ASTM E1160-87(1995)

(Guide)Standard Guide for On-Site Inspection and Verification of Operation of Solar Domestic Hot Water Systems

Standard Guide for On-Site Inspection and Verification of Operation of Solar Domestic Hot Water Systems

SCOPE

1.1 This guide establishes procedures and test methods for conducting an on-site inspection and acceptance test of an installed domestic hot water system (DHW) using flat plate, concentrating-type collectors or tank absorber systems.

1.2 It is intended as a simple and economical acceptance test to be performed by the system installer or an independent tester to verify that critical components of the system are functioning and to acquire baseline data reflecting overall short term system heat output.

1.3 This guide is not intended to generate accurate measurements of system performance (see ASHRAE standard 95-1981 for a laboratory test) or thermal efficiency.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1160 – 87 (Reapproved 1995) An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Guide for

On-Site Inspection and Verification of Operation of Solar

Domestic Hot Water Systems

This standard is issued under the fixed designation E 1160; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 76-1137 Thermal Data Requirements and Performance

Evaluation Procedures for the National Solar Heating and

1.1 This guide covers procedures and test methods for

Cooling Demonstration Program

conducting an on-site inspection and acceptance test of an

installed domestic hot water system (DHW) using flat plate,

3. Summary of Guide

concentrating-type collectors or tank absorber systems.

3.1 This guide recommends inspection procedures and tests

1.2 It is intended as a simple and economical acceptance test

for: general system inspection, collector efficiency, freeze

to be performed by the system installer or an independent tester

protection, and controller and pump/blower operation.

to verify that critical components of the system are functioning

3.1.1 Verification of satisfactory operation of these compo-

and to acquire baseline data reflecting overall short term

nents indicates that the system is functioning. Tests are

system heat output.

designed to take a minimum of time in preparation, testing and

1.3 This guide is not intended to generate accurate measure-

restoration of the system. They may use relatively inexpensive,

ments of system performance (see ASHRAE standard 95-1981

nonintrusive instrumentation which system installers can rea-

for a laboratory test) or thermal efficiency.

sonably be expected to have on hand.

1.4 The values stated in SI units are to be regarded as the

3.2 Recommended tests for each component or subsystem

standard. The values given in parentheses are for information

fall into categories according to the level of complexity and

only.

cost (Note 1).

1.5 This standard does not purport to address all of the

3.2.1 Category A—The most rudimentary tests, such as

safety concerns, if any, associated with its use. It is the

visual inspection.

responsibility of the user of this standard to establish appro-

3.2.2 Category B—Tests that require minimal instrumenta-

priate safety and health practices and determine the applica-

tion and skill.

bility of regulatory limitations prior to use.

3.2.3 Category C—Tests that require most expensive or

2. Referenced Documents sophisticated instrumentation or more time to perform.

2.1 ASTM Standards:

NOTE 1—Category B tests should include Category A tests as prereq-

E 772 Terminology Relating to Solar Energy Conversion

uisite, etc.

E 823 Practice for Nonoperational Exposure and Inspection

3.2.4 Selection of the appropriate test is at the discretion of

of a Solar Collector

the tester and purchaser, who should be aware of the tradeoffs

E 904 Practice for Generating All-Day Thermal Perfor-

between cost and accuracy at each level of testing. The tester

mance Data for Solar Collectors

should make these clearly known to the purchaser of the

E 1056 Practice for Installation and Service of Solar Do-

system who may wish to assume the costs of more sophisti-

mestic Water Heating Systems for One- and Two-Family

cated testing (Note 2). Preferably there should be a part of the

Dwellings

installation contract between the tester and purchaser spelling

2.2 ASHRAE Standards:

out test specifics (for example, Category A, B or C for each

93-1986 (ANSI B198.1-1977) Method of Testing to Deter-

subtest).

mine the Thermal Performance of Solar Collectors

NOTE 2—Consult your local National Balancing Bureau or Associated

95-1981 Method of Testing to Determine the Thermal

3 Air Balance Council.

Performance of Domestic Water Heating System

2.3 NIST Standard: 3.3 Instrumentation includes sensors to monitor some or all

of the following conditions:

3.3.1 Total incident solar radiation (in the plane of the

This guide is under the jurisdiction of ASTM Committee E-44 on Solar,

collector array),

Geothermal, and Other Alternative Energy Sources and is the direct responsibility of

Subcommittee E44.05 on Solar Heating and Cooling Subsystems and Systems.

Current edition approved June 8, 1987. Published August 1987.

2 4

Annual Book of ASTM Standards, Vol 12.02. Available from National Institute of Standards and Technology, Gaithersburg,

Available from ASHRAE, 1791 Tullie Circle, N.E., Altanta, GA 30329. MD 20899.

E 1160

3.3.2 Outdoor ambient temperature, not be used to compare different systems or installations.

3.3.3 Internal building temperature near storage system, 4.6 Test is for a newly installed system and also for periodic

3.3.4 Collector loop flow rate and temperatures, and checking.

3.3.5 Storage temperature.

5. Procedures

3.3.6 Each system should be instrumented to the practical

5.1 Preparation:

level required for calculation (see NIST standard 76-1137 for

5.1.1 Install and operate components and controls in accor-

another method to instrument and evaluate solar systems).

dance with manufacturer’s instructions.

Some sites may need additional instrumentation as a result of

5.1.2 Use temporary portable instrumentation or any perma-

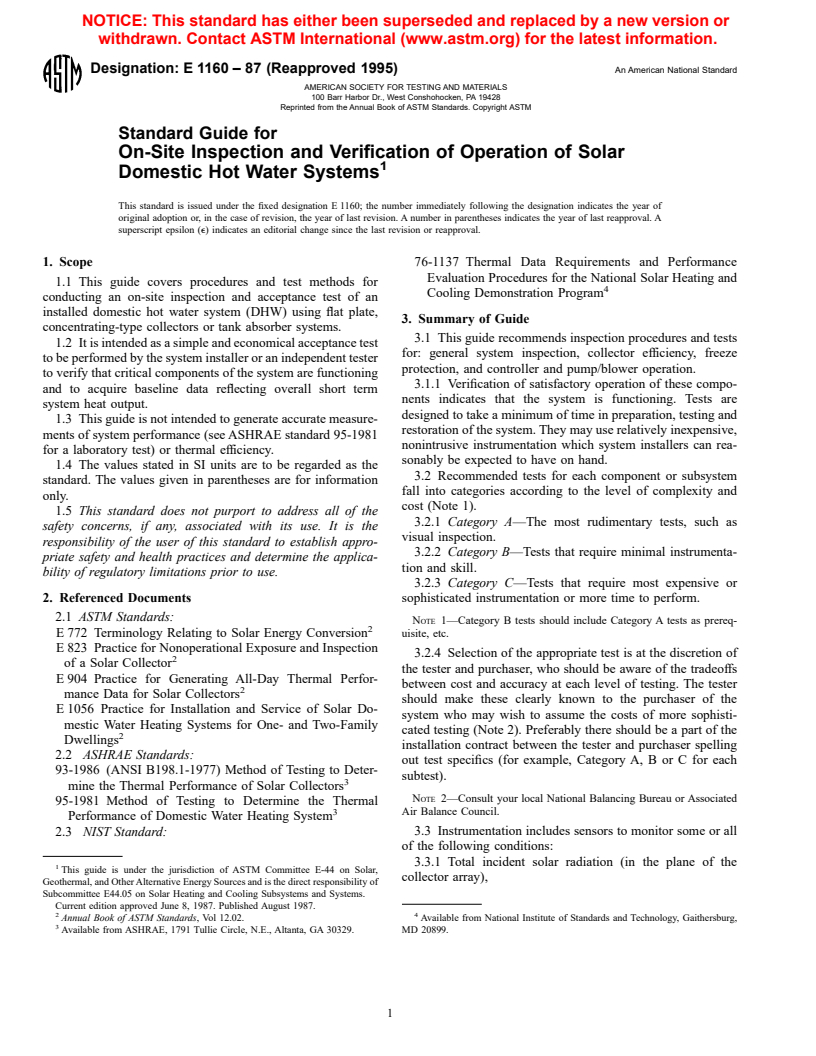

their unique requirements. Fig. 1 shows a typical closed loop

nent instruments installed for continuous monitoring to evalu-

system with the instrumentation required for the various tests.

ate system performance as long as accuracy is 62 % of full

3.4 The various types of available instrumentation are listed

scale and reproducibility is $5 % and instrumentation is

in Tables 1-4. Approximate cost ranges, accuracy and applica-

installed properly in accordance with manufacturer’s instruc-

tion information are given. Most of the necessary instruments

tion.

are presently used in conventional heating and air conditioning

5.1.3 Operate the system in a normal and satisfactory

work except the pyranometer or solar radiation flux-measuring

manner for several days before the on-site performance test.

instruments.

Operate the entire system at a nearly steady-state condition for

4. Significance and Use

at least a 2-h period before testing. Conduct tests for collector

4.1 This guide is intended for on-site assessment of in- effectiveness under clear, sunny conditions.

service operation by short term measurement of appropriate 5.2 General Inspection:

system functions under representative operating conditions. 5.2.1 The ability to perform as intended for the specified

4.2 Primary application is for residential systems and period of time defines system durability and reliability. System

medium-size multi-family units or commercial buildings. Use performance depends on the proper operation of each of the

of back-up conventional DHW heating system is assumed to subsystems. The manual containing drawings, specifications,

augment solar heating. and engineering data shall serve as a benchmark for the

4.3 This guide is intended for use by suppliers, installers, inspection.

consultants and homeowners in evaluating on-site operation of 5.2.2 The following components should be inspected for

an installed system. Emphasis is placed on simplified measure- proper installation (see Practice E 1056) and operation to check

ments that do not require special skills, intrusive instrumenta- for any malfunctions, leaks or improper adjustments. See Ref

tion, system modification or interruption of service to the (1) for an Installation Checklist.

purchaser. 5.2.2.1 Collectors and connections,

4.4 The purpose of this guide is to verify that the system is 5.2.2.2 Controls and sensors,

functioning. Copies of all data and reports must be submitted 5.2.2.3 Insulation,

by the testing group to the owner or his or her designated agent. 5.2.2.4 Interconnections—mechanical and electrical,

4.5 Data and reports from these procedures and tests may be 5.2.2.5 Pumps and motors,

used to compare the system performance over time, but should 5.2.2.6 Valves and fittings,

FIG. 1 Closed Loop System—One Tank

E 1160

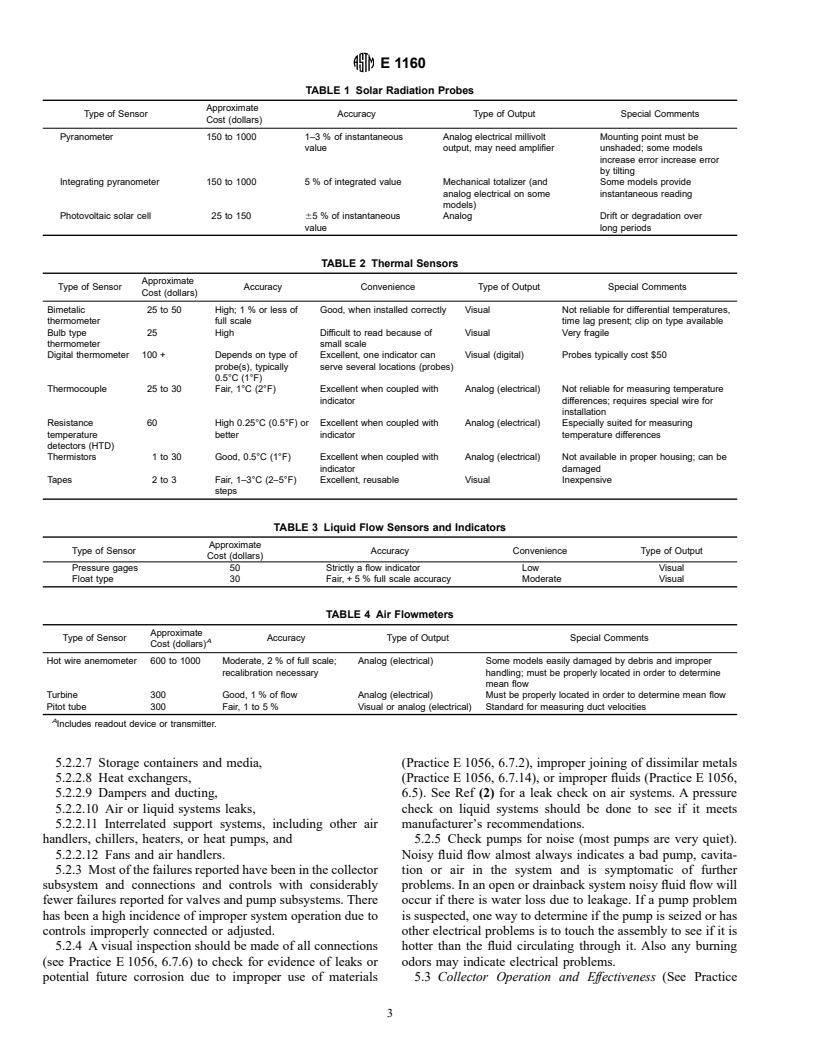

TABLE 1 Solar Radiation Probes

Approximate

Type of Sensor Accuracy Type of Output Special Comments

Cost (dollars)

Pyranometer 150 to 1000 1–3 % of instantaneous Analog electrical millivolt Mounting point must be

value output, may need amplifier unshaded; some models

increase error increase error

by tilting

Integrating pyranometer 150 to 1000 5 % of integrated value Mechanical totalizer (and Some models provide

analog electrical on some instantaneous reading

models)

Photovoltaic solar cell 25 to 150 65 % of instantaneous Analog Drift or degradation over

value long periods

TABLE 2 Thermal Sensors

Approximate

Type of Sensor Accuracy Convenience Type of Output Special Comments

Cost (dollars)

Bimetalic 25 to 50 High; 1 % or less of Good, when installed correctly Visual Not reliable for differential temperatures,

thermometer full scale time lag present; clip on type available

Bulb type 25 High Difficult to read because of Visual Very fragile

thermometer small scale

Digital thermometer 100 + Depends on type of Excellent, one indicator can Visual (digital) Probes typically cost $50

probe(s), typically serve several locations (probes)

0.5°C (1°F)

Thermocouple 25 to 30 Fair, 1°C (2°F) Excellent when coupled with Analog (electrical) Not reliable for measuring temperature

indicator differences; requires special wire for

installation

Resistance 60 High 0.25°C (0.5°F) or Excellent when coupled with Analog (electrical) Especially suited for measuring

temperature better indicator temperature differences

detectors (HTD)

Thermistors 1 to 30 Good, 0.5°C (1°F) Excellent when coupled with Analog (electrical) Not available in proper housing; can be

indicator damaged

Tapes 2 to 3 Fair, 1–3°C (2–5°F) Excellent, reusable Visual Inexpensive

steps

TABLE 3 Liquid Flow Sensors and Indicators

Approximate

Type of Sensor Accuracy Convenience Type of Output

Cost (dollars)

Pressure gages 50 Strictly a flow indicator Low Visual

Float type 30 Fair,+5% full scale accuracy Moderate Visual

TABLE 4 Air Flowmeters

Approximate

Type of Sensor Accuracy Type of Output Special Comments

A

Cost (dollars)

Hot wire anemometer 600 to 1000 Moderate, 2 % of full scale; Analog (electrical) Some models easily damaged by debris and improper

recalibration necessary handling; must be properly located in order to determine

mean flow

Turbine 300 Good, 1 % of flow Analog (electrical) Must be properly located in order to determine mean flow

Pitot tube 300 Fair, 1 to 5 % Visual or analog (electrical) Standard for measuring duct velocities

A

Includes readout device or transmitter.

5.2.2.7 Storage containers and media, (Practice E 1056, 6.7.2), improper joining of dissimilar metals

5.2.2.8 Heat exchangers, (Practice E 1056, 6.7.14), or improper fluids (Practice E 1056,

5.2.2.9 Dampers and ducting, 6.5). See Ref (2) for a leak check on air systems. A pressure

5.2.2.10 Air or liquid systems leaks, check on liquid systems should be done to see if it meets

5.2.2.11 Interrelated support systems, including other air manufacturer’s recommendations.

handlers, chillers, heaters, or heat pumps, and 5.2.5 Check pumps for noise (most pumps are very quiet).

5.2.2.12 Fans and air handlers. Noisy fluid flow almost always indicates a bad pump, cavita-

5.2.3 Most of the failures reported have been in the collector tion or air in the system and is symptomatic of further

subsystem and connections and controls with considerably problems. In an open or drainback system noisy fluid flow will

fewer failures reported for valves and pump subsystems. There occur if there is water loss due to leakage. If a pump problem

has been a high incidence of improper system operation due to is suspected, one way to determine if the pump is seized or has

controls improperly connected or adjusted. other electrical problems is to touch the assembly to see if it is

5.2.4 A visual inspection should be made of all connections hotter than the fluid circulating through it. Also any burning

(see Practice E 1056, 6.7.6) to check for evidence of leaks or odors may indicate electrical problems.

potential future corrosion due to improper use of materials 5.3 Collector Operation and Effectiveness (See Practice

E 1160

E 823, Practice E 904 and ASHRAE Standard 93-1986 for

other tests). Table 5 gives the typical operating ranges of the

test parameters for various collector system configurations.

6. Test Level A—Visual Inspection

6.1 Procedure—Turn on system, observe the pump or

blower comes on with sunshine available. Temperature on

return line from collector should be slightly warmer (about 5°C

(10°F)) than the supply line to the collector. This can be

determined by feel or by temperature gages (see Table 2) if

installed. The return temperature should also show a gradual

increase during daylight hours (will fluctuate depending on

water usage).

6.2 Interpretation and Report of Results—If temperature

rise is unreasonable (too little or too much—see 6.1) check

pump or blower for proper operation and fluid level in system.

7. Test Level B—Estimation of Flow Rates

7.1 Procedures:

7.1.1 In indirect system, record total head (discharge

pressure-suction pressure), and establish flow rate using inter-

FIG. 2 Pump And System Curves (Closed Loop)

section of system curve with blower curve provided by

8. Test Level C—Measure Radiation and Temperature

manufacturer (see Fig. 2 correct for antifreeze percentage). See

Changes (See Ref (3) for similar test)

Ref (2) for more information.

7.1.2 In direct or open system measure discharge pressure 8.1 Procedure:

with drain valve and makeup valve closed. Then open makeup 8.1.1 Measure radiation (q) with pyranometer. To get steady

valve, turn on pump and adjust the drain valve until the state, read every 15 min until two consecutive values are the

pressure is the same as in 7.1.1 (see Fig. 3 for operating point). same within 5 %. Record readings, once at steady state, every

7.2 Instrumentation—A pressure gage (see Fig. 4 and Table 15 min for 2 h. Measure collector inlet (T ) and outlet

in

3), a stopwatch, and a container may be needed for this test. temperatures (T ) every 15 min for 2 h (may need to close off

out

7.3 Interpretation and Report of Results—The system makeup water and backup heater for duration of test. Use flow

3 2 2

should be providing 7 to 27 cm /m s (0.01 to 0.04 gpm/ft )of r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.