ASTM D2525-90(2001)

(Practice)Standard Practice for Sampling Wool for Moisture

Standard Practice for Sampling Wool for Moisture

SIGNIFICANCE AND USE

This recommended practice furnishes directions for the sampling of wool of the various forms indicated in Section 1, in order that correct probability statements may be made about the relationship between the sample mean and the population mean. If these statements are to be correct, certain conditions, which are stated, must hold.

This recommended practice requires that a deliberate act of randomization be performed so that all potential sampling units have approximately the same chance of being taken and no sampling unit is deprived of its chance of being taken.

In any case where insufficient information about the variability of the sampling units within the lot is available, directions are given for calculating confidence limits for the sample mean so that a correct probability statement can still be made.

SCOPE

1.1 This practice covers the design of a sampling plan to be used to obtain samples for the determination of the moisture content of grease wool, scoured wool, carded wool, garnetted wool, wool top and intermediate products, and rovings.

1.2 Directions are given for the designation of sampling units, calculation of the number of sampling units required to achieve a preselected precision and confidence level or, alternatively, for calculating the confidence limits for the mean based on the variability of the sample tested.

Note 1--This practice for devising a sampling plan is intended for use in connection with Test Method D1576 or Test Method D2462. The sampling of raw wool for the determination of clean wool fiber present is covered in Practice D1060.

1.3 This standard does not purport to address the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2525–90(Reapproved 2001)

Standard Practice for

Sampling Wool for Moisture

This standard is issued under the fixed designation D2525; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 laboratory sample, n—a portion of material taken to

represent the lot sample, or the original material, and used in

1.1 This practice covers the design of a sampling plan to be

the laboratory as a source of test specimens.

used to obtain samples for the determination of the moisture

3.1.2 lot, n—in acceptance sampling,thatpartofaconsign-

content of grease wool, scoured wool, carded wool, garnetted

ment or shipment consisting of material from one production

wool, wool top and intermediate products, and rovings.

lot.

1.2 Directions are given for the designation of sampling

3.1.3 lot sample, n—one or more shipping units taken at

units, calculation of the number of sampling units required to

random to represent an acceptance sampling lot and used as a

achieve a preselected precision and confidence level or, alter-

source of laboratory samples.

natively, for calculating the confidence limits for the mean

3.1.4 sample, n—(1) a portion of a lot of material which is

based on the variability of the sample tested.

taken for testing or record purposes.

NOTE 1—This practice for devising a sampling plan is intended for use

(2) the group of specimens used, or observations made,

in connection with Test Method D1576 or Test Method D2462. The

which provide information that can be used for making

sampling of raw wool for the determination of clean wool fiber present is

statistical inferences about the population from which they

covered in Practice D1060.

were drawn.

1.3 This standard does not purport to address all of the

3.1.5 sampling unit, n—in wool,aportionofmaterialthatis

safety concerns, if any, associated with its use. It is the

taken at one time from one physical location and that is

responsibility of the user of this standard to establish appro-

combined with similar portions to make up the laboratory

priate safety and health practices and determine the applica-

sample.

bility of regulatory limitations prior to use.

3.1.5.1 Discussion—A sampling unit may or may not have

the same physical size as a specimen. Examples of sampling

2. Referenced Documents

units include: (1) for bulk materials seen as scoured wool, a

2.1 ASTM Standards:

handful of wool conforming to a stated mass range, (2) for

D123 Terminology Relating to Textiles

cored material, a minimum mass of material collected by one

D1060 Practice for Core Sampling of Raw Wool in Pack-

insertion of a coring tool, (3) for sliver, a stated length of

ages for Determination of Percentage of CleanWool Fiber

material, and (4) a single package, such as a ball of top.

Present

3.1.6 specimen, n—a specific portion of a material or a

D1576 TestMethodforMoistureinWoolbyOven-Drying

laboratory sample upon which a test is performed or which is

D2462 Test Method for Moisture in Wool by Distillation

selected for that purpose.

with Toluene

3.1.7 Fordefinitionsofmoisture,moisturecontent,moisture

E122 Practice for Calculating Sample Size to Estimate,

regain, and other textile terms used in this practice, refer to

With a Specified Tolerable Error, the Average for a

Terminology D123.

Characteristic of a Lot or Process

4. Summary of Practice

3. Terminology

4.1 Directions are given for subdividing a lot of material

3.1 Definitions:

into potential sampling units and for providing each potential

sampling unit with its own unique identification.

4.2 Directions are given for calculating the number of such

ThispracticeisunderthejurisdictionoftheASTMCommitteeD13onTextiles,

and is the direct responsibility of Subcommittee D13.13 on Wool and Wool Felt.

sampling units required to give a preselected allowable varia-

Current edition approved Jan. 26, 1990. Published May 1990. Originally

tion at a stated probability level, or for calculating confidence

published as D2525–66T. Last previous edition D2525–76 (1983).

limitsforthesamplemeanobtainedforagivensizeofsample.

Annual Book of ASTM Standards, Vol 07.01.

Annual Book of ASTM Standards, Vol 14.02.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

D2525

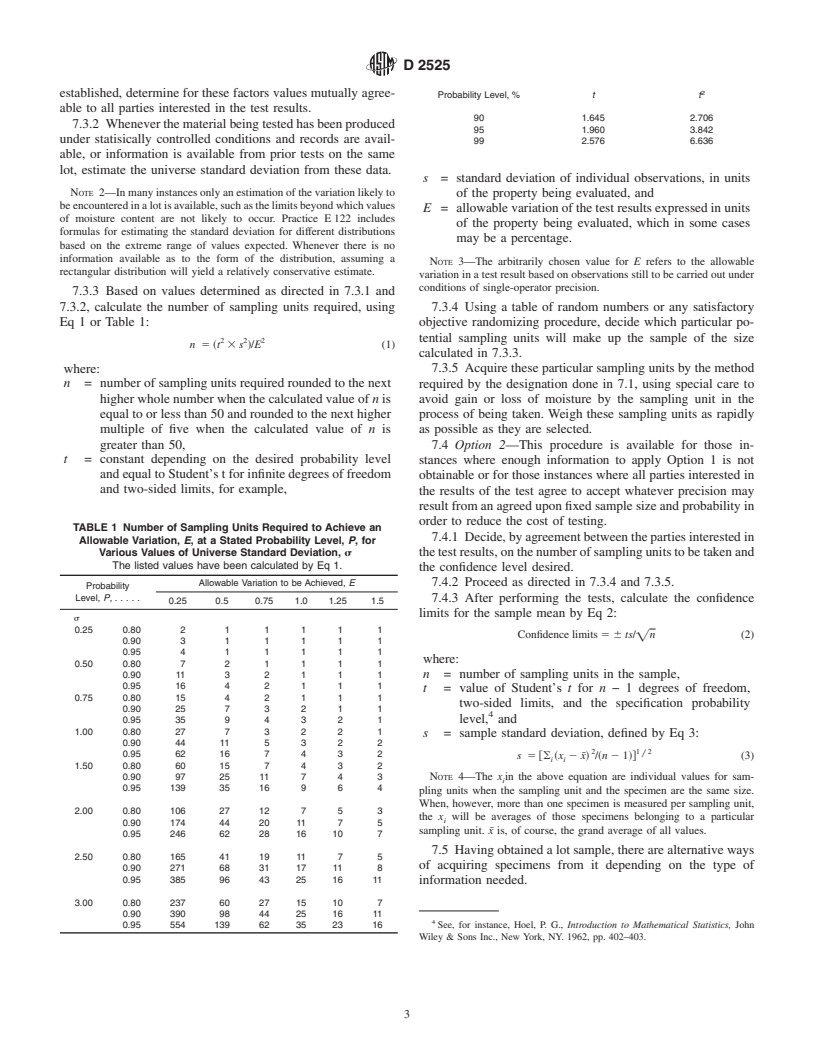

4.3 Directions are given for deciding which particular sam- the information in the sample results. In this case, the only

pling units should be chosen to constitute the required lot condition that applies is 6.1.3.

sample. These directions ensure that all potential sampling

7. Procedure

unitshaveapproximatelythesamechanceofbeingselectedfor

7.1 Designate the form and size of the sampling unit,

the lot sample.

bearing in mind the conditions and precautions discussed in

Sections 5 and 6. Whenever possible, make the size of the

5. Significance and Use

sampling unit and specimen the same.

5.1 This recommended practice furnishes directions for the

7.1.1 The designation of the sampling unit depends on the

sampling of wool of the various forms indicated in Section 1,

form of the material and on the method to be used for making

in order that correct probability statements may be made about

measurements on the sample. The material to be sampled may

the relationship between the sample mean and the population

existinoneofthreebasicforms:bulkmaterialsuchasscoured

mean. If these statements are to be correct, certain conditions,

wool or picked blends of wools, packaged material such as

which are stated, must hold.

baled wool, or material put up in the form of packages within

5.2 Thisrecommendedpracticerequiresthatadeliberateact

packagessuchasballsoftopwithincasesorbales.Themethod

of randomization be performed so that all potential sampling

of measurement may require a specimen as large as a whole

units have approximately the same chance of being taken and

package of material, or as small as a few grams of material.

no sampling unit is deprived of its chance of being taken.

7.1.2 Where the material to be sampled exists in some bulk

5.3 In any case where insufficient information about the

form,suchasscouredwool,orablendthathasbeenpickedand

variability of the sampling units within the lot is available,

stored in a bin, the designation of a sampling unit will depend

directions are given for calculating confidence limits for the

uponthemechanicsofdrawingthesample.Ifhandsamplingis

samplemeansothatacorrectprobabilitystatementcanstillbe

the method employed, the sampling unit will be a handful of a

made.

certain specified size. Whenever possible, the size of a sam-

pling unit should be made to coincide with the size of the

6. Preliminary Conditions

specimen required by the method of measurement because the

6.1 If it is desired to calculate a sample size to achieve a

random variations observed in the test results are then directly

preselected precision at a preselected level of confidence,

applicable to the sampling units.

knowledge of the variation of the moisture content is neces-

7.1.3 When the material to be sampled exists in the form of

sary.

packages such as baled wool or packages within packages,

6.1.1 The test method to be used must be the same method

such as balls of wool top in cases or bales, the sampling unit

that was used to derive any prior information with respect to

can be either an entire package or some portion of a package,

the variability of the moisture content.

depending upon the size of the specimen required.

6.1.2 The sampling unit must be the fundamental unit in

7.2 Identify each potential sampling unit in the lot by

termsofwhichthevarianceisexpressed.Inotherwords,ifthe

numbering, coding, using geometrical coordinates, or by any

sampling unit is chosen to be a 25-g handful of bulk material

other systematic means. It is important that by some means or

ora4-yd(3.65-m)lengthofsliver,thenthevarianceusedmust

other, all potential sampling units must be furnished with their

be the number that expresses the variability of these units, and

ownuniqueidentificationsothatnoneisdeprivedofitschance

the number of sampling units which is calculated will be the

of being sampled.

number of such units required. The sampling unit is not

7.2.1 In designing a sampling plan, it is necessary to devise

necessarily the same thing as a specimen.

a method for assigning to every potential sampling unit in the

6.1.3 The lot designated for sampling must be statistically

lot a unique identification. This is a relatively simple task in

homogeneous.Thisisequivalenttosayingthatthelotshallnot

thoseinstanceswherethesamplingunitsarediscretepackages,

be composed of a mixture of two or more parts, the moisture

such as might be the case with balls of top if an entire ball is

contentofwhichisdistributedsufficientlydifferentlythatifthe

to be the sampling unit.

moisture content of the entire lot were measured, a plot of the

7.2.2 With material in bulk form or with packaged material

moisture content versus the number of sampling units would

in which the sampling unit is to be only a portion of the

show a curve having more than one peak. (SeeAppendix X1.) package, it is not as easy to identify uniquely each potential

IfthetestgiveninAppendixX1leadstotheconclusionthatthe

sampling unit, and some method of approximating the ideal

lot cannot be considered to be statistically homogeneous, then situation must be devised. See, for example, the instructions

itshouldbesubdividedintogroupsthatarehomogeneous.The

given in Practice D1060.

pattern of runs found may indicate what the subgroups should 7.2.3 For materials in loose bulk form, considerable inge-

be.

nuity and imagination may be required to effect a proper

6.1.4 The magnitude of the variation of moisture content identification of the potential sampling units.

within the homogeneous lot must be known.The magnitude of

7.3 Option 1—This procedure is available for those in-

the variation is usually expressed as the standard deviation, stanceswhereinformationissufficienttoenablethecalculation

although the range may also be used.

of sample size required for a specified allowable variation and

6.2 If insufficient knowledge is available to ensure meeting probability level.

the above conditions, a sample of convenient size may be 7.3.1 If the allowable variation and probability level are not

selected and confidence limits calculated for the mean using stated in the applicable material specification or otherwise

D2525

established, determine for these factors values mutually agree-

Probability Level,% tt

able to all parties interested in the test results.

90 1.645 2.706

7.3.2 Wheneverthematerialbeingtestedhasbeenproduced

95 1.960 3.842

under statisically controlled conditions a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.