ASTM B135-02

(Specification)Standard Specification for Seamless Brass Tube

Standard Specification for Seamless Brass Tube

SCOPE

1.1 This specification covers seamless round and rectangular including square copper alloy tube in straight lengths. Ten alloys are specified having the following nominal compositions:CopperPreviously Nominal Composition, %AlloyUsedUNSDesignationNo.Copper ZincLeadTinC22000790.010.0 ......C23000185.015.0 ......C26000270.030.0 ......C27000965.035.0 ......C27200863.037.0 ......C27400...62.537.5 ......C28000560.040.0 ......C33000366.033.5 0.5...C33200466.032.4 1.6...C37000660.039.0 1.0...C44300...71.527.5 ...1.00A Alloy Designations of ASTM Specification B135 - 63, which was published in the 1966 Book of ASTM Standards, Part 5.

Note 1—A complete metric companion to Specification B135 has been developed-B135M; therefore, no metric equivalents are presented in this specification.

1.2 Warning—Mercury is a definite health hazard in use and disposal. (See 10.1.)

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 135 – 02

Standard Specification for

1

Seamless Brass Tube

This standard is issued under the fixed designation B 135; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

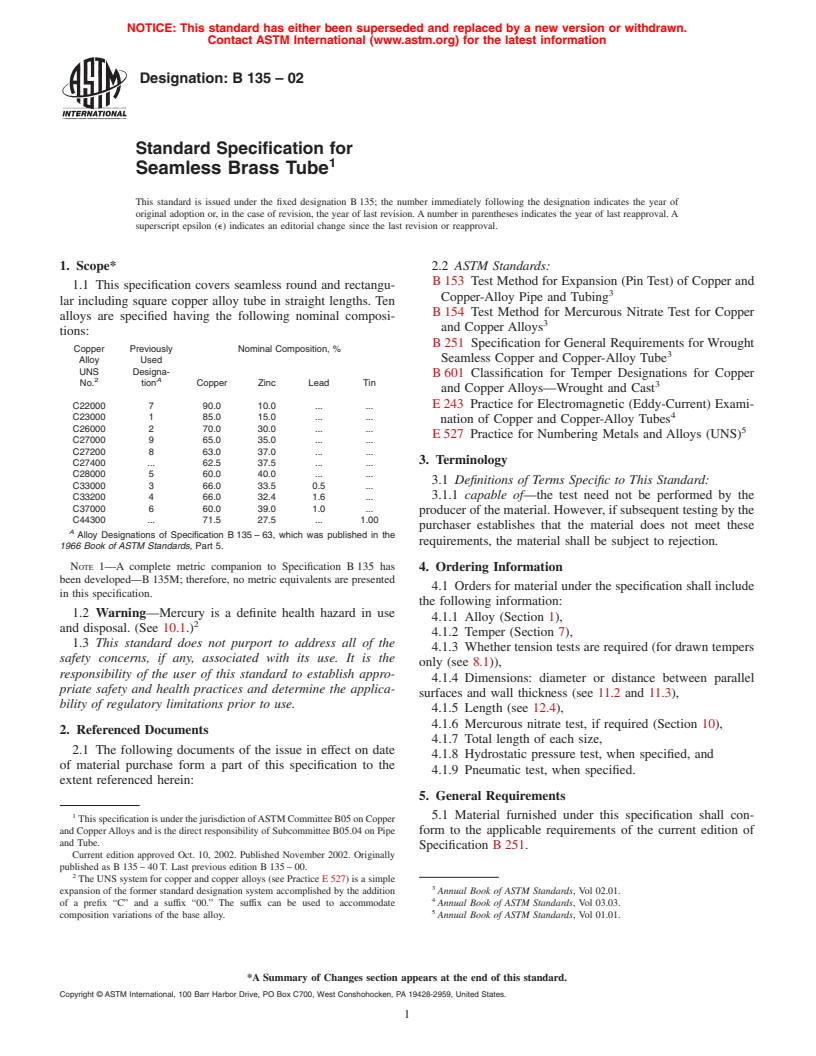

1. Scope* 2.2 ASTM Standards:

B 153 Test Method for Expansion (Pin Test) of Copper and

1.1 This specification covers seamless round and rectangu-

3

Copper-Alloy Pipe and Tubing

lar including square copper alloy tube in straight lengths. Ten

B 154 Test Method for Mercurous Nitrate Test for Copper

alloys are specified having the following nominal composi-

3

and Copper Alloys

tions:

B 251 Specification for General Requirements for Wrought

Copper Previously Nominal Composition, %

3

Seamless Copper and Copper-Alloy Tube

Alloy Used

UNS Designa-

B 601 Classification for Temper Designations for Copper

2 A

No. tion Copper Zinc Lead Tin

3

and Copper Alloys—Wrought and Cast

E 243 Practice for Electromagnetic (Eddy-Current) Exami-

C22000 7 90.0 10.0 . .

4

C23000 1 85.0 15.0 . .

nation of Copper and Copper-Alloy Tubes

C26000 2 70.0 30.0 . .

5

E 527 Practice for Numbering Metals and Alloys (UNS)

C27000 9 65.0 35.0 . .

C27200 8 63.0 37.0 . .

3. Terminology

C27400 . 62.5 37.5 . .

C28000 5 60.0 40.0 . .

3.1 Definitions of Terms Specific to This Standard:

C33000 3 66.0 33.5 0.5 .

3.1.1 capable of—the test need not be performed by the

C33200 4 66.0 32.4 1.6 .

C37000 6 60.0 39.0 1.0 .

producer of the material. However, if subsequent testing by the

C44300 . 71.5 27.5 . 1.00

purchaser establishes that the material does not meet these

A

Alloy Designations of Specification B 135 – 63, which was published in the

requirements, the material shall be subject to rejection.

1966 Book of ASTM Standards, Part 5.

NOTE 1—A complete metric companion to Specification B 135 has

4. Ordering Information

been developed—B 135M; therefore, no metric equivalents are presented

4.1 Orders for material under the specification shall include

in this specification.

the following information:

1.2 Warning—Mercury is a definite health hazard in use

4.1.1 Alloy (Section 1),

2

and disposal. (See 10.1.)

4.1.2 Temper (Section 7),

1.3 This standard does not purport to address all of the

4.1.3 Whether tension tests are required (for drawn tempers

safety concerns, if any, associated with its use. It is the

only (see 8.1)),

responsibility of the user of this standard to establish appro-

4.1.4 Dimensions: diameter or distance between parallel

priate safety and health practices and determine the applica-

surfaces and wall thickness (see 11.2 and 11.3),

bility of regulatory limitations prior to use.

4.1.5 Length (see 12.4),

4.1.6 Mercurous nitrate test, if required (Section 10),

2. Referenced Documents

4.1.7 Total length of each size,

2.1 The following documents of the issue in effect on date

4.1.8 Hydrostatic pressure test, when specified, and

of material purchase form a part of this specification to the

4.1.9 Pneumatic test, when specified.

extent referenced herein:

5. General Requirements

1

5.1 Material furnished under this specification shall con-

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe form to the applicable requirements of the current edition of

and Tube.

Specification B 251.

Current edition approved Oct. 10, 2002. Published November 2002. Originally

published as B 135 – 40 T. Last previous edition B 135 – 00.

2

The UNS system for copper and copper alloys (see Practice E 527) is a simple

3

expansion of the former standard designation system accomplished by the addition Annual Book of ASTM Standards, Vol 02.01.

4

of a prefix “C” and a suffix “00.” The suffix can be used to accommodate Annual Book of ASTM Standards, Vol 03.03.

5

composition variations of the base alloy. Annual Book of ASTM Standards, Vol 01.01.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B135–02

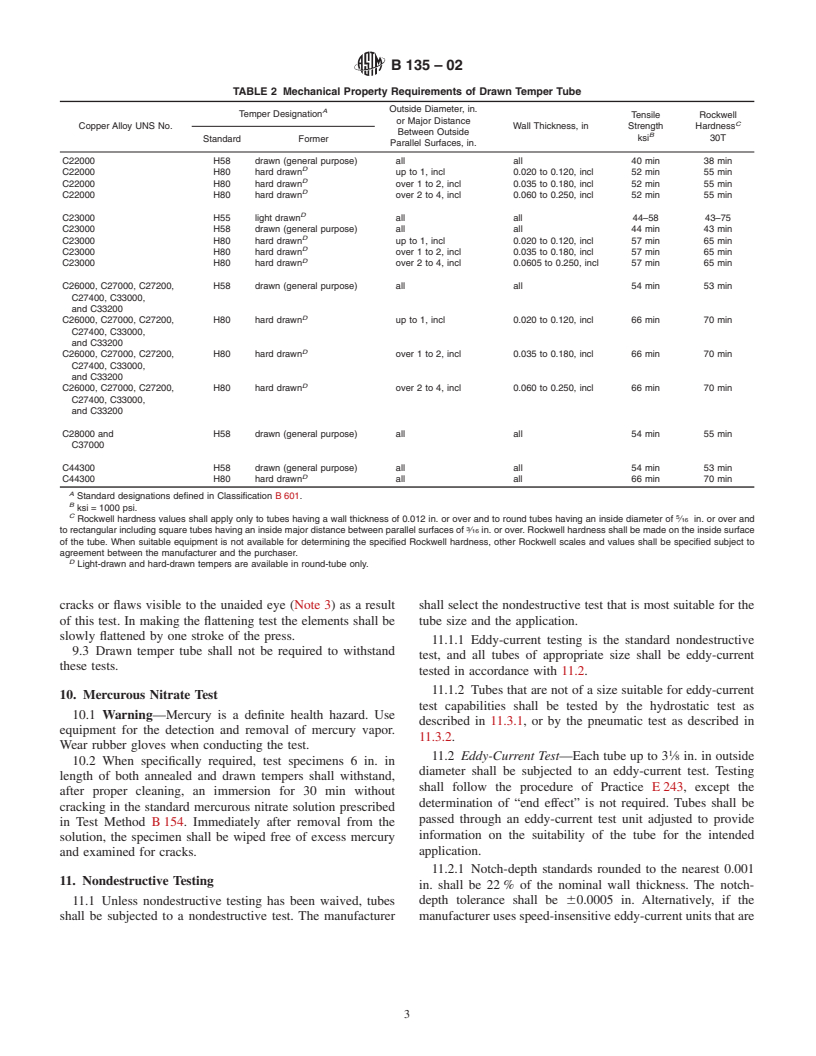

NOTE 2—Tube of Copper Alloy UNS No. C23000, when specified to

6. Chemical Composition

meettherequirementsofthe ASME Boiler and Pressure Vessel Code,shall

6.1 Thematerialshallconformtothechemicalrequirements

have in the annealed condition a minimum tensile strength of 40 ksi and

specified in Table 1.

a minimum yield strength of 12 ksi at 0.5 % extension under load, in

6.2 These specification limits do not preclude the presence

which case the provisions for grain size and Rockwell hardness in 8.2 do

of ot

...

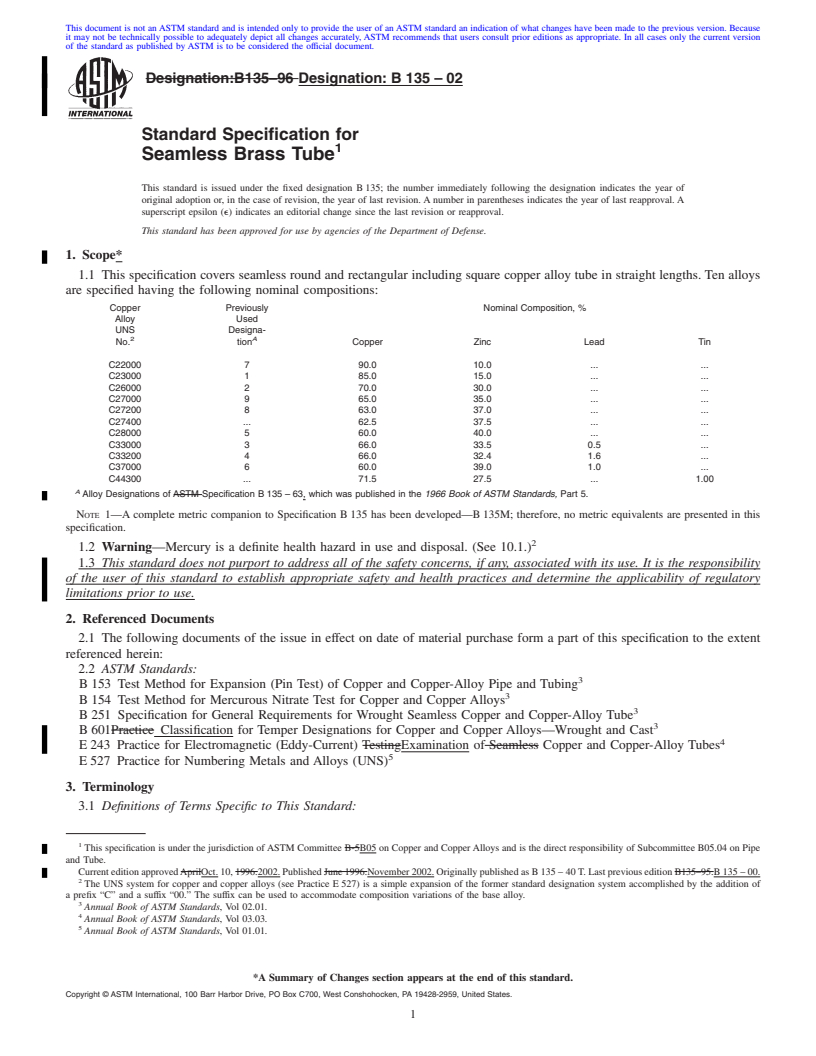

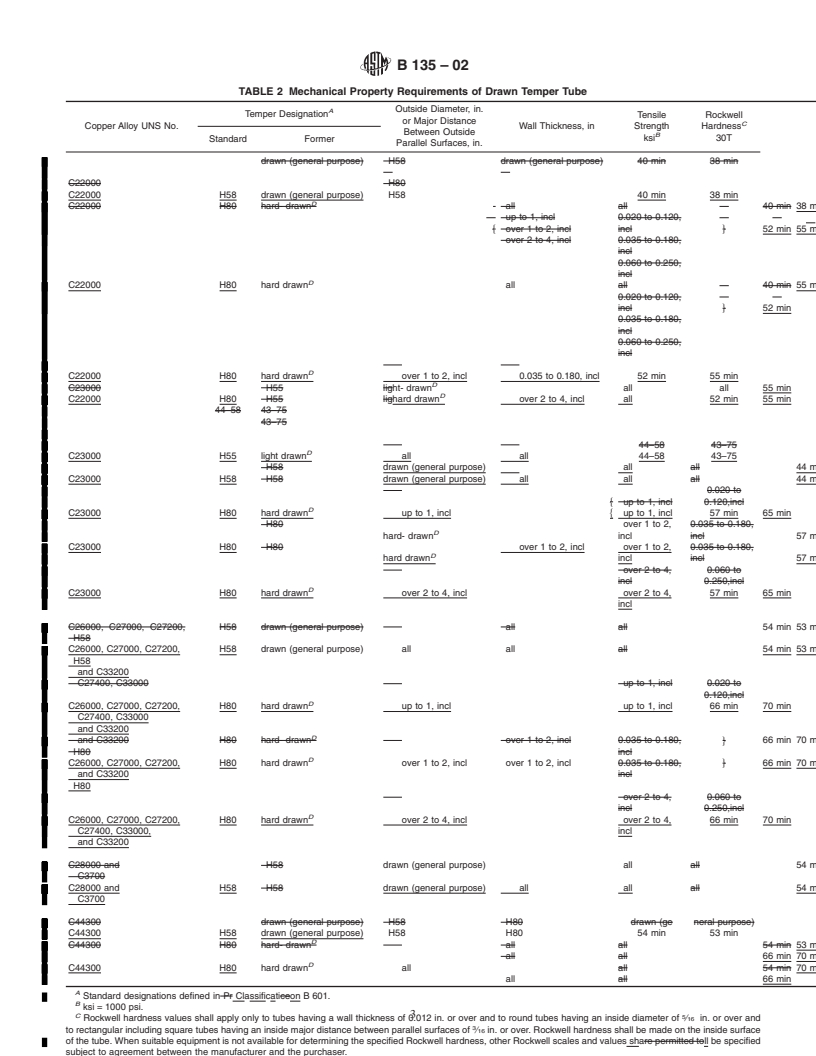

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B135–96 Designation: B 135 – 02

Standard Specification for

1

Seamless Brass Tube

This standard is issued under the fixed designation B 135; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers seamless round and rectangular including square copper alloy tube in straight lengths. Ten alloys

are specified having the following nominal compositions:

Copper Previously Nominal Composition, %

Alloy Used

UNS Designa-

2 A

No. tion Copper Zinc Lead Tin

C22000 7 90.0 10.0 . .

C23000 1 85.0 15.0 . .

C26000 2 70.0 30.0 . .

C27000 9 65.0 35.0 . .

C27200 8 63.0 37.0 . .

C27400 . 62.5 37.5 . .

C28000 5 60.0 40.0 . .

C33000 3 66.0 33.5 0.5 .

C33200 4 66.0 32.4 1.6 .

C37000 6 60.0 39.0 1.0 .

C44300 . 71.5 27.5 . 1.00

A

Alloy Designations of ASTM Specification B 135 – 63, which was published in the 1966 Book of ASTM Standards, Part 5.

NOTE 1—A complete metric companion to Specification B 135 has been developed—B 135M; therefore, no metric equivalents are presented in this

specification.

2

1.2 Warning—Mercury is a definite health hazard in use and disposal. (See 10.1.)

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

2.2 ASTM Standards:

3

B 153 Test Method for Expansion (Pin Test) of Copper and Copper-Alloy Pipe and Tubing

3

B 154 Test Method for Mercurous Nitrate Test for Copper and Copper Alloys

3

B 251 Specification for General Requirements for Wrought Seamless Copper and Copper-Alloy Tube

3

B 601Practice Classification for Temper Designations for Copper and Copper Alloys—Wrought and Cast

4

E 243 Practice for Electromagnetic (Eddy-Current) TestingExamination of Seamless Copper and Copper-Alloy Tubes

5

E 527 Practice for Numbering Metals and Alloys (UNS)

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

1

This specification is under the jurisdiction ofASTM Committee B-5B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

and Tube.

CurrenteditionapprovedAprilOct.10,1996.2002.PublishedJune1996.November2002.OriginallypublishedasB 135 – 40 T.LastpreviouseditionB135–95.B 135 – 00.

2

The UNS system for copper and copper alloys (see Practice E 527) is a simple expansion of the former standard designation system accomplished by the addition of

a prefix “C” and a suffix “00.” The suffix can be used to accommodate composition variations of the base alloy.

3

Annual Book of ASTM Standards, Vol 02.01.

4

Annual Book of ASTM Standards, Vol 03.03.

5

Annual Book of ASTM Standards, Vol 01.01.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B135–02

3.1.1 capable of—as used in this specification, the —the test need not be performed by the producer of the material. However,

shouldif subsequent testing by the purchaser establishes that the material does not meet these requirements, the material shall be

subject to revision. rejection.

4. Ordering Information

4.1 Orders for material under the specification shall include the following information:

4.1.1 Alloy (Section 1),

4.1.2 Temper (Section 7),

4.1.3 Whether tension tests are required (for drawn tempers only (see 8.1)),

4.1.4 Dimensions: diameter or distance between parallel surfaces and wall thickness (see 11.2 and 11.3),

4.1.5Length (see section 11.4),

4.1.5 Length (see 12.4),

4.1.6 Mercurous nitrate test, if required (Section 10),

4.1.7 Total length of each size,

4.1.8 Hydrostatic pressure test, when specified, and

4.1.9 Pneumatic test, when specified.

5. General Requirements

5.1 Material furnished under this specification shall conform to the applicable requirements of the current edition of

Specification B 251.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.