ASTM B501-10(2015)

(Specification)Standard Specification for Silver-Coated, Copper-Clad Steel Wire for Electronic Application

Standard Specification for Silver-Coated, Copper-Clad Steel Wire for Electronic Application

ABSTRACT

This specification deals with silver-coated, round, copper-clad steel wires for electronic applications. The four classes of steel wires covered here are Classes 30HS, 30A, 40HS, and 40A. Specimens shall undergo tests that shall evaluate their conformance to the following physical properties: tensile strength, elongation, electrical resistivity, continuity and mass of the coating, and dimensions and density of the wire.

SCOPE

1.1 This specification covers silver-coated, round, copper-clad steel wire for electronic application.

1.2 Silver coatings in mass percentages of the total mass of the coated wire are as follows: 1.25, 2.5, 4.0, 6.1, and 8.0.

1.2.1 Silver-coated wire having different minimum percentage of silver by mass may be obtained by mutual agreement between the manufacturer and the purchaser. For information purposes, the thickness of coating in microinches provided by the mass percentages listed in 1.2 is shown in Table 1.

1.3 Four classes of copper-clad steel wire are covered as follows: Class 30HS nominal 30 % conductivity hard-drawn, Class 30A nominal 30 % conductivity annealed, Class 40HS nominal 40 % conductivity hard-drawn, and Class 40A nominal 40 % conductivity annealed.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4.1 Exception—In resistivity the SI units are to be regarded as the standard

1.5 The following safety hazards caveat pertains to the test method described in this specification. This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (Caution—Consideration should be given to toxicity and flammability when selecting solvent cleaners.)

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B501 −10 (Reapproved 2015)

Standard Specification for

Silver-Coated, Copper-Clad Steel Wire for Electronic

Application

This standard is issued under the fixed designation B501; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2.2 ASTM Standards:

B193 Test Method for Resistivity of Electrical Conductor

1.1 This specification covers silver-coated, round, copper-

Materials

clad steel wire for electronic application.

B258 Specification for Nominal Diameters and Cross-

1.2 Silver coatings in mass percentages of the total mass of

SectionalAreasofAWGSizesofSolidRoundWiresUsed

the coated wire are as follows: 1.25, 2.5, 4.0, 6.1, and 8.0.

as Electrical Conductors

1.2.1 Silver-coated wire having different minimum percent-

B452 Specification for Copper-Clad Steel Wire for Elec-

age of silver by mass may be obtained by mutual agreement

tronic Application

between the manufacturer and the purchaser. For information

purposes, the thickness of coating in microinches provided by

3. Terminology

the mass percentages listed in 1.2 is shown in Table 1.

3.1 Definitions of Terms Specific to This Standard:

1.3 Four classes of copper-clad steel wire are covered as

3.1.1 lot—any amount of wire of one class and size pre-

follows: Class 30HS nominal 30 % conductivity hard-drawn,

sented for acceptance at one time, such amount, however, not

Class 30A nominal 30 % conductivity annealed, Class 40HS

to exceed 10 000 lb (4500 kg) (Note 1).

nominal 40 % conductivity hard-drawn, and Class 40A nomi-

3.1.2 sample—a quantity of production units (coils, reels,

nal 40 % conductivity annealed.

and so forth) selected at random from the lot for the purpose of

1.4 The values stated in inch-pound units are to be regarded

determining conformance of the lot to the requirements of this

as standard. The values given in parentheses are mathematical specification.

conversions to SI units that are provided for information only

3.1.3 specimen—a length of wire removed for test purposes

and are not considered standard.

from any individual production unit of the sample.

1.4.1 Exception—In resistivity the SI units are to be re-

NOTE 1—Alot should comprise material taken from a product regularly

garded as the standard

meeting the requirements of this specification. Inspection of individual

1.5 The following safety hazards caveat pertains to the test

lots of less than 500 lb (250 kg) of wire cannot be justified economically.

method described in this specification. This standard does not For small lots of 500 lb (250 kg) or less, the purchaser may agree to the

manufacturer’sregularinspectionoftheproductasawholeasevidenceof

purport to address all of the safety problems, if any, associated

acceptability of such small lots.

with its use. It is the responsibility of the user of this standard

to establish appropriate safety and health practices and

4. Ordering Information

determine the applicability of regulatory limitations prior to

4.1 Orders for material under this specification shall include

use. (Caution—Consideration should be given to toxicity and

the following information:

flammability when selecting solvent cleaners.)

4.1.1 Quantity of each size,

2. Referenced Documents

4.1.2 Wire size (see 7.1 and Table 1),

4.1.3 Class of basis wire (see 1.3),

2.1 The following documents of the issue in effect on date

4.1.4 Mass percentage of coating (see 1.2 and Table 1),

of material purchase form a part of this specification to the

4.1.5 Package size (see Section 12),

extent referenced herein:

4.1.6 Special packaging marking, if required, and

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductors and is the direct responsibility of Subcommittee B01.06 on

Bi-Metallic Conductors. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2015. Published April 2015. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1969. Last previous edition approved in 2010 as B501 – 10. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/B0501-10R15. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B501−10 (2015)

TABLE 1 Silver Mass Percent and Thickness of Coating

Thickness of Silver, µin.

Diameter Cross-Sectional Area at 20°C

(for information only)

1.25 2.5 4.0 6.1 8.0

2 2

in. mm cmil in. mm

% % % % %

0.0720 1.829 5 180 0.00407 2.63 176 352 569 876 1 158

0.0641 1.628 4 110 0.00323 2.08 156 313 507 779 1 031

0.0571 1.450 3 260 0.00256 1.65 139 279 451 694 918

0.0508 1.290 2 580 0.00203 1.31 124 248 401 618 817

0.0453 1.151 2 050 0.00161 1.04 111 222 358 551 728

0.0403 1.024 1 620 0.00128 0.823 98 197 318 490 648

0.0359 0.912 1 290 0.00101 0.653 88 176 284 437 577

0.0320 0.813 1 020 0.000804 0.519 78 156 253 389 515

0.0285 0.724 812 0.000638 0.412 70 139 225 347 458

0.0253 0.643 640 0.000503 0.324 62 124 200 308 407

0.0226 0.574 511 0.000401 0.259 55 111 179 275 363

0.0201 0.511 404 0.000317 0.205 49 98 159 244 323

0.0179 0.455 320 0.000252 0.162 44 88 141 218 288

0.0159 0.404 253 0.000199 0.128 39 78 126 193 256

0.0142 0.361 202 0.000158 0.102 35 69 112 173 228

0.0126 0.320 159 0.000125 0.0804 31 62 100 153 203

0.0113 0.287 128 0.000100 0.0647 28 55 89 137 182

0.0100 0.254 100 0.0000785 0.0507 24 49 79 122 161

0.0089 0.226 79.2 0.0000622 0.0401 22 44 70 108 143

0.0080 0.203 64.0 0.0000503 0.0324 39 63 97 129

0.0071 0.180 50.4 0.0000396 0.0255 35 56 86 114

0.0063 0.160 39.7 0.0000312 0.0201 31 50 77 101

0.0056 0.142 31.4 0.0000246 0.0159 26 44 68 90

0.0050 0.127 25.0 0.0000196 0.0127 24 40 61 80

0.0045 0.114 20.2 0.0000159 0.0103 22 36 55 72

0.0040 0.102 16.0 0.0000126 0.00811 32 49 64

0.0035 0.089 12.2 0.00000962 0.00621 28 43 56

0.0031 0.079 9.61 0.00000755 0.00487 24 38 50

TABLE 2 Resistivity

4.1.7 Place of inspection (see 9.1).

Resistivity, max at 20°C

Class of Wire Ω·mm /m

5. Materials and Manufacture

30HS and 30A 0.05862

40HS and 40A 0.04397

5.1 Thebasismaterialshallconsistofcopper-cladsteelwire

conforming to the product description, quality and specifica-

tion requirements of Specification B452.

6.3 Continuity of Coating—Thecoatingshallbecontinuous.

5.2 The silver-coated wire shall consist of the basis wire

The continuity of the coating shall be determined on represen-

coatedwithsilver.Thequalityofthesilver-coatedwireshallbe

tative samples taken before stranding or insulating and shall be

such that the finished product meets the properties and require-

determined by the sodium polysulfide test, in accordance with

ments in this specification (Note 2).

10.2.3.1. Wire whose coating mass corresponds to a thickness

NOTE 2—Silver coatings on copper-clad steel provide for:

less than 0.00005 in. (50 µin.) shall not be subject to this test.

(a)Abarrier between the copper and insulation whose curing temperature

6.4 Mass of Coating—The mass of coating expressed in

in the process of fabricating is too high for the use of tin-coated wires.

(b) A low contact resistance between the strands of outer conductors of

percent of the total mass of the wire shall be not less than the

coaxial conductors used in high-frequency circuits.

percentage specified and referred to in this specification or the

(c)Alow radio-frequency resistance of conductors used in high-frequency

percentage as agreed on between the manufacturer and pur-

circuits (skin effect).

chaser at the time of the placing of the order. For ease of

(d) Good solderability for high-temperature hook-up wires which prohibit

the use of tin-coated wires due to high curing temperatures used in comparison, the thickness of coating for various percentages

fabricating the finished wire.

has been included in Table 1.

6.5 Joints—Necessary joints in the wire and rods prior to

6. General Requirements

final coating and drawing shall be made in accordance with

6.1 Tensile strength and elongation of the silver-coated wire

good commercial practice. Joints made after coating shall not

shallconformtotherequirementsofSpecificationB452forthe

be allowed to remain in the final product.

applicable size and class of copper-clad steel wire.

NOTE 3—Relationships which may be useful in connection with the

6.2 Resistivity—The electrical resistivity at a temperature of

values of electrical resistivity prescribed in this specification are shown in

20°C shall not exceed the values prescribed in Table 2. See

Table 2. Resistivity units are based on the InternationalAnnealed Copper

Note 3 for calculating electrical resistance. Standard (IACS) adopted by IEC in 1913, which is ⁄58Ω·mm /m at 20°C

B501−10 (2015)

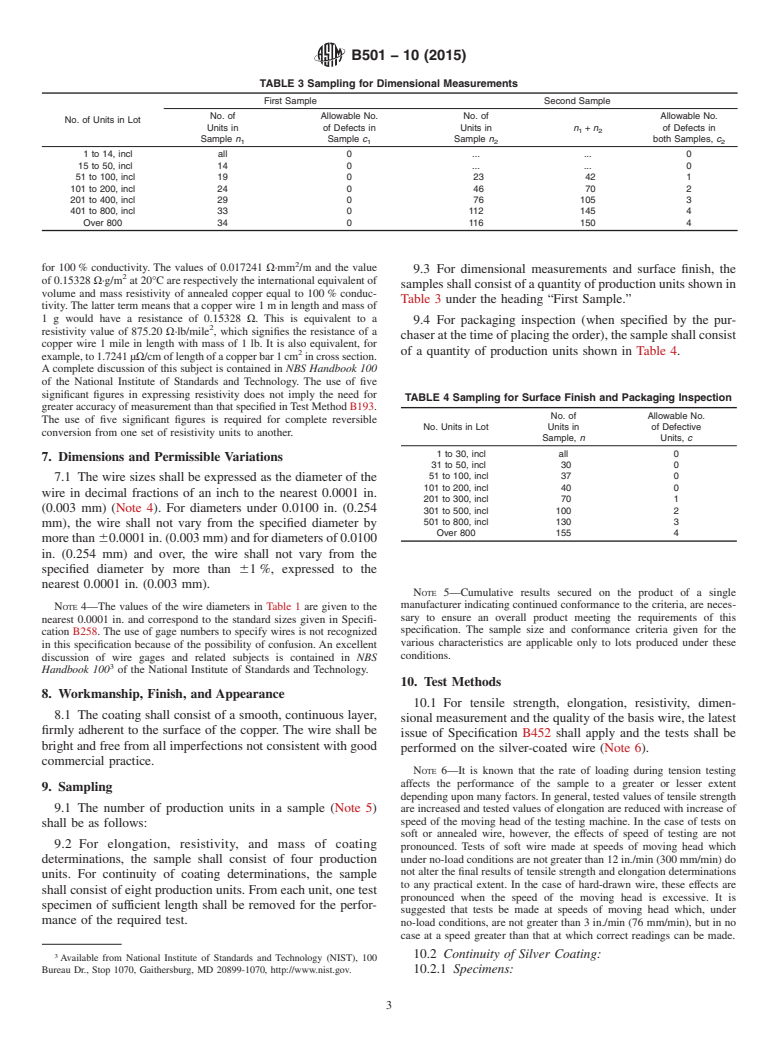

TABLE 3 Sampling for Dimensional Measurements

First Sample Second Sample

No. of Allowable No. No. of Allowable No.

No. of Units in Lot

Units in of Defects in Units in n + n of Defects in

1 2

Sample n Sample c Sample n both Samples, c

1 1 2 2

1 to 14, incl all 0 . . 0

15 to 50, incl 14 0 . . 0

51 to 100, incl 19 0 23 42 1

101 to 200, incl 24 0 46 70 2

201 to 400, incl 29 0 76 105 3

401 to 800, incl 33 0 112 145 4

Over 800 34 0 116 150 4

for 100 % conductivity. The values of 0.017241Ω·mm /m and the value

9.3 For dimensional measurements and surface finish, the

of 0.15328Ω·g/m at 20°C are respectively the international equivalent of

samplesshallconsistofaquantityofproductionunitsshownin

volume and mass resistivity of annealed copper equal to 100 % conduc-

Table 3 under the heading “First Sample.”

tivity. The latter term means that a copper wire1min length and mass of

1 g would have a resistance of 0.15328 Ω. This is equivalent to a

9.4 For packaging inspection (when specified by the pur-

resistivity value of 875.20Ω·lb/mile , which signifies the resistance of a

chaseratthetimeofplacingtheorder),thesampleshallconsist

copper wire 1 mile in length with mass of 1 lb. It is also equivalent, for

2 of a quantity of production units shown in Table 4.

example,to1.7241µΩ/cmoflengthofacopperbar1cm incrosssection.

A complete discussion of this subject is contained in NBS Handbook 100

of the National Institute of Standards and Technology. The use of five

significant figures in expressing resistivity does not imply the need for

TABLE 4 Sampling for Surface Finish and Packaging Inspection

greater accuracy of measurement than that specified inTest Method B193.

No. of Allowable No.

The use of five significant figures is required for complete reversible

No. Units in Lot Units in of Defective

conversion from one set of resistivity units to another.

Sample, n Units, c

1 to 30, incl all 0

7. Dimensions and Permissible Variations

31 to 50, incl 30 0

51 to 100, incl 37 0

7.1 The wire sizes shall be expressed as the diameter of the

101 to 200, incl 40 0

wire in decimal fractions of an inch to the nearest 0.0001 in.

201 to 300, incl 70 1

(0.003 mm) (Note 4). For diameters under 0.0100 in. (0.254

301 to 500, incl 100 2

501 to 800, incl 130 3

mm), the wire shall not vary from the specified diameter by

Over 800 155 4

morethan 60.0001in.(0.003mm)andfordiametersof0.0100

in. (0.254 mm) and over, the wire shall not vary from the

specified diameter by more than 61 %, expressed to the

nearest 0.0001 in. (0.003 mm).

NOTE 5—Cumulative results secured on the product of a single

manufacturer indicating continued conformance to the criteria, are neces-

NOTE 4—The values of the wire diameters in Table 1 are given to the

sary to ensure an overall product meeting the requirements of this

nearest 0.0001 in. and correspond to the standard sizes given in Specifi-

specification. The sample size and conformance criteria given for the

cation B258. The use of gage numbers to specify wires is not recognized

various characteristics are applicable only to lots produced under these

in this specification because of the possibility of confusion. An excellent

conditions.

discussion of wire gages and related subjects is contained in NBS

Handbook 100 of the National Institute of Standards and Technology.

10. Test Methods

8. Workmanship, Finish, and Appearance

10.1 For tensile strength, elongation, resistivity, dimen-

8.1 The coating shall consist of a smooth, continuous layer,

sional measurement and the quality of the basis wire, the latest

firmly adherent to the surface of the copper. The wire shall be

issue of Specification B452 shall apply and the tests shall be

bright and free from all imperfections not consistent with good

performed on the silver-coated wire (Note 6).

commercial practice.

NOTE 6—It is known that the rate of loading during tension testing

affects the performance of the sample to a greater or lesser extent

9. Sampling

depending upon many factors. In general, tested values of tensile strength

9.1 The number of production units in a sample (Note 5) are increased and tested values of elongation are reduced with increase of

speed of the moving head of the testing machine. In the case of tests on

shall be as follows:

soft or annealed wire, however, the effects of speed of testing are not

9.2 For elongation, resistivity, and mass of coating

pronounced. Tests of soft wire made at speeds of moving head which

determinations, the sample shall consist of four production under no-load conditions are not greater than 12 in./min (300 mm/min) do

not alter the final results of tensile strength and elongation determinations

units. For continuity of coating determinations, the sample

to any practical extent. In the case of hard-drawn wire, these effects are

shall consist of eight production units. From each unit, one test

pronounced when the speed of the moving head is excessive. It is

specimen of sufficient length shall be removed for the perfor-

suggested that tests be made at speeds of moving head which, under

mance of the required test.

no-load conditions, are not greater than 3 in./min (76 mm/min), but in no

case at a speed greater than that at which correct readings can be made.

10.2 Continuity of Silver Coating:

Available from National Institute of Standards and Technology (NIST), 100

Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov. 10.2.1 Specimens:

B501−10 (2015)

10.2.1.1 Length of Specimens—Test specimens shall each 10.2.3.3 Immersion in Hydrochloric Acid—After washing

have a length of about 6 in. (150 mm). They shall be tagged or thespecimenimmerseimmediatelyfor15sintheHClsolu

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B501 − 10 B501 − 10 (Reapproved 2015)

Standard Specification for

Silver-Coated, Copper-Clad Steel Wire for Electronic

Application

This standard is issued under the fixed designation B501; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers silver-coated, round, copper-clad steel wire for electronic application.

1.2 Silver coatings in mass percentages of the total mass of the coated wire are as follows: 1.25, 2.5, 4.0, 6.1, and 8.0.

1.2.1 Silver-coated wire having different minimum percentage of silver by mass may be obtained by mutual agreement between

the manufacturer and the purchaser. For information purposes, the thickness of coating in microinches provided by the mass

percentages listed in 1.2 is shown in Table 1.

1.3 Four classes of copper-clad steel wire are covered as follows: Class 30HS nominal 30 % conductivity hard-drawn, Class

30A nominal 30 % conductivity annealed, Class 40HS nominal 40 % conductivity hard-drawn, and Class 40A nominal 40 %

conductivity annealed.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4.1 Exception—In resistivity the SI units are to be regarded as the standard

1.5 The following safety hazards caveat pertains to the test method described in this specification. This standard does not

purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

(Caution—CautionConsideration—Consideration should be given to toxicity and flammability when selecting solvent clean-

ers.)cleaners.)

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

2.2 ASTM Standards:

B193 Test Method for Resistivity of Electrical Conductor Materials

B258 Specification for Nominal Diameters and Cross-Sectional Areas of AWG Sizes of Solid Round Wires Used as Electrical

Conductors

B452 Specification for Copper-Clad Steel Wire for Electronic Application

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 lot—any amount of wire of one class and size presented for acceptance at one time, such amount, however, not to exceed

10 000 lb (4500 kg) (Note 1).

3.1.2 sample—a quantity of production units (coils, reels, and so forth) selected at random from the lot for the purpose of

determining conformance of the lot to the requirements of this specification.

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.06 on Composite

Conductors.

Current edition approved April 1, 2010April 1, 2015. Published May 2010April 2015. Originally approved in 1969. Last previous edition approved in 20042010 as

B501 – 04.B501 – 10. DOI: 10.1520/B0501-10.10.1520/B0501-10R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B501 − 10 (2015)

TABLE 1 Silver Mass Percent and Thickness of Coating

Thickness of Silver, μin.

Diameter Cross-Sectional Area at 20°C

(for information only)

1.25 2.5 4.0 6.1 8.0

2 2

in. mm cmil in. mm

% % % % %

0.0720 1.829 5 180 0.00407 2.63 176 352 569 876 1 158

0.0641 1.628 4 110 0.00323 2.08 156 313 507 779 1 031

0.0571 1.450 3 260 0.00256 1.65 139 279 451 694 918

0.0508 1.290 2 580 0.00203 1.31 124 248 401 618 817

0.0453 1.151 2 050 0.00161 1.04 111 222 358 551 728

0.0403 1.024 1 620 0.00128 0.823 98 197 318 490 648

0.0359 0.912 1 290 0.00101 0.653 88 176 284 437 577

0.0320 0.813 1 020 0.000804 0.519 78 156 253 389 515

0.0285 0.724 812 0.000638 0.412 70 139 225 347 458

0.0253 0.643 640 0.000503 0.324 62 124 200 308 407

0.0226 0.574 511 0.000401 0.259 55 111 179 275 363

0.0201 0.511 404 0.000317 0.205 49 98 159 244 323

0.0179 0.455 320 0.000252 0.162 44 88 141 218 288

0.0159 0.404 253 0.000199 0.128 39 78 126 193 256

0.0142 0.361 202 0.000158 0.102 35 69 112 173 228

0.0126 0.320 159 0.000125 0.0804 31 62 100 153 203

0.0113 0.287 128 0.000100 0.0647 28 55 89 137 182

0.0100 0.254 100 0.0000785 0.0507 24 49 79 122 161

0.0089 0.226 79.2 0.0000622 0.0401 22 44 70 108 143

0.0080 0.203 64.0 0.0000503 0.0324 39 63 97 129

0.0071 0.180 50.4 0.0000396 0.0255 35 56 86 114

0.0063 0.160 39.7 0.0000312 0.0201 31 50 77 101

0.0056 0.142 31.4 0.0000246 0.0159 26 44 68 90

0.0050 0.127 25.0 0.0000196 0.0127 24 40 61 80

0.0045 0.114 20.2 0.0000159 0.0103 22 36 55 72

0.0040 0.102 16.0 0.0000126 0.00811 32 49 64

0.0035 0.089 12.2 0.00000962 0.00621 28 43 56

0.0031 0.079 9.61 0.00000755 0.00487 24 38 50

3.1.3 specimen—a length of wire removed for test purposes from any individual production unit of the sample.

NOTE 1—A lot should comprise material taken from a product regularly meeting the requirements of this specification. Inspection of individual lots

of less than 500 lb (250 kg) of wire cannot be justified economically. For small lots of 500 lb (250 kg) or less, the purchaser may agree to the

manufacturer’s regular inspection of the product as a whole as evidence of acceptability of such small lots.

4. Ordering Information

4.1 Orders for material under this specification shall include the following information:

4.1.1 Quantity of each size,

4.1.2 Wire size (see 7.1 and Table 1),

4.1.3 Class of basis wire (see 1.3),

4.1.4 Mass percentage of coating (see 1.2 and Table 1),

4.1.5 Package size (see Section 12),

4.1.6 Special packaging marking, if required, and

4.1.7 Place of inspection (see 9.1).

5. Materials and Manufacture

5.1 The basis material shall consist of copper-clad steel wire conforming to the product description, quality and specification

requirements of Specification B452.

5.2 The silver-coated wire shall consist of the basis wire coated with silver. The quality of the silver-coated wire shall be such

that the finished product meets the properties and requirements in this specification (Note 2).

NOTE 2—Silver coatings on copper-clad steel provide for:

(a) A barrier between the copper and insulation whose curing temperature in the process of fabricating is too high for the use of tin-coated wires.

(b) A low contact resistance between the strands of outer conductors of coaxial conductors used in high-frequency circuits.

(c) A low radio-frequency resistance of conductors used in high-frequency circuits (skin effect).

(d) Good solderability for high-temperature hook-up wires which prohibit the use of tin-coated wires due to high curing temperatures used in

fabricating the finished wire.

B501 − 10 (2015)

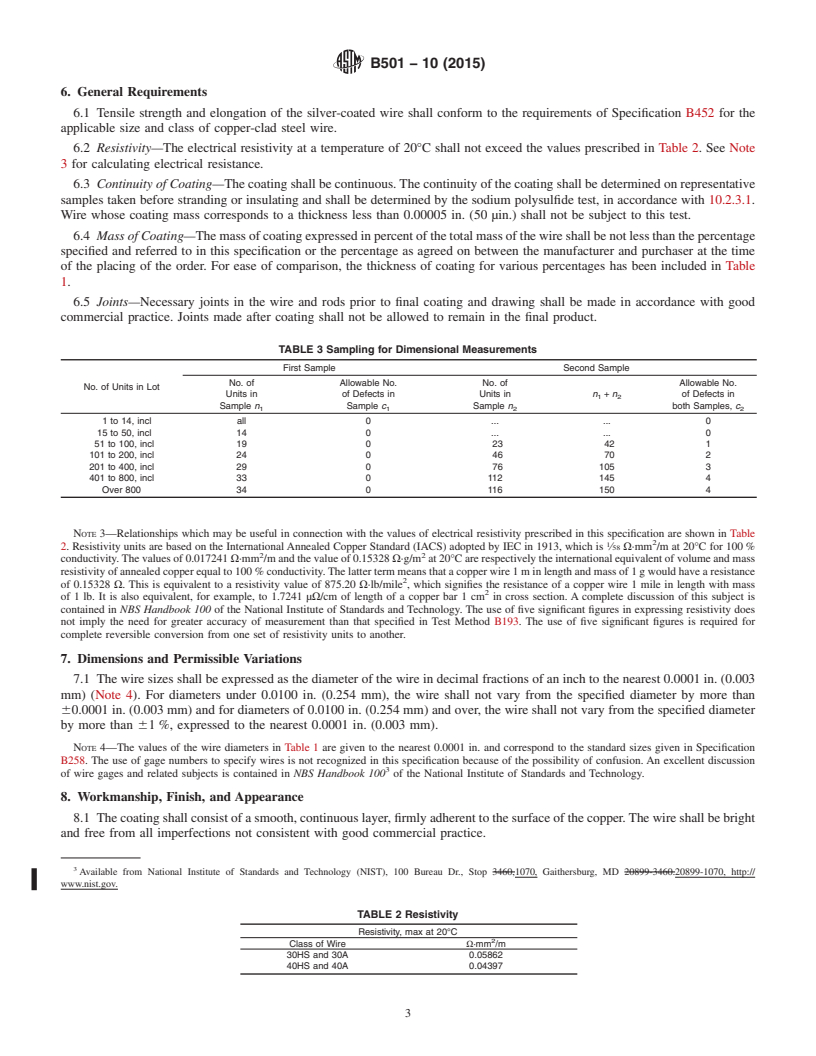

6. General Requirements

6.1 Tensile strength and elongation of the silver-coated wire shall conform to the requirements of Specification B452 for the

applicable size and class of copper-clad steel wire.

6.2 Resistivity—The electrical resistivity at a temperature of 20°C shall not exceed the values prescribed in Table 2. See Note

3 for calculating electrical resistance.

6.3 Continuity of Coating—The coating shall be continuous. The continuity of the coating shall be determined on representative

samples taken before stranding or insulating and shall be determined by the sodium polysulfide test, in accordance with 10.2.3.1.

Wire whose coating mass corresponds to a thickness less than 0.00005 in. (50 μin.) shall not be subject to this test.

6.4 Mass of Coating—The mass of coating expressed in percent of the total mass of the wire shall be not less than the percentage

specified and referred to in this specification or the percentage as agreed on between the manufacturer and purchaser at the time

of the placing of the order. For ease of comparison, the thickness of coating for various percentages has been included in Table

1.

6.5 Joints—Necessary joints in the wire and rods prior to final coating and drawing shall be made in accordance with good

commercial practice. Joints made after coating shall not be allowed to remain in the final product.

TABLE 3 Sampling for Dimensional Measurements

First Sample Second Sample

No. of Allowable No. No. of Allowable No.

No. of Units in Lot

Units in of Defects in Units in n + n of Defects in

1 2

Sample n Sample c Sample n both Samples, c

1 1 2 2

1 to 14, incl all 0 . . 0

15 to 50, incl 14 0 . . 0

51 to 100, incl 19 0 23 42 1

101 to 200, incl 24 0 46 70 2

201 to 400, incl 29 0 76 105 3

401 to 800, incl 33 0 112 145 4

Over 800 34 0 116 150 4

NOTE 3—Relationships which may be useful in connection with the values of electrical resistivity prescribed in this specification are shown in Table

2. Resistivity units are based on the International Annealed Copper Standard (IACS) adopted by IEC in 1913, which is ⁄58 Ω·mm /m at 20°C for 100 %

2 2

conductivity. The values of 0.017241 Ω·mm /m and the value of 0.15328 Ω·g/m at 20°C are respectively the international equivalent of volume and mass

resistivity of annealed copper equal to 100 % conductivity. The latter term means that a copper wire 1 m in length and mass of 1 g would have a resistance

of 0.15328 Ω. This is equivalent to a resistivity value of 875.20 Ω·lb/mile , which signifies the resistance of a copper wire 1 mile in length with mass

of 1 lb. It is also equivalent, for example, to 1.7241 μΩ/cm of length of a copper bar 1 cm in cross section. A complete discussion of this subject is

contained in NBS Handbook 100 of the National Institute of Standards and Technology. The use of five significant figures in expressing resistivity does

not imply the need for greater accuracy of measurement than that specified in Test Method B193. The use of five significant figures is required for

complete reversible conversion from one set of resistivity units to another.

7. Dimensions and Permissible Variations

7.1 The wire sizes shall be expressed as the diameter of the wire in decimal fractions of an inch to the nearest 0.0001 in. (0.003

mm) (Note 4). For diameters under 0.0100 in. (0.254 mm), the wire shall not vary from the specified diameter by more than

60.0001 in. (0.003 mm) and for diameters of 0.0100 in. (0.254 mm) and over, the wire shall not vary from the specified diameter

by more than 61 %, expressed to the nearest 0.0001 in. (0.003 mm).

NOTE 4—The values of the wire diameters in Table 1 are given to the nearest 0.0001 in. and correspond to the standard sizes given in Specification

B258. The use of gage numbers to specify wires is not recognized in this specification because of the possibility of confusion. An excellent discussion

of wire gages and related subjects is contained in NBS Handbook 100 of the National Institute of Standards and Technology.

8. Workmanship, Finish, and Appearance

8.1 The coating shall consist of a smooth, continuous layer, firmly adherent to the surface of the copper. The wire shall be bright

and free from all imperfections not consistent with good commercial practice.

Available from National Institute of Standards and Technology (NIST), 100 Bureau Dr., Stop 3460,1070, Gaithersburg, MD 20899-3460.20899-1070, http://

www.nist.gov.

TABLE 2 Resistivity

Resistivity, max at 20°C

Class of Wire Ω·mm /m

30HS and 30A 0.05862

40HS and 40A 0.04397

B501 − 10 (2015)

9. Sampling

9.1 The number of production units in a sample (Note 5) shall be as follows:

9.2 For elongation, resistivity, and mass of coating determinations, the sample shall consist of four production units. For

continuity of coating determinations, the sample shall consist of eight production units. From each unit, one test specimen of

sufficient length shall be removed for the performance of the required test.

9.3 For dimensional measurements and surface finish, the samples shall consist of a quantity of production units shown in Table

3 under the heading “First Sample.”

9.4 For packaging inspection (when specified by the purchaser at the time of placing the order), the sample shall consist of a

quantity of production units shown in Table 4.

TABLE 4 Sampling for Surface Finish and Packaging Inspection

No. of Allowable No.

No. Units in Lot Units in of Defective

Sample, n Units, c

1 to 30, incl all 0

31 to 50, incl 30 0

51 to 100, incl 37 0

101 to 200, incl 40 0

201 to 300, incl 70 1

301 to 500, incl 100 2

501 to 800, incl 130 3

Over 800 155 4

NOTE 5—Cumulative results secured on the product of a single manufacturer indicating continued conformance to the criteria, are necessary to ensure

an overall product meeting the requirements of this specification. The sample size and conformance criteria given for the various characteristics are

applicable only to lots produced under these conditions.

10. Test Methods

10.1 For tensile strength, elongation, resistivity, dimensional measurement and the quality of the basis wire, the latest issue of

Specification B452 shall apply and the tests shall be performed on the silver-coated wire (Note 6).

NOTE 6—It is known that the rate of loading during tension testing affects the performance of the sample to a greater or lesser extent depending upon

many factors. In general, tested values of tensile strength are increased and tested values of elongation are reduced with increase of speed of the moving

head of the testing machine. In the case of tests on soft or annealed wire, however, the effects of speed of testing are not pronounced. Tests of soft wire

made at speeds of moving head which under no-load conditions are not greater than 12 in./min (300 mm/min) do not alter the final results of tensile

strength and elongation determinations to any practical extent. In the case of hard-drawn wire, these effects are pronounced when the speed of the moving

head is excessive. It is sug

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.