ASTM D4599-03(2009)e1

(Practice)Standard Practice for Measuring the Concentration of Toxic Gases or Vapors Using Length-of-Stain Dosimeters

Standard Practice for Measuring the Concentration of Toxic Gases or Vapors Using Length-of-Stain Dosimeters

SIGNIFICANCE AND USE

The U.S. Occupational Safety and Health Administration (OSHA) in 29 CFR 1910.1000 Subpart Z designates that certain gases and vapors present in work place atmospheres must be controlled so that their concentrations do not exceed specified limits. Other countries have similar regulations.

This practice will provide a means for the determination of airborne concentrations of certain gases and vapors listed in 29 CFR 1910.1000 and in other countries’ regulations.

A partial list of chemicals for which this practice is applicable is presented in Annex A1 with current Threshold Limit Values (TLV) (2) and typical measurement ranges for the selected chemicals as obtained from various manufacturer's specifications.

This practice may be used for either personal or area monitoring.

SCOPE

1.1 This practice describes the detection and measurement of time weighted average (TWA) concentrations of toxic gases or vapors using length-of-stain colorimetric dosimeter tubes. A list of some of the gases and vapors that can be detected by this practice is provided in Annex A1. This list is given as a guide and should be considered neither absolute nor complete.

1.2 Length-of-stain colorimetric dosimeters work by diffusional sampling. The results are immediately available by visual observation; thus no auxiliary sampling, test nor analysis equipment are needed. The dosimeters, therefore, are extremely simple to use and very cost effective.

1.3 The values stated in SI units shall be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D4599 − 03(Reapproved 2009)

Standard Practice for

Measuring the Concentration of Toxic Gases or Vapors

Using Length-of-Stain Dosimeters

This standard is issued under the fixed designation D4599; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Reapproved with editorial changes in October 2009.

1. Scope 3. Terminology

3.1 For definitions of terms used in this practice, refer to

1.1 This practice describes the detection and measurement

of time weighted average (TWA) concentrations of toxic gases Terminology D1356.

orvaporsusinglength-of-staincolorimetricdosimetertubes.A

4. Summary of Practice

listofsomeofthegasesandvaporsthatcanbedetectedbythis

practice is provided in AnnexA1. This list is given as a guide

4.1 Length-of-stain colorimetric dosimeters consist of a

and should be considered neither absolute nor complete.

sealed glass tube containing a detector inside the tube (1-5).

The detector is a length of granulated material impregnated

1.2 Length-of-stain colorimetric dosimeters work by diffu-

with a reactive chemical that is sensitive to the particular gas

sional sampling. The results are immediately available by

for which the dosimeter is designed. To use the tube, one end

visualobservation;thusnoauxiliarysampling,testnoranalysis

is opened. The gas, if present, diffuses into the tube and reacts

equipment are needed. The dosimeters, therefore, are ex-

with the chemical reagent on the carrier material, causing the

tremely simple to use and very cost effective.

latter to change color. Each lot of dosimeters is individually

1.3 The values stated in SI units shall be regarded as the

calibratedsothatbymeasuringthelengthofstainandthetime

standard.

ofexposure,theTWAconcentrationtowhichthedosimeterhas

1.4 This standard does not purport to address all of the

been exposed can be determined directly and immediately.

safety concerns, if any, associated with its use. It is the

4.2 Information on the correct use of length of stain dosim-

responsibility of the user of this standard to establish appro-

eter tubes is presented.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5. Significance and Use

5.1 The U.S. Occupational Safety and Health Administra-

2. Referenced Documents

tion (OSHA) in 29 CFR 1910.1000 Subpart Z designates that

2.1 ASTM Standards:

certain gases and vapors present in work place atmospheres

D1356Terminology Relating to Sampling and Analysis of

must be controlled so that their concentrations do not exceed

Atmospheres

specified limits. Other countries have similar regulations.

2.2 Other Document:

5.2 Thispracticewillprovideameansforthedetermination

U.S. Occupational Safety and Health Standard—Title

of airborne concentrations of certain gases and vapors listed in

291910.1000 Subpart Z

29 CFR 1910.1000 and in other countries’regulations.

5.3 A partial list of chemicals for which this practice is

applicable is presented in Annex A1 with current Threshold

This practice is under the jurisdiction of ASTM Committee D22 on Air

LimitValues(TLV) (2)andtypicalmeasurementrangesforthe

Qualityand is the direct responsibility of Subcommittee D22.04 on WorkplaceAir

selected chemicals as obtained from various manufacturer’s

Quality.

Current edition approved Oct. 1, 2009. Published December 2009. Originally

specifications.

approved in 1986. Last previous edition approved in 2003 as D4599–03. DOI:

5.4 This practice may be used for either personal or area

10.1520/D4599-03R09E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

monitoring.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Code of Federal Regulations, available from U.S. Government Printing Office, The boldface numbers in parentheses refer to the list of references appended to

Washington, DC 20402. this practice.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D4599 − 03 (2009)

6. Interferences dm

dl 5 (2)

kA

6.1 The instructions may provide correction factors to be

applied when certain interferences are present. Some common

where:

interfering gases or vapors for each dosimeter are listed in the

k = absorption capacity of a layer element, ng/cm , and

instruction sheets for the dosimeter provided by the manufac-

A = cross-sectional area of the reagent layer, cm (assumed

turers

constant).

7. Apparatus

Thisprocess,calledchemisorption,hasthefollowingeffects

on the remaining measuring process:

7.1 Dosimeter Tube:

7.1.1 General Description—A length-of-stain dosimeter 9.1.1 Since the gas molecules to be measured are bound

tube consists of a glass tube containing an inert granular chemically, they are practically no longer present in the

material impregnated with a chemical system that reacts with

atmosphere directly above the granular carrier material. Thus,

the gas or vapor of interest. As a result of this reaction, the additional sample molecules are able to flow into the detector

impregnated chemical changes color. The granular material is

tube according to Fick’s First Law of Diffusion, since the

heldinplacewithintheglasstubebyporousplugsofasuitable

concentration gradient ∆c is maintained.

inert material. To protect the contents during storage, the ends

9.1.2 The effect of the color zone formed in the process is

of the glass tube are flame sealed. The calibration scale is

thatthesubsequentcontaminantmoleculesmustcoveralonger

printed on the tube to make it easy to read the length of stain

diffusionpath,l,untiltheyreachtheunusedreagentlayer.This

of reacted chemical.

means that the diffusion path, l, as defined in the diffusion law,

7.1.2 Stability on Storage—Stability on storage may vary

isnotconstant,butbecomesgreaterwithprogressiveexposure.

depending on manufacturer and type of dosimeter, but most

The transport rate dm/dt of the sample molecules decreases in

dosimeter tubes can be stored for at least 24 months with no

theprocess.Theslowdowninmasstransporthasadirecteffect

deleterious effects.

on the shape of the calibration curves of the indicating tubes.

7.2 TubeHolders—Duringuse,thedosimetertubeisheldin

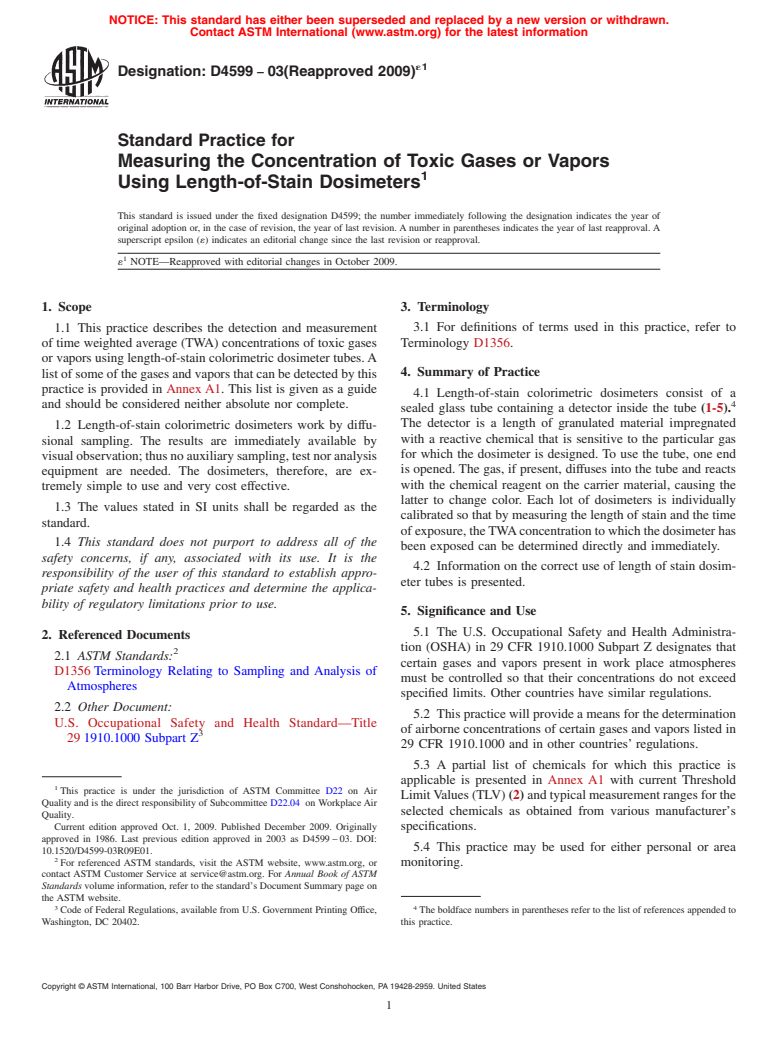

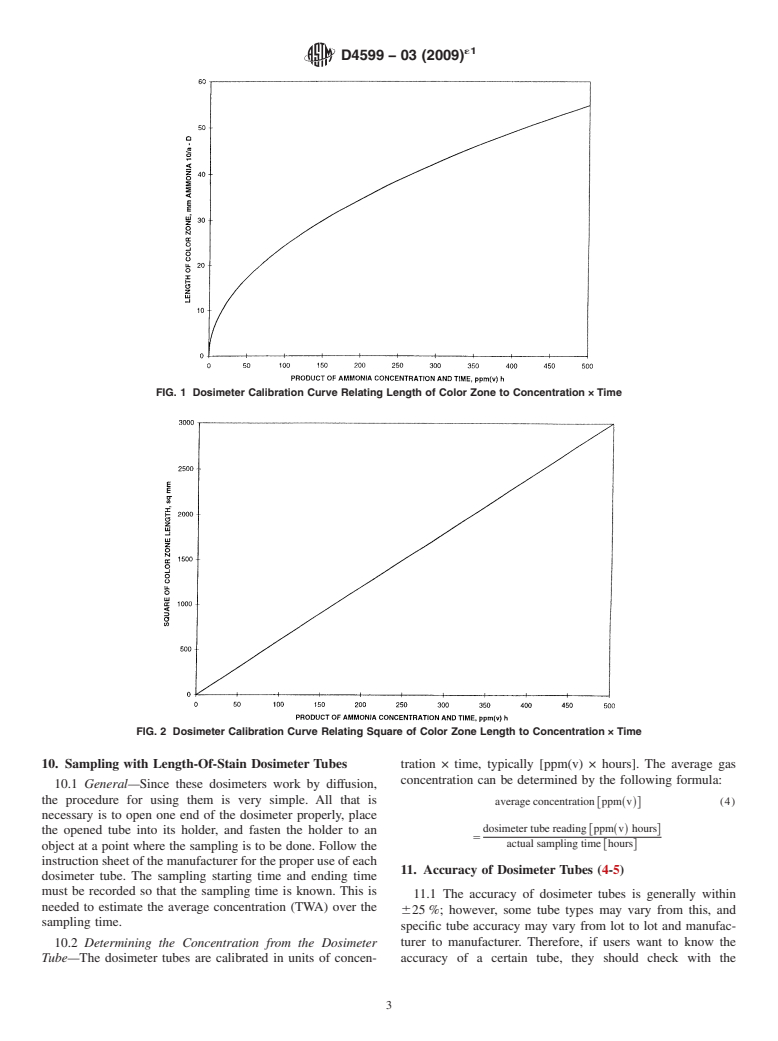

The mathematical correlation can be traced to Formulas 1 and

a lightweight, plastic holder. The tube holder protects the

2. Eliminating the contaminant mass, dm, from Eq 1 and 2 and

dosimeter during use and also helps to minimize effects of air

integrating yields:

currentsonperformance.Theholderhasaclipthatallowsitto

1 t k

befastenedtoacollarorpocketduringpersonalsamplingorto

c [ * ∆cdt 5 3l (3)

S D

TWA

t 2Dt

some appropriate object during area sampling.

where c is the time-weighted average of the time-

TWA

8. Reagents

dependent concentration, ∆c. Calibration curves described by

8.1 Thereagentsusedtoimpregnatethegranularmaterialin

this equation are not linear, but have the shape of a parabola

the dosimeters are specific for each tube, and, to dete

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.