ASTM E601-81(1997)

(Test Method)Standard Test Method for Comparing EMF Stability of Single-Element Base-Metal Thermocouple Materials in Air (Withdrawn 2006)

Standard Test Method for Comparing EMF Stability of Single-Element Base-Metal Thermocouple Materials in Air (Withdrawn 2006)

SCOPE

1.1 This test method provides comparison of emf stability of single-element base-metal thermocouple materials in air referenced to platinum at specified constant elevated temperatures.

1.2 Since the useful life of a thermocouple depends on the stability of the emf generated at given temperatures for a required time period, the method includes emf drift measurements with time. The emf is measured against platinum, which may be the platinum leg of the platinum-rhodium/platinum reference thermocouple used to indicate the temperature at the time of taking the emf readings, or an additional platinum reference.

1.3 The total life is included as added information, if required.

Note 1-Some thermoelements may show insignificant emf drift while undergoing relatively rapid oxidation. In these cases, failure of the thermoelement may be indicated only by open circuit.

Note 2-See ASTM STP 470B for recommended upper temperature limits in air.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method provides comparison of emf stability of single-element base-metal thermocouple materials in air referenced to platinum at specified constant elevated temperatures.

Formerly under the jurisdiction of Committee E20 on Temperature Measurement, this test method was withdrawn in January 2006 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E601–81 (Reapproved 1997)

Standard Test Method for

Comparing EMF Stability of Single-Element

Base-Metal Thermocouple Materials in Air

This standard is issued under the fixed designation E601; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Significance and Use

1.1 Thistestmethodprovidescomparisonofemfstabilityof 3.1 This test is useful in comparing various alloy thermo-

single-element base-metal thermocouple materials in air refer- elements under the same conditions.

enced to platinum at specified constant elevated temperatures. 3.2 The relative stability determined by this method is valid

1.2 Since the useful life of a thermocouple depends on the onlyunderthespecifictestconditionsandwouldbeaffectedby

stability of the emf generated at given temperatures for a changes in the following conditions: (1) temperature gradient;

required time period, the method includes emf drift measure- (2)abundance,velocity,andcompositionoftheairsurrounding

ments with time.The emf is measured against platinum, which the test pieces; (3) relative inhomogeneity of test thermoele-

may be the platinum leg of the platinum-rhodium/platinum ments; (4) the relative purity of the platinum.

reference thermocouple used to indicate the temperature at the 3.3 Thistestmethodinitspresentformdoesnotincludethe

time of taking the emf readings, or an additional platinum determination of stability following changes in the operating

reference. temperature.

1.3 The total life is included as added information, if 3.4 The reliability of this test method depends on the emf

required. stability of the platinum reference element. For testing the

relative emf stability of base-metal thermoelements, it is

NOTE 1—Somethermoelementsmayshowinsignificantemfdriftwhile

suggested that a reference element of 99.96% platinum, or

undergoing relatively rapid oxidation. In these cases, failure of the

greater, is sufficiently stable to determine a relative significant

thermoelement may be indicated only by open circuit.

change in emf of base-metal thermoelements.

NOTE 2—See ASTM STP470B for recommended upper temperature

limits in air.

3.5 If there is concern that a change in the platinum

reference element may have occurred during this test, the

1.4 This standard does not purport to address all of the

procedure described in the appendix may be used to determine

safety concerns, is any, associated with its use. It is the

such a change.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Terminology

bility of regulatory limitations prior to use.

4.1 Definitions—The definitions given in Terminology

2. Referenced Documents E344 shall apply to this test method.

4.2 Definitions of Terms Specific to This Standard:

2.1 ASTM Standards:

4.2.1 emf stability—the change in emf output expressed in

E230 Specification and Temperature Electromotive Force

millivolts (or in equivalent degrees), over a period of time.

(EMF) Tables for Standardized Thermocouples

4.2.2 total life—the time required for open circuit to occur

E344 Terminology Relating to Thermometry and Hydrom-

in the test thermoelement.

etry

5. Test Specimen

5.1 The test specimen shall be at least 0.8 m (30 in.) long

This test method is under the jurisdiction of ASTM Committee E-20 on

and free of kinks or other defects due to mechanical working.

Temperature Measurement and is the direct responsibility of Subcommittee E20.04

on Thermocouples.

6. Reference Junction

Current edition approved Nov. 27, 1981. Published January 1982. Originally

published as E 601 – 77. Discontinued February 1996 and reinstated as

6.1 The reference junction ends of the test specimens,

E601–81(1997).

platinum reference element, if used, and of the platinum-

Available from ASTM Headquarters, 100 Barr Harbor Drive, West Consho-

rhodium/platinum reference thermocouple must be maintained

hocken, PA 19428.

Annual Book of ASTM Standards, Vol 14.03. at a known constant temperature during the periods of taking

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

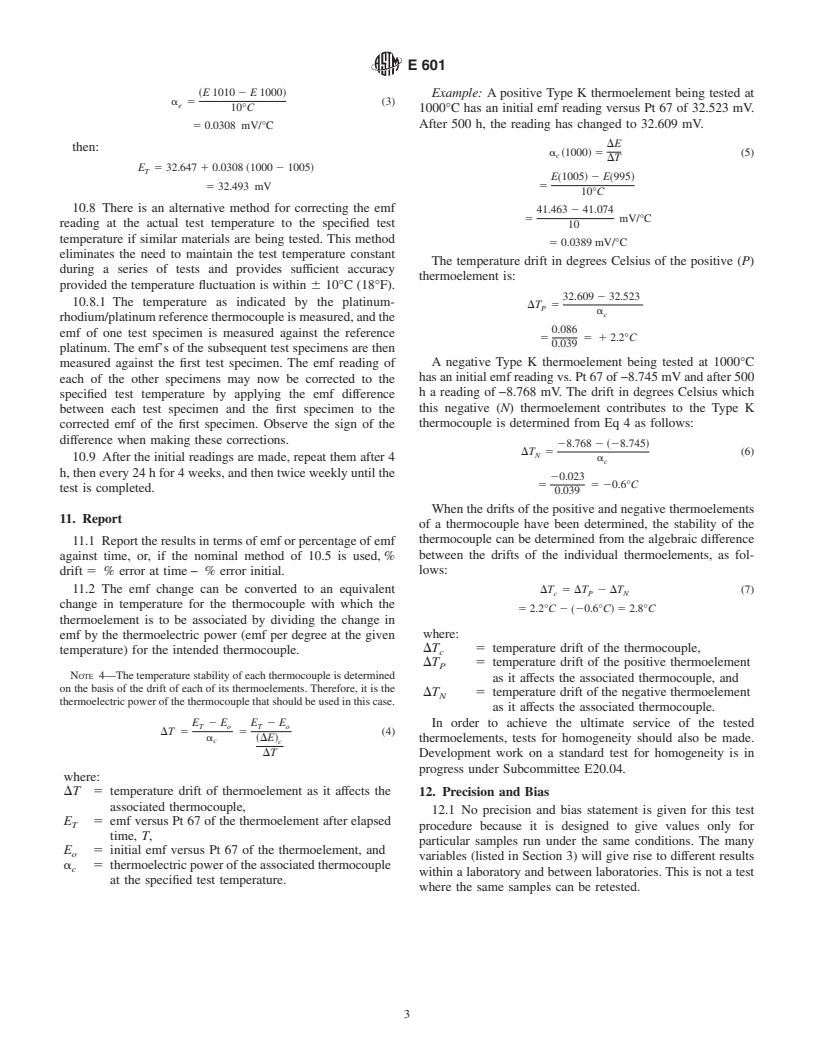

E601

emf readings. Ice point reference junction baths provide a ture as indicated by the emf of the platinum-rhodium/platinum

relatively simple and reliable means for maintaining the reference thermocouple. Measure and record the emf between

reference junction at 0°C (32°F) when proper precautions are theplatinumreferencelegandeachofthetestspecimenswhile

exercised in their use. maintaining the test temperature.

10.5 Thermoelectricinstabilitymaybereportedonthebasis

7. Measuring Junction

of the nominal test temperature 6 10°C (6 18°F) or on the

7.1 The measuring junction shall consist of a union of the

basis of an exact specified temperature.

test specimens and platinum reference.The platinum reference

10.6 If the nominal method is used, compute the true

may be the platinum leg of the platinum-rhodium/

temperature (T ) from the measured emf of the platinum-

s

platinum temperature reference thermocouple.

rhodium/platinum reference thermocouple, applying only cali-

bration corrections. Determine the emf expected (E) for the

t

8. Test Temperature Medium

test combination at that temperature (T ) from the single-leg

s

8.1 The test shall be conducted in a uniformly heated

tables in Tables E230. Using these values, calculate the

furnaceprovidinganisothermalworkzonesufficientlylargeto

percentage of error by the equation:

maintain all junctions at the same temperature. The zone shall

E – E

m t

be probed to determine if it meets this requirement. The

%error 5 3100 (1)

E

t

temperatureofthefurnaceshallbecontrolledtowithin 610°C

(618°F) of the test temperature.

where:

E 5 measured emf, and

m

9. Electromotive Force Indicator

E 5 table emf for the true temperatures of test.

t

9.1 An instrument that has limits of error of not more than 10.7 If the exact method is used, proceed as follows: since

1 µV at 1000 µV and 12 µV at 50 000 µV shall be used as the

the test temperature may depart 6 10°C (618°F) from the

means for determining emf in this test. specified test temperature, the measured temperature and emf

at the time of reading must be corrected to the specified test

10. Procedures

temperature using the thermoelectric power of the test thermo-

element versus Pt 67. For standard thermoelements, the ther-

10.1 The union shall be prepared by welding, using a

procedure proven by experience or by testing to reliably moelectric power (a ) may be obtained from the thermoele-

e

ment temperature—emf tables in Specification E230. Using

produce mechanically and thermoelectrically stable junctions.

The number of test specimens joined to the platinum reference these or other established tables, the emf deviation from the

emf at the specified test temperature can be determined and

may be as many as the volume of the testing medium permits

providedthattheirthermalconductiondoesnotimpairisother- used as the correction. For thermoelements not covered by

mal conditions. these or other established tables, the thermoelectric power,a ,

e

10.2 Weld a platinum-rhodium/platinum reference thermo- may be determined by taking emf readings 10°C (18°F) below

couple to the test specimen to form a sound junction assembly. and at the test temperature, dividing the emf difference by the

An additional platinum wire may be welded to this junction if temperature difference. Given the thermoelectric power, the

two measuring instruments are used for the simultaneous emf of a thermoelement versus platinum may be corrected

reading of temperature (platinum-rhodium/ platinum thermo- from the actual test temperature to the specified test tempera-

ture by the use of the following equation:

couple) a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.