ASTM A511-04

(Specification)Standard Specification for Seamless Stainless Steel Mechanical Tubing

Standard Specification for Seamless Stainless Steel Mechanical Tubing

SCOPE

1.1 This specification covers seamless stainless tubing for use in mechanical applications where corrosion-resistant or high-temperature strength is needed. The grades covered are listed in Tables 1 and 2.

1.2 This specification covers seamless cold-finished mechanical tubing and seamless hot-finished mechanical tubing in sizes up to 12 3/4 in. (313.8 mm) in outside diameter (for round tubing) with wall thicknesses as required.

1.3 Tubes shall be furnished in one of the following shapes, as specified by the purchaser: round, square, rectangular, or special.

1.4 Optional supplementary requirements are provided and when desired, shall be stated in the order.

1.5 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

Designation: A 511 – 04

Standard Specification for

1

Seamless Stainless Steel Mechanical Tubing

This standard is issued under the fixed designation A 511; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* MIL-STD-163 Steel Mill Products Preparation for Ship-

3

ment and Storage

1.1 This specification covers seamless stainless tubing for

2.3 Federal Standard:

use in mechanical applications where corrosion-resistant or

3

Fed. Std. No. 123 Marking for Shipments (CivilAgencies)

high-temperature strength is needed. The grades covered are

listed in Table 1 and Table 2.

3. Ordering Information

1.2 This specification covers seamless cold-finished me-

3.1 Orders for material under this specification should

chanicaltubingandseamlesshot-finishedmechanicaltubingin

include the following as required to describe the desired

3

sizes up to 12 ⁄4 in. (313.8 mm) in outside diameter (for round

material adequately:

tubing) with wall thicknesses as required.

3.1.1 Quantity (feet, mass, or number of pieces),

1.3 Tubes shall be furnished in one of the following shapes,

3.1.2 Name of material (seamless stainless steel mechanical

as specified by the purchaser: round, square, rectangular, or

tubing),

special.

3.1.3 Form (round, square, rectangular, special, see Section

1.4 Optional supplementary requirements are provided and

1),

when desired, shall be stated in the order.

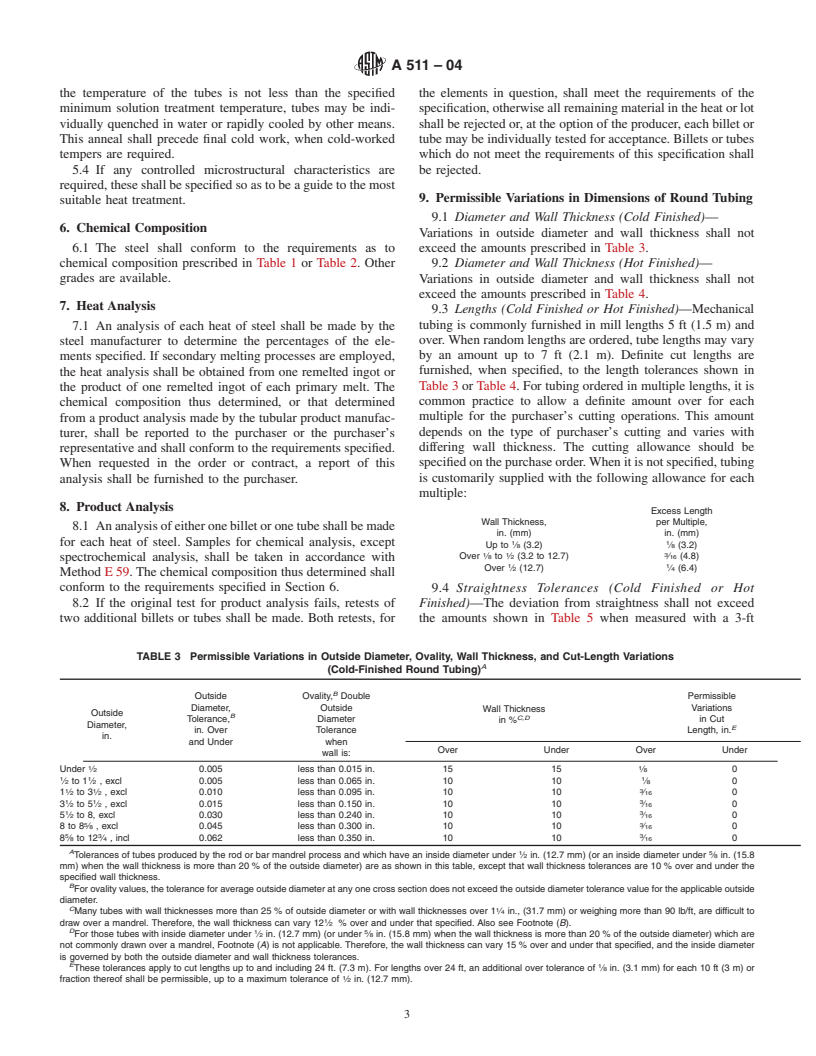

3.1.4 Dimensions (round, outside diameter and wall thick-

1.5 The values stated in inch-pound units are to be regarded

ness, see Section 9; square and rectangular, outside dimensions

as the standard.

and wall thickness, see Section 10; other, specify),

2. Referenced Documents 3.1.5 Length (specific or random, see 9.3),

2

3.1.6 Manufacture (cold- or hot-finished, see 4.5),

2.1 ASTM Standards:

3.1.7 Grade (Section 6),

A 370 Test Methods and Definitions for MechanicalTesting

3.1.8 Condition (annealed, as cold worked, or with special

of Steel Products

heat treatment, controlled microstructural characteristics, or

A 1016/A 1016M Specification for General Requirements

other condition as required, see Section 5),

for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stain-

3.1.9 Surface finish (special pickling, shot blasting, or

less Steel Tubes

polishing, as required, see Supplementary Requirement S5),

E59 PracticeforSamplingSteelandIronforDetermination

3.1.10 Specification designation,

of Chemical Composition

3.1.11 Report of ChemicalAnalysis, if required (Sections 7

2.2 Military Standards:

3 and 8),

MIL-STD-129 Marking for Shipment and Storage

3.1.12 Individual supplementary requirements, if required,

3.1.13 End use,

1

3.1.14 Packaging,

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and RelatedAlloys, and is the direct responsibility of Subcommittee

3.1.15 Special marking (see 15.2),

A01.10 on Tubing.

3.1.16 Special packing (see 16.2), and

Current edition approved March 1, 2004. Published April 2004. Originally

3.1.17 Special requirements.

approved in 1964. Last previous edition approved in 1996 as A 511 – 96.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4. Materials and Manufacture

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

4.1 The steel may be made by any process.

the ASTM website.

3

4.2 If a specific type of melting is required by the purchaser,

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. it shall be as stated on the purchase order.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 511–04

TABLE 1 Chemical Requirements of Austenitic Stainless Steels

Composition, %

Phos- Sul- Columbium

Grade

Manga- pho- fur, Silicon, plus

Carbon Nickel Chromium Molybdenum

Titanium Selenium

nese, max rus, max max Tantalum

max

MT 302 0.08 to 0.20 2.00 0.040 0.030 1.00 8.0–10.0 17.0–19.0 . . . .

MT 303Se 0.15 max 2.00 0.040 0.040 1.00 8.0–11.0 17.0–19.0 . . . 0.12–0.2

MT 304 0.08 max 2.00 0.040 0.030 1.00 8.0–11.0 18.0–20.0 . . . .

A

MT 304L 0.035 max 2.00 0.040 0.030 1.00 8.0–13.0 18.0–20.0 . . . .

MT 305 0.12 2.00 0.040 0.030 1.00 10.0–13.0 17.0–19.0 . . . .

MT 309S 0.08 max 2.00 0.040 0.030 1.00 12.0–15.0 22.0–24.0 . . . .

MT 310S 0.08 max 2.00 0.040 0.030 1.00 19.0–22.0 24.0–26.0 . . . .

MT 316 0.08 max 2.00 0.040 0.030 1.00 11.0–14.0 16.0–18.0 2.0–3.0 .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.