ASTM E783-02(2018)

(Test Method)Standard Test Method for Field Measurement of Air Leakage Through Installed Exterior Windows and Doors

Standard Test Method for Field Measurement of Air Leakage Through Installed Exterior Windows and Doors

SIGNIFICANCE AND USE

5.1 This test method is a standard procedure for determining the air leakage characteristics of installed exterior windows and doors under specified static air pressure differences.

Note 1: The air pressure differences acting across a building envelope vary greatly. The factors affecting air pressure differences and the implications of the resulting air leakage relative to the environment within buildings are discussed in the literature.3, 4, 5 These factors should be fully considered in specifying the test pressure differences to be used.

5.2 Rates of air leakage are sometimes used for comparison purposes. Such comparisons may not be valid unless the components being tested and compared are of essentially the same size, configuration, and design.

5.3 Rates of air leakage of essentially identical windows or doors, as determined in the laboratory (Test Method E283) and as measured in the field by this test method, have sometimes been used for comparison purposes. The correlation between the laboratory and field test results, and the correlation between actual performance of in-service products and the response to these tests has not been established because of insufficient data.

5.4 Rates of air leakage, as determined by this test method may be affected by: the age or physical condition of the test specimen; the type or quality of installation; the care exercised in the attachment of the test apparatus and the determination of extraneous leakage; and the actual conditions to which the test specimen is exposed beyond those imposed by the test method, that is temperature, relative humidity, wind impingement, etc. Consideration must be given to the proper selection of test specimens, the choice of appropriate test technique (when a choice is given within this test method), and the proper use and interpretation of the results obtained from this test to minimize the effect of these conditions.

5.5 Rates of air leakage, as determined by this test method may i...

SCOPE

1.1 This test method provides a field procedure for determining the air leakage rates of installed exterior windows and doors.

1.2 This test method is applicable to exterior windows and doors and is intended to measure only such leakage associated with the assembly and not the leakage through openings between the assemblies and adjacent construction. The test method can be adapted for the latter purpose, provided the potential paths of air movement and the sources of infiltration and exfiltration can be identified, controlled, or eliminated.

1.3 This test method attempts to create and given set of natural environmental conditions. There is a strong possibility that the test method or the test apparatus may, by virtue of their design and use, induce air leakage that does not occur under natural environmental exposure.

1.4 This test method is intended for the field testing of installed exterior windows or doors. Persons interested in laboratory testing of fenestration products should reference Test Method E283.

1.5 Persons using this procedure should be knowledgeable in the area of fluid mechanics and instrumentation practices, and shall have a general understanding of fenestration products and components.

1.6 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 7.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established ...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E783 − 02 (Reapproved 2018)

Standard Test Method for

Field Measurement of Air Leakage Through Installed

Exterior Windows and Doors

This standard is issued under the fixed designation E783; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.8 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This test method provides a field procedure for deter-

ization established in the Decision on Principles for the

mining the air leakage rates of installed exterior windows and

Development of International Standards, Guides and Recom-

doors.

mendations issued by the World Trade Organization Technical

1.2 This test method is applicable to exterior windows and

Barriers to Trade (TBT) Committee.

doors and is intended to measure only such leakage associated

2. Referenced Documents

with the assembly and not the leakage through openings

between the assemblies and adjacent construction. The test

2.1 ASTM Standards:

method can be adapted for the latter purpose, provided the

E283Test Method for Determining Rate of Air Leakage

potential paths of air movement and the sources of infiltration

Through ExteriorWindows, Skylights, CurtainWalls, and

and exfiltration can be identified, controlled, or eliminated.

Doors Under Specified Pressure Differences Across the

Specimen

1.3 This test method attempts to create and given set of

E631Terminology of Building Constructions

natural environmental conditions. There is a strong possibility

thatthetestmethodorthetestapparatusmay,byvirtueoftheir

3. Terminology

design and use, induce air leakage that does not occur under

3.1 Definitions—Terms used in this test method are defined

natural environmental exposure.

in Terminology E631.

1.4 This test method is intended for the field testing of

3.2 Definitions of Terms Specific to This Standard:

installed exterior windows or doors. Persons interested in

3.2.1 air leakage rate (q or q )—theairleakageperunitof

A L

laboratory testing of fenestration products should reference

specimen area (A) or per unit length of operable crack

Test Method E283. 3 2 3 2 3

perimeter (L), expressed as m/s−m (ft /min−ft ), or m /

1.5 Persons using this procedure should be knowledgeable

s−m(ft /min−ft).

in the area of fluid mechanics and instrumentation practices,

3.2.2 extraneous air leakage (Q)—the volume of air

e

andshallhaveageneralunderstandingoffenestrationproducts

flowing per unit of time through the test chamber and test

and components.

apparatus, exclusive of the air flowing through the test

1.6 The values stated in SI units are to be regarded as specimen, under a test pressure difference and test temperature

difference, converted to standard conditions, expressed in m /s

standard. The values given in parentheses are mathematical

conversions to inch-pound units that are provided for informa- (ft /min).

3.2.2.1 Discussion—Extraneous leakage is the sum of all

tion only and are not considered standard.

leakage other than that intended to be measured by the test.

1.7 This standard does not purport to address all of the

3.2.3 specimen air leakage (Q )—the volume of air flowing

safety concerns, if any, associated with its use. It is the

s

responsibility of the user of this standard to establish appro- per unit of time through the specimen, under a test pressure

difference and test temperature difference, converted to stan-

priate safety, health, and environmental practices and deter-

3 3

mine the applicability of regulatory limitations prior to use. dard conditions, expressed in m /s (ft /min).

For specific precautionary statements, see Section 7.

3.2.4 specimen area (A)—theareadeterminedbytheoverall

dimensions of the frame that fits into the rough opening,

2 2

expressed as m (ft ).

This test method is under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.51

on Performance of Windows, Doors, Skylights and Curtain Walls. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2018. Published October 2018. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1981. Last previous edition approved in 2010 as E783-02 (2010). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E0783-02R18. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E783 − 02 (2018)

3.2.5 test pressure differences—the specified differential 5.4 Rates of air leakage, as determined by this test method

static air pressure across the specimen, expressed as Pa may be affected by: the age or physical condition of the test

(lbf/ft ). specimen; the type or quality of installation; the care exercised

intheattachmentofthetestapparatusandthedeterminationof

3.2.6 test specimen—the assembled window or door unit as

extraneous leakage; and the actual conditions to which the test

installed in the exterior wall of a building. The test specimen

specimenisexposedbeyondthoseimposedbythetestmethod,

consistsofthemajorcomponentsoftheassembly,includingall

that is temperature, relative humidity, wind impingement, etc.

joints, cracks, or openings between such components and any

Consideration must be given to the proper selection of test

panning, receptors, extenders, sills, mullions, or other parts or

specimens, the choice of appropriate test technique (when a

components used for assembly and installation. The test

choiceisgivenwithinthistestmethod),andtheproperuseand

specimen excludes any joints, cracks, or openings between the

interpretation of the results obtained from this test to minimize

assemblyandanyinteriororexteriortrimthatisnotanintegral

the effect of these conditions.

partofthesystem,andexcludesanyjoints,cracks,oropenings

between the assembly and the adjacent wall construction.

5.5 Rates of air leakage, as determined by this test method

may include air leakage that does not occur during normal

3.2.7 total air flow (Q)—the volume of air flowing per unit

t

operation and exposure, or that does not contribute to the

oftimethroughthetestchamberandtestapparatusinclusiveof

overall air leakage for the structure.Air may be supplied to or

the air flowing through the test specimen, under a test pressure

exhausted from wall cavities or adjacent construction, or may

difference and test temperature difference, converted to stan-

3 3

bypass interior or exterior trim or components in a manner not

dard conditions, expressed in m /s (ft /min).

experienced during normal operation or exposure. Care must

3.2.8 unit length of operable crack perimeter (L)—the sum

be taken to prevent such leakage from occurring, or consider-

of all perimeters of operable ventilators, sash, or doors con-

ation must be given that such leakage may have occurred

tained in the test specimen, based on the overall dimensions of

during the test.

such parts, expressed in m (ft).Where two such operable parts

5.6 This test method addresses the issue of air leakage

meet,thetwoadjacentlengthsofperimetershallbecountedas

through the high pressure face of the test specimen only. Air

only one length.

leakage from the adjacent wall cavity through sill, head, and

jambs of the window frame is considered extraneous air

4. Summary of Test Method

leakage and, therefore, not a component of the measured

4.1 The test consists of sealing a chamber to cover the

specimen air leakage. Such extraneous air leakage through the

interior or exterior face of a test specimen, supplying air to or

perimeterframeofthetestspecimencanbeasignificantsource

exhausting air from the chamber at a rate required to maintain

of air leakage into, or out of, the building if the frame is not

the specified test pressure difference across the specimen, and

sealed against air infiltration from the adjacent wall cavity.

measuring the resultant air flow across the specimen.

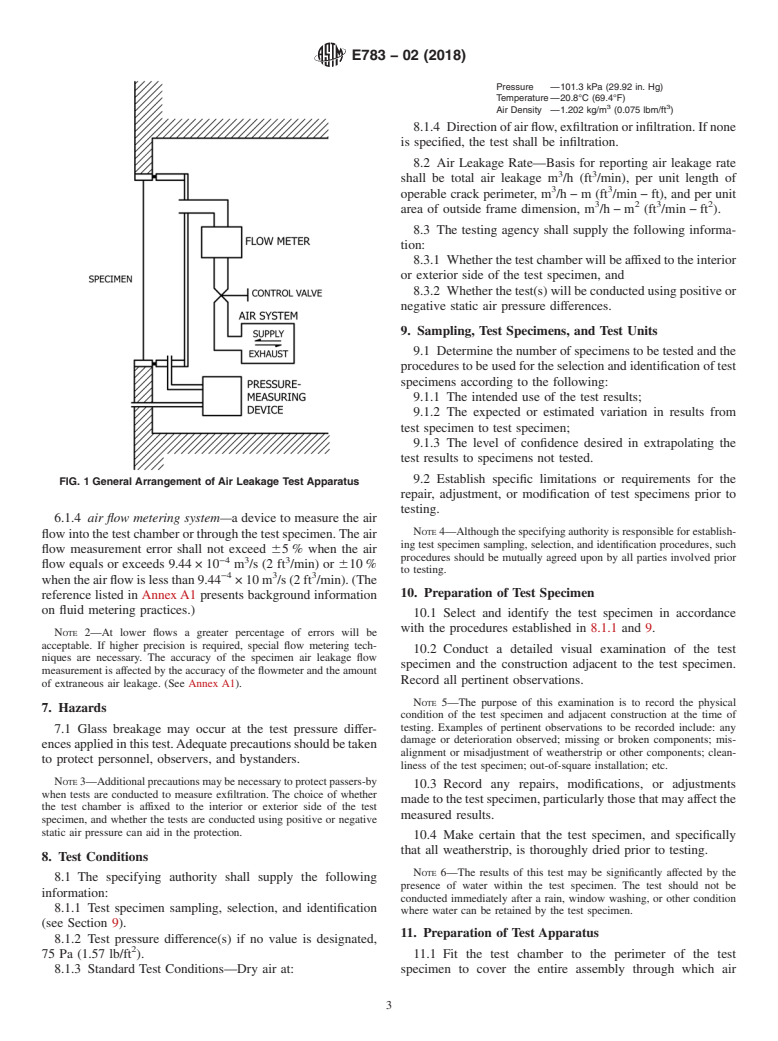

6. Apparatus

5. Significance and Use

6.1 The description of the apparatus in this section is

5.1 Thistestmethodisastandardprocedurefordetermining

general in nature (see Fig. 1). Any suitable arrangement of

theairleakagecharacteristicsofinstalledexteriorwindowsand

equipment capable of maintaining the required test tolerances

doors under specified static air pressure differences.

is permitted.

6.1.1 test chamber—achamberformedbysealingasheetof

NOTE 1—The air pressure differences acting across a building envelope

vary greatly. The factors affecting air pressure differences and the plywood,plastic,orothersuitablematerialagainsttheframeof

implicationsoftheresultingairleakagerelativetotheenvironmentwithin

the test specimen.At no time during the test shall the sheet or

3, 4, 5

buildingsarediscussedintheliterature. Thesefactorsshouldbefully

any other part of the testing assembly, come in contact with or

considered in specifying the test pressure differences to be used.

restrict any point where air leakage may occur. At least one

5.2 Rates of air leakage are sometimes used for comparison

static air pressure tap shall be provided on each side of the

purposes. Such comparisons may not be valid unless the

specimen to measure the chamber pressure versus the ambient

components being tested and compared are of essentially the

(indoortooutdoor)airpressure,andshallbelocatedsothatthe

same size, configuration, and design.

reading is unaffected by outdoor impinging wind, or by the air

5.3 Rates of air leakage of essentially identical windows or supply to or exhaust from the test chamber. The air supply

opening to the chamber shall be located in an area in which it

doors,asdeterminedinthelaboratory(TestMethodE283)and

as measured in the field by this test method, have sometimes does not directly impinge upon the test specimen.

6.1.2 supply air system—a controllable blower, exhaust fan,

been used for comparison purposes. The correlation between

thelaboratoryandfieldtestresults,andthecorrelationbetween or reversible blower designed to provide the required air flow

at the specified test pressure difference. The system should

actual performance of in-service products and the response to

thesetestshasnotbeenestablishedbecauseofinsufficientdata. provide essentially constant air flow at the specified test

pressure difference for a time period sufficient to obtain

readings of air flow.

6.1.3 pressure measuring apparatus—a device to measure

ASHRAE Handbook of Fundamentals, 1989.

the differential test pressures to 62% of setpoint or 62.5 Pa

Fluid Meters—Their Theory and Application, 5th Edition, 1959.

Chapter 4, “Flow Measurements,” Power Test Code, 2nd Edition, Part 5, 1956. (60.01 in. of water column), whichever is greater.

E783 − 02 (2018)

Pressure —101.3 kPa (29.92 in. Hg)

Temperature—20.8°C (69.4°F)

3 3

Air Density —1.202 kg/m (0.075 lbm/ft )

8.1.4 Directionofairflow,exfiltrationorinfiltration.Ifnone

is specified, the test shall be infiltration.

8.2 Air Leakage Rate—Basis for reporting air leakage rate

3 3

shall be total air leakage m /h (ft /min), per unit length of

3 3

operable crack perimeter, m /h−m (ft /min−ft), and per unit

3 2 3 2

area of outside frame dimension, m/h−m (ft /min−ft ).

8.3 The testing agency shall supply the following informa-

tion:

8.3.1 Whetherthetestchamberwillbeaffixedtotheinterior

or exterior side of the test specimen, and

8.3.2 Whetherthetest(s)willbeconductedusingpositiveor

negative static air pressure differences.

9. Sampling, Test Specimens, and Test Units

9.1 Determinethenumberofspecimenstobetestedandthe

procedurestobeusedfortheselectionandidentificationoftest

specimens according to the following:

9.1.1 The intended use of the test results;

9.1.2 The expected or estimated variation in results from

test specimen to test specimen;

9.1.3 The level of confidence desired in extrapolating the

test results to specimens not tested.

9.2 Establish specific limitations or requirements for the

FIG. 1 General Arrangement of Air Leakage Test Apparatus

repair, adjustment, or modification of test specimens prior to

testing.

6.1.4 air flow metering system—a device to measure the air

NOTE4—Althoughthespecifyingauthorityisresponsibleforestablish-

flowintothetestchamberorthroughthetestspecimen.Theair

ing test specimen sampling, selection, and identification procedures, such

flow measurement error shall not exceed 65% when the air

procedures should be mutually agreed upon by all parties involved prior

−4 3 3

flow equals or exceeds 9.44×10 m /s (2 ft /min) or 610%

to testing.

−4 3 3

whentheairflowislessthan9.44 ×10m /s(2ft /min).(The

10. Preparation of Test Specimen

reference listed in AnnexA1 presents background information

on fluid metering practices.)

10.1 Select and identify the test specimen in accordance

with the procedures established in 8.1.1 and 9.

NOTE 2—At lower flows a greater percentage of errors will be

acceptable. If higher precision is required, special flow metering tech-

10.2 Conduct a detailed visual examination of the test

niques are necessary. The accuracy of the specimen air leakage flow

specimen and the construction adjacent to the test specimen.

measurement is affected by the accuracy of the flowmeter and the amount

Record all pertinent observations.

of extraneous air leakage. (See Annex A1).

NOTE 5—The purpose of this examination is to record the physical

7. Hazards

condition of the test specimen and adjacent construction at the time of

testing. Examples of pertinent observations to be recorded include: any

7.1 Glass breakage may occur at the test pressure differ-

damage or deterioration observed; missing or broken components; mis-

encesappliedinthistest.Adequateprecautionsshouldbetaken

alignment or misadjustment of weatherstrip or other components; clean-

to protect personnel, observers, and bystanders.

liness of the test specimen; out-of-square installation; etc.

NOTE3—Additionalprecautionsmaybenecessarytoprotectpassers-by

10.3 Record any repairs, modifications, or adjustments

when tests are conducted to measure exfiltration. The choice of whether

madetothetestspecimen,particularlythosethatmayaffectthe

the test chamber is affixed to the interior or exterior side of the test

measured results.

specimen, and whether the tests are conducted using positive or negative

static air pressure can aid in the protection.

10.4 Make certain th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.