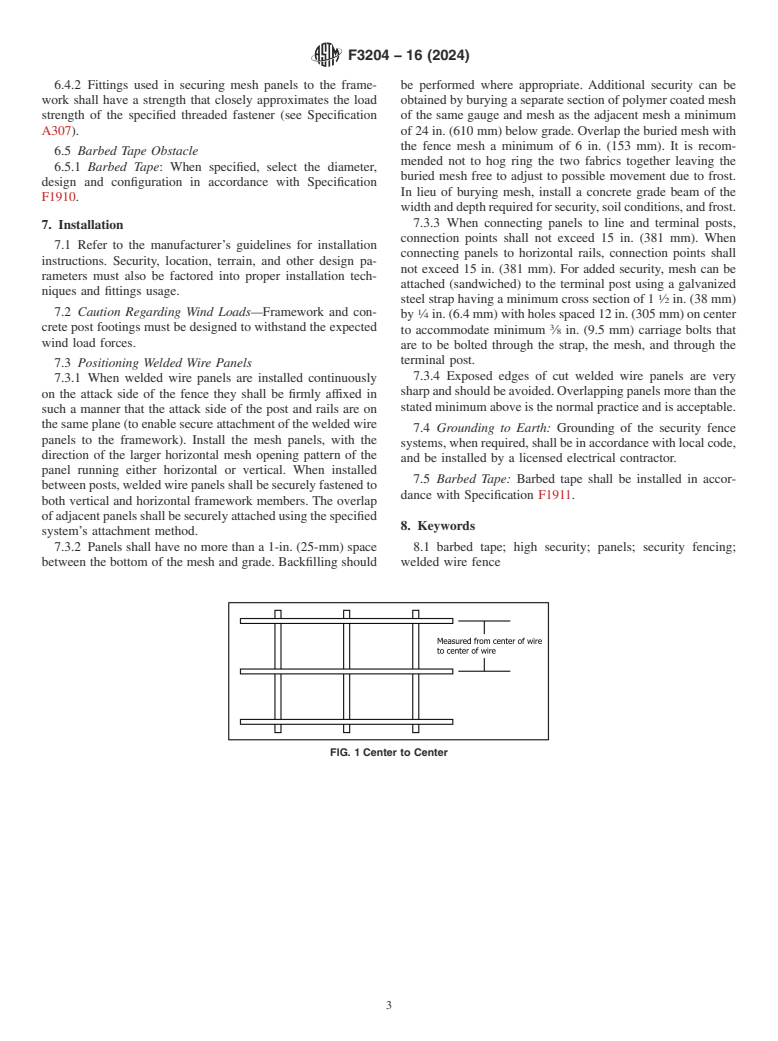

F2453 Specification for Welded Wire Mesh Fence Fabric

and are not considered standard.

(Metallic-Coated or Polymer Coated) for Meshes of 6 in.

1.5 This standard does not purport to address all of the 2

[3871 mm ] or Less, in Panels or Rolls, with Uniform

safety concerns, if any, associated with its use. It is the

Meshes

responsibility of the user of this standard to establish appro-

2.2 American Society of Civil Engineers Standards:

priate safety, health, and environmental practices and deter-

ASCE/SEI 7-10 (or latest edition) Minimum Design Loads

mine the applicability of regulatory limitations prior to use.

for Buildings and Other Structures

Some specific hazards statements are given in Section 7 on

3. Terminology

Hazards.

1.6 This international standard was developed in accor-

3.1 Definitions—Refer to the terminology listed in Specifi-

dance with internationally recognized principles on standard-

cation F2453.

ization established in the Decision on Principles for the

4. Classification

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical 4.1 The welded wire mesh selected for security systems is

Barriers to Trade (TBT) Committee.

classified in Specification F2453 in accordance with the

following coatings:

4.1.1 Type 1, consists of welded wire mesh manufactured

from wire zinc-coated prior to being welded into fabric, known

as galvanized before welding.

1 2

This test method is under the jurisdiction of ASTM Committee F14 on Fences For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and is the direct responsibility of Subcommittee F14.50 on High Security Fences contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and Perimeter Barriers. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Feb. 1, 2024. Published February 2024. Originally the ASTM website.

approved in 2016. Last previous edition approved in 2016 as F3204 – 16. DOI: Available from American Society of Civil Engineers (ASCE), 1801 Alexander

10.1520/F3204-16R24. Bell Dr., Reston, VA 20191, http://www.asce.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F3204 − 16 (2024)

4.1.2 Type 2, consists of welded wire mesh manufactured spacing and post dimension, select the post specification and

from uncoated wire, the fabric of which is subsequently protective coating from Specification F1043, Heavy Industrial

zinc-coated after fabrication, known as galvanized after weld- Fence Framework; Group IA Round Steel Pipe (Specification

ing. F1083 Schedule 40), Group IC Round Steel Pipe (Electric

4.1.3 Type 3, consists of welded wire mesh manufactured Resistance Welded Pipe), Group II Roll-Formed Steel Shapes

from wire coated with zinc-5 % aluminum-mischmetal alloy (C-Sections), Group IV Alternate Design.

(Zn-5A1-MM) before being welded into fabric, known as zinc

6.2.2 Terminal Posts: End, corner, or pull posts are to be in

5 % aluminum-mischmetal alloy-coated steel before welding.

accordance with Specification F1043, Heavy Industrial Fence

4.1.4 Type 4, consists of welded wire mesh manufactured

Framework; Group IA (Specification F1083 schedule 40 pipe),

from wire zinc-coated prior to being welded into fabric, known

Group IC Electric Resistance Welded Pipe). Select the terminal

as galvanized before welding, and subsequently polymer color

post size based on the line post size.

coated.

6.2.3 Rails: Top, intermediate and terminal post brace rails

when specified shall be in accordance with Specification

5. Ordering Information

F1043, Heavy Industrial Fence Framework; Group IA, (F1083

5.1 When ordering or specifying welded wire mesh fence

schedule 40 pipe) Group IC (Electric resistance welded pipe)

systems for security applications, the appropriate mesh type,

or Group II (Roll-formed steel shapes).

mesh description, fence height, post size, post spacing, allow-

6.2.4 Polymer-coated Framework: Specify the type of coat-

able mesh-to-framework attachment methods, and finish

ing in accordance with Specification F1043 and the color in

should all be defined to ensure that welded wire mesh panels

accordance with Specification F934.

and all associated system components will be compatible in the

6.3 Barbed Wire

total system installation.

6.3.1 When specified, select the type and coating from one

6. Materials and Manufacture

of the following:

6.1 Welded Wire Mesh Panels 6.3.2 If metallic coated steel barbed wire, specify Specifi-

6.1.1 Finish

cation A121 design number 12-4-3-14R having four-point

6.1.1.1 If Type 2 galvanized mesh is selected, the panels barbs spaced 3 in. [76 mm] on center or 12-4-5-14R having

shall be completely and uniformly zinc-coated by the hot-dip

four-point barbs spaced 5 in. [127 mm] on center.

process in accordance with Specification F2453 after welding,

6.3.3 Aluminum Metallic-Coated: Specify Coating A for the

shall be free from excessive accumulations of zinc in the

strand wire and aluminum alloy barbs.

apexes of mesh openings, and free from bare spots.

6.3.4 Zinc Metallic-Coated:

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.